Patents

Literature

116results about How to "Issues affecting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel PET (polyethylene terephthalate) master batch and manufacturing technique thereof

The invention discloses an aerogel PET (polyethylene terephthalate) master batch and a manufacturing technique thereof. The manufacturing technique comprises the following steps: uniformly mixing an activator, a dispersing agent and an aerogel, and carrying out activating treatment to obtain a mixture A; adding PET (polyethylene terephthalate) slices into the mixture A, uniformly mixing, and drying at 120 DEG C for 6 hours to obtain a mixture B; and putting the dried mixture B into double screw extruder, and carrying out granulation under the frequency of 32.5-35.5Hz. By using the aerogel and PET slices as the generation raw materials, the favorable heat-insulating property of the aerogel and the characteristics of high toughness and high wear resistance of the PET material are combined, so that the obtained aerogel composite fibers have high toughness. The heat conductivity coefficient of the adopted aerogel is 0.019 W / (m.K) which is much lower than the heat conductivity coefficient 0.092 W / (m.K) of pure wool, and therefore, the off-the-rack suit prepared from the fibers made from the aerogel PET master batch has excellent heat-insulating property.

Owner:SHENZHEN AEROGEL TECH CO LTD

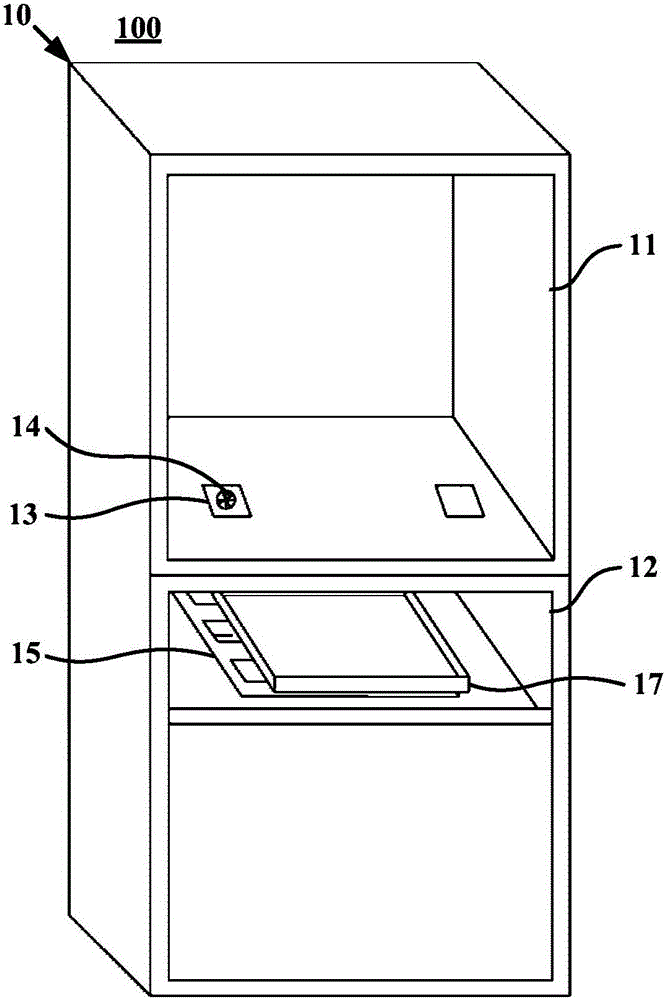

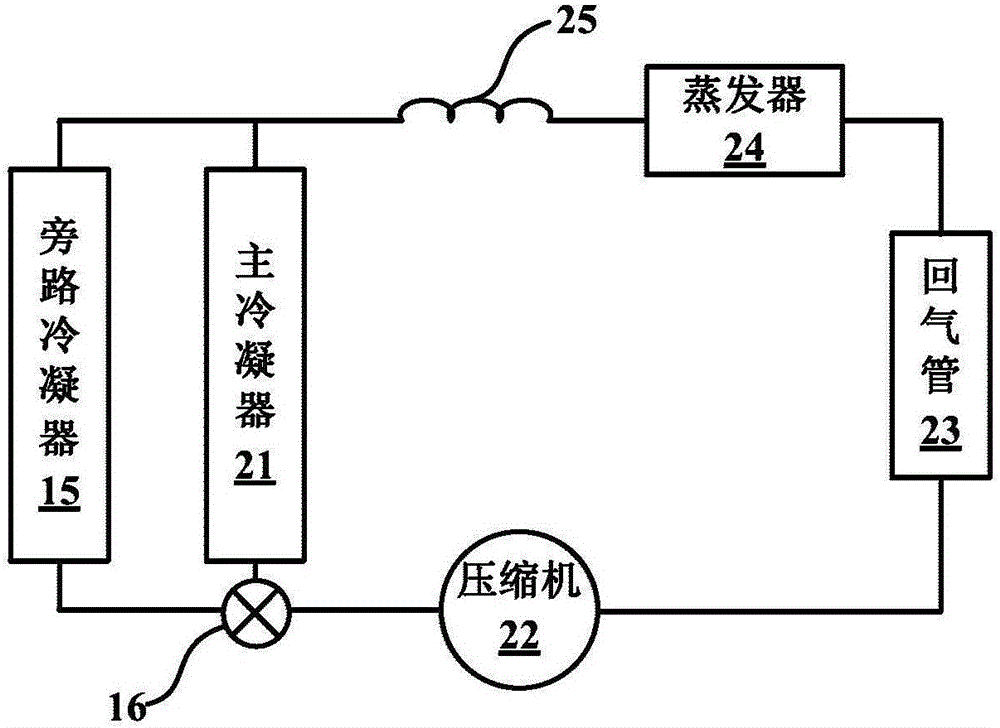

Thawing method for refrigerator stored objects and refrigerator

ActiveCN105972919AReduce stepsAvoid being forgottenLighting and heating apparatusDomestic refrigeratorsComputer scienceRefrigerated temperature

The invention provides a thawing method for refrigerator stored objects and a refrigerator. The thawing method for the refrigerator stored objects comprises the following steps: acquiring the thawing information of the stored objects put in an independent compartment and thawing time set by a user; according to the thawing information, separately estimating estimated time required for thawing by using different thawing modes, wherein the estimated time comprises first estimated time required for thawing by utilizing the environmental heat of the refrigerator, second estimated time required for thawing by utilizing heat released by a bypass condenser and third estimated time required for thawing by combining the environmental heat and the heat released by the bypass condenser; matching the set thawing time with the estimated time so as to select a thawing mode meeting the thawing time requirement; and driving the independent compartment to execute a thawing process corresponding to the selected thawing mode. According to the technical scheme, various thawing modes are provided for the user, the thawing mode is selected according to the thawing time set by the user, and the use experience of the user is improved.

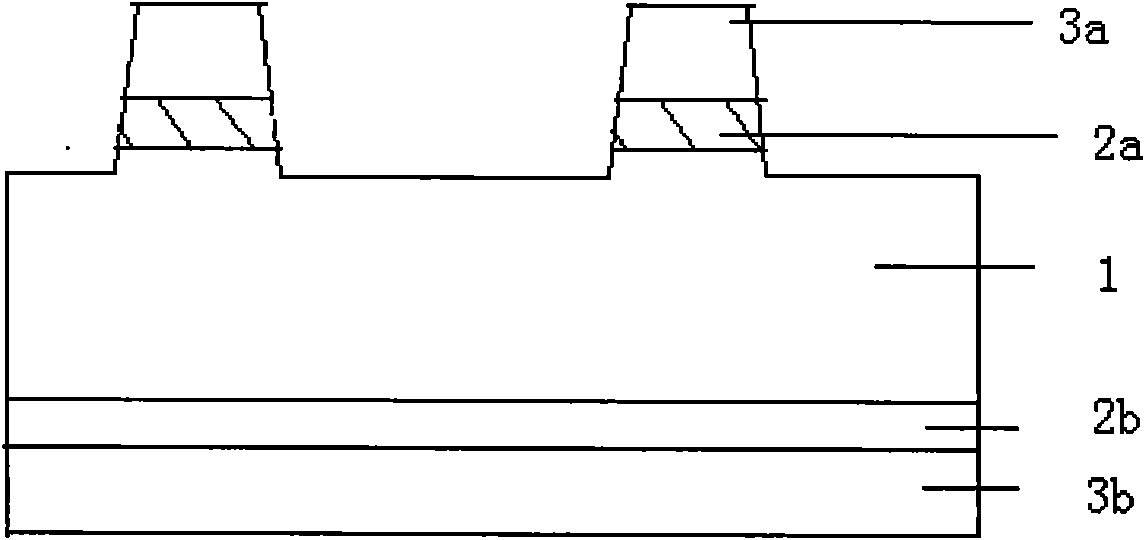

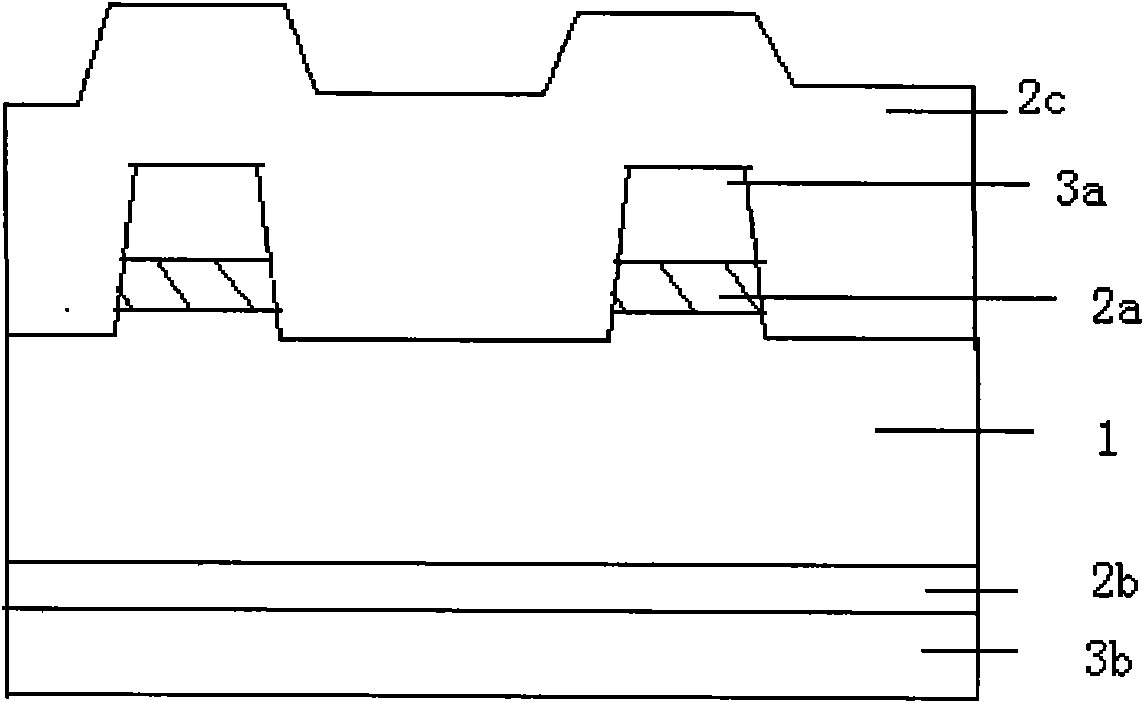

Method for manufacturing metal gate

InactiveCN102044421AIssues affecting qualityAffect focusSemiconductor/solid-state device manufacturingSemiconductor devicesOxideSilicon based

The invention relates to a method for manufacturing a metal gate, comprising the following steps: firstly providing a wafer with a silicon base, respectively forming a first oxide layer and a second oxide layer on the front surface and the back surface of the silicon base, and respectively forming a first protective layer and a second protective layer on the first oxide layer and the second oxide layer; etching the first protective layer, the first oxide layer and the silicon base; depositing third oxide layers on the first protective layer and an exposed silicon base, and flattening the third oxide layer until the first protective layer is exposed; removing part of the first protective layer by using dry etching; removing the residual first protective layer and part of second protective layer by using wet etching; forming a well region, and removing the first oxide layer by precleaning to form a gate oxide layer; and forming the metal gate. Metal atoms which are exposed out of the side of a grid do not spread to the silicon base, so that the silicon substrate with a certain thickness at the back of the wafer is in no need of removing after the metal gate is etched, thus avoiding the problems that the loss of silicon atoms are resulted from the uneven back surface of the wafer to influence the sequent exposure, and the like.

Owner:SEMICON MFG INT (SHANGHAI) CORP

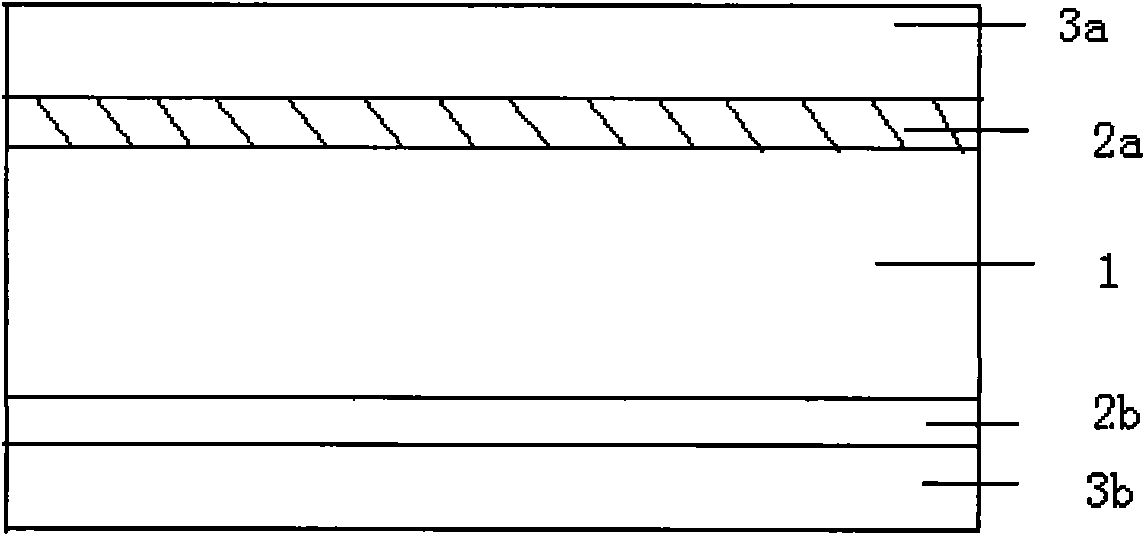

Aerogel composite fiber and manufacturing process thereof

InactiveCN106757513AImprove toughnessImprove wear resistanceElectroconductive/antistatic filament manufactureMelt spinning methodsFiberPolyethylene terephthalate glycol

The invention discloses an aerogel composite fiber and a manufacturing process thereof. The manufacturing process comprises the following steps: mixing an aerogel PET (Polyethylene Terephthalate) master batch and a PET chip according to a ratio of 1:(5-10), and melting to form a spinning melt under the melt temperature of 285-290 DEG C and the melt pressure of 1-2MPa; drawing the spinning melt to form nascent fibers, and finally stretching the nascent fibers, thereby obtaining the aerogel composite fiber. The aerogel PET master batch and the PET chip are taken as production materials, and the characteristics of good heat-insulating property of aerogel and high toughness and high wear resistance of the PET material are combined, so that the produced aerogel composite fiber is high in toughness. Meanwhile, the heat conductivity coefficient of the aerogel composite fiber is 0.032W / (m*K) and is much lower than the heat conductivity coefficient 0.092W / (m*K) of pure wool. Therefore, ready-to-wear made from the aerogel composite fiber has excellent heat retaining property.

Owner:SHENZHEN AEROGEL TECH CO LTD

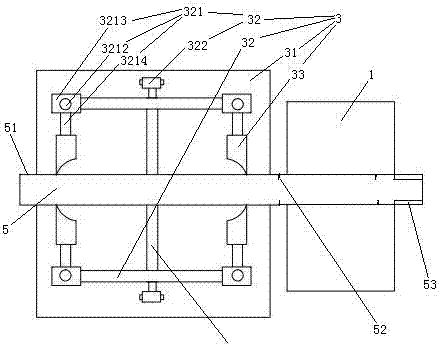

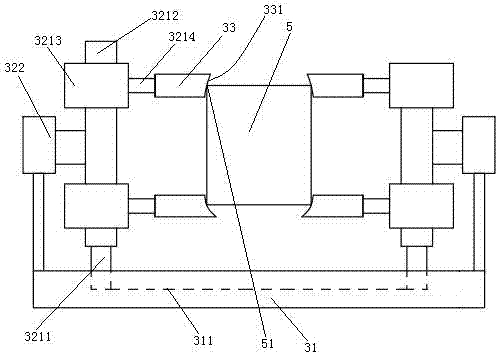

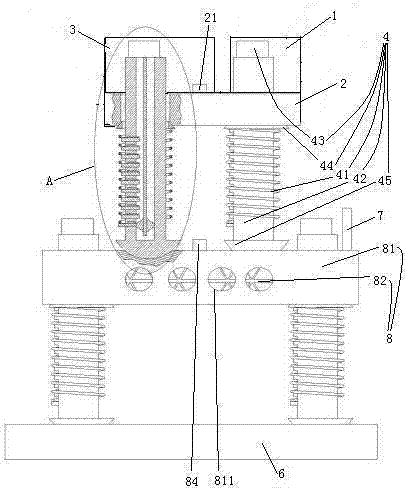

Copper rod manufacturing method and milling machine suitable for copper rod manufacturing method and capable of scoring

InactiveCN103706664AImprove roundnessIssues affecting qualityMilling equipment detailsHigh surfaceWork in process

The invention relates to the technical field of copper rod processing, specifically to a milling machine capable of scoring. The milling machine comprises a mill and a scoring mechanism, wherein the scoring mechanism comprises four cutter blades and a cutter blade drive mechanism for driving the cutter blades to score scores on four edges of a copper rod billet. The copper rod manufacturing method comprises: 1, adopting a continuous casting process to produce a copper rod billet with a rectangular cross-section; 1.1, scoring scores circumferential extending and circumferential distributing along the copper rod billet circumference on four edges of the copper rod billet; 1.2, milling off the copper rod billet surface and the four edges of the copper rod billet to form chamfers, wherein swarfs break from the scoring position during the chamfer forming process through milling the edges of the copper rod billet so as to fall down; and 2, adopting a continuous rolling process to produce the semi-finished product copper rod with a round cross-section. A purpose of the present invention is to provide a copper rod manufacturing method and a milling machine capable of scoring, wherein the produced copper rod has characteristics of good circumferential extension uniformity and less surface defect proportion, such that the problems of high surface defect proportion and high circumferential extension difference of the existing copper rod can be solved.

Owner:XINXING PIPES ZHEJIANG COPPER

Processing method for autumn sweet osmanthus flower fragrance green tea

ActiveCN105028742AAvoid quality issuesIssues affecting qualityPre-extraction tea treatmentClimate change adaptationGreen teaTea leaf

Provided is a processing method for autumn sweet osmanthus flower fragrance green tea. The method includes the following steps: 1, raw sweet osmanthus flower making; 2, tea leaf picking; 3, airing; 4, blending; 5, primary rolling; 6, steam beating; 7, secondary rolling; 8, polishing, wherein tea leaves obtained after secondary rolling are placed in a tea leaf polisher be polished; 9, drying, wherein the polished tea leaves are placed in a dryer to be dried till the water content of the tea leaves ranges from 3% to 4%; 10, packaging, wherein sterilization is performed under the vacuum condition, and then bag packaging is performed. Because sweet osmanthus flowers are processed and deeply integrated into the tea leaves in the green tea processing process, the problem that the sweet osmanthus flowers are separated from the tea leaves, and consequently the tea leaf quality is influenced is avoided. In this way, the green tea has the delicate fragrance of sweet osmanthus flowers and the attractive appearance of green team, and tea water obtained by brewing the green tea is light in color, mild in taste, slightly sweet and slightly fragrant and has soft infused leaves and many single coppery sheets.

