Belt type sintering machine protection device capable of continuously working

A belt-type sintering machine and protective device technology, applied in descaling devices, furnaces, charge control and other directions, can solve the problems of easily hitting the sintering port of the sintering machine, the influence of the surface of the trolley, and the cracking of ore, so as to avoid uneven heating. , to ensure rapid recovery and avoid the effect of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

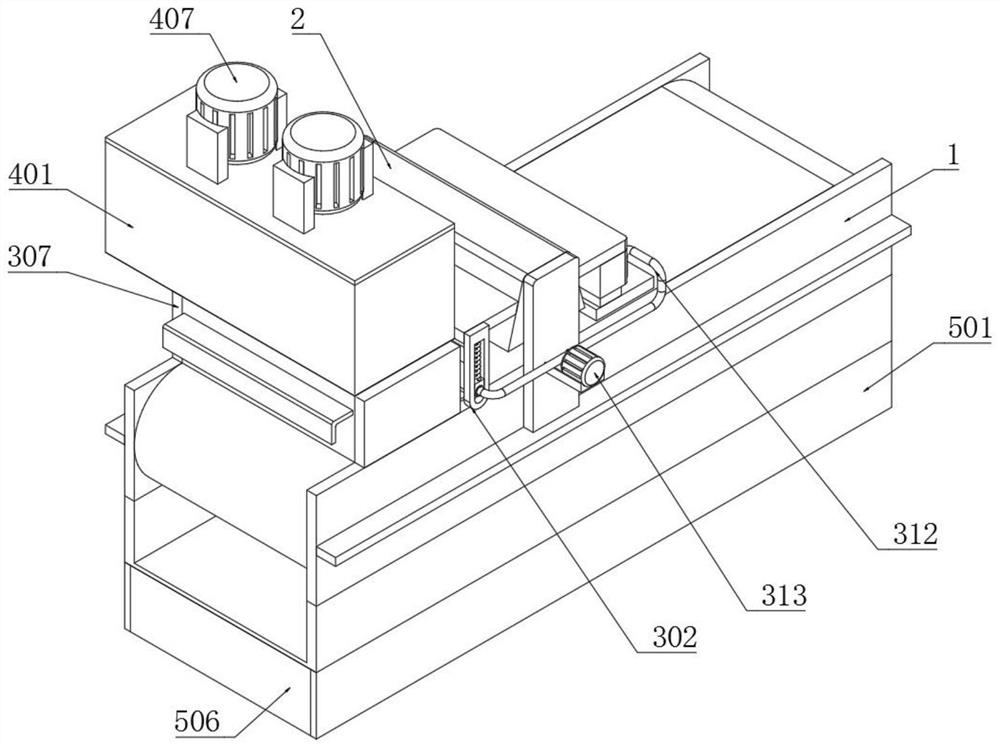

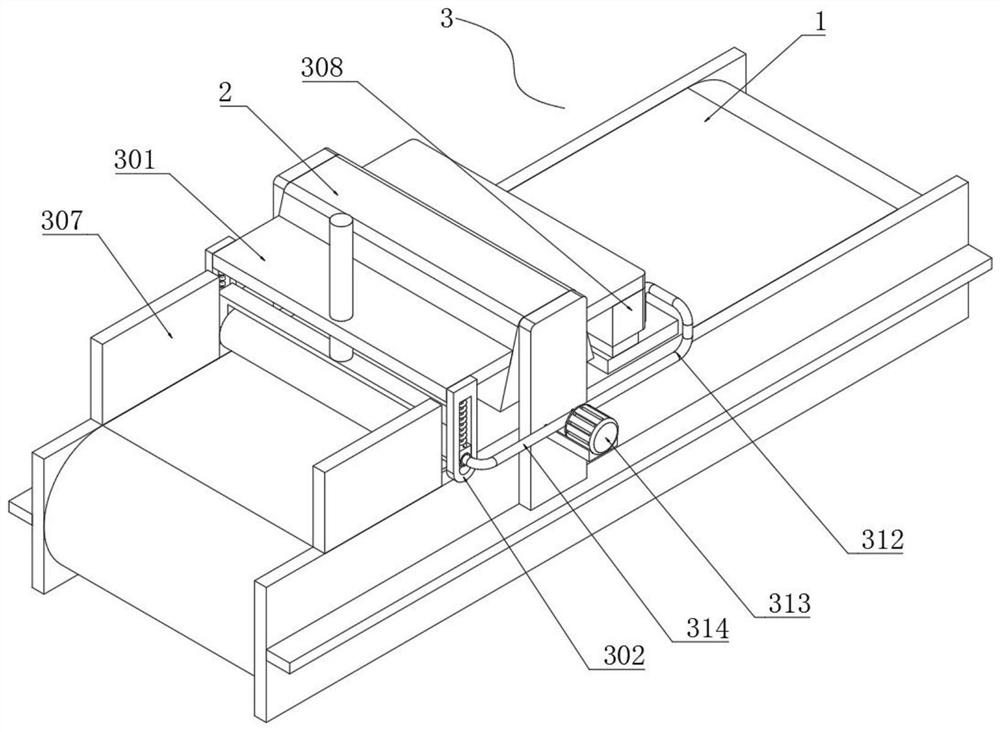

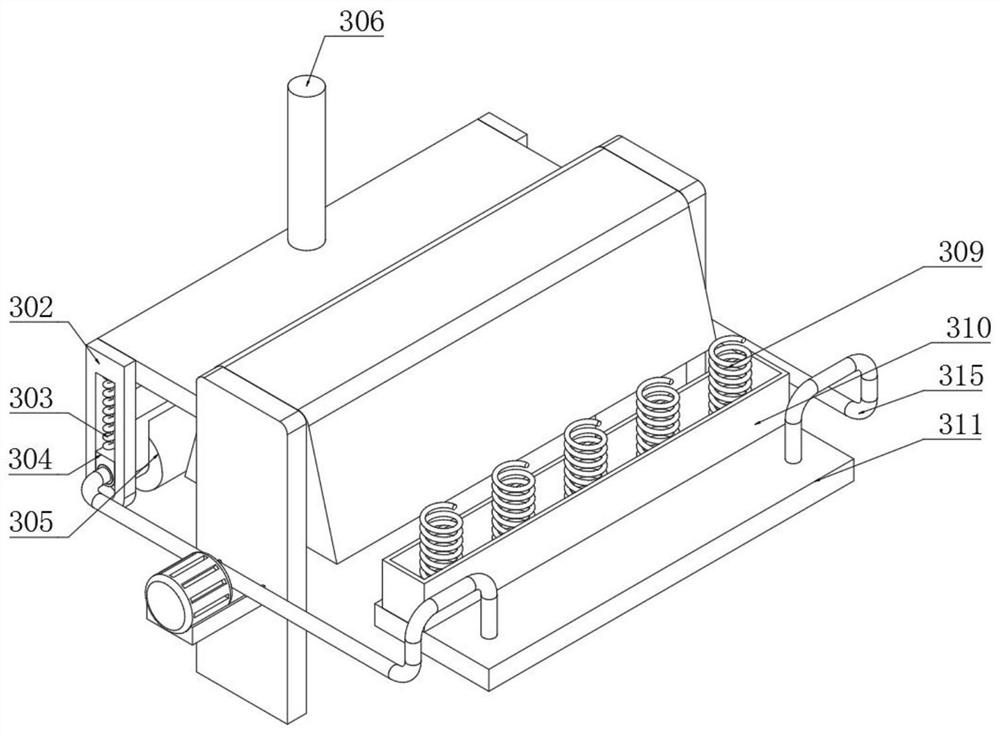

[0034] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0035] Example: as Figure 1-6 As shown, the present invention provides a technical solution, a belt-type sintering machine protection device that can work continuously, including a mobile frame 1, a trolley 2 is installed on one side of the top of the movable frame 1, and a protection component is installed on one side of the trolley 2 3. The protection assembly 3 includes a fixed support plate 301, an inner hole limiting plate 302, a lower pressure spring 303, an inner ring limit frame 304, a lower pressure heat conduction cylinder 305, a lower pressure hydraulic cylinder 306, a limit protection plate 307, and a fixed support box. 308, limit spring 309, fixed connection box 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com