High temperature tunnel furnace for powder material sintering

A powder material, sintering molding technology, applied to the used abrasive processing device, furnace, abrasive, etc., can solve the problems that the reliability of the sintered material is not guaranteed, the temperature is difficult to control accurately, and the heating and cooling time is time-consuming. To achieve the effect of improving sintering reliability, ensuring density and improving internal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

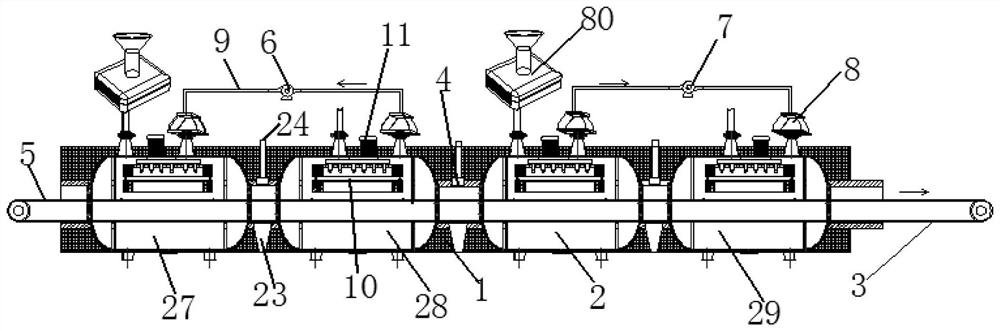

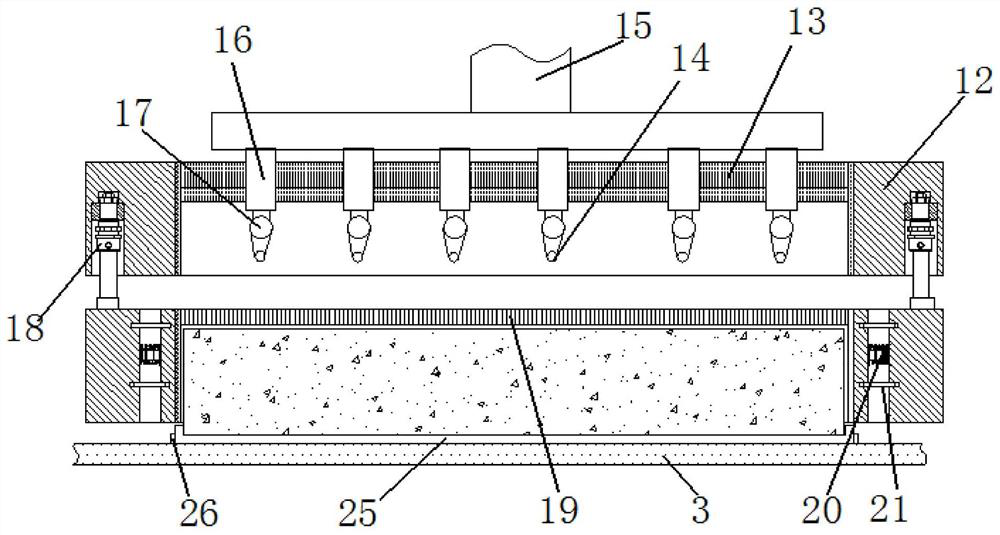

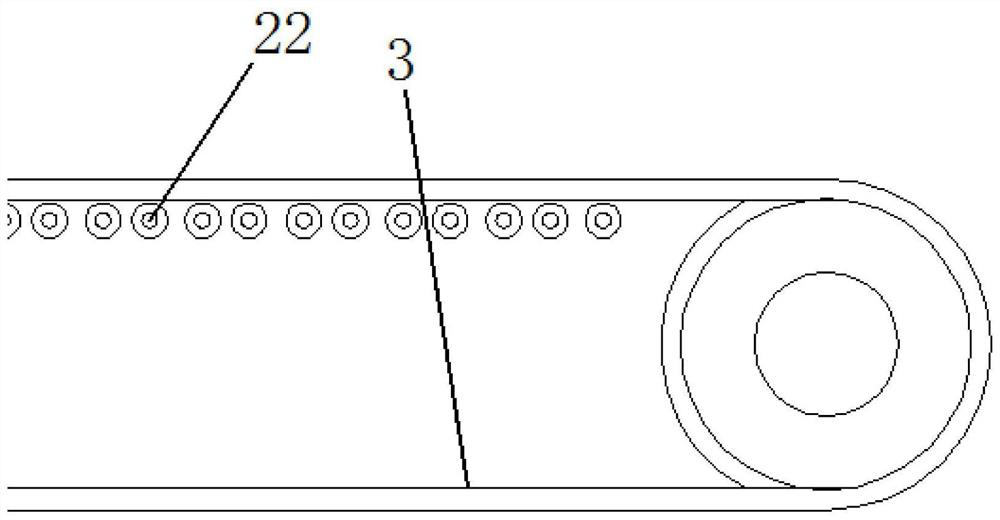

[0031] see Figure 1~4 , in the embodiment of the present invention, the high-temperature tunnel furnace used for sintering and molding powder materials includes a tunnel furnace body 1, a first sintering furnace unit 27, a second sintering furnace unit 28, a third sintering furnace unit 2 and a fourth sintering furnace Unit 29, wherein the tunnel furnace body 1 extends in a straight line along the length direction, one end of the tunnel furnace body 1 is the feeding part 5, and the other end of the tunnel furnace body is the discharge part, the In the tunnel furnace body 1, the first sintering furnace unit 27, the second sintering furnace unit 28, the third sintering furnace unit 2 and the fourth sintering furnace are sequentially arranged at intervals from the feeding part to the discharging part. Unit 29, the tunnel furnace 1 is also provided with a transmission assembly that passes through and communicates with the first sintering furnace unit, the second sintering furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com