Owner:贵州省凤冈县永田露茶业有限公司

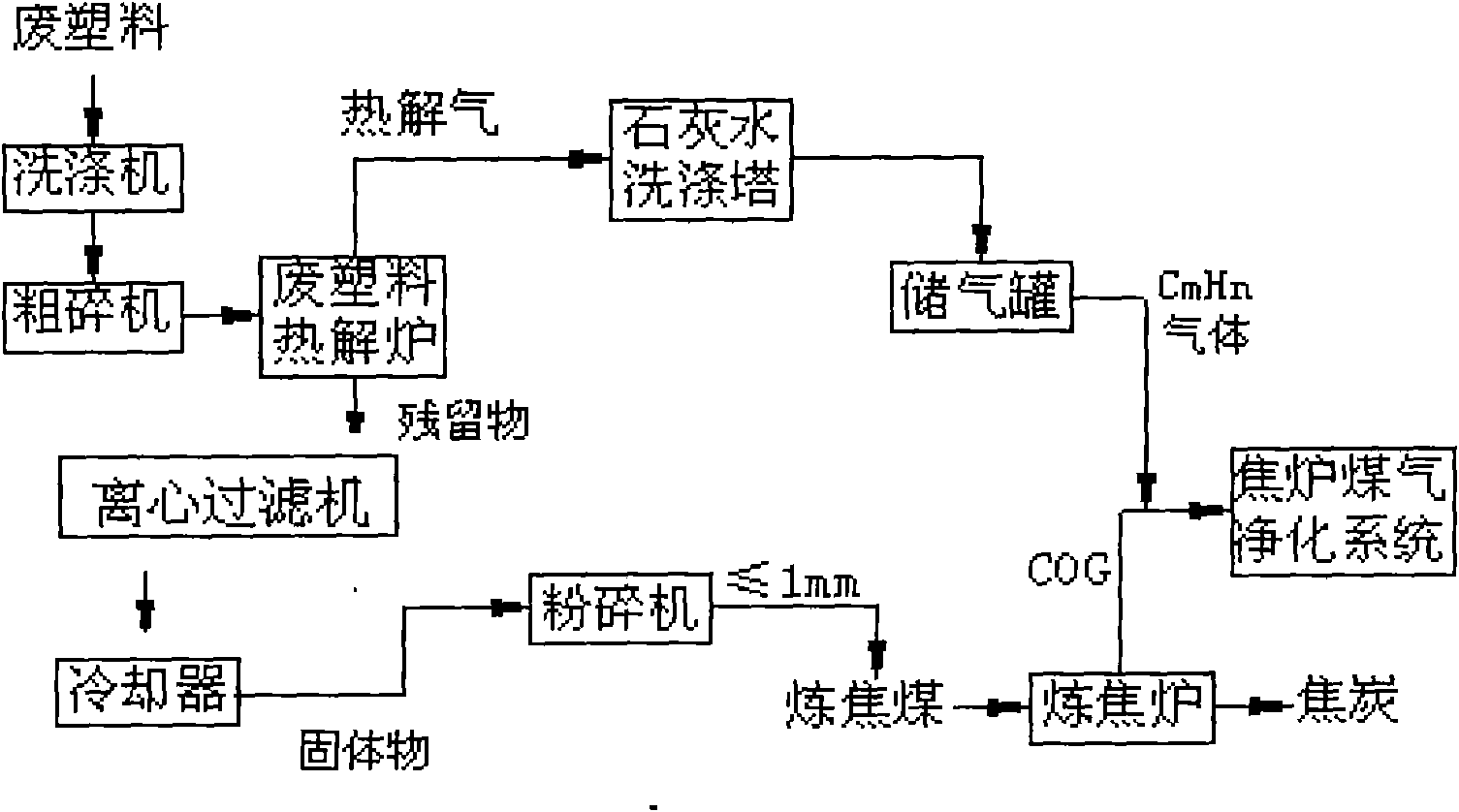

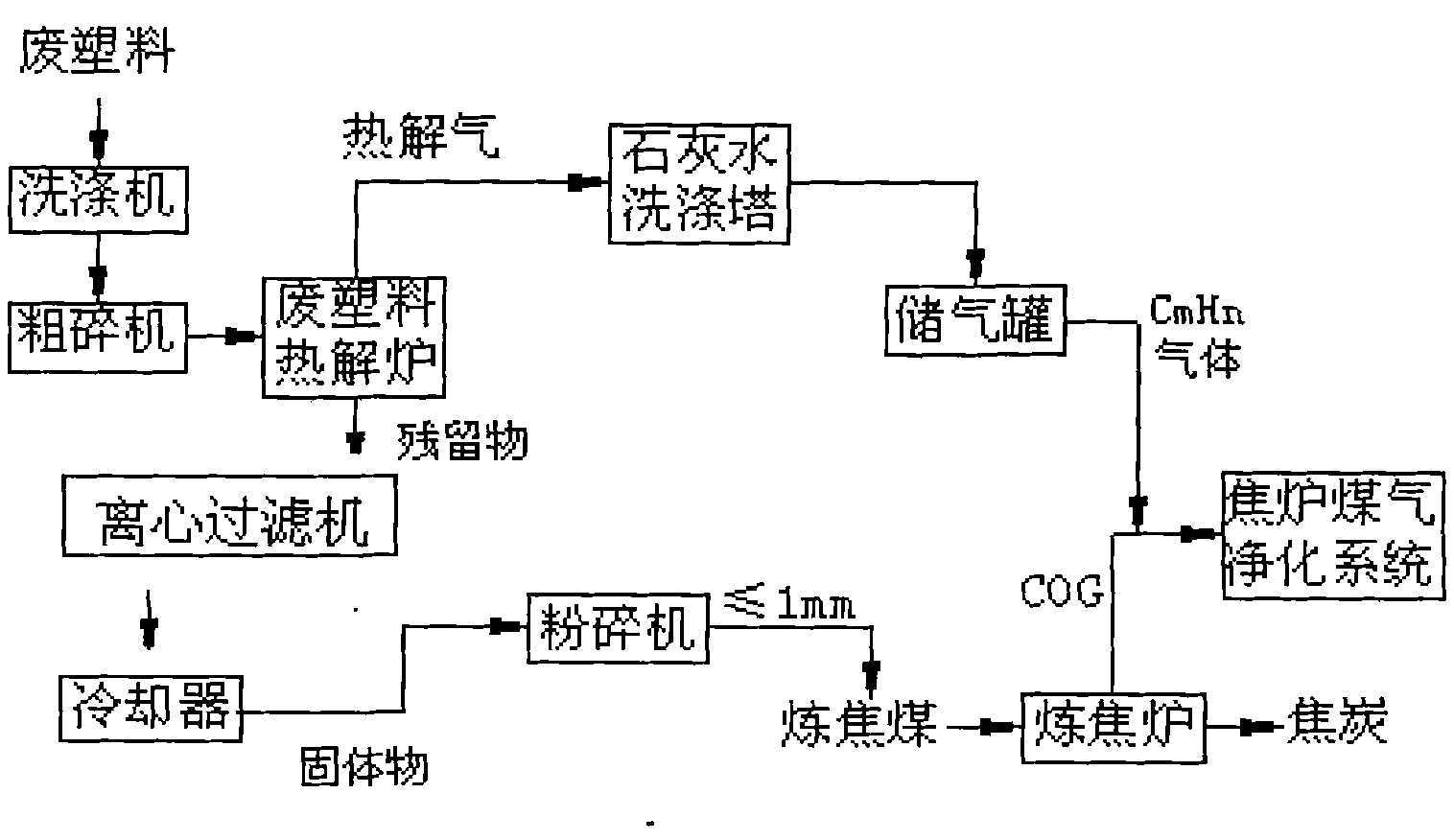

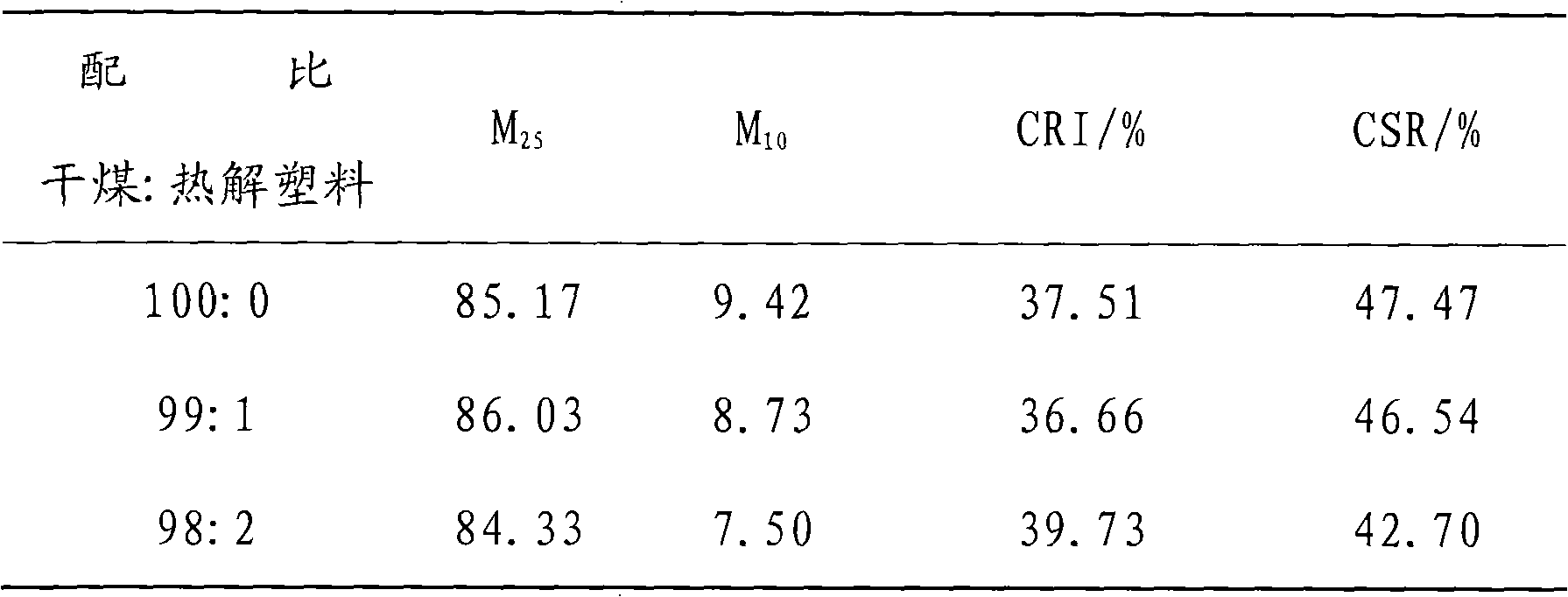

Waste plastics pretreatment process based on coking by coke oven

InactiveCN101831313AAvoid corrosionAvoid uneven dispersionProductsReagentsEnvironmental effectEnvironmental engineering

The invention discloses a waste plastics pretreatment process based on coking by a coke oven, which solves the problems of low equipment life, large environmental influence and influenced coke quality after coal blending in the process of treating waste plastics by using the coking process in the prior art. The technical scheme adopted by the invention is as follows: (1) performing coarse crushing on the waste plastics by a crusher until the grain size is 8-12mm; (2) feeding the waste plastics with the grain size of 8-12mm after coarse crushing in a pyrolysis oven, heating to 225-275 DEG C under the condition of air isolation, pyrolyzing for 30-90min at a constant temperature and dissolving out pyrolysis gas; (3) cooling the fluid residue of the waste plastics after pyrolysis to form solid-state solids, and feeding the solid-state solids in the crusher again for crushing until the grain size is no more than 1mm; and (4) blending the solid-state solids in coking coal according to the proportioning of 1% by weight. The invention has the advantages of simple process, no environment pollution and no influence on coke quality.

Owner:武钢集团有限公司 +2

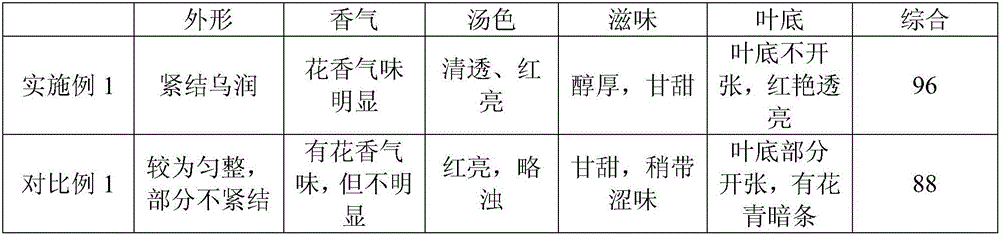

Black tea processing method

The invention provides a black tea processing method. The black tea processing method comprises the following steps of firstly pretreating tea leaves, then performing withering, performing rolling, then performing fermentation, then performing a working procedure of hot blowing for quality improvement, and finally performing drying so as to obtain black tea, wherein in the working procedure of hot blowing for quality improvement, fermented tea blanks are uniformly heated by hot blowing for quality improvement equipment, and besides, peculiar smell is eliminated. According to the black tea processing method disclosed by the invention, a technology of hot blowing for quality improvement is newly added, so that the activity of enzymes is effectively restrained, besides, mixed peculiar smell of herbal flavor, wet stuffiness and the like in the tea blanks is eliminated, the tea blanks are uniformly dehydrated, and the problem that the quality of the black tea is influenced by water stifling taste and the like produced in the working procedure of drying is solved. After quick-freeze withering treatment, microwave treatment is performed, so that tea leaves are soft in leaves, the tenacity of the tea leaves is strengthened, and shaping is facilitated. In the rolling treatment process of the tea leaves, ultrasonic treatment is performed, so that the cytoclasis of the tea leaves is thorough, and later-stage fermentation treatment is facilitated. The fragrance fresh and brisk degree, the mellow degree, the brewing resistant degree and the tea soup brightness of black tea products made by the black tea processing method disclosed by the invention are obviously improved, and the green and astringency sense of the black tea products is reduced.

Owner:朱步泉 +2

Car capsule coffee machine

PendingCN107485287AIssues affecting qualitySolve cleaning problemsBeverage vesselsIn vehicleProcess engineering

The invention discloses a car capsule coffee machine which is provided with a water storage chamber for storing cold water, a heating unit which is used for heating the cold water and arranged below and connected with the water storage chamber, and a capsule accommodating cavity which is used for accommodating and puncturing a coffee capsule. A water inlet hole, which is communicated with the water storage chamber, and a water outlet hole are formed in the capsule accommodating cavity, wherein the water inlet hole is connected with a first puncturing structure for hot water to enter the coffee capsule, and the water outlet hole is connected with a second puncturing structure for extracted coffee fluid to flow out. The car capsule coffee machine further solves the problem of cleaning caused by coffee powder spilling when coffee powder or an easy serve bag is used to brew coffee in an existing car coffee machine while satisfying users' requirement of drinking coffee in a car, improves operating experience of brewing coffee on the existing car coffee machine and solves problems that consumables are not easy to store well and coffee quality is reduced after the coffee powder or the easy service bag is opened.

Owner:江门市锶源进出口有限公司

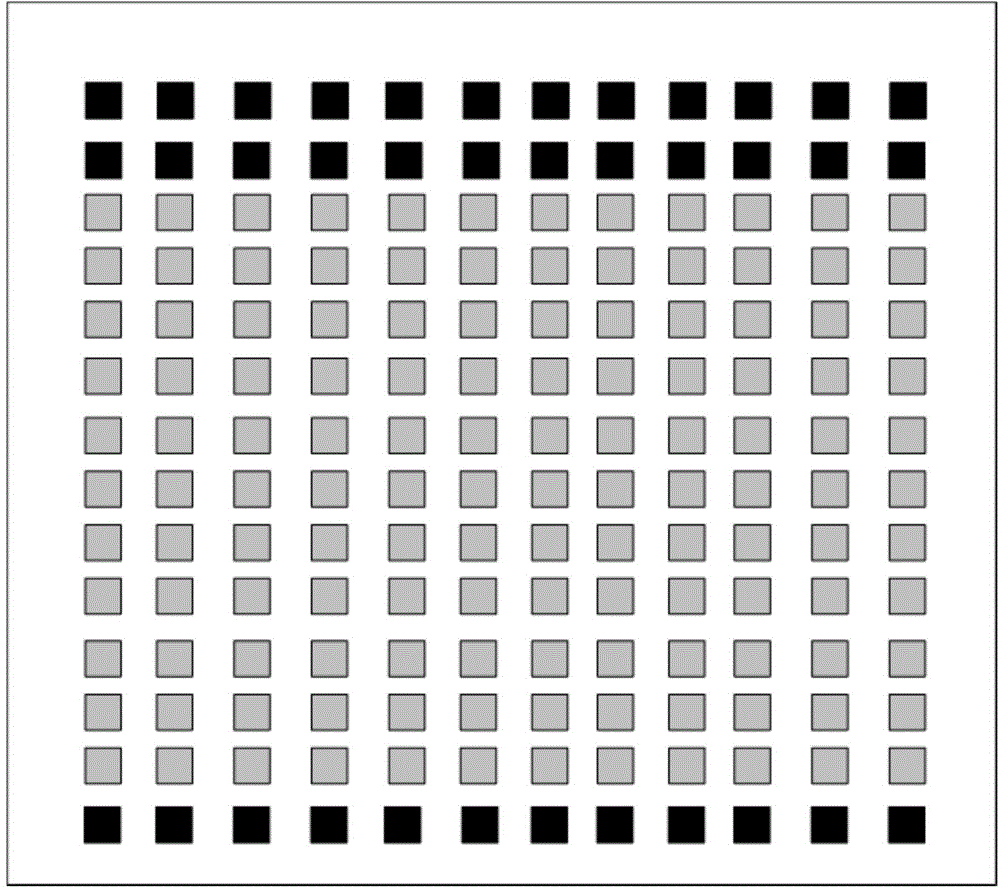

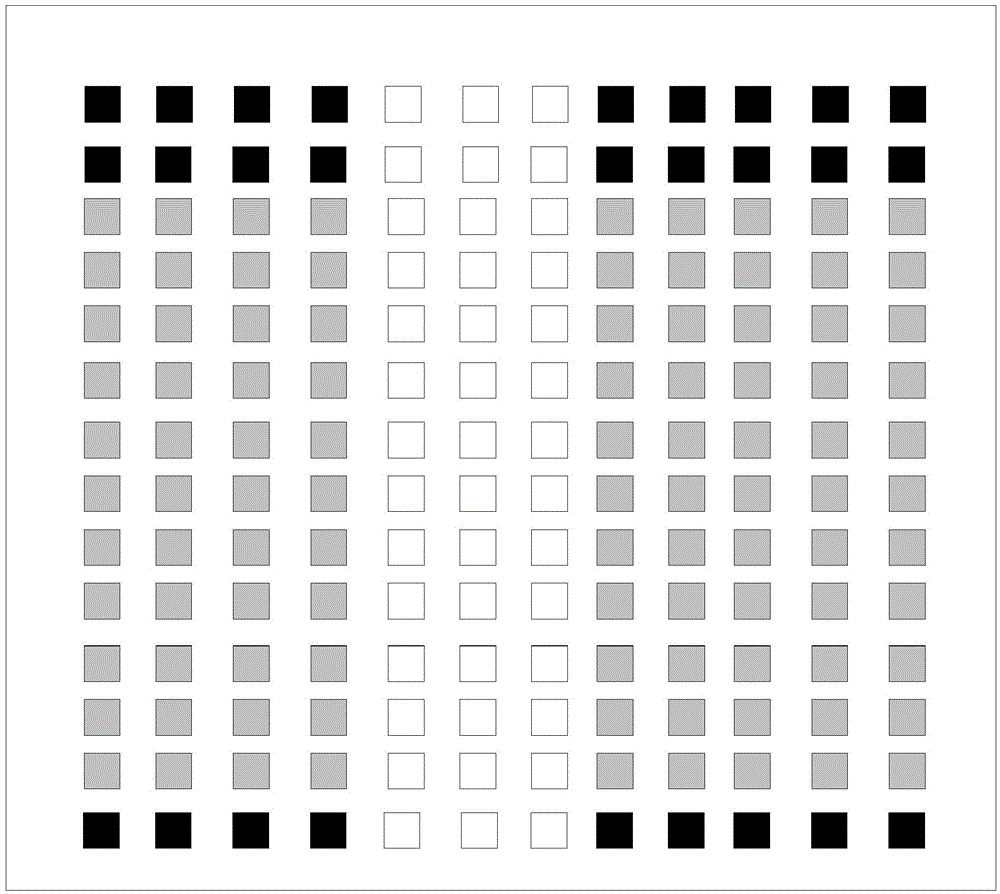

Method and device for eliminating light leak phenomenon in picture

ActiveCN104318531AIssues affecting qualityEliminate light leaksImage enhancementGray levelComputer science

The application discloses a method and a device for eliminating a light leak phenomenon in a picture. The method for eliminating the light leak phenomenon in the picture includes steps: using rough positioning to obtain a start column and an end column of a light leak region in a dark pixel region, and using the start column, the end column and picture elements between the start column and the end column as an undetermined light leak region. When the light leak region shakes, the undetermined light leak region and the periphery of the undetermined light leak regions are likely to be the light leak region. Under the circumstance, the method and the device for eliminating the light leak phenomenon in the picture regulate gray levels of the undetermined light leak region and picture elements on the periphery of the undetermined light leak region according to a gray level correlation of the picture elements in the undetermined light leak region and the picture elements on the periphery of the undetermined light leak region, and thereby can restore the light leak region which shakes, and eliminate the light leak phenomenon. Furthermore, due to the fact that the gray levels of the undetermined light leak region and the picture elements on the periphery of the undetermined light leak region are regulated according to the gray level correlation among the picture elements in the picture during the light leak phenomenon eliminating process, the problem that quality of the picture is influenced due to the fact that picture element gray level change in the picture is overlarge can not occur.

Owner:BEIJING LUSTER LIGHTTECH

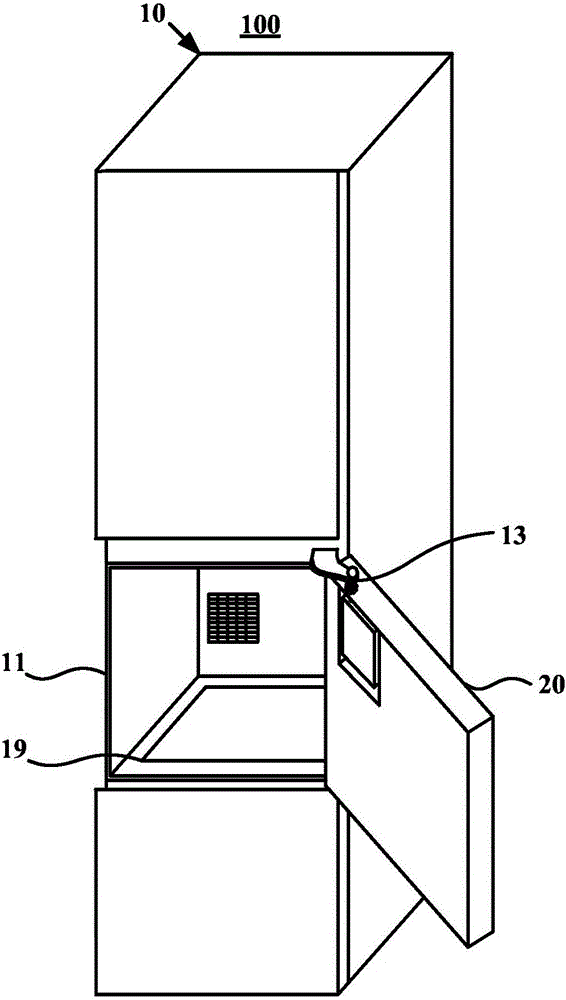

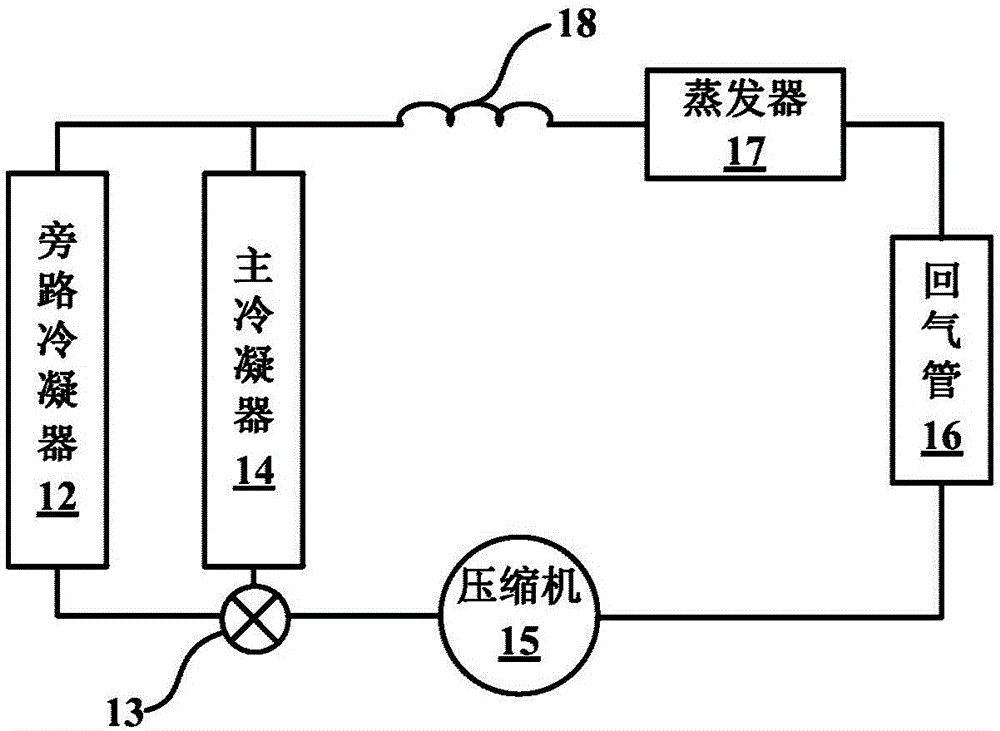

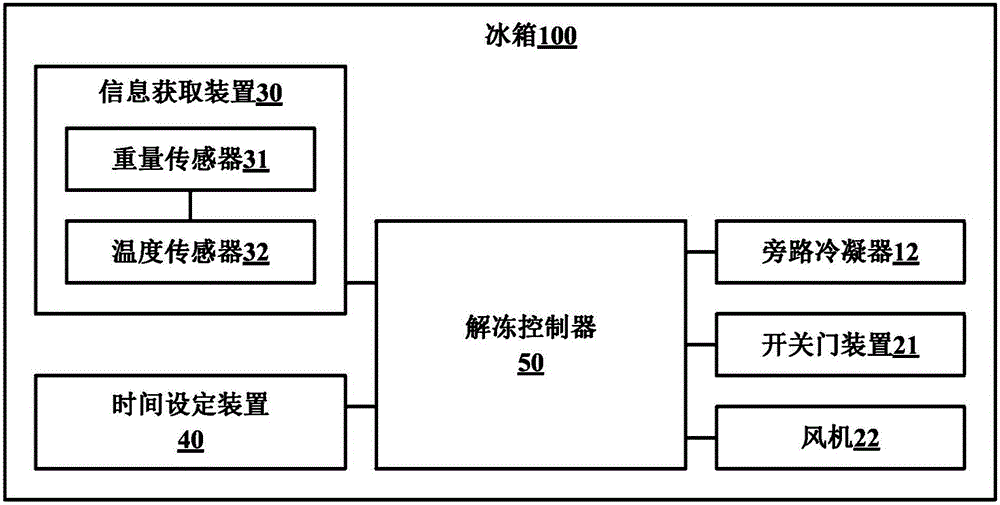

Refrigerator and unfreezing method of storage articles in refrigerator

ActiveCN106016949AMeet various needsImprove user experienceLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The invention provides a refrigerator and an unfreezing method of storage articles in the refrigerator. The unfreezing method of the storage articles in the refrigerator comprises the steps that unfreezing information of the storage articles put in independent compartments and unfreezing time set by a user are acquired; according to the unfreezing information, the estimation time required when different unfreezing modes are used for unfreezing is estimated, wherein the estimation time comprises first estimation time required when an air flow in a refrigerating compartment is used to unfreeze, second estimation time required when heat released by a bypass condenser is used to unfreeze, and third estimation time required when the air flow in the refrigerating compartment and the heat released by the bypass condenser are jointly used to unfreeze; the set unfreezing time is matched with the estimation time, and the unfreezing modes meeting the requirements of the unfreezing time are selected; and the independent compartments are forced to execute unfreezing procedures corresponding to the selected unfreezing modes. With the adoption of the scheme, various unfreezing modes are provided for the user, the unfreezing modes are selected according to the unfreezing time set by the user, and user experience is improved.

