Waste plastics pretreatment process based on coking by coke oven

A waste plastics pretreatment technology, applied in coking ovens, petroleum industry, special forms of dry distillation, etc., can solve the problems of coke quality degradation, impact on coke quality, uneven dispersion of waste plastic particles, etc., to meet energy saving and consumption reduction, guarantee The effect of coke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

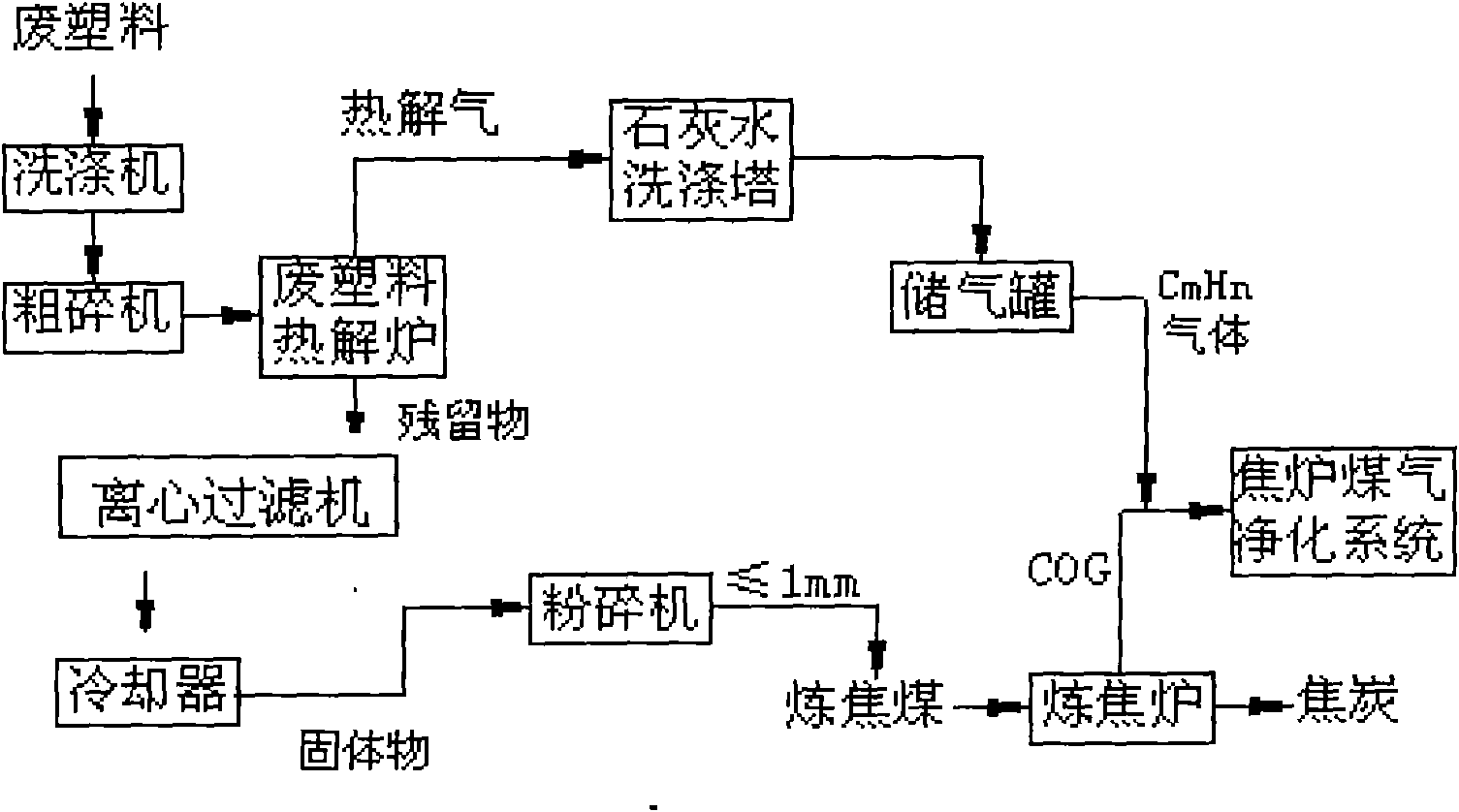

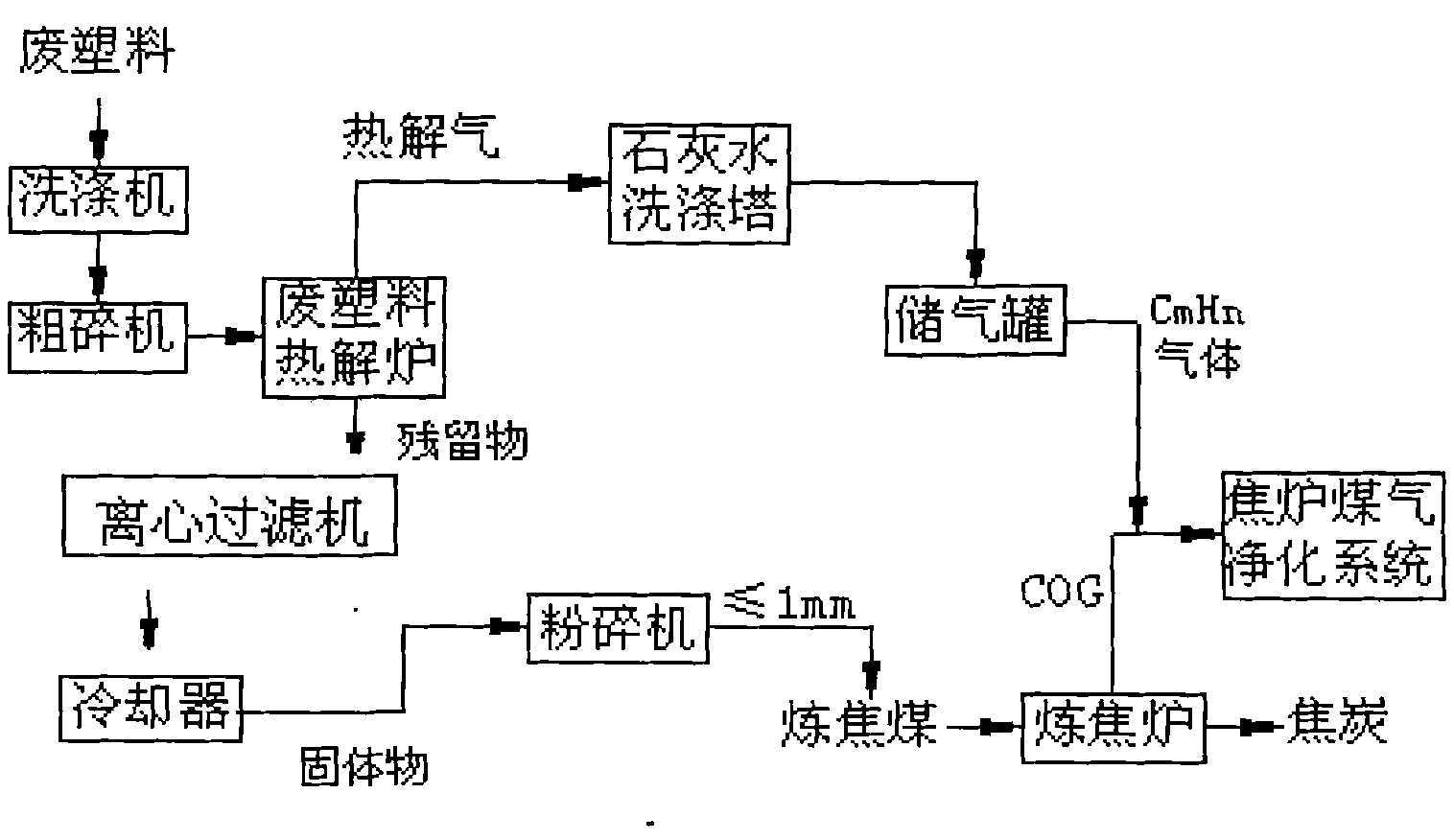

Method used

Image

