Anti-solidification constant-temperature system for corn oil and constant-temperature control method thereof

A constant temperature system and constant temperature control technology, applied in the direction of temperature control using multiple sensors, temperature control using electric methods, etc., can solve problems such as uneven heating at constant temperature, difficult work in barreling, and large temperature difference between day and night, so as to improve the constant temperature The effect of solving the large temperature difference between day and night and improving the effect of preventing solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

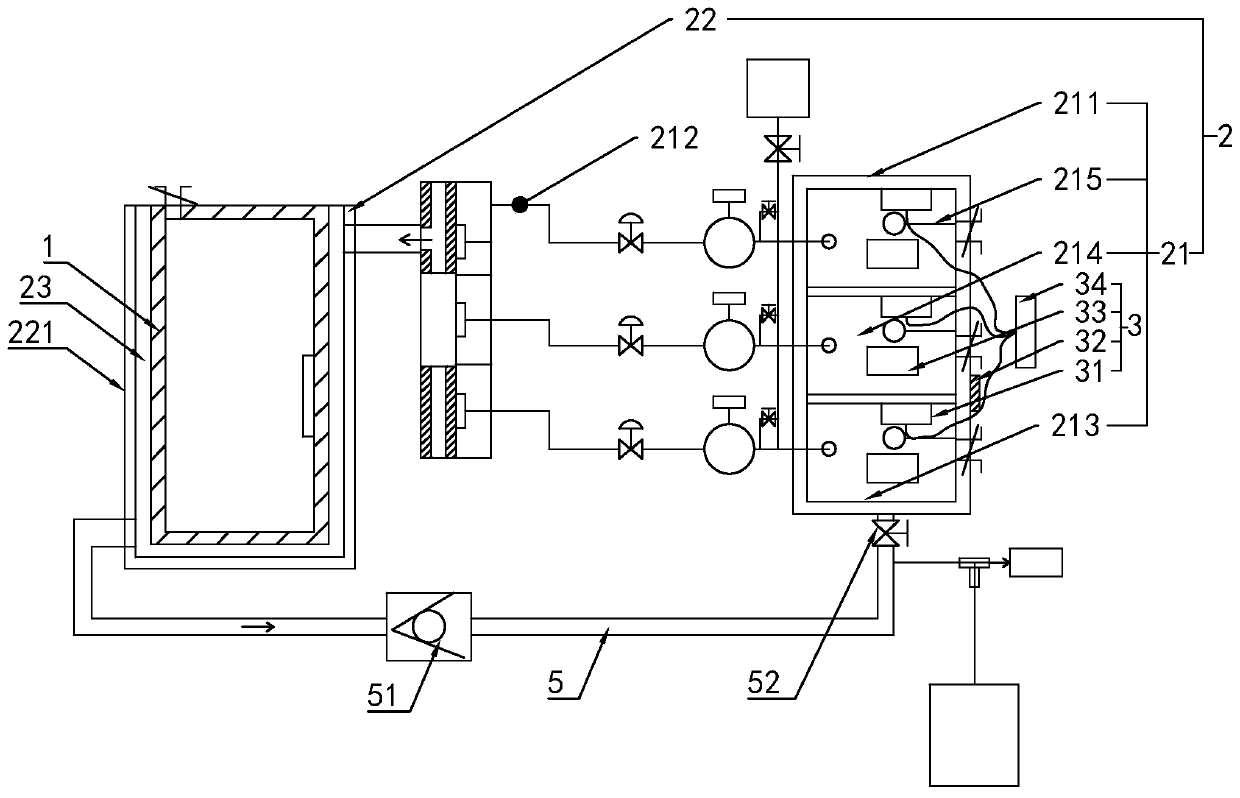

[0038] Such as figure 1As shown, the present invention discloses an anti-freezing constant temperature system for corn oil. In a specific embodiment of the present invention, it includes an oil storage tank 1 and a constant temperature control device 2 for keeping the inside of the oil storage tank 1 constant; the constant temperature control device 2 includes a heating module 21 and a constant temperature module 22; the constant temperature module 22 includes a constant temperature barrel 221 arranged outside the oil storage tank 1; A liquid storage space 23 is formed; the thermostat barrel 221 is provided with a water inlet and a water outlet, and the heating module 21 includes a hot water tank 211 and a water delivery system 212; the hot water in the hot water tank 211 passes through the The water delivery system 212 is transported into the liquid storage space 23 along the water inlet of the thermostatic barrel 22; the hot water tank 211 includes a low temperature water ta...