Owner:HAIER SMART HOME CO LTD

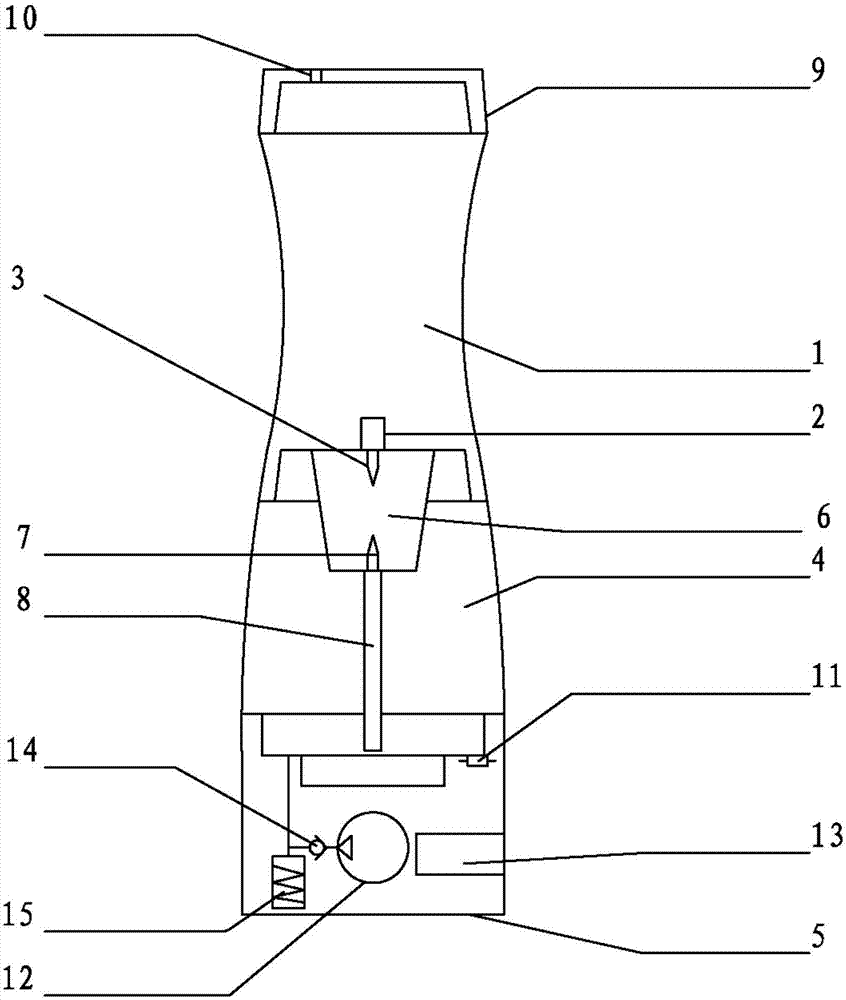

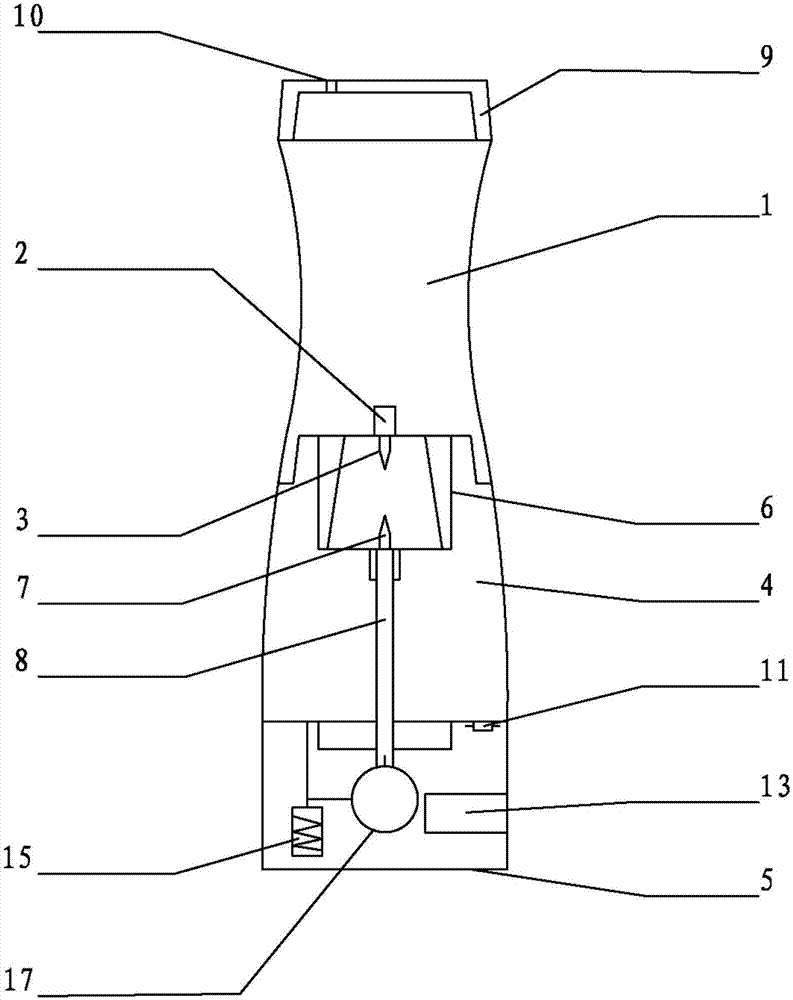

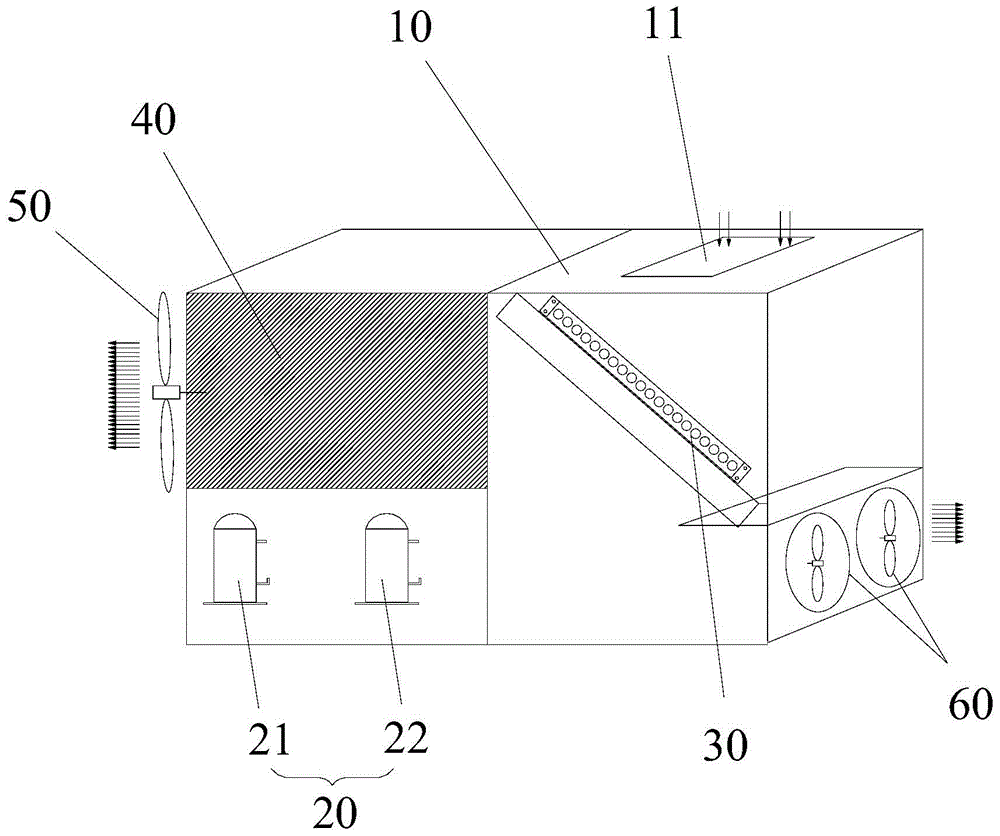

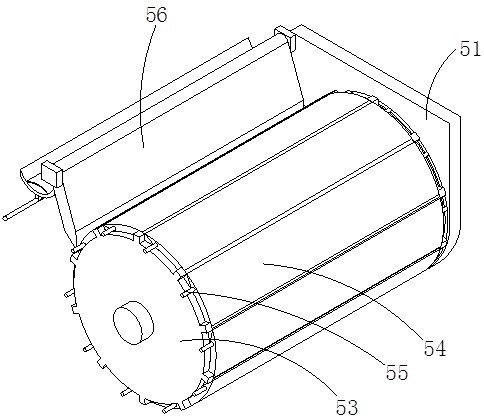

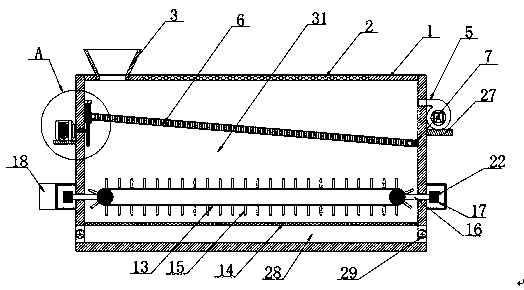

Tobacco drying machine and tobacco drying room

InactiveCN105495673BPrecise control of temperature and humidityAffect qualityTobacco preparationProcess engineeringEngineering

The invention discloses a tobacco dryer and a tobacco drying room. The tobacco dryer comprises a case shell, a compressor, a mixing condenser, an evaporator and a throttling device. The compressor, the mixing condenser, the evaporator and the throttling device are arranged in the case shell and communicated through a pipe to form a circulation system. The evaporator is arranged towards the outside of the tobacco drying room, and an evaporator heat-exchange fan is arranged on the evaporator. The mixing condenser is arranged towards the inside of the tobacco drying room, and a drying circulation heat-exchange fan is arranged on the mixing condenser. A traditional coal fuel heating type tobacco heating energy consumption mode is changed, the effects of energy conservation and emission reduction and reduction of environmental pollution can be achieved, potential production safety hazards in the traditional coal fuel heating type drying mode are avoided, precise control over the temperature and humidity in the tobacco drying room can be achieved, the influence on tobacco quality due to loss of essence during tobacco drying caused by exhaust and dehumidification is prevented, and accordingly quality of finished tobacco is guaranteed.

Owner:曾文

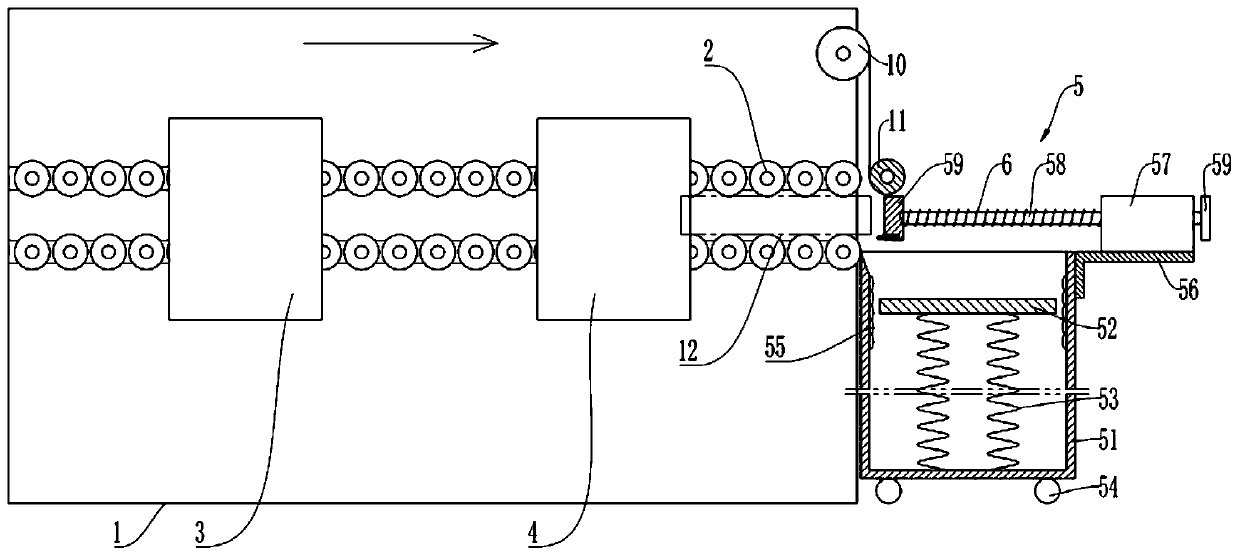

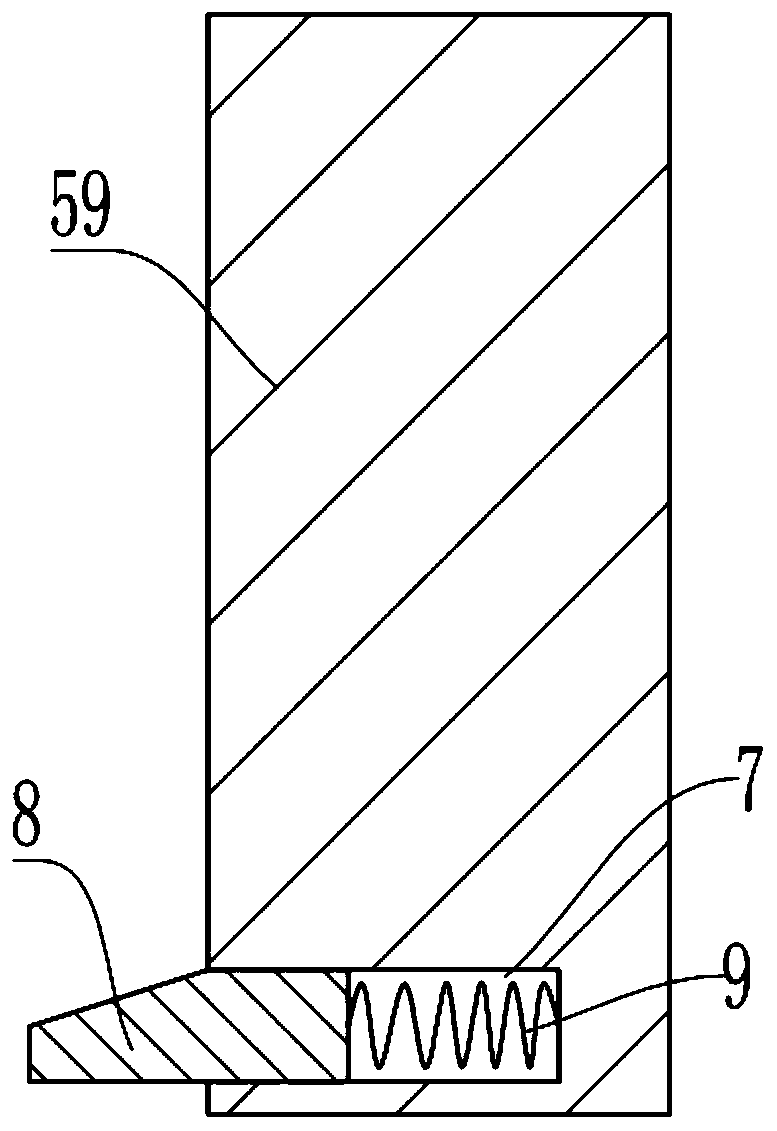

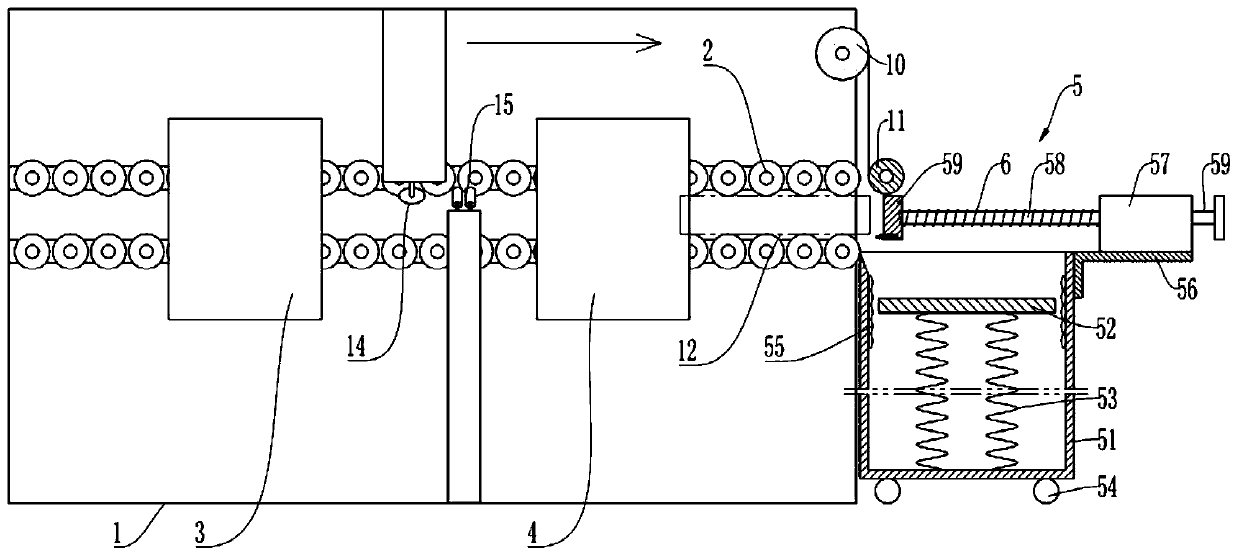

Edge-sealing device for paint-free door

ActiveCN110948617AGuaranteed flatnessAvoid random scatteringOther plywood/veneer working apparatusGrinding machinesStructural engineeringTransfer line

The invention relates to the technical field of edge-sealing for door bodies, and specifically discloses an edge-sealing device for a paint-free door. The edge-sealing device for the paint-free door comprises a rack, a conveying line, an edge-sealing machine and a transfer machine which are arranged on the rack, and a collection vehicle, wherein the collection vehicle and the edge-sealing machineare located at the two sides of the transfer machine; the collection vehicle comprises a collection frame; travelling wheels are arranged at the bottom of the collection frame; a support table is arranged in the collection frame; a first elastic element is arranged between the support table and the bottom of the collection frame; and the conveying line is capable of conveying a door plate onto thesupport table of the collection frame. According to the scheme, the edge-sealing device for the paint-free door is used for solving the problem of high labor intensity existing in a door plate completed through manual carrying edge-sealing and transfer in the prior art.

