A method for preparing ultrafine, high-purity, high-solid-solubility tungsten-based alloy powder

A tungsten-based alloy, high-solid technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of uneven particle size, low solid solubility, high impurity introduction, etc., to solve the problem of low solid solubility, promote Homogenize and improve the effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take 60 g of auxiliary tantalum powder with an average particle size of 27 μm and a purity of ≥99.95%, and put it in a 1L ball milling jar of cemented carbide containing 0.4L of absolute ethanol. Add 2kg of cemented carbide balls with a diameter of 6mm and 1kg of cemented carbide balls with a diameter of 10mm. The cemented carbide grade is YG8 and the composition is WC-8Co. After encapsulating the ball mill jar, evacuate it to 133 Pa through a vacuum valve, then fill it with high-purity argon, and repeat 4 times. Install the ball mill jar on the omnidirectional planetary ball mill, add the counterweight at the corresponding position to balance the ball mill, set the rotation speed to 150rpm, stop for 5min every 1h, change the forward and reverse directions once, and start the omnidirectional reverse for 4 weeks at the same time. Second-rate. The ball milling time is 8h, so that a layer of ductile auxiliary material coating layer is formed on the surface of the ball mil...

Embodiment 2

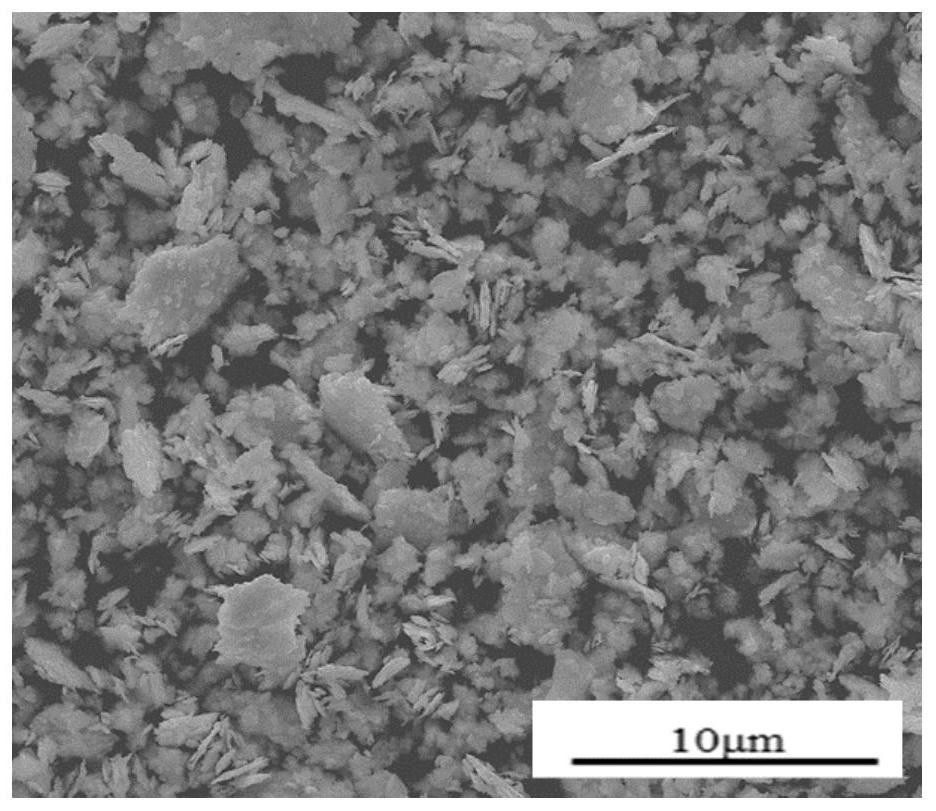

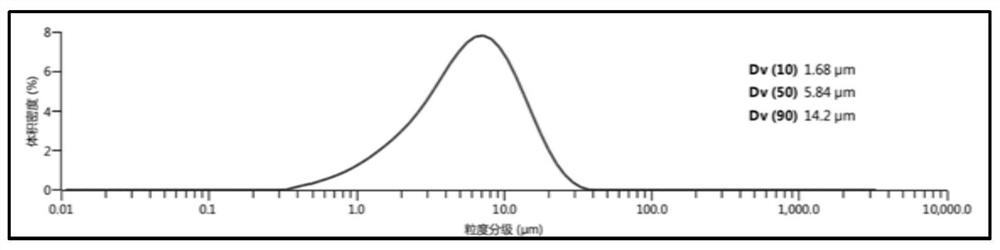