Embodiment 2

[0046] Embodiment 2, the difference with embodiment 1 is

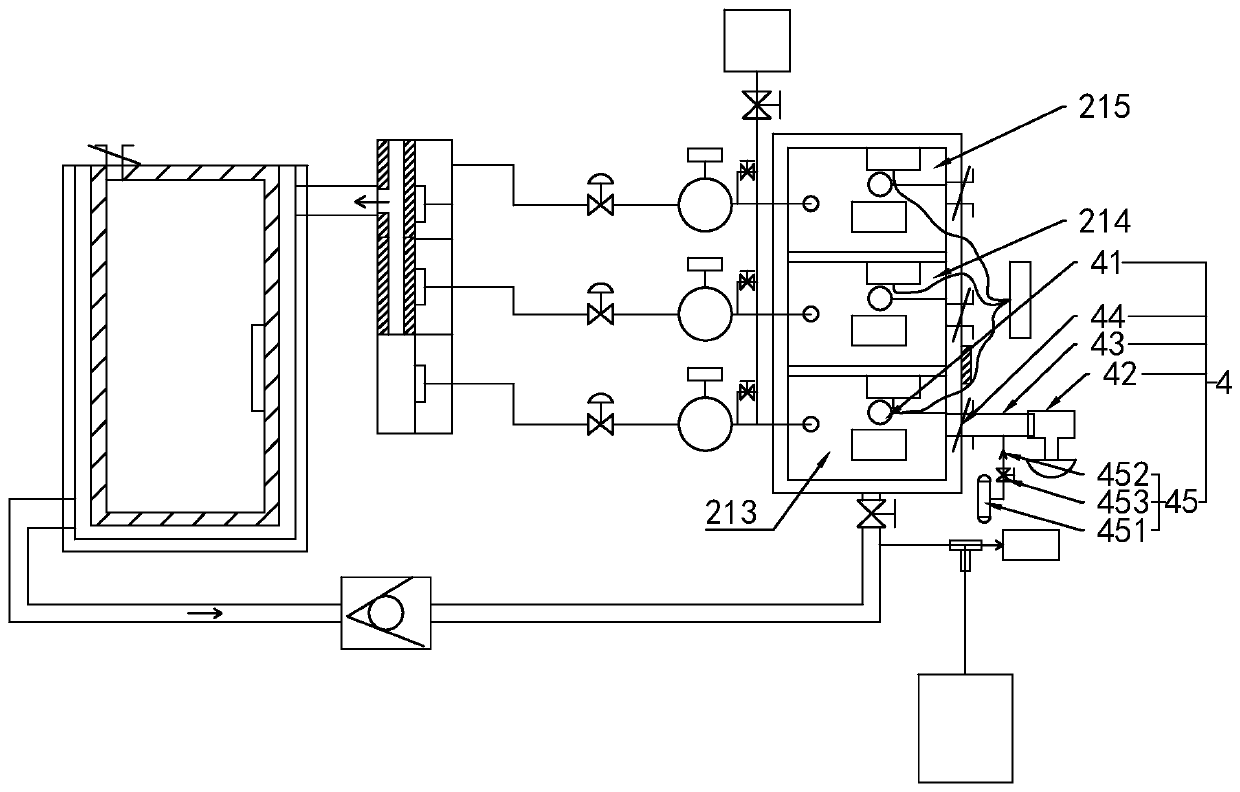

[0047] Such as figure 2 As shown, in the specific embodiment of the present invention, the low-temperature water tank 213, the transition water tank 214, and the high-temperature water tank 215 inside the hot water tank 211 are all provided with automatic replenishment units 4 juxtaposed to each other; the automatic replenishment units 4 include A ball float valve 41, a water pump 42, a filling pipe 43, a filling shut-off valve 44, and an antifreeze addition module 45 for limiting the liquid level in the hot water tank 211; the ball float valve 41 is installed on the side of the hot water tank 211 On the wall, one end of the filling pipe 43 communicates with the input end of the float valve 41; the filling stop valve 44 is installed on the filling pipe 43; the output end of the water pump 42 communicates with the input end of the filling pipe 43 The antifreeze adding module 45 includes a liquid storage tank 451 and a...