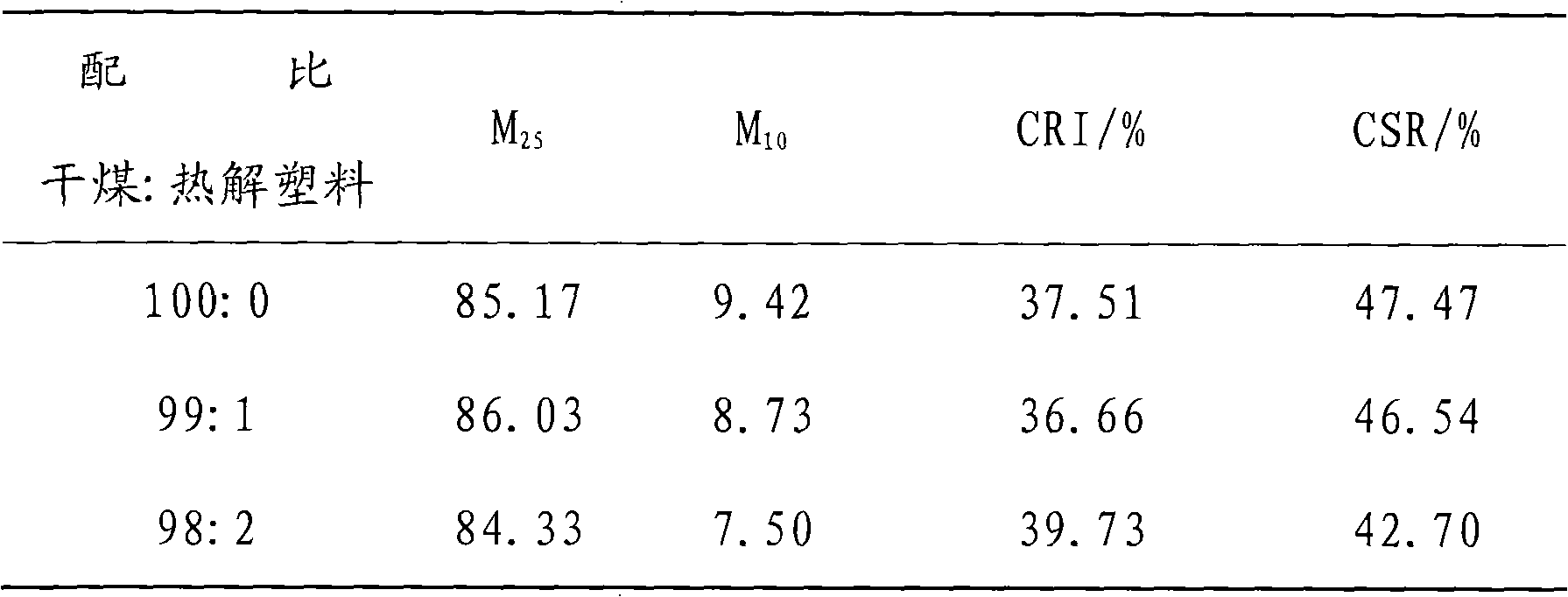

Examples

Embodiment 1

[0032] Source of waste plastics: Waste plastics used for coal blending and coking are collected from various mixed waste plastics recovered from society in Wudong Waste Plastics Processing Plant, Wuhan City, with a chlorine content of 51.10% (mass percentage).

[0033] Pretreatment process:

[0034] (1) Wash the above-mentioned waste plastics with water through a washing machine to remove the surface soil and then send them to the coarse crusher, and coarsely crush the waste plastics to 8-12mm;

[0035] (2) The coarsely crushed waste plastics are sent to the waste plastics pyrolysis furnace, and the waste plastics are heated to 225-275°C at a heating rate of 5°C / min under the condition of isolating the air, and after 30-90min constant temperature pyrolysis, the heat is obtained Decomposed gas and fluid pyrolysis residues, the precipitated pyrolysis gas accounts for 56% of the mass of waste plastics, which contains HCl gas generated by more than 96% (mass percentage) of chlorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com