Nodulant for alloying nodular cast iron

A nodulizer and alloy ball technology, applied in the field of nodular cast iron production, can solve problems such as the limitation of the amount of returned charge, reduce the low-temperature impact toughness of nodular cast iron, etc., achieve less oxidation slag inclusions, improve purity and performance, and have a stable reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

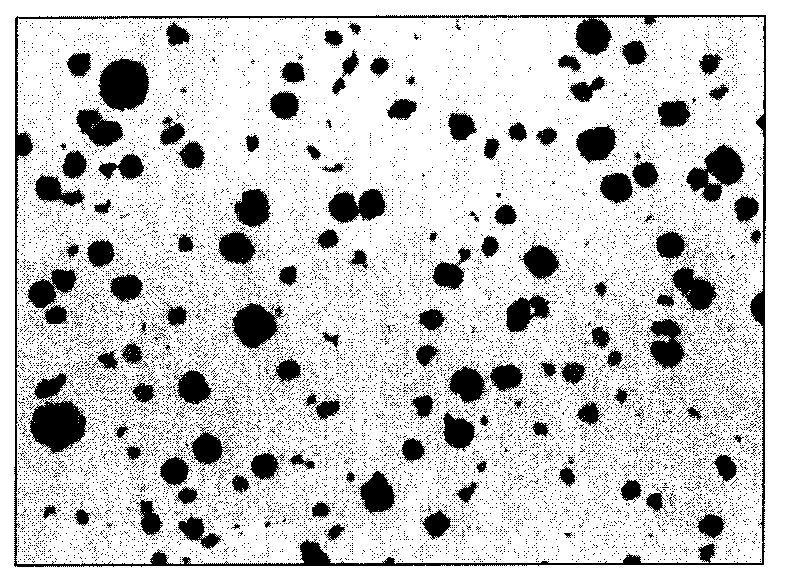

Image

Examples

Embodiment 1

[0019] ① Melt molten iron in a 500Kg intermediate frequency induction furnace by conventional methods.

[0020] ② with Cu-Mg-R E Nodulizer, nodulizer composition: 85wt% Cu, 14wt% Mg, 1.0wt% R E , the addition amount is 0.6wt% of molten iron.

[0021] ③Spheroidizing the original molten iron of ductile iron by the flushing method, the temperature of the molten iron is 1480°C, and the composition of the original molten iron is: 3.95wt%C, 1.25wt%Si, 0.20wt%Mn, 0.03wt%P, 0.022wt% S.

[0022] ④Using secondary inoculation treatment, the inoculant is 75wt% Si-Fe. In the first bag inoculation, the amount of inoculant added is 0.8wt% of the molten iron, and for the second inoculation with flow, the amount of inoculant added is 0.15wt% of the molten iron.

[0023] ⑤ Pouring castings and 70mm Y-shaped test blocks, furan resin sand casting molds, the pouring temperature is 1340 ℃ ~ 1360 ℃.

[0024] ⑥ Cut the sample on the 70mm Y-shaped test block and process it into 14mm tensile spe...

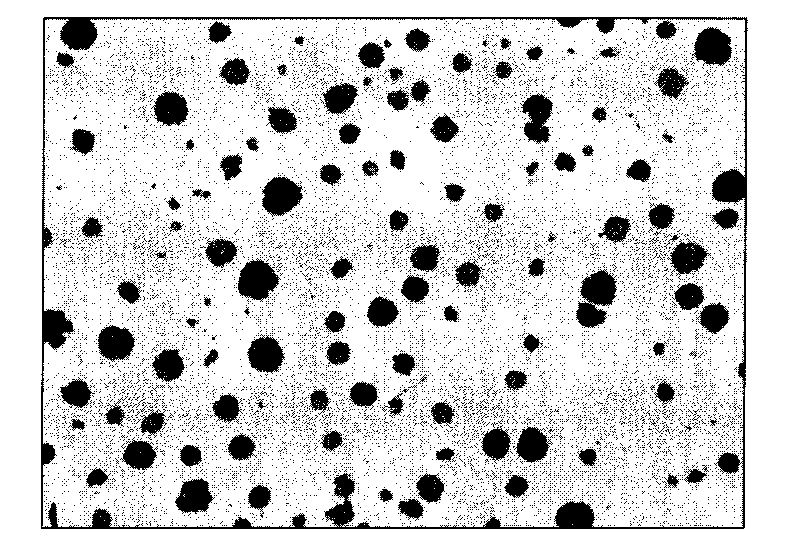

Embodiment 2

[0026] ① Melt molten iron in a 500Kg intermediate frequency induction furnace by conventional methods.

[0027] ② Use Cu-Mg-RE nodulizer, the nodulizer composition is: 92.5wt% Cu, 6.0wt% Mg, 1.5wt% R E , the addition amount is 1.2wt% of molten iron.

[0028] ③Spheroidizing the original molten iron of ductile iron by the flushing method, the temperature of the molten iron is 1500°C, and the composition of the original molten iron is: 3.90wt%C, 1.35wt%Si, 0.25wt%Mn, 0.025wt%P, 0.020wt% S.

[0029] ④Using secondary inoculation treatment, the inoculant is 75wt% Si-Fe. In the first bag inoculation, the amount of inoculant added is 0.8wt% of the molten iron, and for the second inoculation with flow, the amount of inoculant added is 0.15wt% of the molten iron.

[0030] ⑤ Pouring castings and 70mm Y-shaped test blocks, furan resin sand casting molds, the pouring temperature is 1340 ℃ ~ 1360 ℃.

[0031] ⑥ Cut the sample on the 70mm Y-shaped test block and process it into 14mm ten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com