Black tea processing method

A processing method and technology for black tea, which are applied in the fields of black tea processing and thermal blowing and upgrading equipment, can solve the problems of inconsistent water loss of tea leaves when heated, unsynchronized conversion of cyanine strips, and inconsistency in preventing enzyme activity, and achieve enhanced brightness of tea water. , the effect of reducing cyanine strips, which is beneficial to fermentation treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

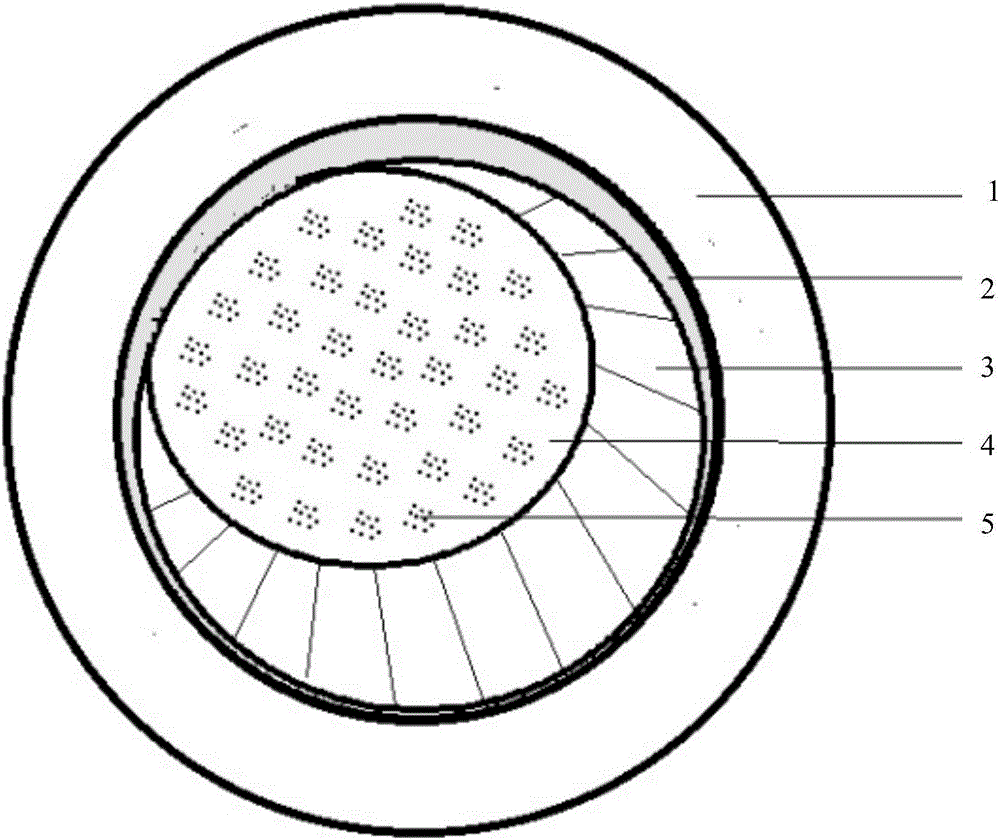

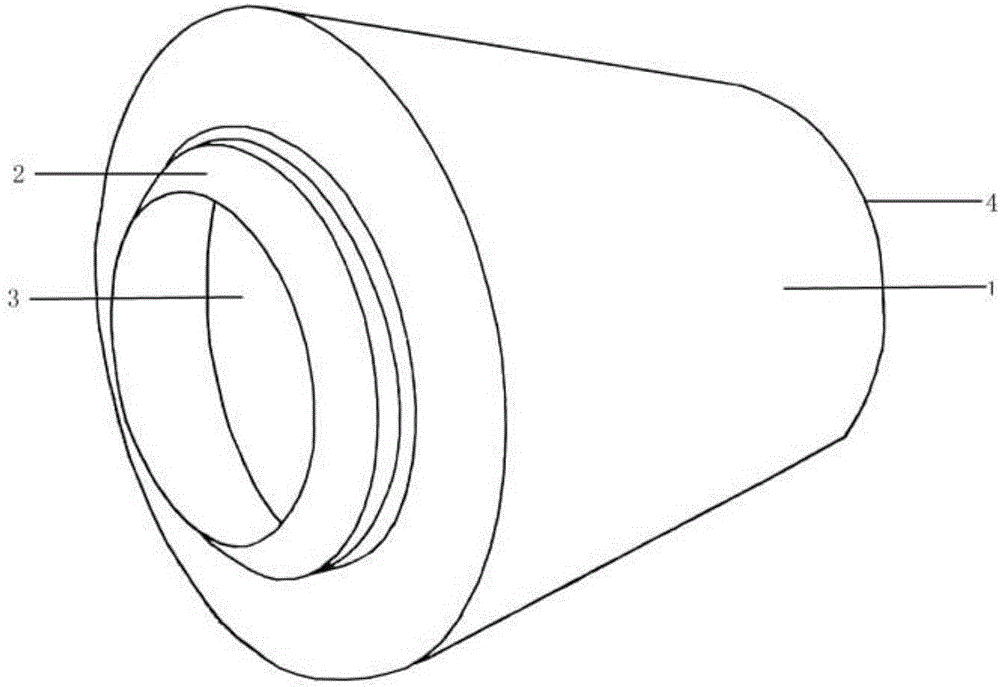

Image

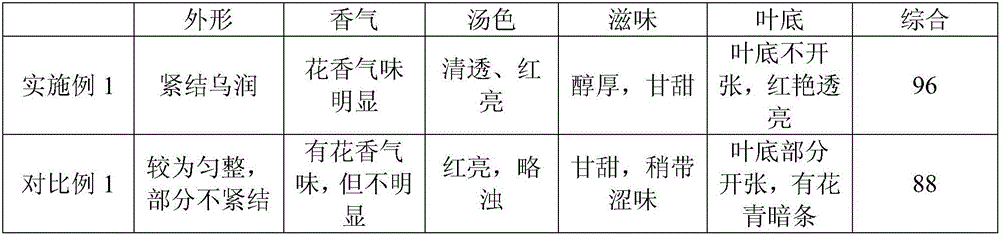

Examples

Embodiment 1

[0020] A kind of black tea processing method, comprises the following steps:

[0021] (1) Fresh tea leaves are pretreated by washing and removing impurities;

[0022] (2) Withering: Place the pretreated fresh tea leaves below -20°C for 8 hours, then microwave them at 750Mhz for 6 minutes, and finally place them at room temperature; you can also use a heated withering tank for 15- 18h.

[0023] (3) Rolling: the tea leaves are formed during the rolling process and the concentration of color, aroma and flavor are increased. At the same time, because the leaf cells are destroyed, it is convenient to carry out necessary oxidation under the action of enzymes, which is beneficial to the smooth progress of fermentation; Treat the tea leaves under ultrasonic conditions for 45 minutes, and the cell wall is further broken, which is beneficial to the later fermentation process;

[0024] (4) Fermentation: Fermentation is a unique stage of black tea production. After fermentation, the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com