Owner:重庆金华兴门业有限公司

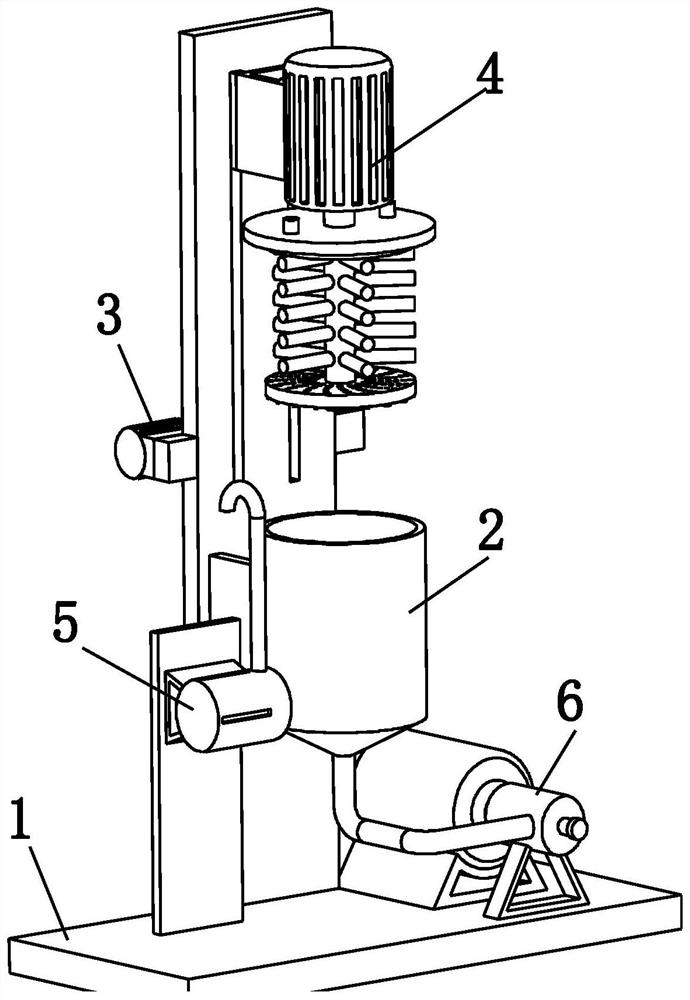

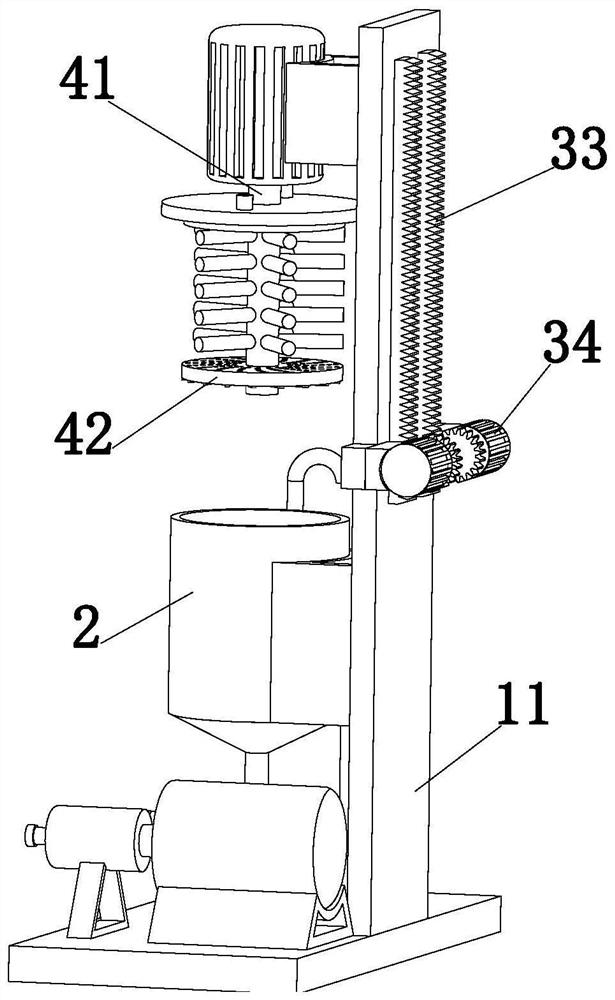

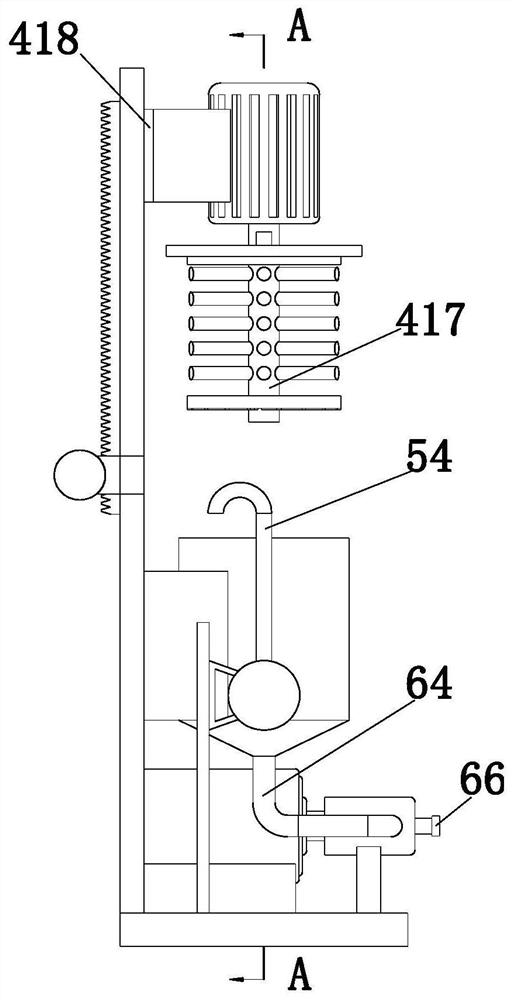

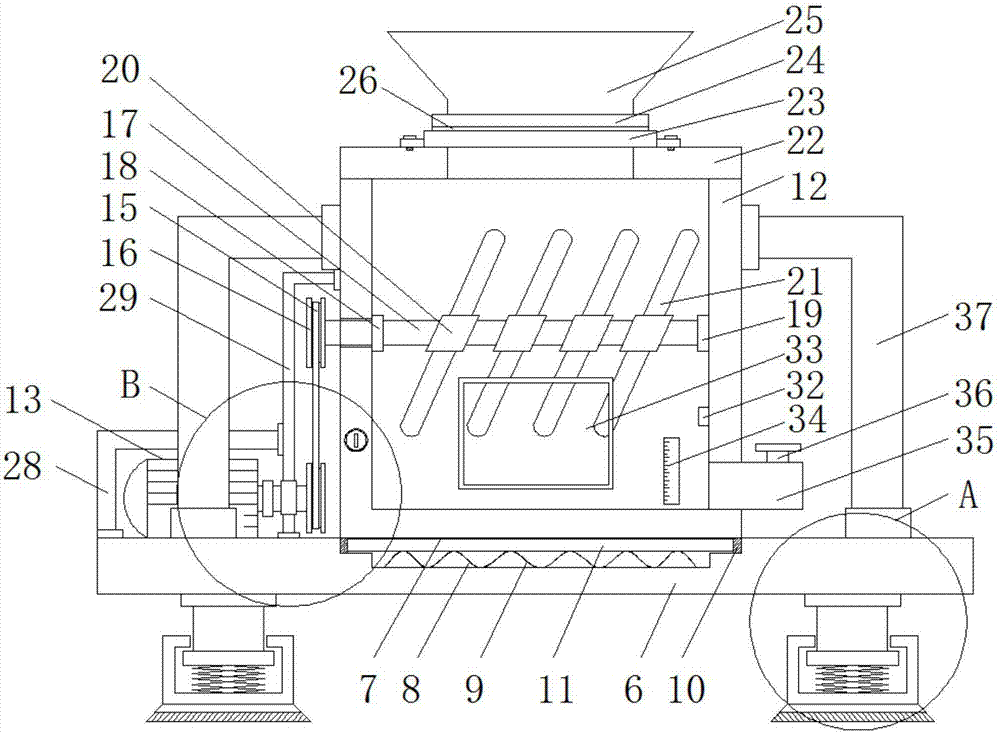

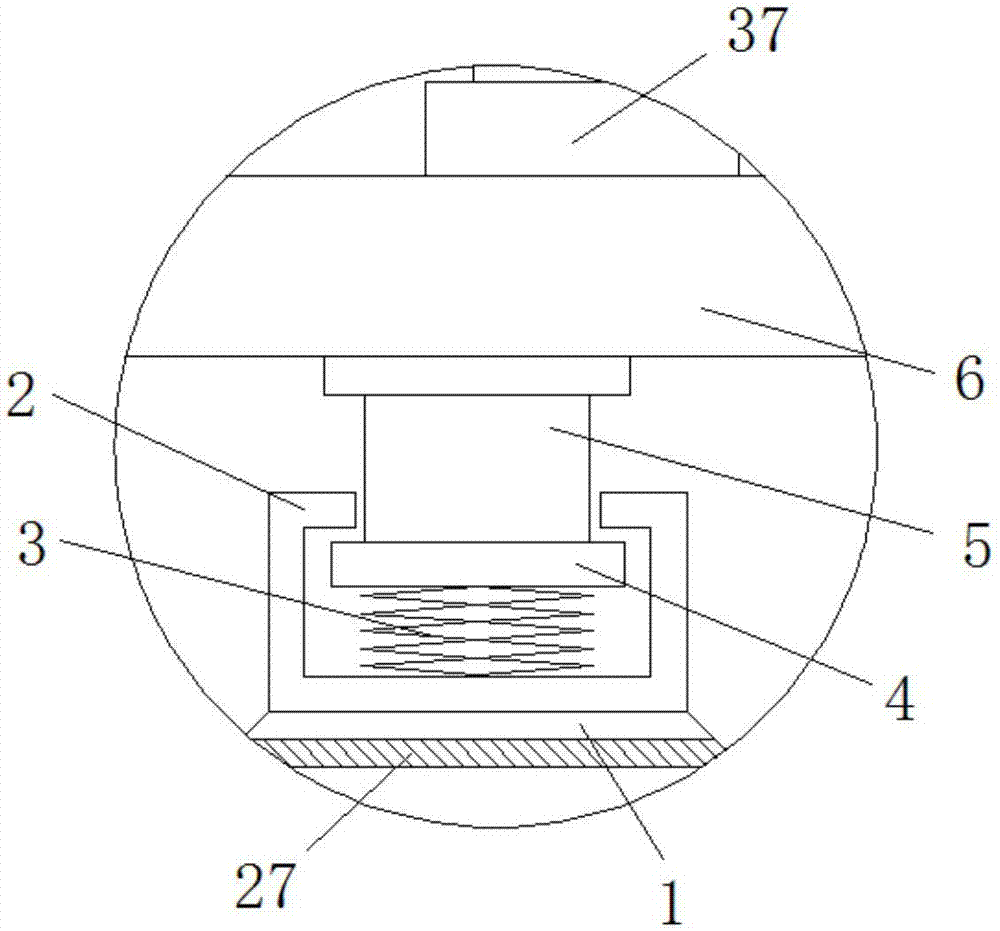

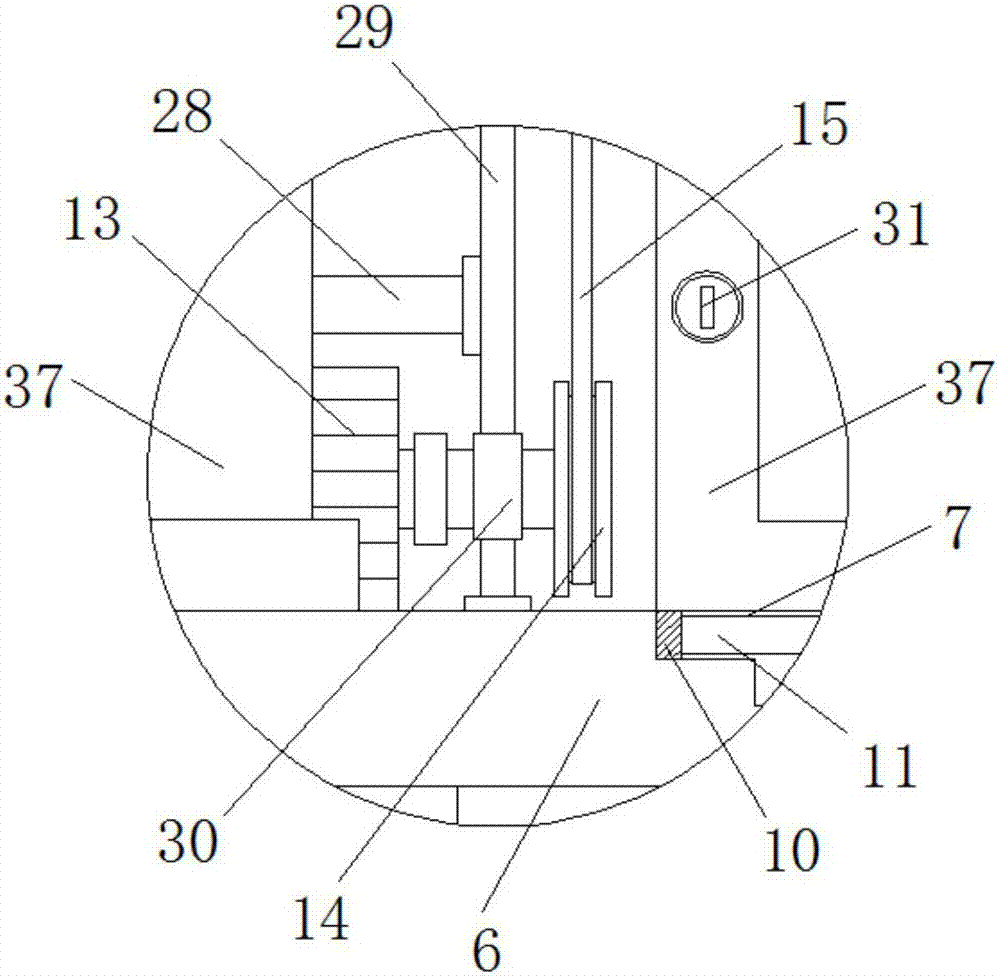

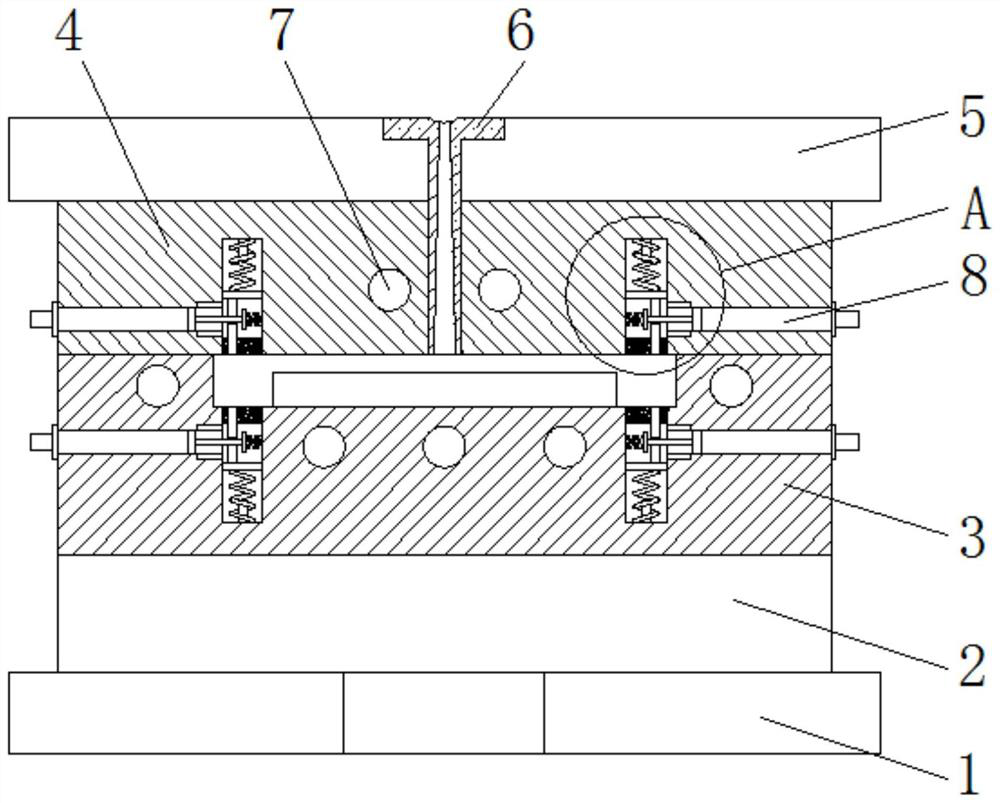

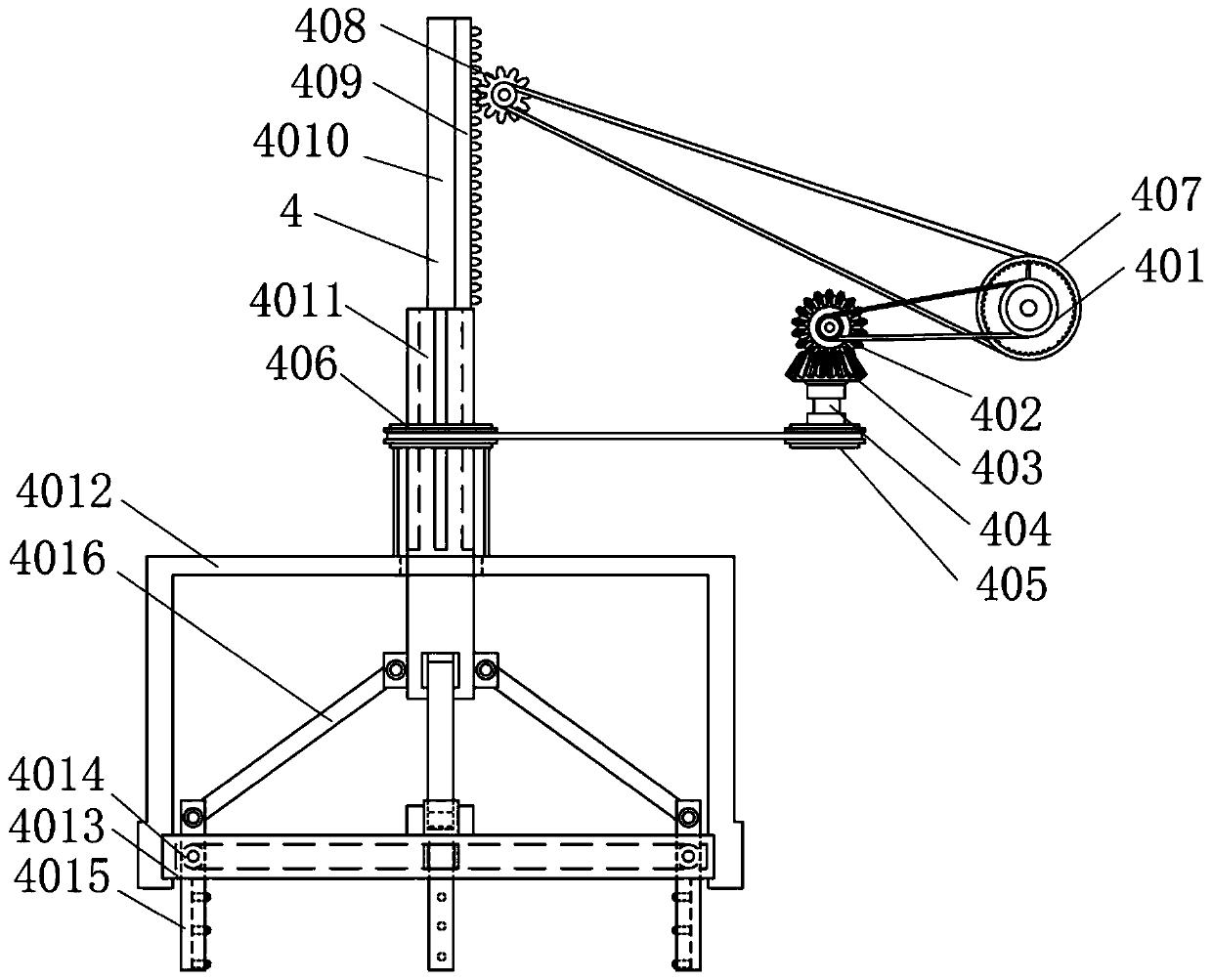

Paint grinding device

InactiveCN111760645AQuality improvementImproves the effect of abrasive coatingsCocoaGrain treatmentsEngineeringMechanical engineering

The invention relates to the technical field of paint production, in particular to a paint grinding device. The paint grinding device comprises a bottom plate, a material barrel, a lifting device, a grinding device, a returning device and a pumping device. The bottom plate is arranged on the horizontal plane, a vertical plate is arranged on the top of the bottom plate, two symmetric sliding holesare formed in the vertical plate, the material barrel is arranged on the front side of the vertical plate and mounted on the side wall of the vertical plate through a fixing seat, the lifting device is arranged on the side wall of the vertical plate and is in sliding fit with the two sliding holes, the grinding device is arranged on the lifting device, the returning device is arranged above the bottom plate and communicates with the material barrel, and the pumping device is arranged on the top of the bottom plate and communicates with the bottom of the material barrel. Through mutual cooperation work of procedures of the lifting device, the grinding device, the returning device and the pumping device, the effect of grinding paint is improved, the grinding quality of the paint can be improved, and when the grinding device does not work, the grinding device is convenient to clean.

Owner:姚啸云

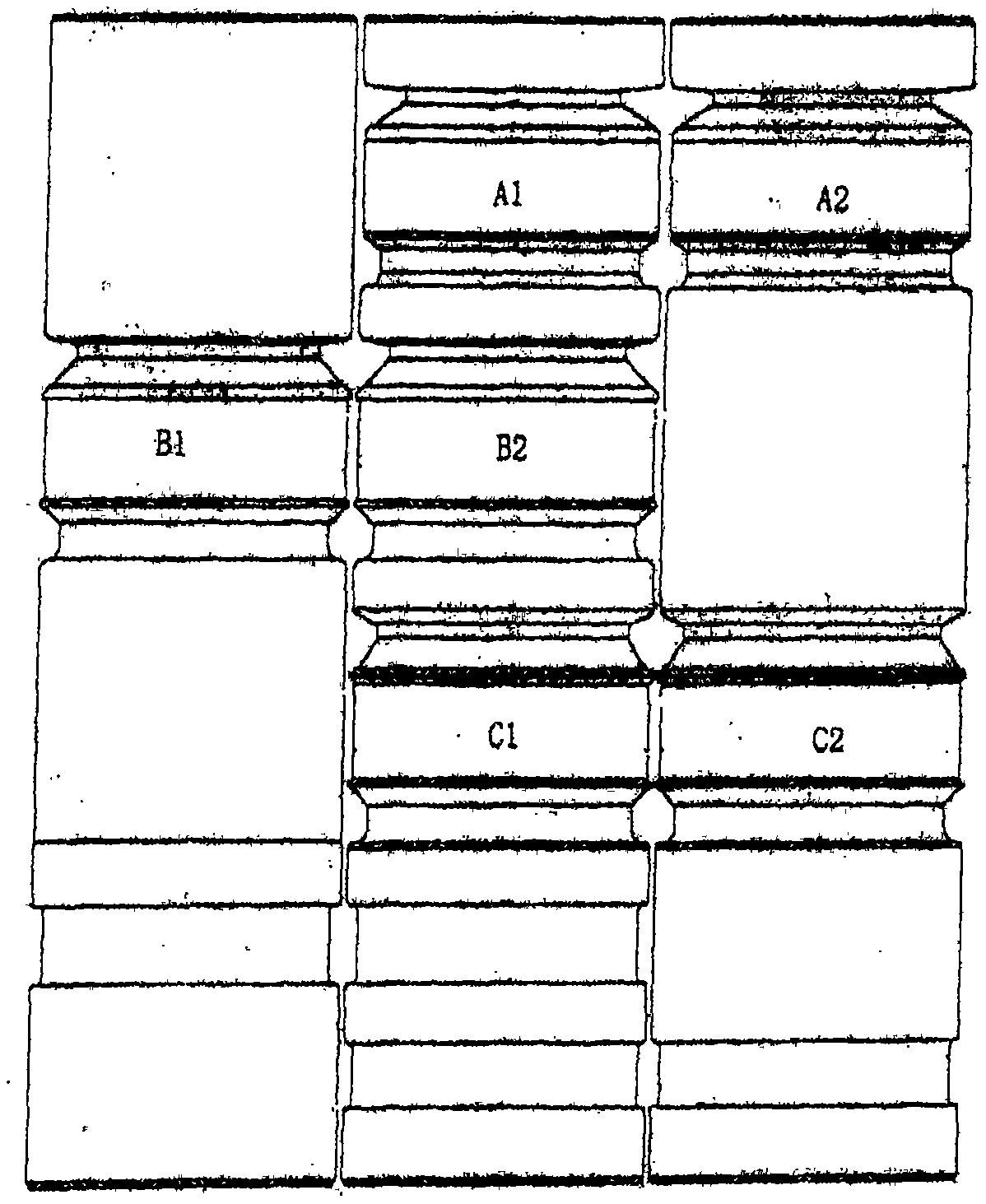

Rolling roller set system for rolling waste railway steel rail

InactiveCN109433805AReduce consumptionIssues affecting qualitySolid waste disposalEconomic benefitsEngineering

The invention provides a rolling roller set system for rolling a waste railway steel rail. The rolling roller set system comprises three rolling roller sets, the first rolling roller set is the rolling roller set which is used for carrying out groove expanding along a heated railway steel rail hole shape, the second rolling roller set is the rolling roller set which is used for carrying out indentation rolling along a boundary of the rail top, the rail web and the rail bottom on the steel rail subjected to groove expanding through the first rolling roller set, and the third rolling roller setis the disassembly device which is used for finally tearing the steel rail subjected to rolling though the second rolling roller set into three portions, namely, the rail top, the rail web and the rail bottom. Compared with a previously applied cutting technology carried out before a heating link, by using the rolling roller set system, the development and utilization cost can be saved, the economic benefit can be improved, and favorable conditions are also created for marching to the automation.

Owner:临沂市兴华工程机械有限公司

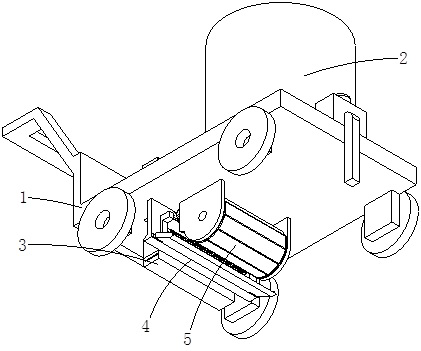

Discharging and sorting device for color sorter

InactiveCN108714567AIssues affecting qualityImprove sorting efficiencySortingGradingEngineeringMechanical engineering

The invention discloses a discharging and sorting device for a color sorter, and relates to the technical field of color sorter equipment. The device comprises a sorting device and a discharging hopper, a first motor is fixedly connected to one surface of a shell, one end of an output shaft of the first motor is fixedly connected with a first roller, one end of the first roller is rotationally connected with the shell, the peripheral side surface of the first roller is in transmission connection with a first conveying belt, a first soft baffle plate and a second soft baffle plate are fixedly connected to the peripheral side surface of the first conveying belt correspondingly, and a first through hole and a second through hole are formed in one surface of the shell correspondingly. According to the device, the sorting device is used for screening materials, so that the problem that due to the fact that particles of the materials sorted by an existing color sorter are different in size,the overall quality of the materials is influenced is solved; and rubber baffle plates in the discharging hopper is used for buffering the materials entering the discharging hopper at a high speed, sothat the situation that due to collision caused by direct contact between the materials and the side wall of the discharging hopper, the material particles are damaged is prevented.

