Saccharifying device for beer

A chemical device and technology of beer sugar, which is applied in the field of beer brewing, can solve problems such as low efficiency, and achieve the effects of improving efficiency, avoiding energy consumption, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

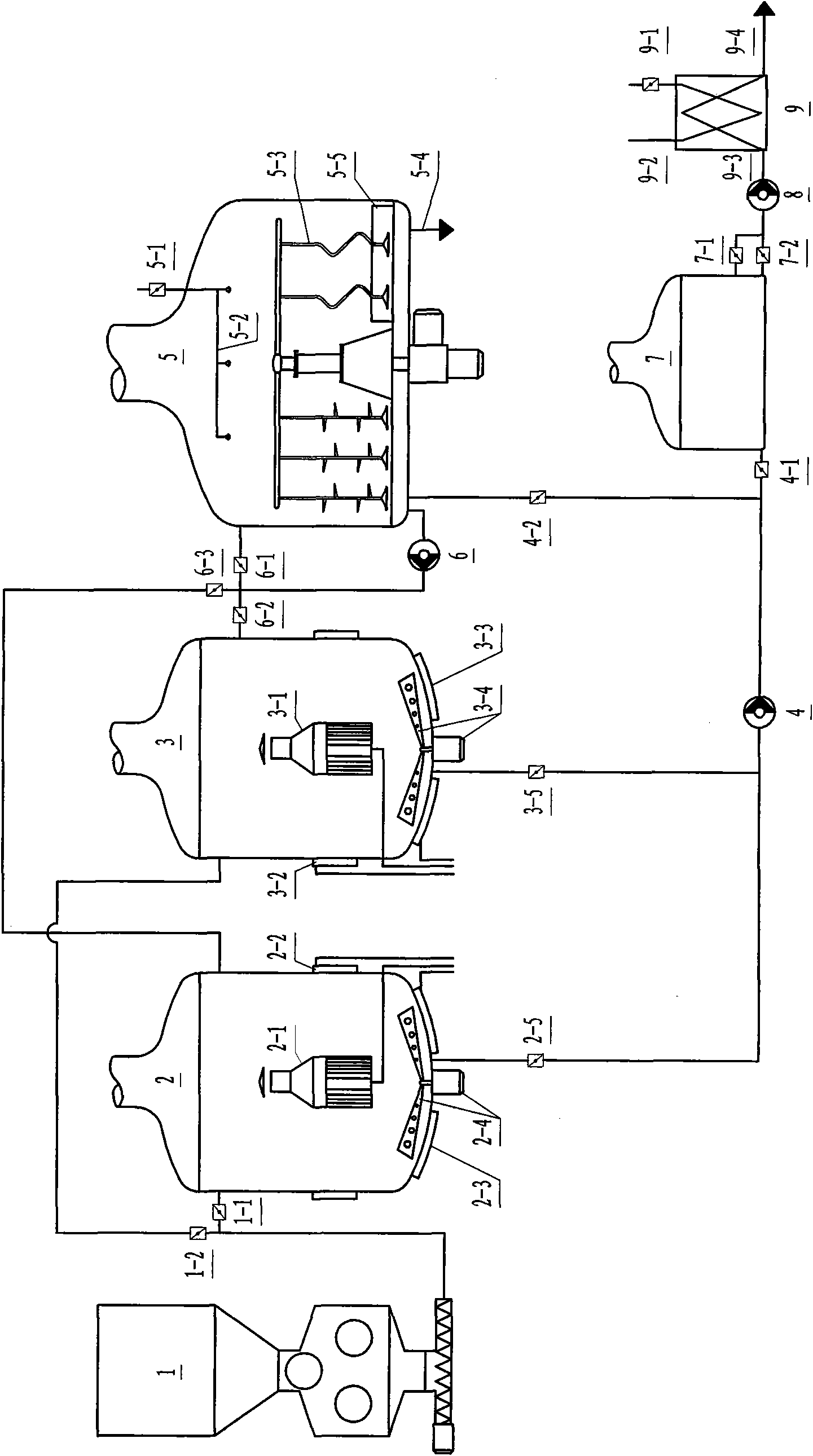

[0018] Such as figure 1 As shown, the beer saccharification device of this embodiment has a malt grinder 1, a filter tank 5 and a swirling flow sedimentation tank 7, and a material circulation channel composed of a filter tank centrifugal pump 6 and pipelines is arranged outside the filter tank 5, and the malt grinder 1 and the lauter tank 5 are connected in parallel with two saccharification kettles 2 and 3, thereby forming a material channel from the malt grinder 1 through the saccharification kettles 2 and 3 to the lauter tun 5; at the same time, the two saccharification kettles 2, 3 is also connected in parallel between the filter tank 5 and the cyclone settling tank 7, thereby forming a material channel from the filter tank 5 through the saccharification kettle 2, 3 to the cyclone sedimentation tank 7; and, the saccharification kettle is provided with a steam jacket , The saccharification boiling pot is equipped with an internal heater and a bottom stirrer. The two sacch...

Embodiment approach

[0021] After the malt is crushed in the malt grinder 1, it is mixed with hot water, and the malt mash enters the No. 1 mash pot 2 through the malt mash delivery valve 1-1 of the No. 1 mash pot; 2-3 and No. 1 saccharification boiling pot cylinder jacket 2-2 steam, heated to different temperatures in sequence according to the saccharification process and kept warm, during which any jacket turns on the steam, and the No. 1 saccharification boiling pot bottom stirs 2-4 After the saccharification is completed, the mash enters the lauter tank 5 through the No. 1 saccharification kettle saccharification mash outlet valve 2-5, the saccharification kettle centrifugal pump 4 and the saccharification mash inlet valve 4-2; After a period of time, turn on the filter tank centrifugal pump 6, and the wort circulates in the filter tank 5 through the wort return port valve 6-1. After the wort is clarified, close the wort return port valve 6-1, and turn on No. 2 saccharification and boiling Pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com