A vacuum laser wire filling processing device and a vacuum laser wire filling method

A technology of laser wire filling and processing device, which is used in laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of solving the burning loss of alloy elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

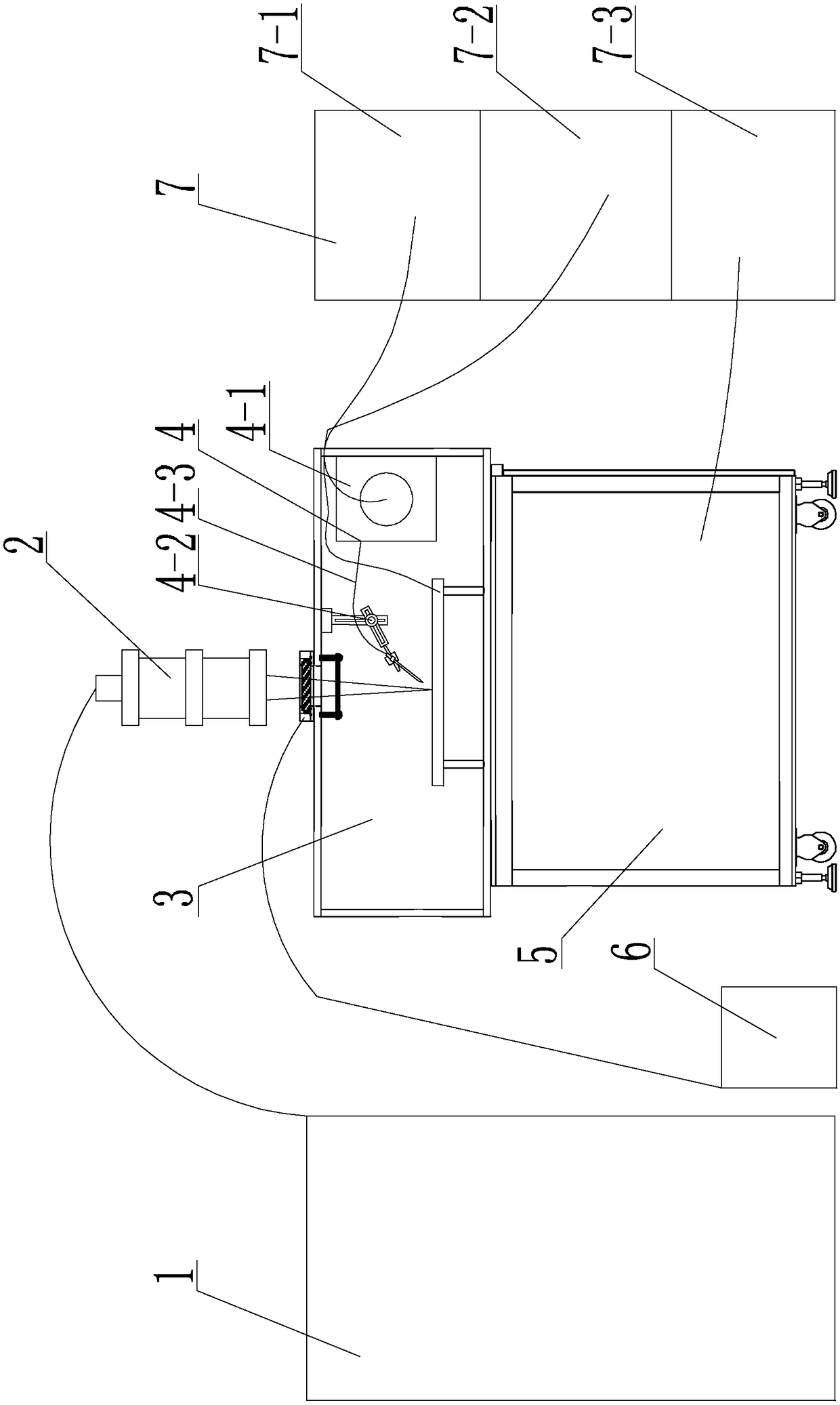

[0018] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, a vacuum laser wire filling processing device and a vacuum laser wire filling method described in this embodiment, which include a laser 1, a laser processing head 2, a vacuum chamber assembly 3, a wire feeding assembly 4, a vacuum pumping mechanism 5, The water-cooling circulation mechanism 6 and the digital control mechanism 7, the vacuum chamber assembly 3 is arranged on the vacuum pumping mechanism 5, the laser processing head 2 is arranged above the vacuum chamber assembly 3, the wire feeding assembly 4 is installed in the vacuum chamber assembly 3, and the laser 1 passes through The optical fiber line is connected with the laser processing head 2, the water-cooled circulation tube of the water-cooled circulation mechanism 6 is installed on the top of the vacuum chamber assembly 3, the laser 1 and the water-cooled circulation mechanism 6 are arranged close to the vacuum pumping me...