Owner:合肥通快钣金科技有限公司

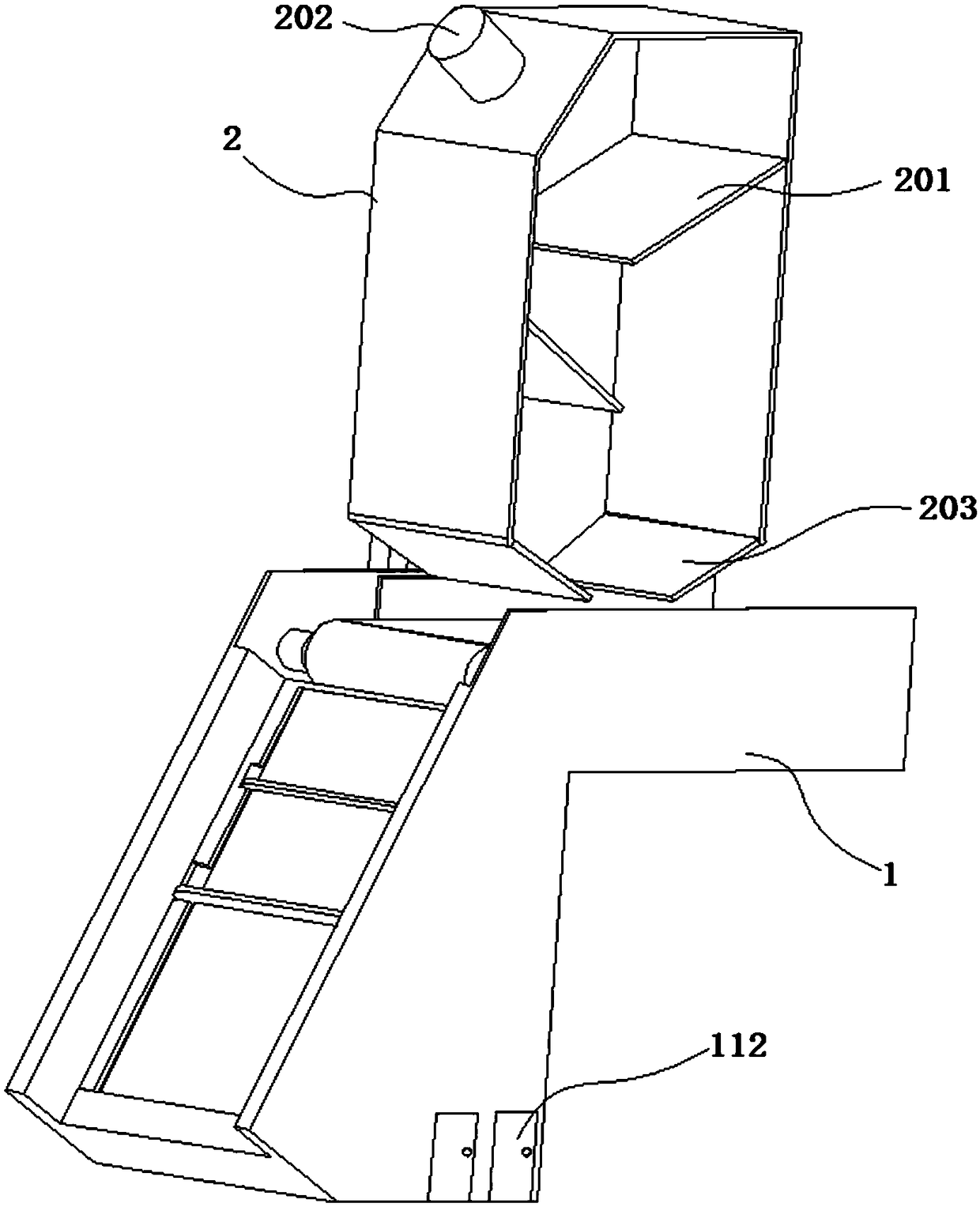

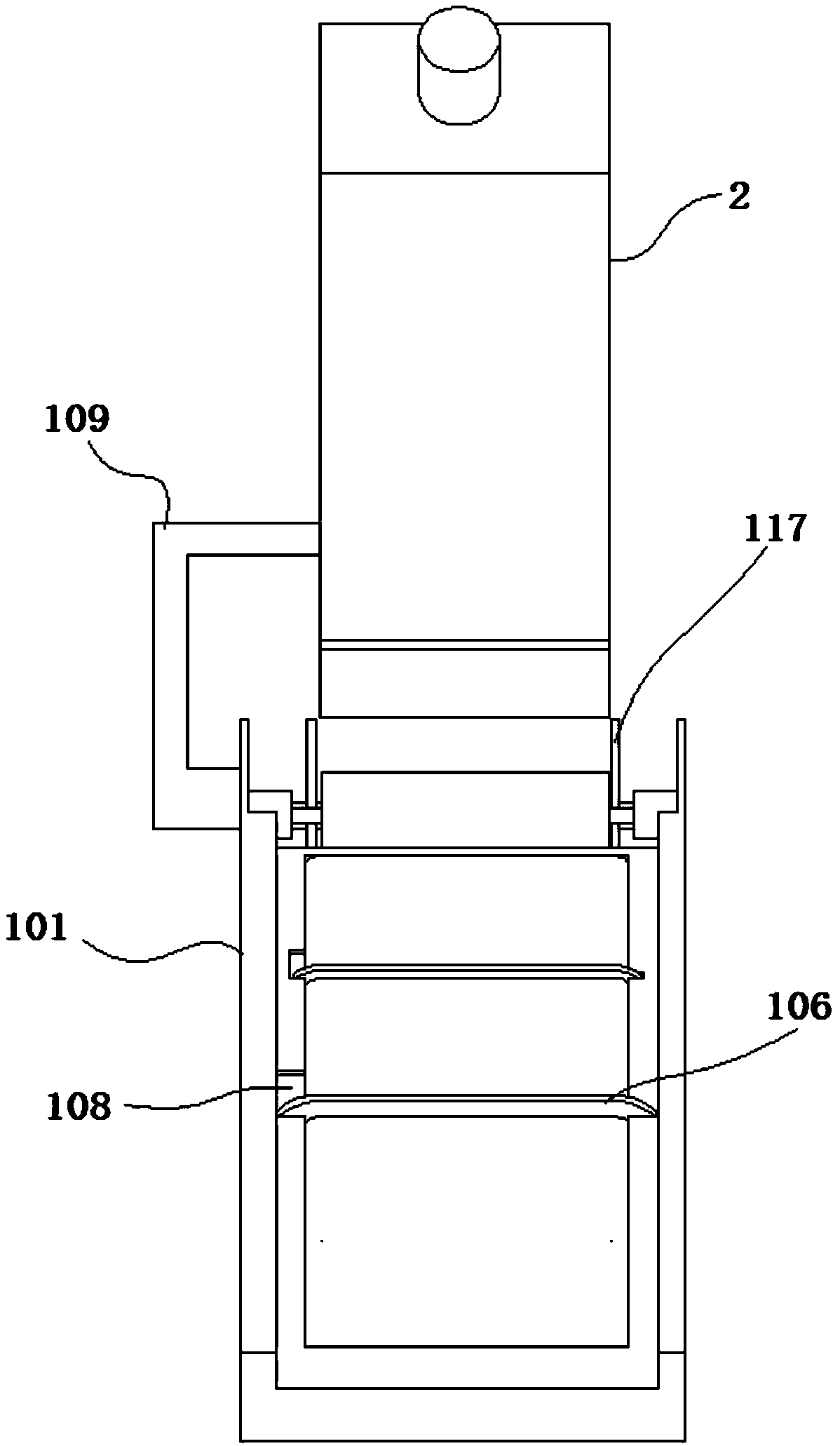

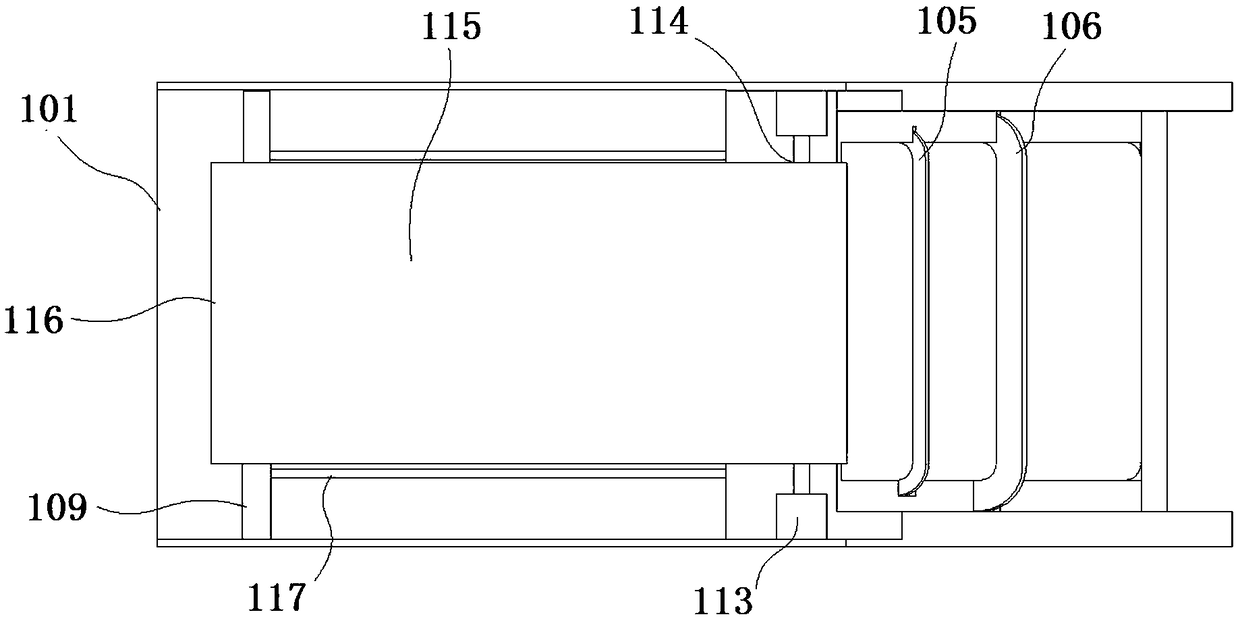

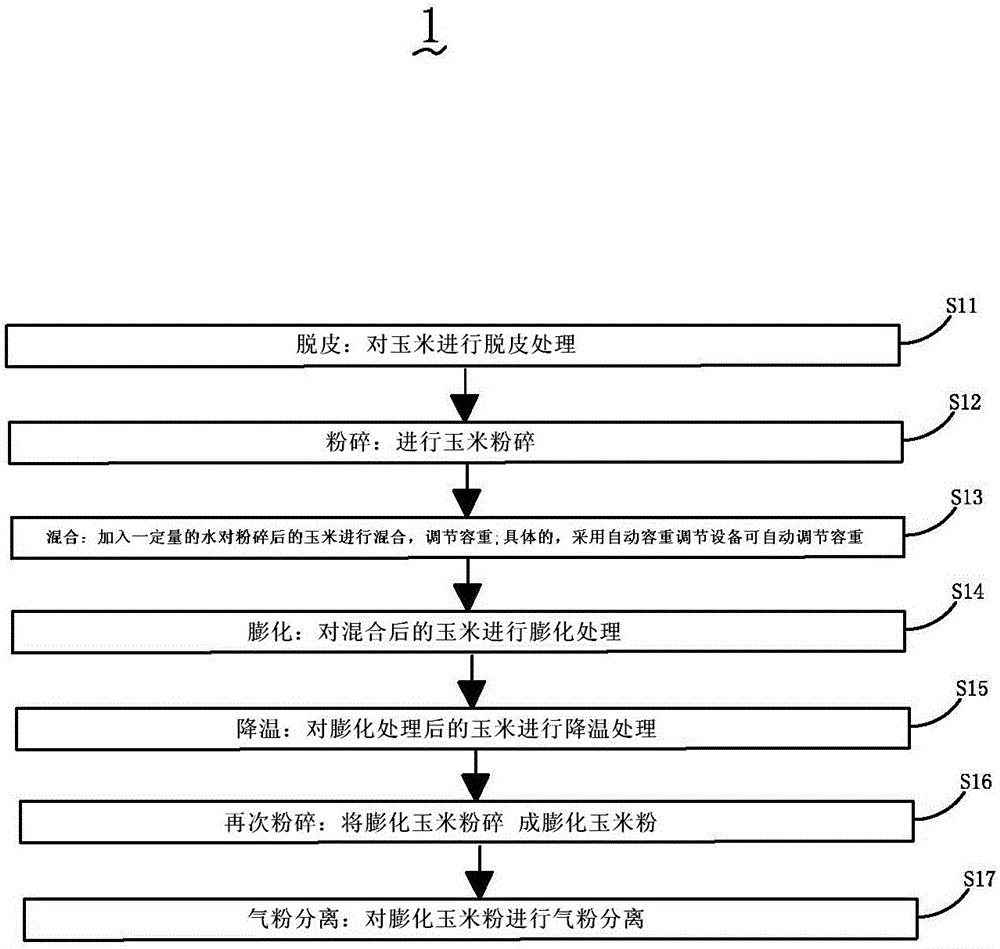

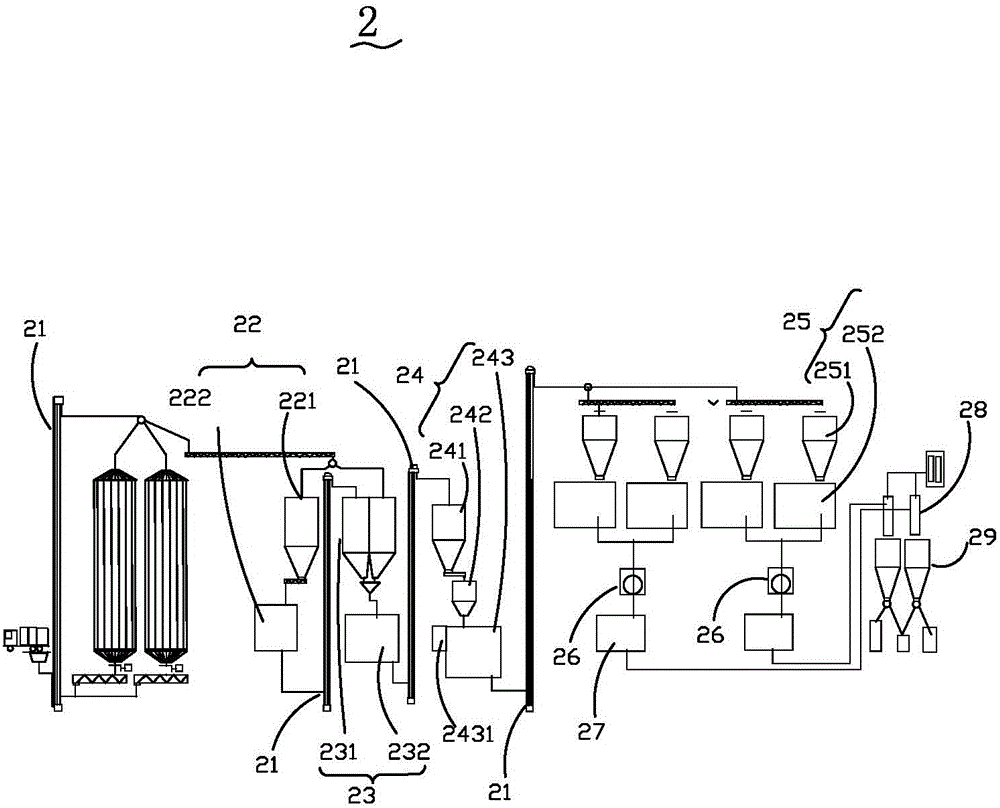

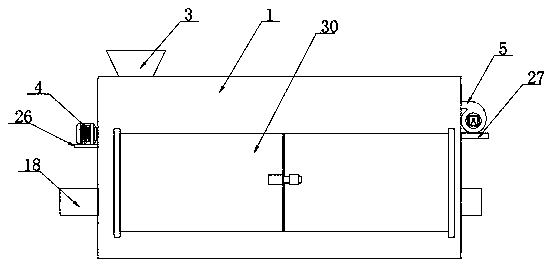

Production method and production equipment of dry method peeled extruded corn

PendingCN105994989AHigh degree of automationGuaranteed qualityGrain huskingGrain polishingAgricultural scienceAgricultural engineering

The present invention provides a production method and production equipment of dry method peeled extruded corn. The dry method peeled extruded corn production equipment comprises dry method peeled extruded corn production devices, specific mortar for building blocks, pouring concrete and reinforced steel bars. The adjacent dry method peeled extruded corn production devices are connected with each other using the specific mortar for building blocks, the pouring concrete is filled into the cavities of the adjacent dry method peeled extruded corn production devices in a vertical direction of a specific position, and the reinforced steel bars pass through the cavities of the adjacent dry method peeled extruded corn production devices in the vertical direction of the specific position. The dry method peeled extruded corn production equipment has high degree of automation, is safe and reliable, and convenient and succinct, can produce the high-quality peeled extruded corn, realize automatic regulation volume weight under a non-stop state condition, and realize the reduction of extruded corn semi-finished products under a condition of increasing energy consumption, and ensures quality.

Owner:临沂正能量生物有限公司

Determination technology for encapsulation quality of aluminum plastic film of polymer lithium-ion battery

InactiveCN108615944AEasy to operateSimple methodFinal product manufactureElectrolyte accumulators manufactureLithium electrodePlastic film

The invention provides a determination technology for encapsulation quality of aluminum plastic film of a polymer lithium-ion battery. The other batch of aluminum plastic film which is about to be applied to the polymer lithium-ion battery is prepared into a simulation battery according to heat-sealing technological parameters of the aluminum plastic film of the previous batch, then the simulationbattery is subjected to extrusion testing and simulation testing, and according to testing results, the heat-sealing quality of the aluminum plastic film is judged comprehensively; then, according tothe heat-sealing quality, the heat-sealing technological parameters are pre-adjusted to guarantee that the aluminum plastic film has qualified encapsulation quality, the aim of controlling the encapsulation quality of the aluminum plastic film of the polymer lithium-ion battery is achieved accordingly, and the problem is solved that the difference of the encapsulation quality of the aluminum plastic film of different batches exists, and accordingly the quality of the polymer lithium-ion battery is influenced. According to the determination technology, the heat-sealing technological parametersare adjusted according to the extrusion testing results and insulation performance testing results, and the method is easy and quick to use and high in accuracy.

