Multi-element negative material magnesium alloy and preparation method thereof

A negative electrode material, magnesium alloy technology, applied in the field of multi-component negative electrode material magnesium alloy and its preparation, can solve the problems of undisclosed discharge performance, achieve the effects of shortening the activation time, stabilizing the discharge curve, and improving the intragranular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

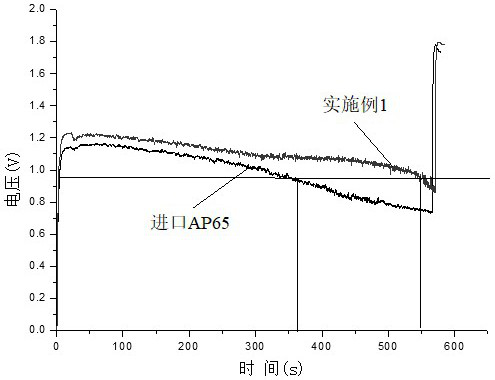

Image

Examples

Embodiment 1~3

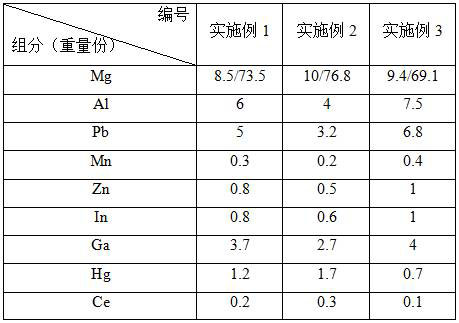

[0040] Table 1 shows the components and parts by weight of the magnesium alloy examples 1-3 of a multi-element negative electrode material.

[0041] Table 1 Components and parts by weight of Examples 1-3 of a magnesium alloy as a multi-element negative electrode material

[0042]

[0043] Note: In the table, the parameters before and after " / " in Mg are the amount of Mg in Mg-Hg alloy and Mg melt respectively.

Embodiment 1

[0045] (1) Preparation of Mg-Hg master alloy: According to the weight parts of each raw material in Example 1 in Table 1, put Mg and Hg in a sealed tank, heat and seal the smelting at 720°C for 2.0h, pour it on the flat ground 3 times, Water cooling to get Mg-Hg master alloy;

[0046] (2) According to the weight parts of each raw material in Example 1 in Table 1, first add Al, Pb, Mn, Zn, In, Ga, and the Mg-Hg master alloy obtained in step (1) into the Mg melt at 715°C in sequence, and At a speed of 2 turns / min, stir and smelt for 15 minutes, then add Ce at 740°C, stir and smelt for 25 minutes at a speed of 2 turns / min, and keep it for 20 minutes to obtain a mixed melt;

[0047] (3) The mixed melt obtained in step (2) is semi-continuously cast: the mixed melt is uniformly poured into the interlayer crystallizer filled with cooling water at 740°C, and the flow rate of the cooling water is 280L / min. After the first water cooling, the magnesium alloy melt solidifies and crystall...

Embodiment 2

[0049] (1) Preparation of Mg-Hg master alloy: According to the weight parts of each raw material in Example 2 of Table 1, put Mg and Hg in a sealed tank, heat and seal at 710°C for 2.5 hours, pour it on the flat ground 4 times, Water cooling to get Mg-Hg master alloy;

[0050] (2) According to the parts by weight of the raw materials in Example 2 of Table 1, first add Al, Pb, Mn, Zn, In, Ga, and the Mg-Hg master alloy obtained in step (1) into the Mg melt at 700°C in sequence, and in 1 At a speed of 1 revolution / min, stir and smelt for 20 minutes, then add Ce at 735°C, stir and smelt for 30 minutes at a speed of 1 revolution / min, and keep it for 10 minutes to obtain a mixed melt;

[0051] (3) The mixed melt obtained in step (2) is subjected to semi-continuous casting: the mixed melt is evenly poured into the interlayer crystallizer filled with cooling water at 730°C, and the flow rate of the cooling water is 250L / min. After the first water cooling, the magnesium alloy melt so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com