Embodiment 3

[0050] Embodiment 3, differs from Embodiment 2 in that

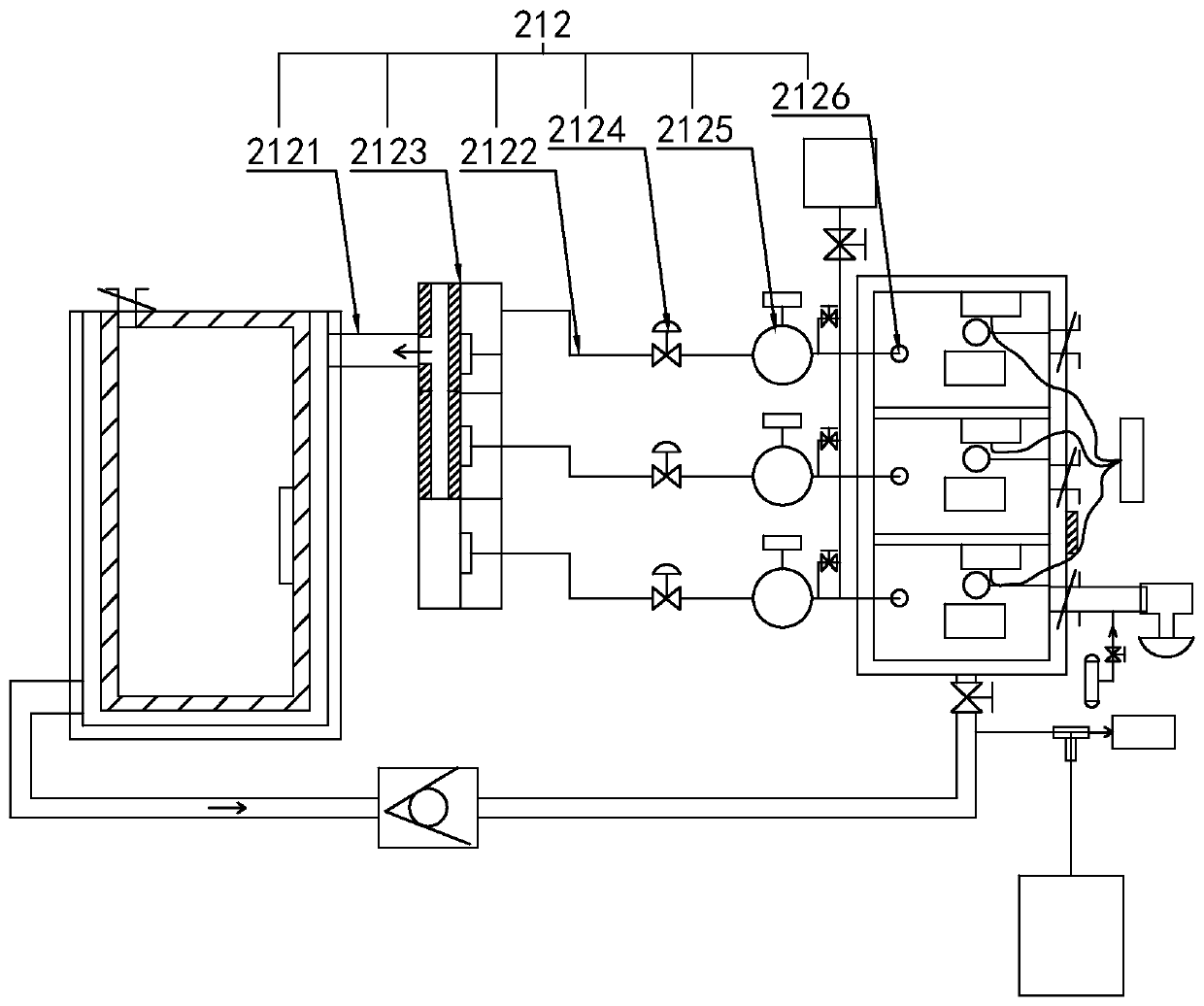

[0051] Such as Figure 3-4 As shown, in a specific embodiment of the present invention, the water delivery system 212 includes a main water delivery pipe 2121, three water delivery branch pipes 2122 that communicate with the low temperature water tank 213, the transition water tank 214 and the high temperature water tank 215 respectively, and connect the main water delivery pipe 2121 with the high temperature water tank 212. The three water delivery branch pipes 2122 are connected with a single-channel communication device 2123; the three water delivery branch pipes 2122 are equipped with a stop valve 2124 for controlling the flow of the pipeline and a regulating valve 2125 for controlling the flow of the pipeline; The single-channel communication device 2123 controls each water delivery branch pipe 2122 to be connected with the main water delivery pipe 2122 at the same time; the input ends of the three output branch pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com