Owner:SHENZHEN GPC ENERGY GRP CO LTD

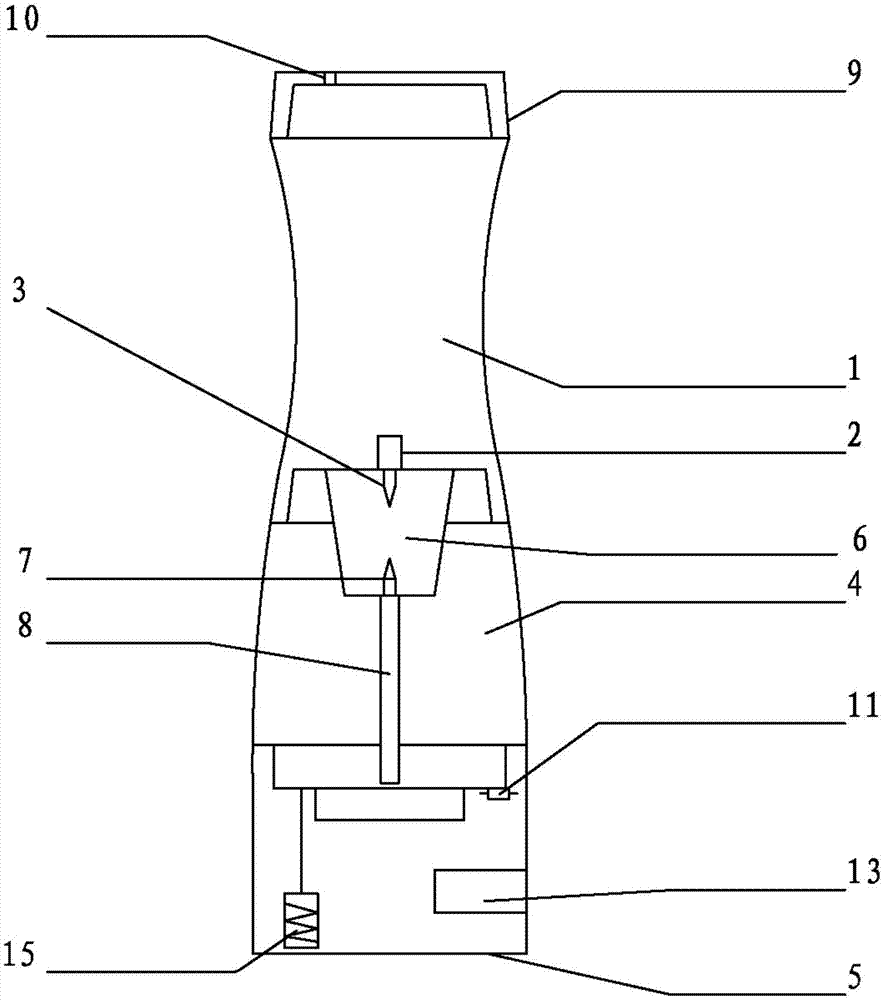

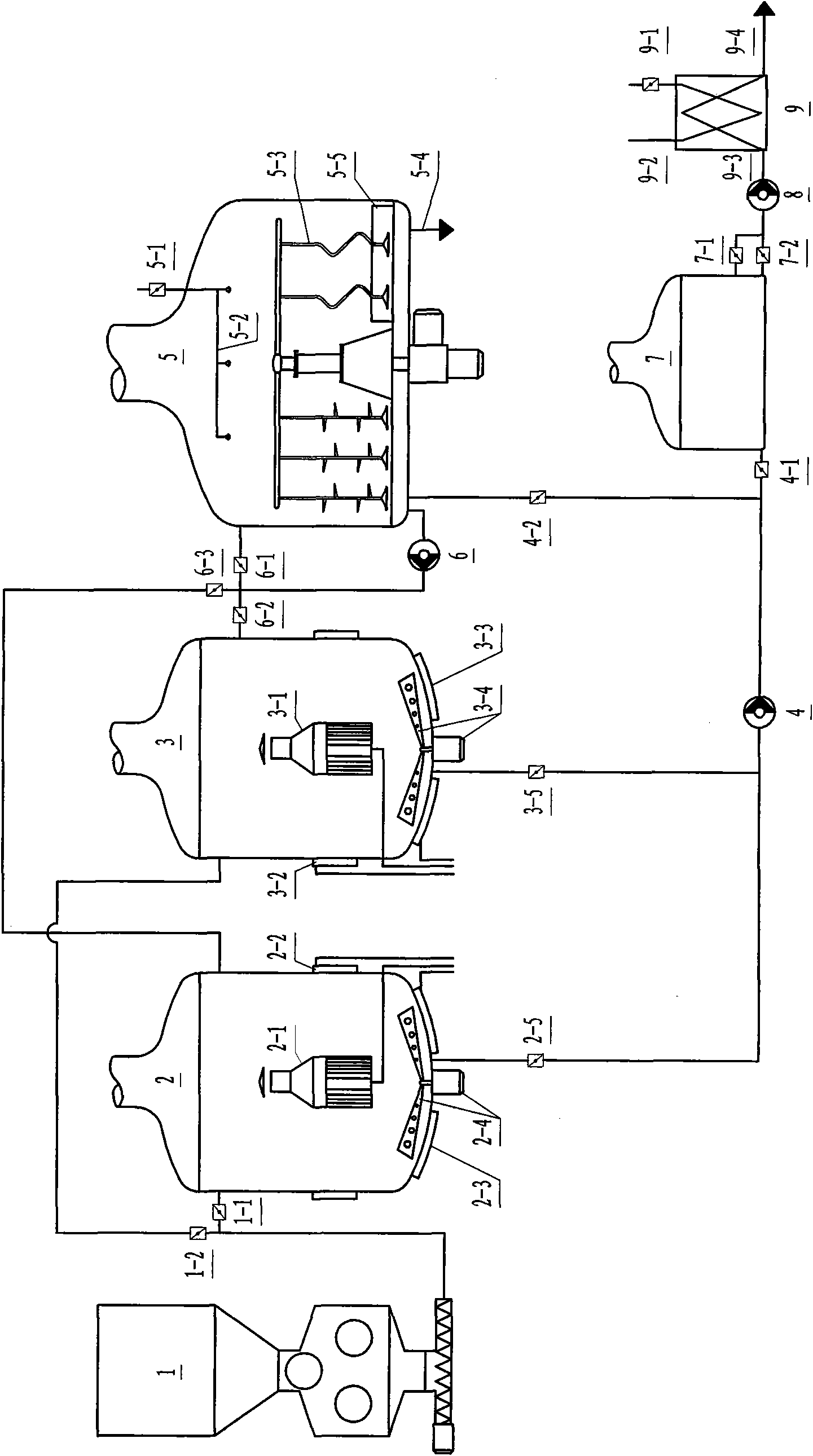

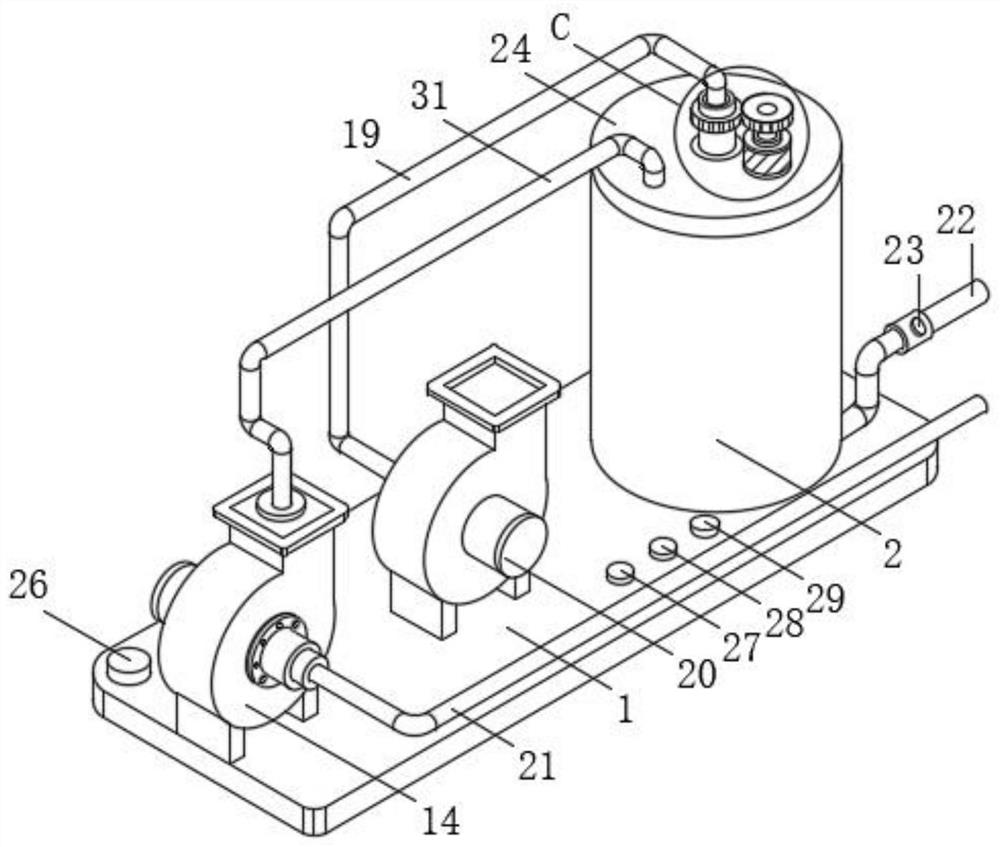

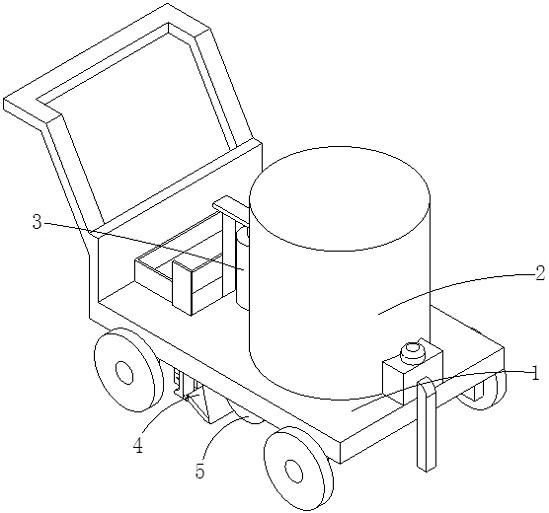

Saccharifying device for beer

ActiveCN101619277AIssues affecting qualityIncrease productivityWort preparationBiochemical engineeringCrusher

The invention discloses a saccharifying device for beer, comprising a malt crusher, a filter groove and a swirl sedimentation groove, wherein a material circulation channel consisting of a centrifugal pump of the filter groove and a pipeline of the filter groove is arranged outside the filter groove. The saccharifying device for the beer is characterized in that two saccharification wort kettles are connected in parallel between the malt crusher and the filter groove, thereby a material channel from the malt crusher to the filter groove by passing through the saccharification wort kettles is formed; meanwhile, the two saccharification wort kettles are also connected in parallel between the filter groove and the swirl sedimentation groove, thereby a material channel from the filter groove to the swirl sedimentation groove by passing through the saccharification wort kettles is formed; in addition, each saccharification wort kettle is provided with a steam jacket, and an inside heater and a boiler bottom stirrer are arranged in each saccharification wort kettle. The device is suitable for saccharification in middle and small breweries, has higher production efficiency than equipmentof a beer house and lower cost than large-scale brewery type saccharifying equipment, and is simple to control and operate.

Owner:宁波沪港食品机械制造有限公司

Anti-stretching device for fixing plate of bending machine

InactiveCN108927426AAchieve clampingRealize real-time clampingMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses an anti-stretching device for fixing a plate of a bending machine, and belongs to the technical field of fixing and stretching prevention of plates of the bending machine. Theanti-stretching device is characterized in that top blocks cooperating with bending grooves are arranged at the top of a workbench, the left side and the right side of the top of the workbench are correspondingly provided with slideways, assembling cavities are formed in the bottoms of the slideways, clamping plates are nested in the assembling cavities, the top ends of the clamping plates penetrate through the slideways and extend to the parts above the workbench, inner rods of electric telescopic rods extend to the bottoms, connected with the clamping plates, of the side walls of the assembling cavities, compression springs are connected to the bottoms of the side walls of one sides, far away from the electric telescopic rods, of the clamping plates, the other ends of the compression springs are fixed on one sides, far away from openings, of the assembling cavities, and supporting springs are connected to the side walls of one sides, far away from the top blocks, of the clamping plates. And therefore, the thin plate can be positioned longitudinally and transversely, then the phenomenon of stretching of the thin plate is effectively prevented, and the situations that the quality of the thin plate is influenced due to the fact that the stretching phenomenon occurs after the thin plate is bent are avoided.

Owner:高邮市金利达机械有限公司

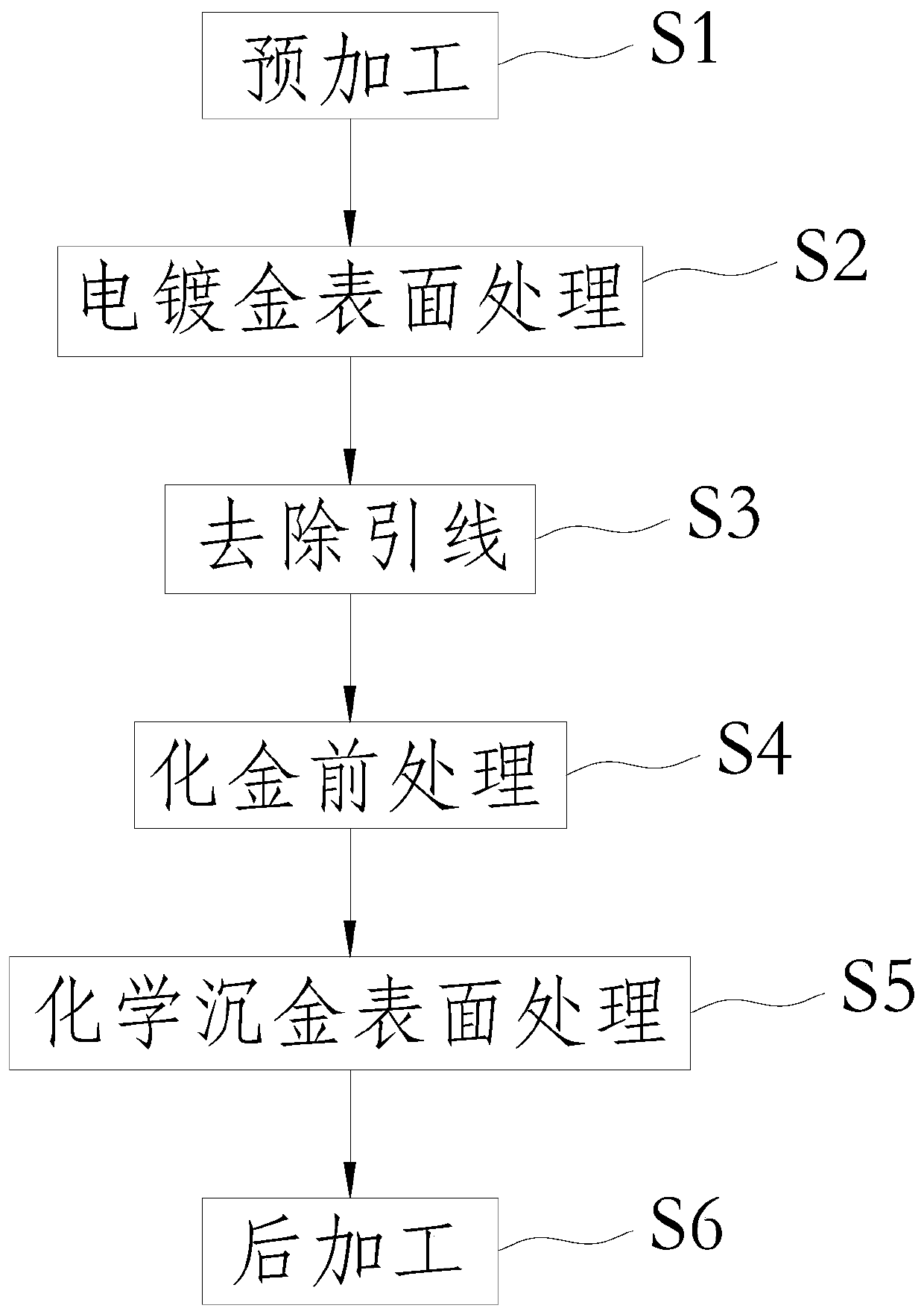

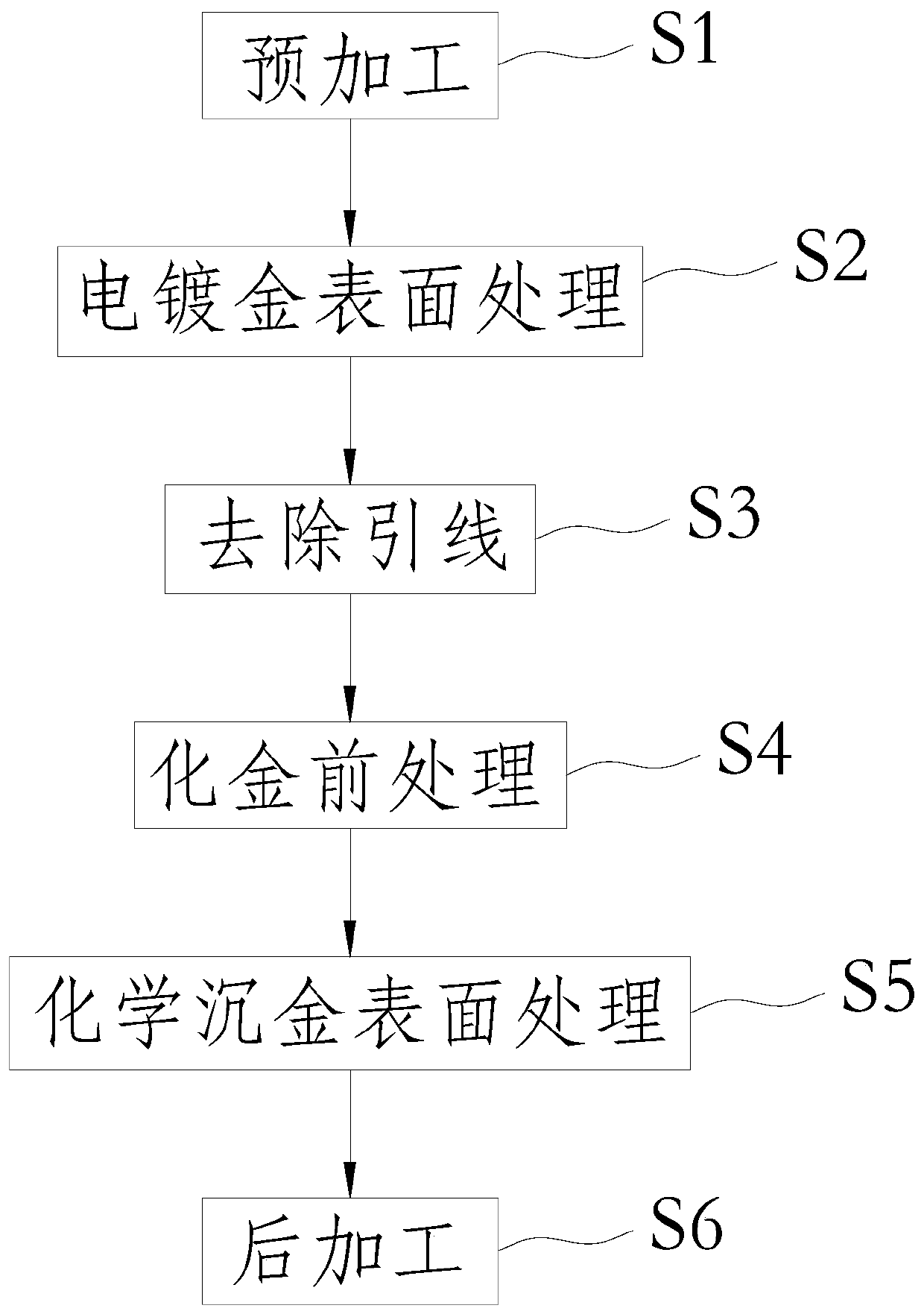

PCB (Printed Circuit Board) manufacturing method with gold plating and gold melting processes

InactiveCN110049625ASolve the problem of gold seepageAvoid overwritingNon-metallic protective coating applicationOxidation resistantPrinted circuit board

The invention provides a PCB (Printed Circuit Board) manufacturing method with gold plating and gold melting processes, which comprises the following steps of: pre-processing to obtain a multi-layer circuit board with an outer-layer circuit; performing electrogilding surface treatment; removing the lead; pretreatment of gold melting: respectively carrying out oxidation resistance treatment and resistance welding on the multi-layer circuit board; carrying out chemical immersion gold surface treatment; and performing post-processing to obtain the PCB. According to the PCB manufacturing method with gold plating and gold melting processes, firstly, electrogilding surface treatment and lead removal are carried out on the multi-layer circuit board; then gold melting pretreatment is carried out;oxidation resistance treatment and resistance welding are carried out on the multi-layer circuit board; and then, chemical immersion gold surface treatment is carried out, according to the process flow, not only is the product quality of the gold plating area ensured, but also the product quality of the gold melting area is ensured, the problem of lead gold seepage during electrogilding surface treatment is more effectively solved, and meanwhile leads can be completely removed in the lead removal step.