specific Embodiment approach 2

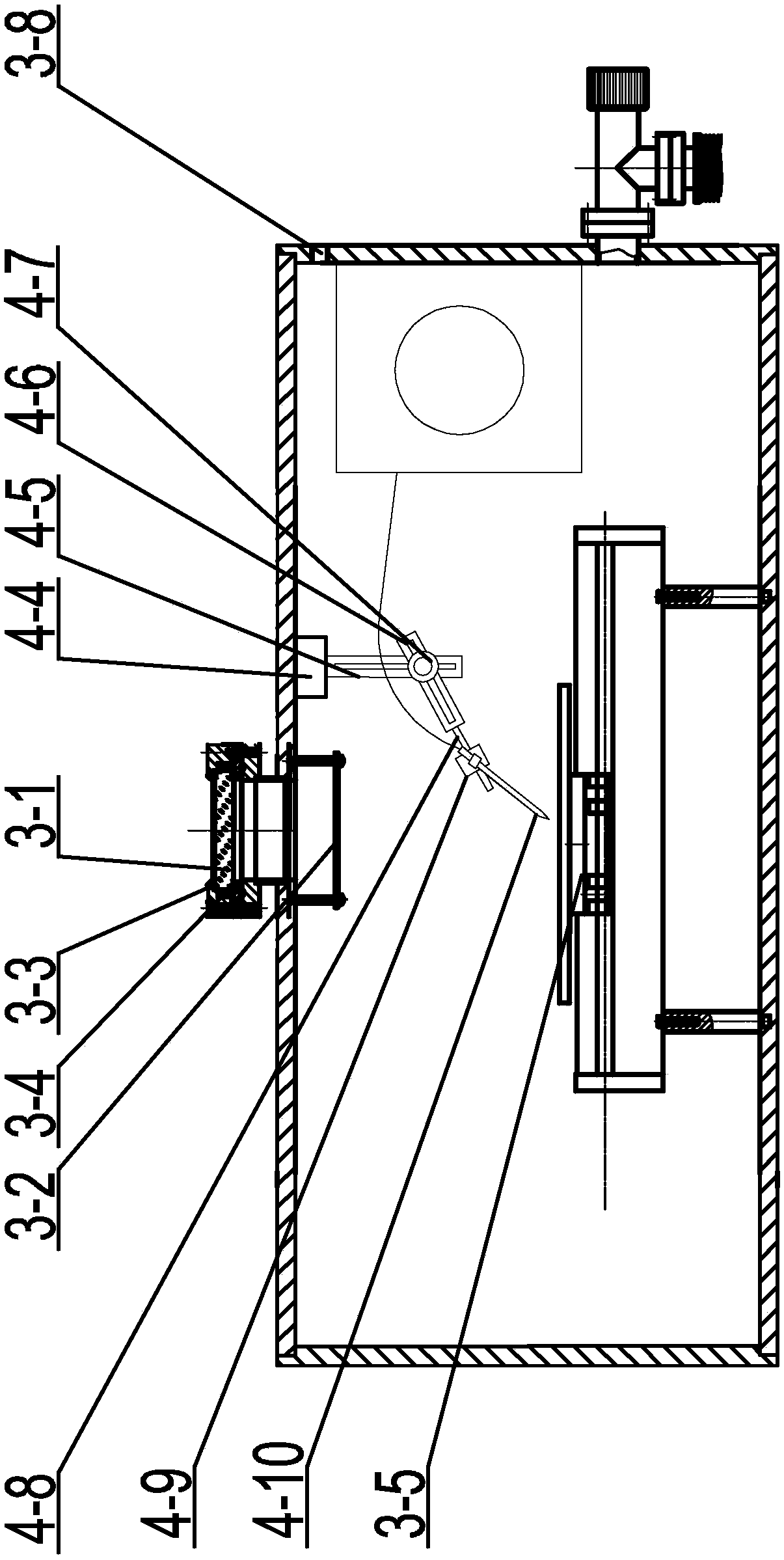

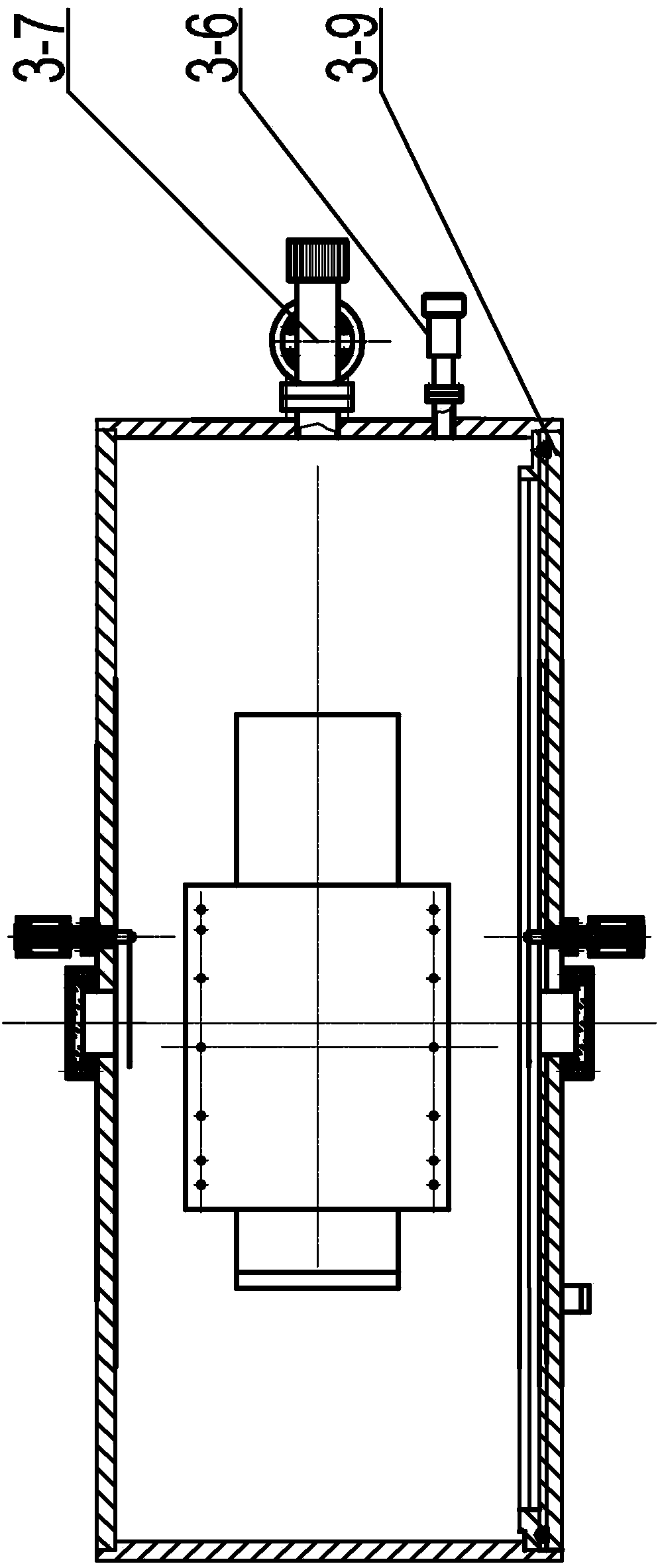

[0022] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, a vacuum laser wire filling processing device and a vacuum laser wire filling method described in this embodiment, the vacuum chamber assembly 3 includes a vacuum chamber box, a laser transmission lens 3-1, and an anti-splash lens 3-2 , sealing ring 3-3, workbench 3-5, air release valve 3-6, air extraction valve 3-7 and hatch door 3-9, the top of the vacuum chamber box is processed with a laser projection window, laser transmission lens 3- 1. It is horizontally sealed and installed on the laser projection window through the sealing ring 3-3. The edge of the laser transmission lens 3-1 is provided with a water cooling channel 3-4. The water cooling circulation mechanism 6 communicates with the water cooling channel 3-4. The horizontal anti-splash lens 3 -2 is set under the laser transmissive lens 3-1, and the horizontal anti-splash lens 3-2 is installed at the laser projection wind...

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, a vacuum laser wire filling processing device and a vacuum laser wire filling method described in this embodiment, the wire feeding assembly 4 includes a wire feeding machine 4-1, a wire feeding nozzle assembly 4-2 and a wire feeding tube 4-3, the wire feeder 4-1 is installed on the inner wall of the vacuum chamber box, the wire feeding nozzle assembly 4-2 is fixedly installed on the inner wall of the top of the vacuum chamber box, and one end of the wire feeding tube 4-3 is set On the wire feeder 4-1, the other end of the wire feed tube 4-3 is set on the wire feed nozzle assembly 4-2, and the other end is the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com