[0048] Take 60g of auxiliary niobium powder (average particle size 40μm, purity ≥99.9%), raw material tungsten powder 240g (average particle size 4μm, purity ≥99.95%), carry out two-step ball milling in the same way as in Example 1, and the second step ball milling time for 35h. The heat treatment temperature is 800 ° C, and other conditions are the same as in Example 1, and the tungsten-niobium alloy powder is obtained as follows image 3 , see the particle size distribution Figure 4 . The average particle diameter of the obtained powder was 3.37 μm. (The span of powder particle size is less than or equal to 8 microns). The impurity content of the powder analyzed by ICP-OES and carbon, hydrogen and oxygen tester is shown in Table 4.

Embodiment 3

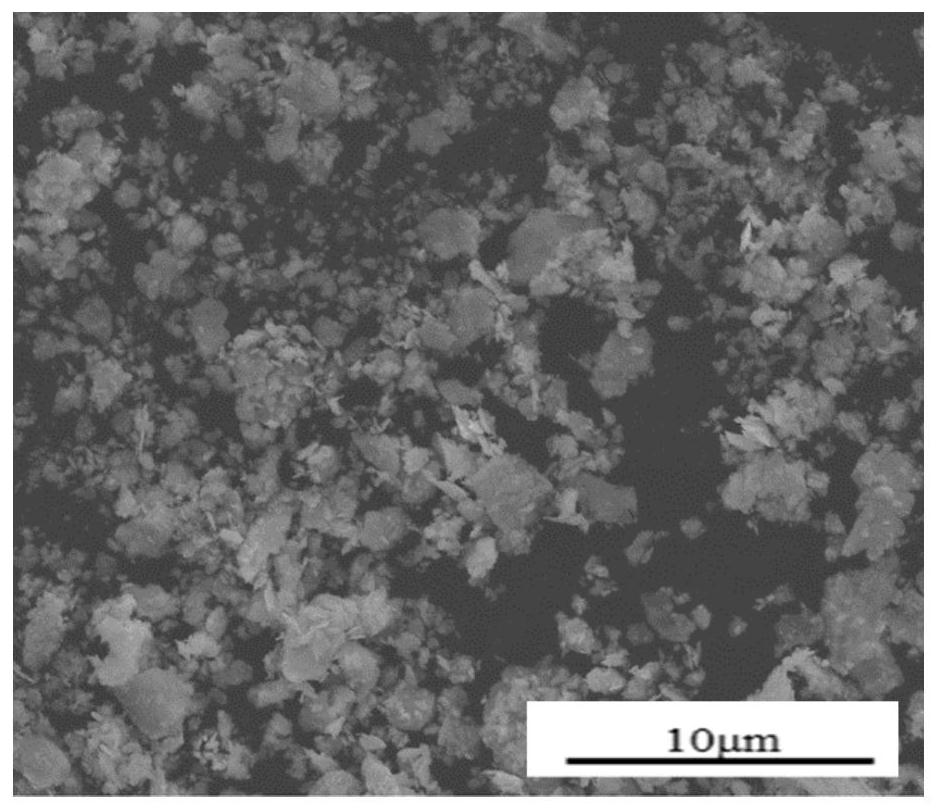

[0050] Take 60g of auxiliary niobium powder (average particle size 40μm, purity ≥99.9%), 60g auxiliary tantalum powder (average particle size 27μm, purity ≥99.95%), and raw tungsten powder 180g (average particle size 4μm, purity ≥99.95%), In the same way as in Example 1, firstly add the auxiliary materials tantalum powder and niobium powder to carry out the first ball milling, then add tungsten powder to carry out the second stage ball milling. , to obtain tungsten-tantalum-niobium alloy powder. The solid solution effect was analyzed by XRD as Figure 5 As can be seen from the figure, the alloy powder only has the main peak of tungsten, indicating that niobium and tantalum have been solid-dissolved into the lattice of tungsten to achieve alloying. The average particle diameter of the obtained powder was 4.8 μm. (The span of powder particle size is less than or equal to 12 microns). The analysis of its powder impurity content is shown in Table 1.

[0051] Table 1: Main elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com