Owner:ZHUHAI CHINA EAGLE ELECTRONIC CIRCTCUIS CO LTD

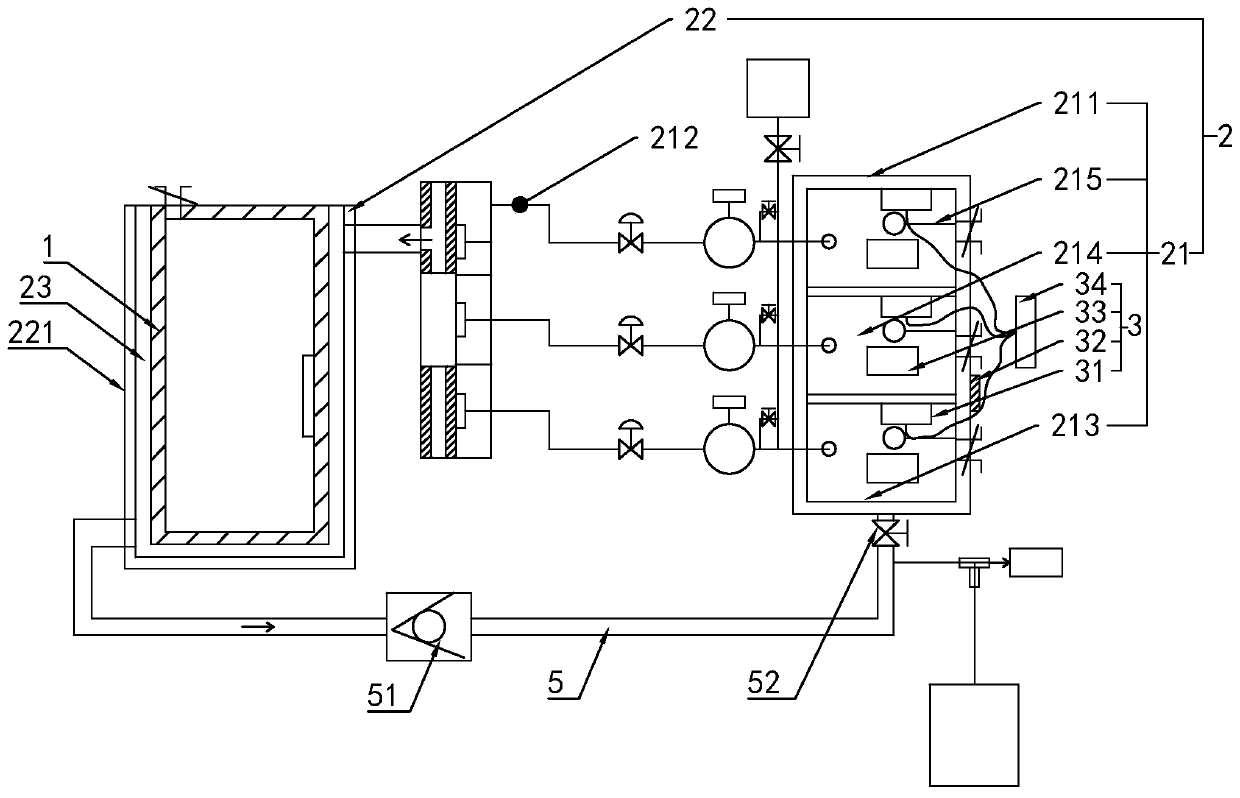

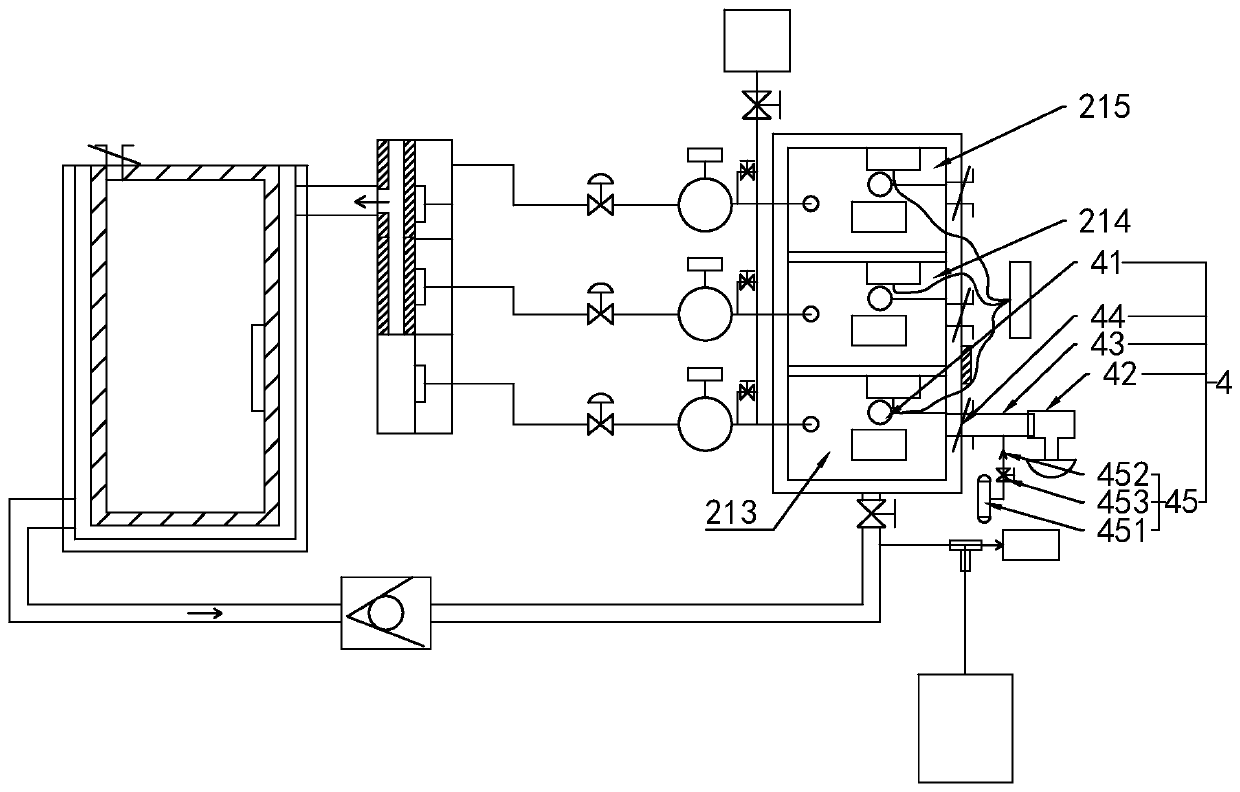

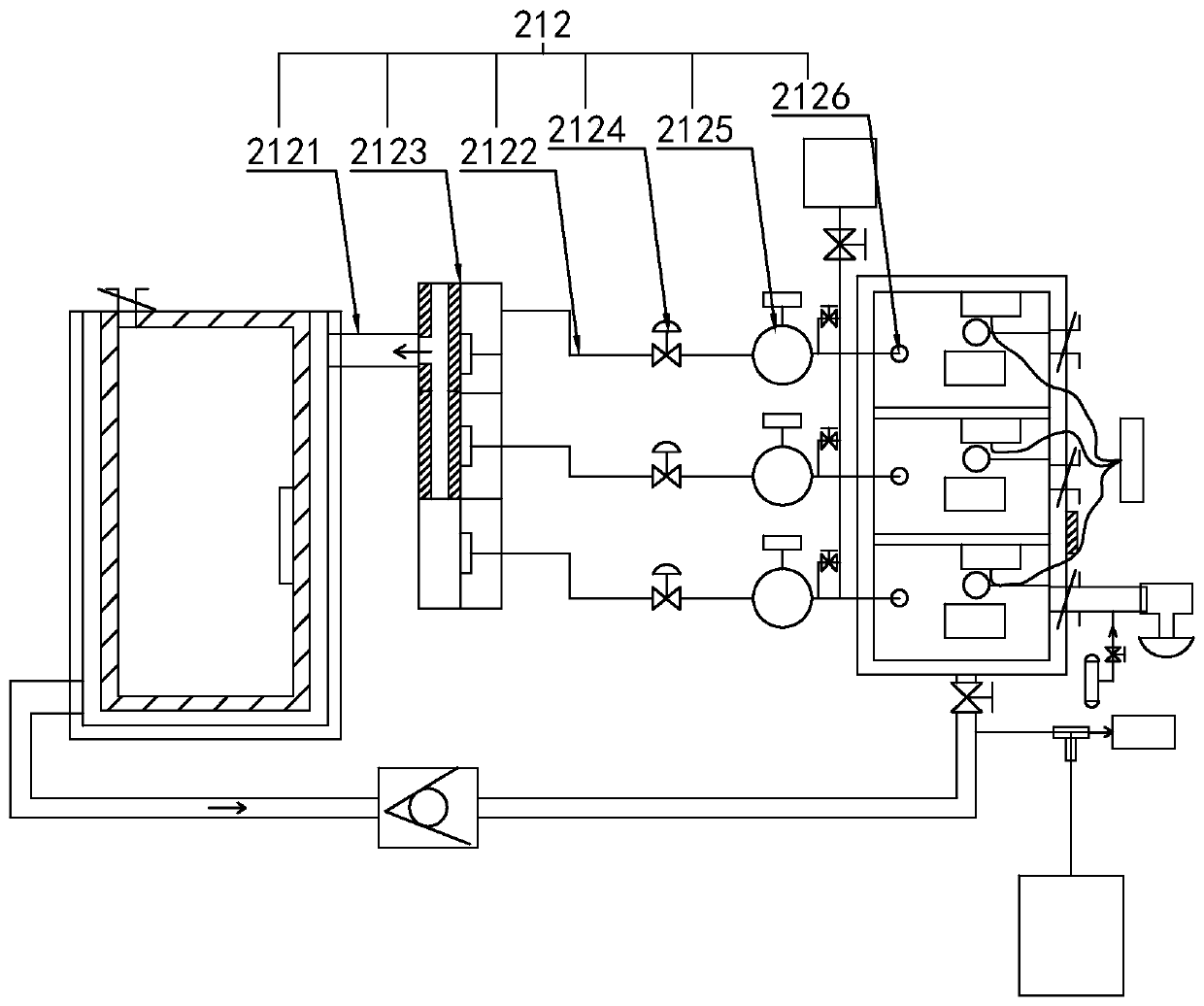

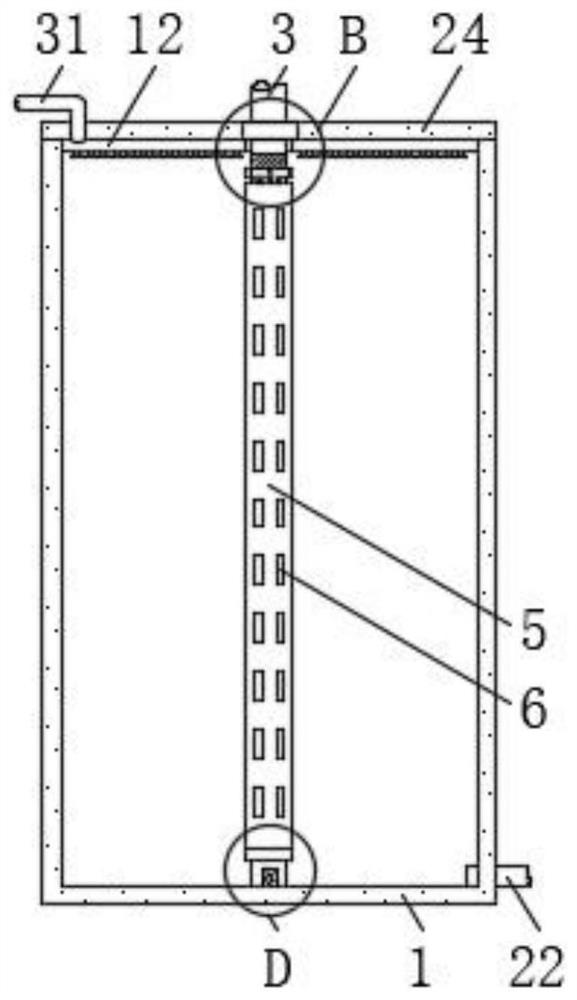

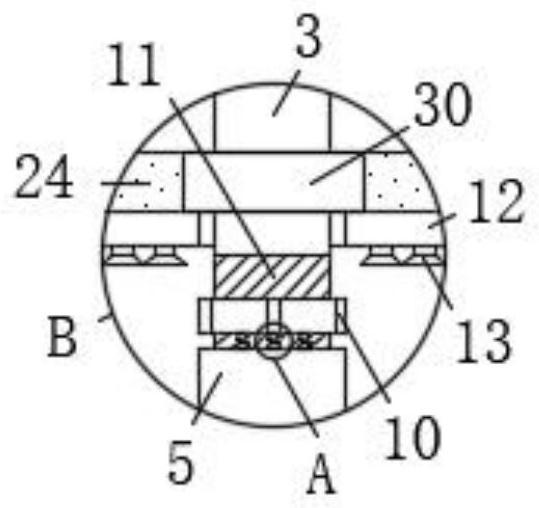

Anti-solidification constant-temperature system for corn oil and constant-temperature control method thereof

PendingCN111045463AIssues affecting qualityConstant temperature heating evenlyTemperature control using plurality of sensorsTemperature controlOutdoor temperature

The invention relates to an anti-solidification constant temperature system for corn oil. The anti-solidification constant temperature system comprises an oil storage tank and a constant temperature control device. The constant temperature control device comprises a heat supply module and a constant temperature module; the constant-temperature module comprises a constant-temperature barrel; the constant-temperature barrel sleeves the oil storage tank, and a liquid storage space is formed between the constant-temperature barrel and the oil storage tank; the heat supply module comprises a hot water tank and a water delivery system; hot water in the hot water tank is conveyed into the liquid storage space through the water delivery system along a water inlet of the constant-temperature barrel; and the hot water tank comprises a low-temperature water tank, a transition water tank and a high-temperature water tank which are separated through partition plates. The hot water tank is providedwith a heating unit used for controlling water temperatures in the low-temperature water tank, the transition water tank and the high-temperature water tank according to outdoor temperature changes. The anti-solidification constant-temperature system for the corn oil is good in anti-solidification effect, does not influence product quality of the corn oil and is wide in application range.

Owner:衢州刘家香食品有限公司

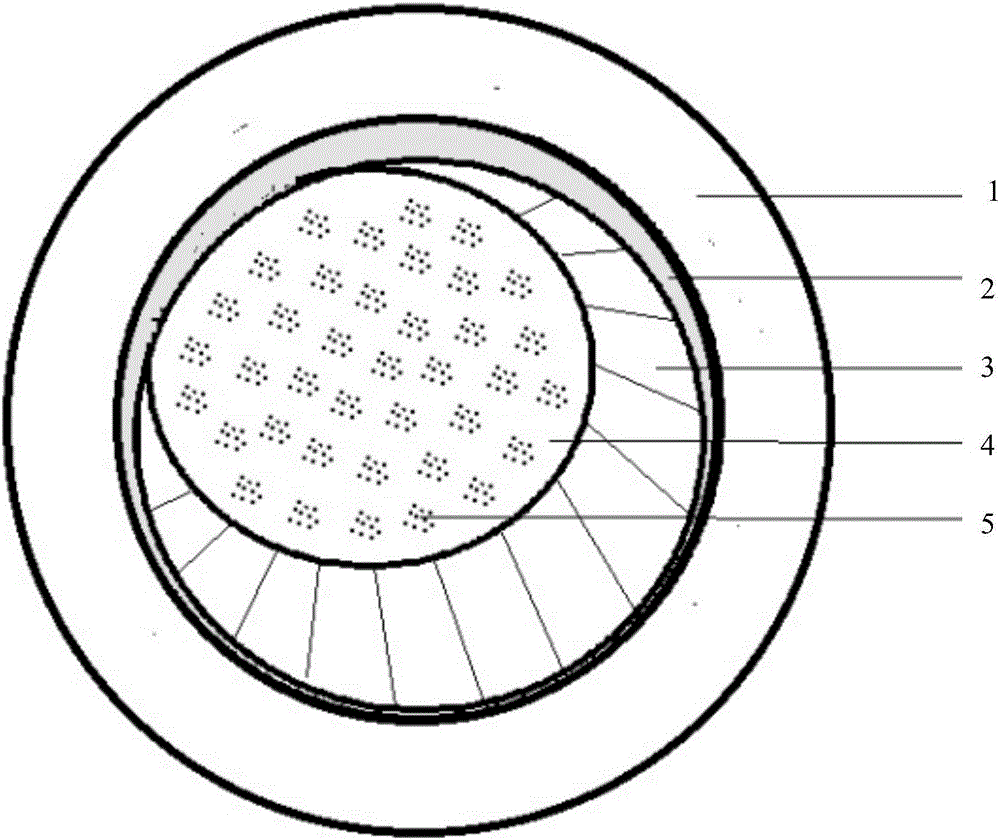

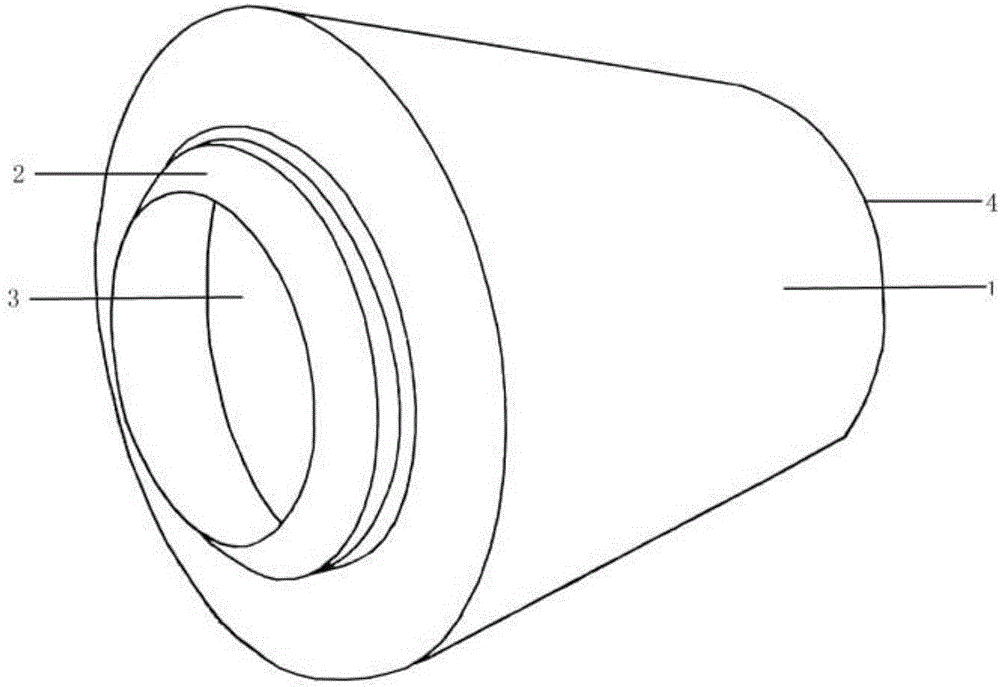

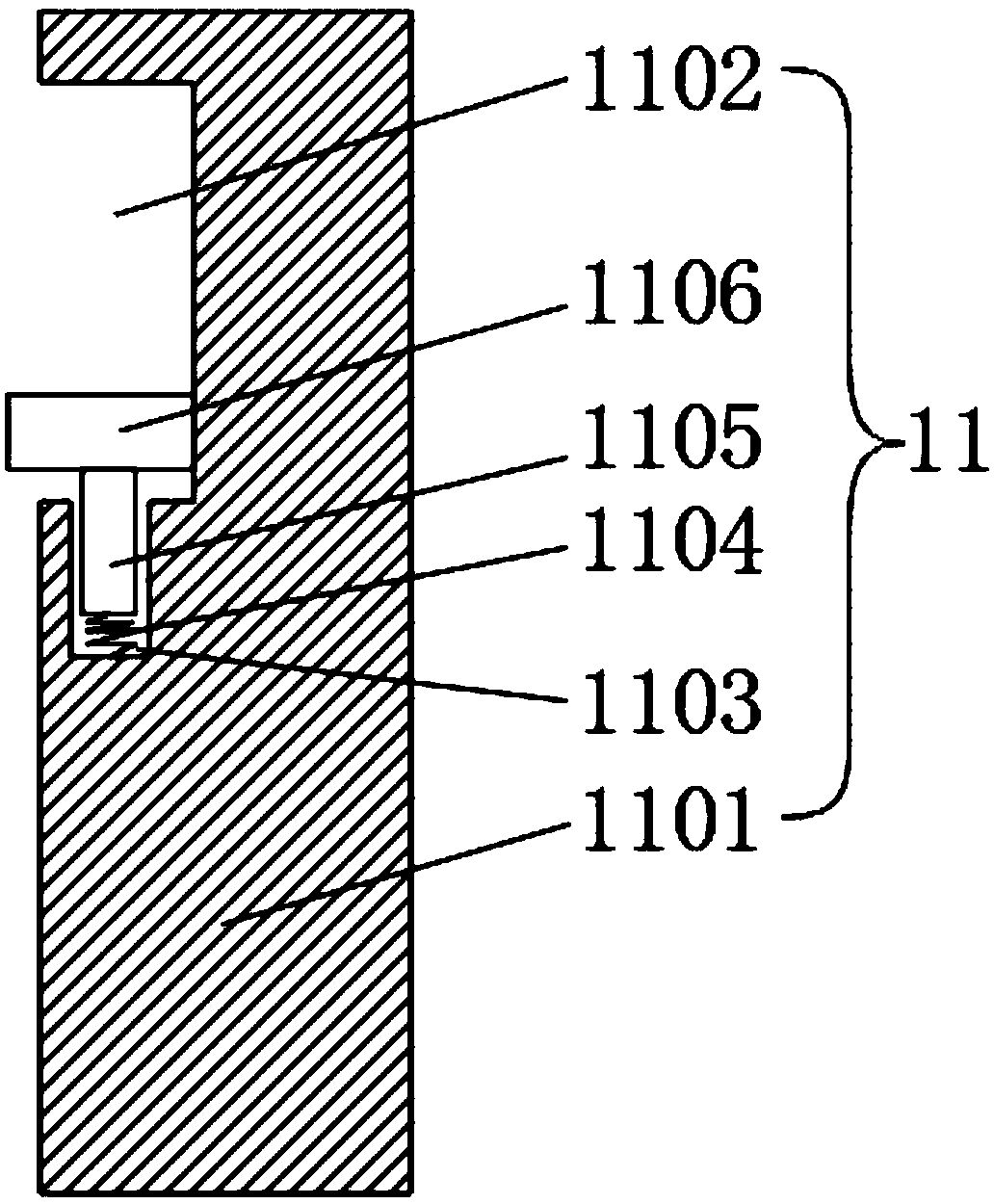

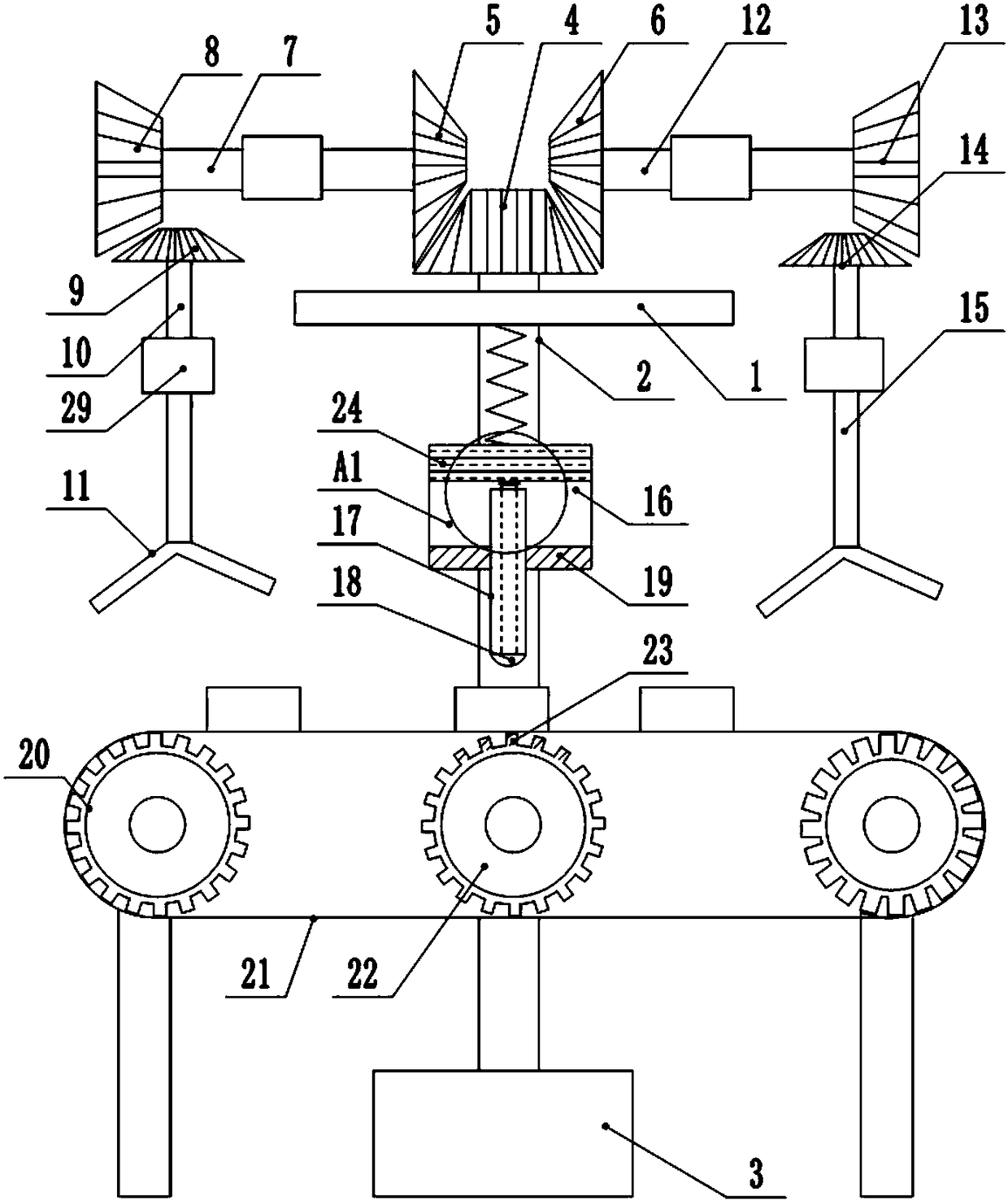

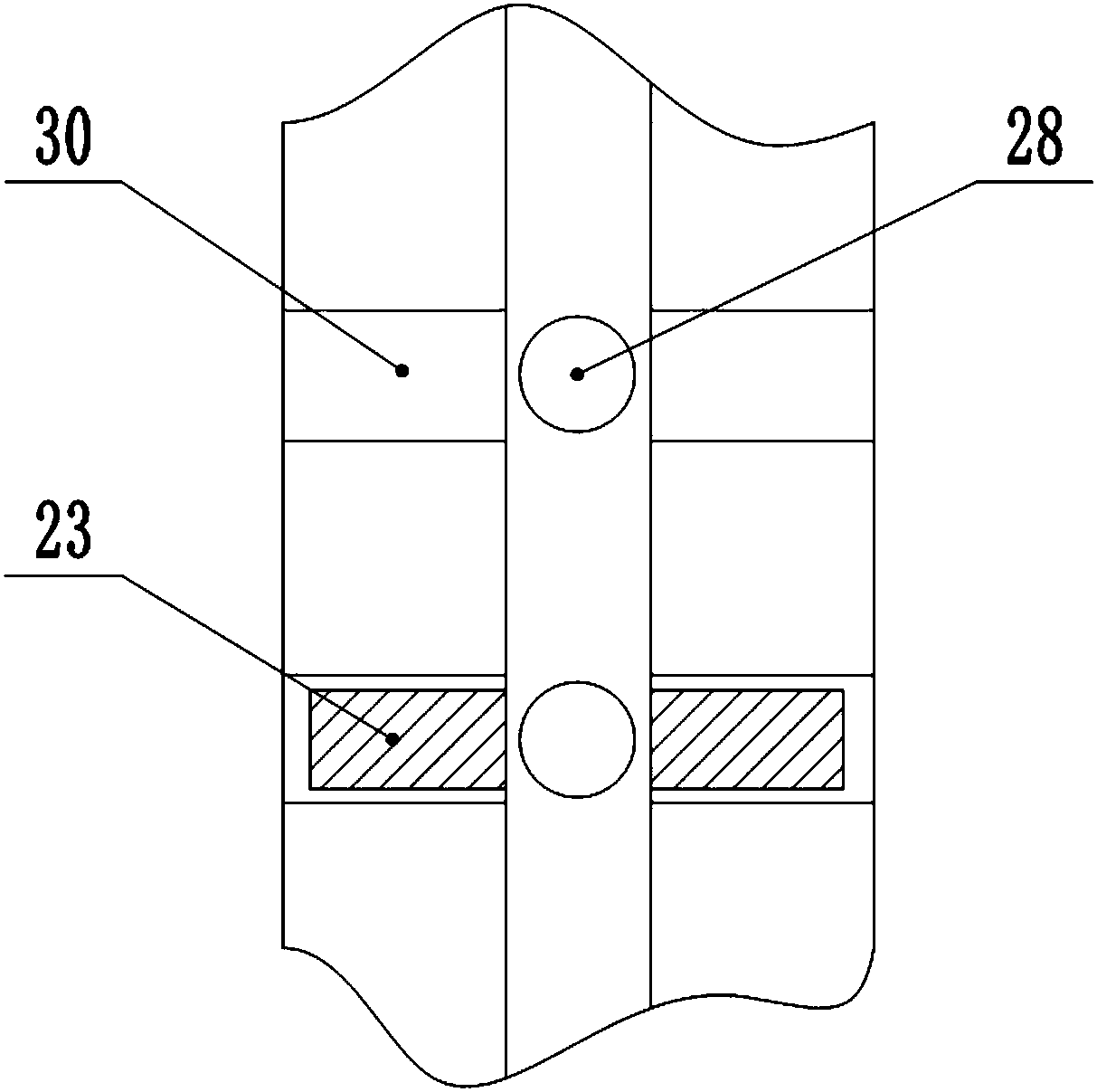

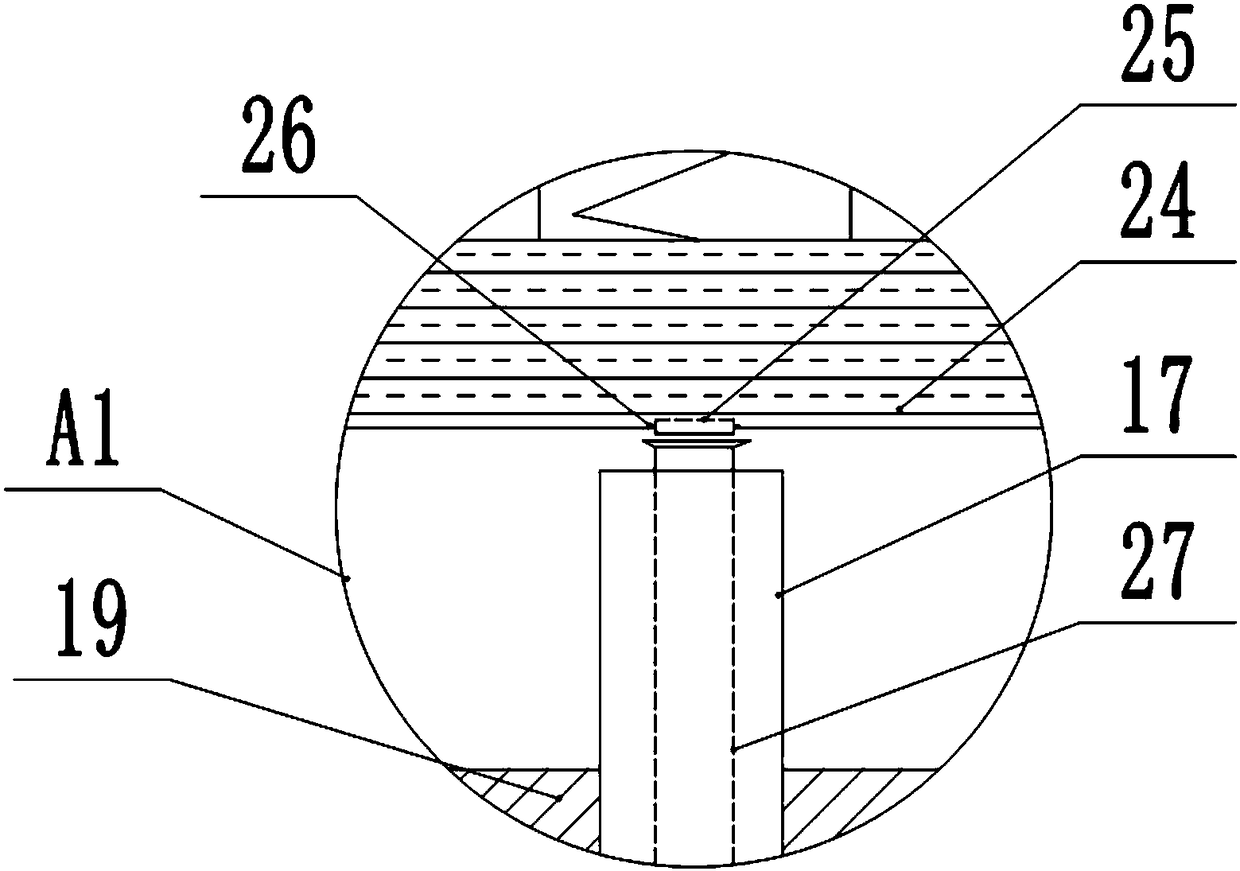

Mineral wool fiber centrifugal fiber forming device and process

InactiveCN111689684AAddresses susceptibility to slag ballsImprove stabilityGlass making apparatusCotton fibreMechanical engineering

The invention discloses a mineral wool fiber centrifugal fiber forming device. The mineral wool fiber centrifugal fiber forming device comprises a base, a centrifugal cylinder is arranged at the top of the base, a centrifugal roller is arranged in the centrifugal cylinder, the surface of the centrifugal roller is sleeved with a first bearing, the first bearing is connected to the bottom of a cylinder cover in a clamped mode, the bottom of the cylinder cover is arranged at the top of the centrifugal cylinder, and first centrifugal spray holes are formed in the surface of the centrifugal roller.The centrifugal roller, a centrifugal sleeve, the first centrifugal spray holes, second centrifugal spray holes, a nut, an external thread, an elastic device, a wheel disc, a wheel disc groove and afilter screen are designed to be matched with one another; the problems of an existing mineral wool fiber centrifugal fiber forming device and the problems in the operation of process that mineral wool fiber melt liquid is always attached to a centrifugal roller, the melt liquid is subjected to chemical fibers under the action of centrifugal force of the centrifugal roller, randomness is large, the thickness of fiber filaments obtained after chemical fibers are made to be uncontrollable, and the melt liquid is prone to being affected by slag balls in the centrifugal process are solved.

Owner:浙江浦森新材料科技有限公司

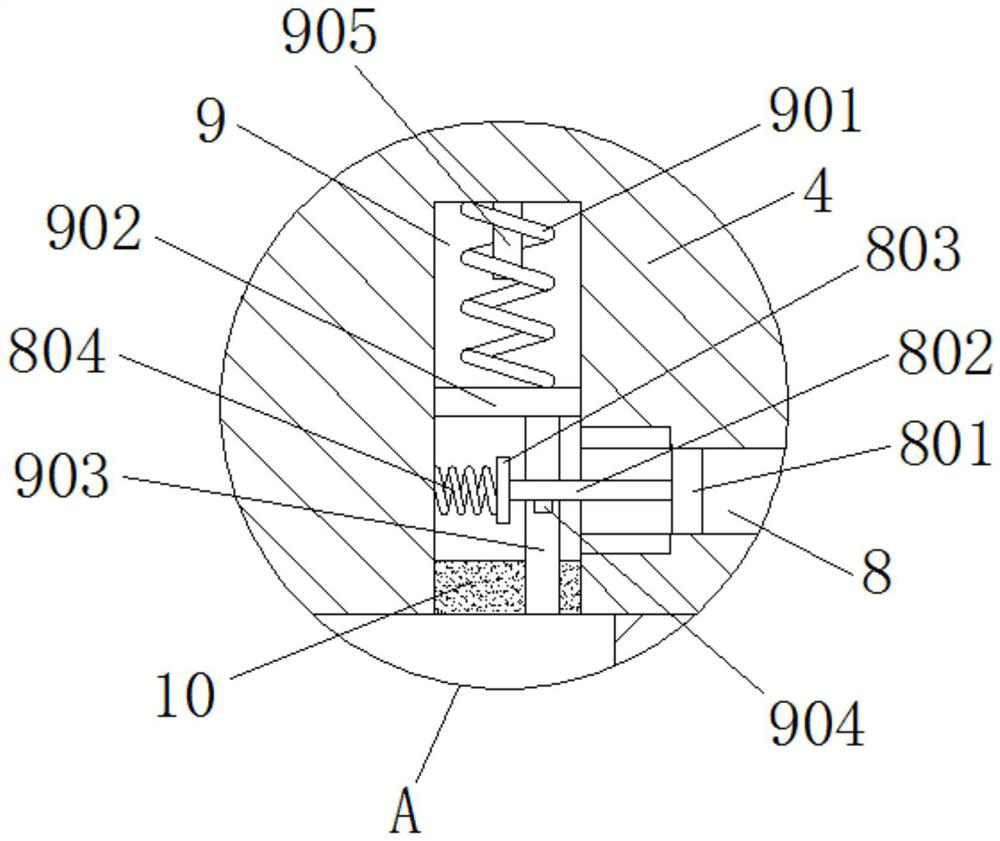

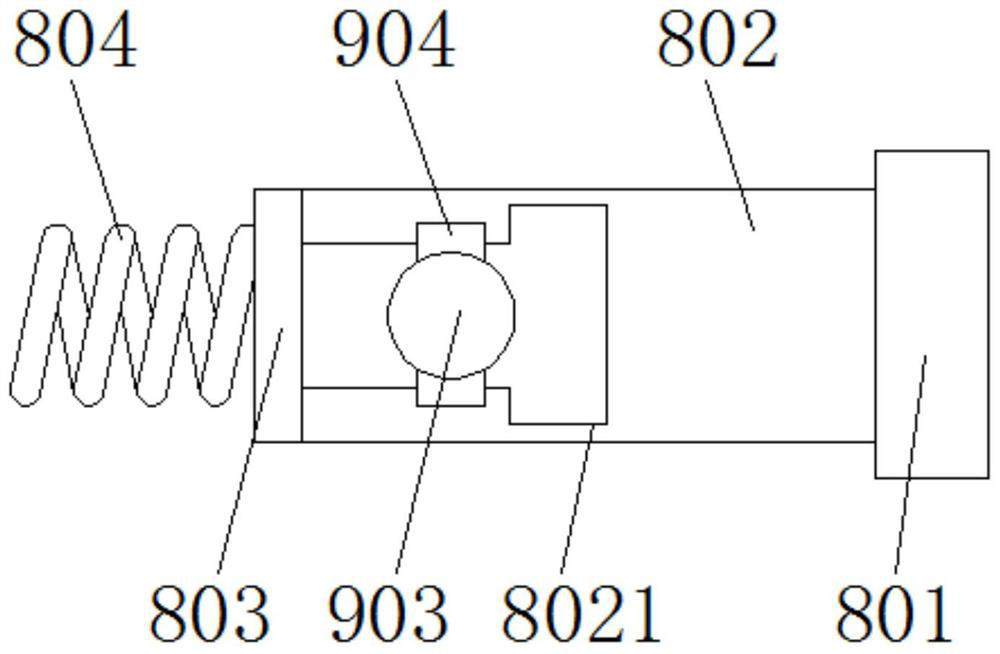

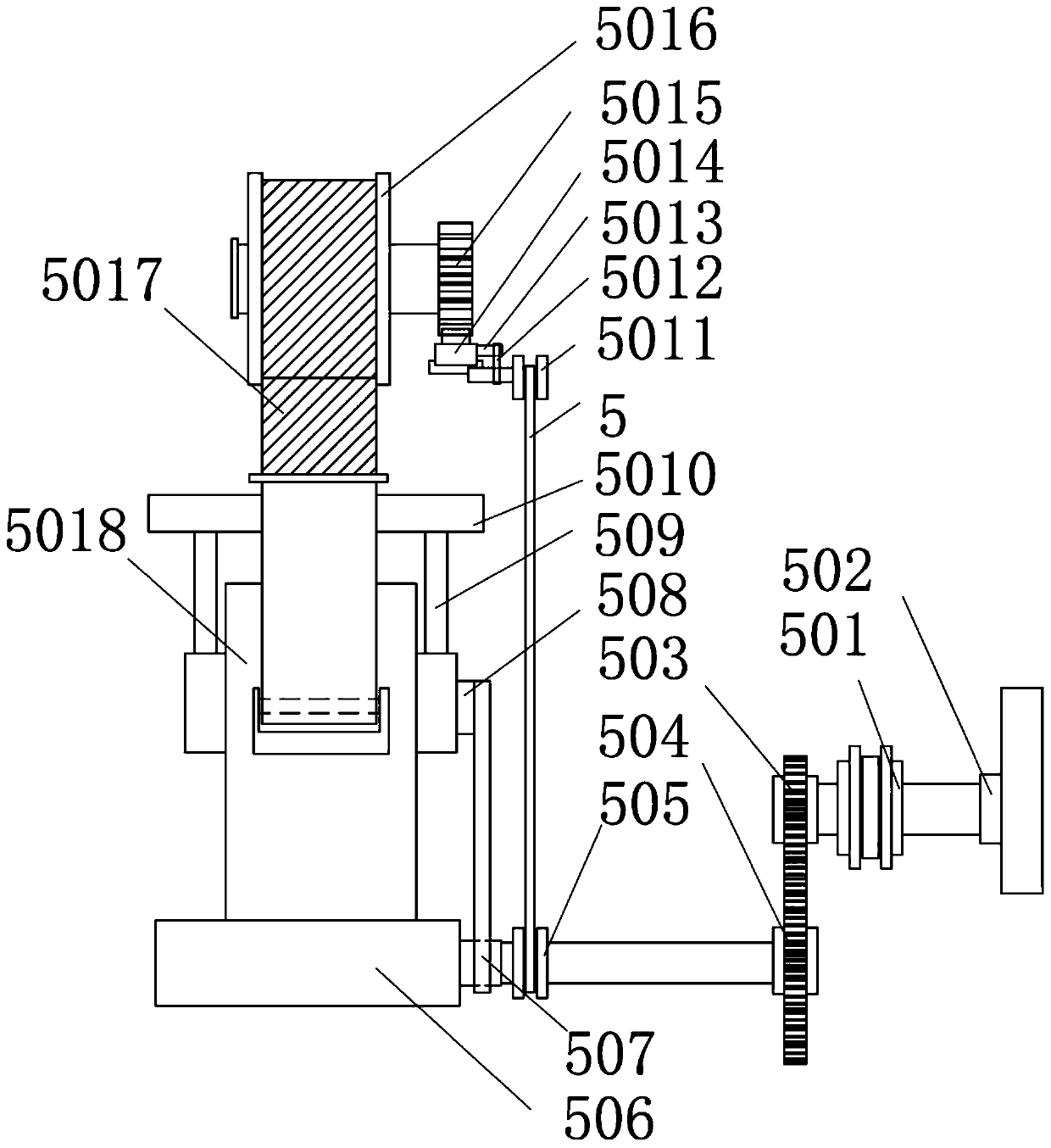

Stable pulping and stirring robot

InactiveCN107537354AGuaranteed stabilityReduce vibration amplitudeRotary stirring mixersMixer accessoriesPulp and paper industryCushion

Owner:吴莉锋

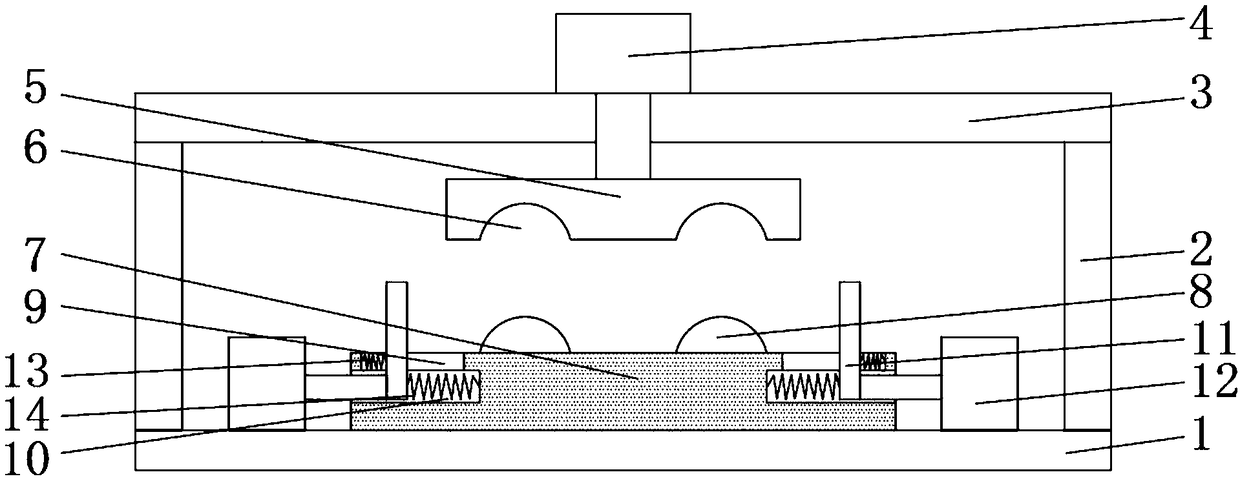

High-precision injection mold

The invention relates to the field of injection molding equipment, and discloses a high-precision injection mold. The high-precision injection mold comprises a lower die holder plate, an isolation plate, a lower die core fixing plate, an upper die core fixing plate and an upper die holder plate, wherein the isolation plate is fixedly mounted at the top of the lower die holder plate, the lower moldcore fixing plate is fixedly mounted at the top of the isolation plate, and the upper mold core fixing plate is fixedly mounted at the bottom of the upper die holder plate. According to the high-precision injection mold, through the structural design of a first sliding groove and a second sliding groove which communicate with each other in the lower die core fixing plate and the upper die core fixing plate, during demolding, water is injected into the first sliding groove for pressurization, so that a first piston plate reaches a through hole, the water pressure in the second sliding groove is increased, and a second piston plate drives an inserting rod to move upwards; and the injected water directly acts on the mold adhered to the upper die core fixing plate through a packing block, sothat the mold is separated from the upper die core fixing plate, and the problem that the quality of the mold is influenced due to the fact that an ejector pin damages the surface of the mold is avoided.

Owner:东莞市勤博塑胶制品有限公司

Asphalt lifting device for crack sealing machine

ActiveCN113373783AImprove construction efficiencyAvoid unevennessRoads maintainenceArchitectural engineeringStructural engineering

The invention discloses an asphalt lifting device for a crack sealing machine, and relates to the technical field of building equipment. The asphalt lifting device comprises a moving base, a crack pouring machine body and a lifting mechanism, the crack pouring machine body is fixedly embedded in the right side of the top of the moving base, the lifting mechanism is fixedly installed on the left side of the moving base, a scraping mechanism is arranged at the bottom of the moving base, and a compacting mechanism used for compacting an asphalt pavement is arranged on the right side of the scraping mechanism. According to the device, the movable base is matched with the compression roller so that the movable base drives the compression roller to rotate, and the compression roller can compact and level the asphalt pavement subjected to crack pouring treatment, thus the problem that the labor intensity of workers is increased due to the fact that the asphalt pavement subjected to crack pouring treatment needs to be compacted by the workers subsequently is solved, and the construction efficiency of the asphalt pavement is improved; meanwhile, excessive asphalt poured in the crack pouring process can be extruded out by the compression roller so that the problem that the asphalt pavement is uneven due to the fact that more asphalt is poured is avoided.

Owner:REED XINXIANG ROAD INC

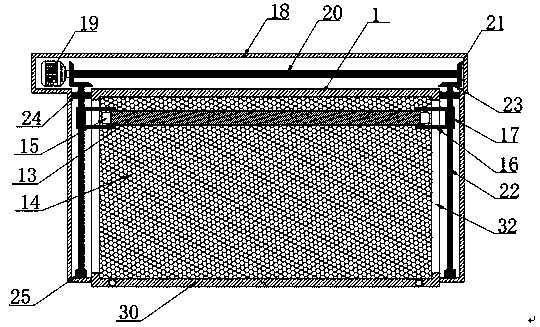

Tea leaf freshness-keeping-storing device

InactiveCN110810556AFluffy and evenly distributedAvoid backlogPre-extraction tea treatmentAgricultural engineeringConveyor belt

The present invention discloses a tea leaf freshness-keeping-storing device and particularly relates to the technical field of tea leaf storage. The tea leaf freshness-keeping-storing device comprisesa box body, a ventilation net is arranged at a top end of the box body, one side of the ventilation net is provided with a material feeding hopper, a bottom end of the material feeding hopper communicates with the top end of the box body, the box body is internally provided with a shaking and sieving mechanism, and an outside of the box body is provided with a transmission mechanism. The tea leaffreshness-keeping-storing device is provided with a conveyor belt, vertical plates and the transmission mechanism, the transmission mechanism drives the conveyor belt to move back and forth in a freshness-keeping-storing chamber, the conveyor belt drives the vertical plates to move, the vertical plate moves to enable the tea leaves to be fluffily and uniformly distributed in the freshness-keeping-storing chamber, the tea leaves at a bottom part of the freshness-keeping-storing chamber can be turned over to a top part, a problem that the tea leaves at the bottom part are accumulated and pressed to further influence overall quality of the tea leaves is solved, a ventilation plate is arranged at the bottom part of the freshness-keeping-storing chamber, a ventilation chamber is arranged at abottom end of the ventilation plate, the tea leaves accumulated and pressed at the bottom part can ventilate through the ventilation plate, and the tea leaves at the bottom part are prevented from being damp and yellow after being accumulated and pressed.

Owner:汪涌泉

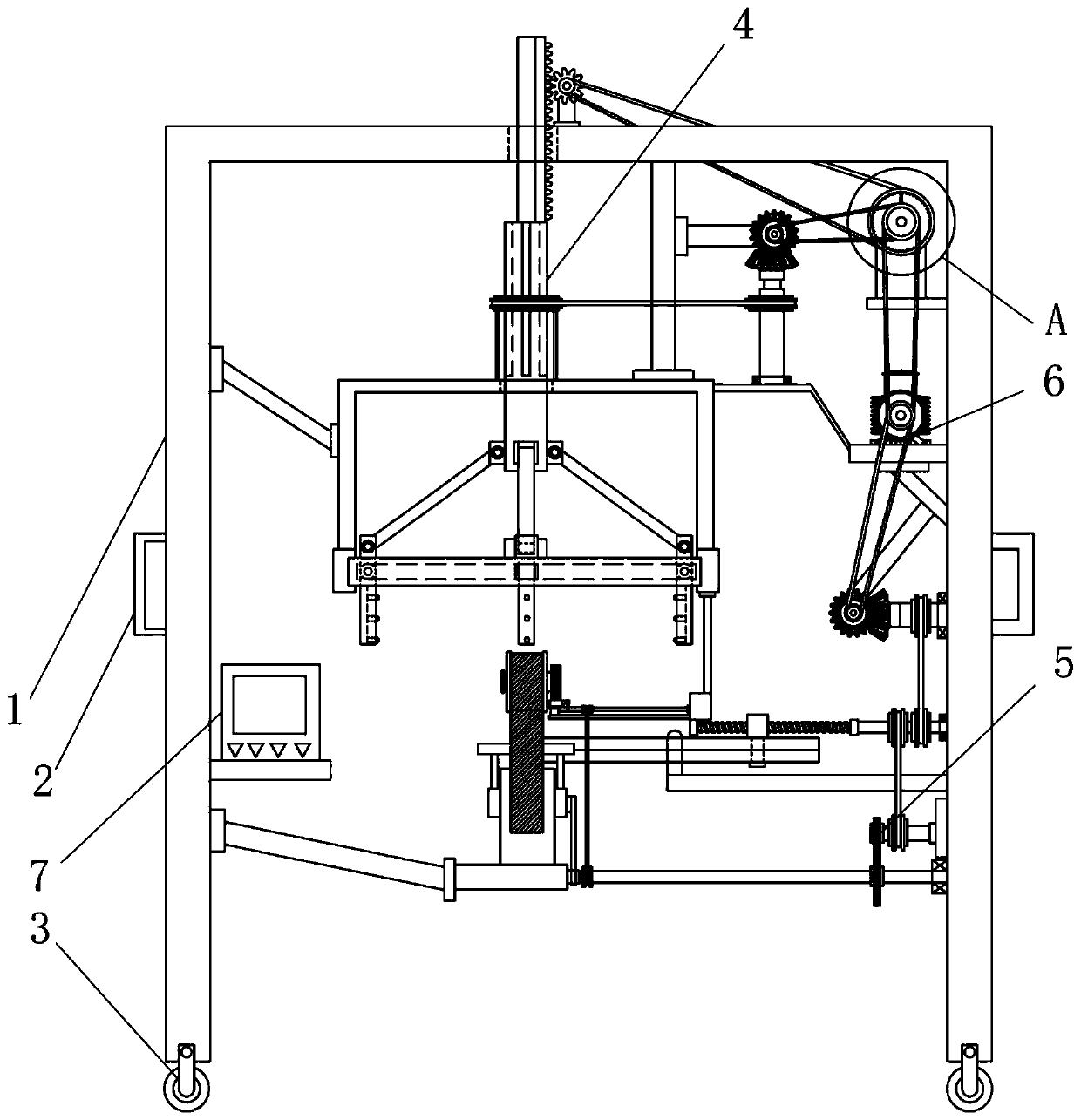

Camera mark printing device

InactiveCN108128026AFast dryingIssues affecting qualityRotary pressesPrinting press partsEngineeringGear tooth

The invention relates to a camera mark printing device. The device comprises a machine frame and a rotating shaft, wherein the lower end of the rotating shaft is connected with a first motor, the upper end of the rotating shaft is fixedly connected with bevel gears, the bevel gears are connected with vertical shafts, and the bottom end of each vertical shaft is fixedly provided with blades; the rotating shaft is slidably connected with a mark printing mechanism, the mark printing mechanism comprises a mark printing base slidably connected to the rotating shaft, the upper end of the mark printing mark is fixedly connected with a spring, the other end of the spring is fixedly connected to the machine frame, the mark printing base is provided with a mark printing rod, the bottom end of the mark printing rod is provided with a printing head, and the bottom end of the mark printing base is provided with a first magnet; the lower portion of the printing head is provided with a delivery mechanism, the delivery mechanism comprises delivery wheels and a delivery belt, a strip-shaped hole is formed in the delivery belt, the side edges of the delivery belts are provided with feed holes, supporting wheels are arranged between the two delivery wheels, the supporting wheels are provided with gear teeth, the gear teeth are meshed with the feed holes, and the supporting wheels are provided with second magnets. The camera mark printing device solves the problem that the mark printing quality of a camera shell is affected due to low ink drying speed.

Owner:重庆轩腾科技有限公司

Public service method of international sports events

The invention relates to a public service method of international sports events. A mobile-terminal application platform is established on the basis of athlete experience. An integrated multi-lingual 'smart YOG (Youth Olympic Games) mobile application platform' is established by utilizing present resources. Contents including competition schedule information, cultural and educational activity information, Youth Olympic Village information, tournament news, traffic information, arrival / departure information and Nanjing local information are displayed. Bluetooth 4.0 communication technology and application are introduced. A social network platform is established, and contents of the social network platform mainly comprise competition, culture and education schedule information issuing and exhibiting, culture and education management, tournament comprehensive information exhibiting and issuing, the social network, a travel information service, a multi-lingual calling service, automatic WiFi authentication, TV program play, close-quarter information interaction, a personal center and a Nanjing local consultation information issuing and exhibiting system.

Owner:JIANGSU HONGXIN SYST INTEGRATION

Edible fungus helvella crispa picking device

ActiveCN110999725AEasy to cutEasy to pinchCultivating equipmentsMushroom cultivationHelvella crispaEdible mushroom

The invention relates to the field of edible fungi, in particular to an edible fungus helvella crispa picking device. The edible fungus helvella crispa picking device comprises a main frame, a fungusfixing device, a soil loosening and pollution preventing device, a cutting and collecting device and a control screen. The left middle portion of the main frame is welded to a handle. The cutting andcollecting device is arranged on the right top of the inside of the main frame. The edible fungus helvella crispa picking device aims at solving the problems that when helvella crispa is picked through an existing method, due to the fact that helvella crispa is small, thin and long, soft in texture and quite smooth in surface, fungus supports can only be clamped by fingers of workers, and then thebases of the fungus supports are cut off through a cutter. By the edible fungus helvella crispa picking device, stipes are fixed rapidly and stably in all directions, culture soil is removed to prevent the cut faces from being polluted during cutting, through two-way cutting, the cutting stability is improved, and the cutting speed is increased.

Owner:柴玉霜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com