A kind of mg-ti hydrogen storage alloy powder and preparation method thereof

A technology of hydrogen storage alloy powder and alloy powder, which is applied in the direction of electrical components, circuits, battery electrodes, etc., can solve the problems of unstable cycle, poor kinetic performance, and difficult preparation, and achieve chemical properties that are inactive and good storage Hydrogen performance and the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

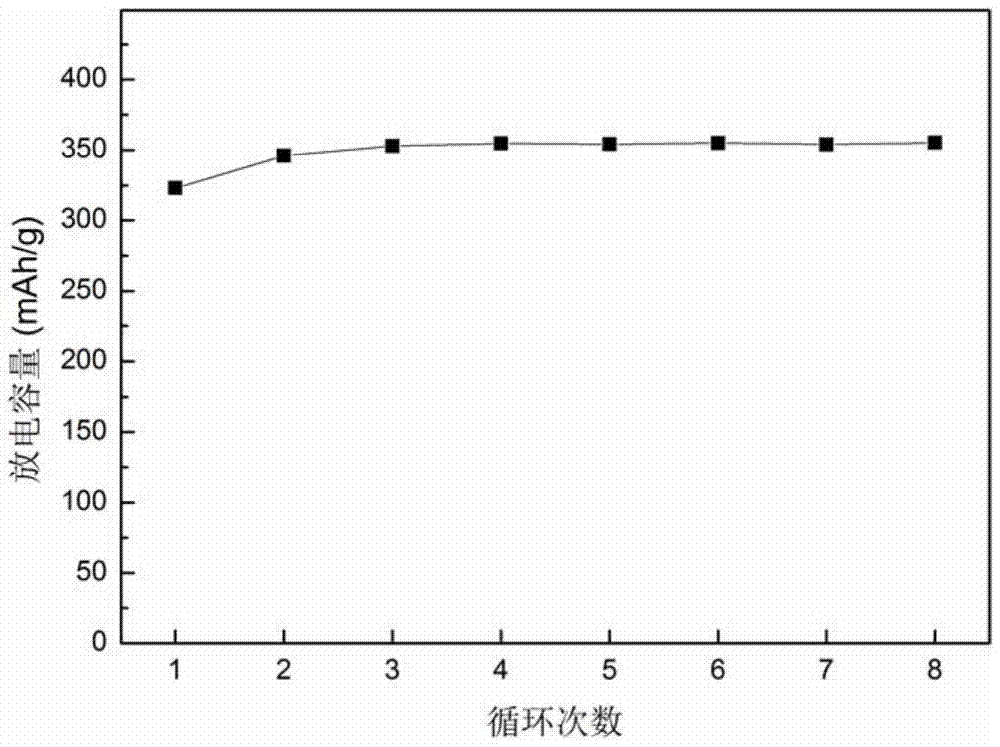

Examples

Embodiment 1

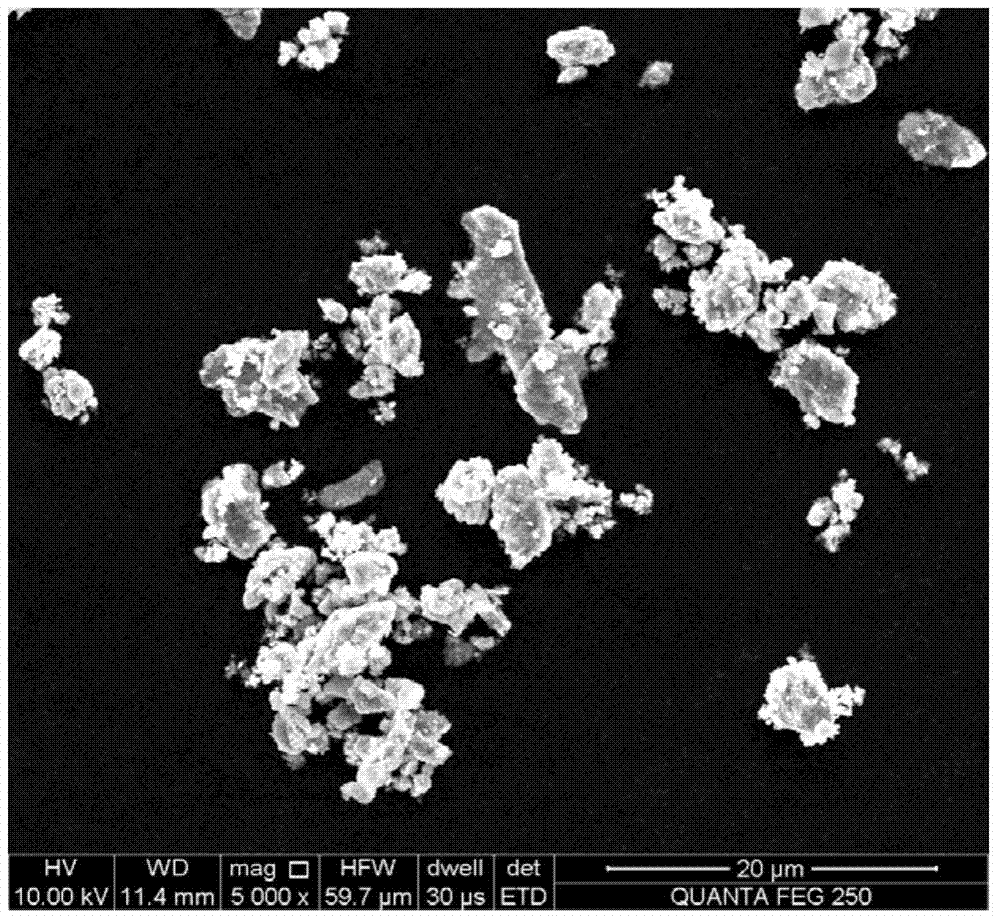

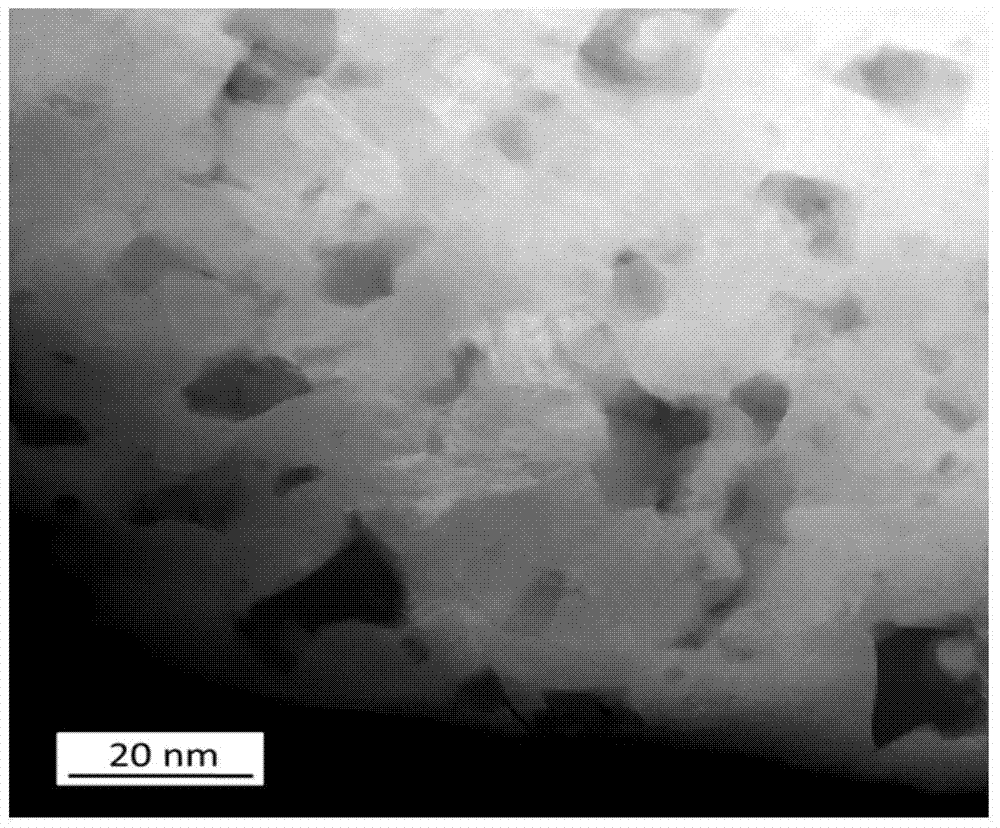

[0044] The particle size of pure magnesium powder is 100-210nm, and the particle size of pure titanium powder is 50-100nm;

[0045] FeCl 3 The particle size of the powder is 0.8-1.5 μm.

[0046] Multi-walled carbon nanotubes have a diameter of 10-50 nm.

[0047] Powder mixing: according to the ratio of mass ratio pure magnesium powder: pure titanium powder=55:45 (converted into atomic number ratio: 71.3:28.7), weigh the element powder and put it into the ball mill jar, inject alcohol into the ball mill jar, and Make sure the alcohol fills the entire mill jar with no air trapped. Add ZrO at a ball-to-material ratio of 20:1 2 Grinding balls, the ball milling process is set as: the ball milling speed is 800r / min, and the ball milling time is 40h. After ball milling is finished, treat that ball mill jar is cooled, take powder in the glove box that argon gas atmosphere protects, will obtain Mg-Ti alloy powder (the median diameter of powder is about 146nm), put into vacuum oven,...

Embodiment 2

[0050] The particle size of pure magnesium powder is 100-150nm, and the particle size of pure titanium powder is 60-90nm;

[0051] FeCl 3 The particle size of the powder is 0.8-1.0 μm.

[0052] Multi-walled carbon nanotubes have a diameter of 10-15 nm.

[0053] Organic solvent, by mass ratio, absolute ethanol: butane: pentane=100:5:1

[0054] Powder mixing: Weigh the element powder according to the mass ratio of pure magnesium powder: titanium powder=55:45 (converted into atomic number ratio: 71.3:28.7) and put it into the ball mill jar, inject the organic solvent into the ball mill jar, and Make sure that the organic solvent fills the entire mill jar without air entrapment. Add ZrO at a ball-to-material ratio of 20:1 2 Grinding balls, the ball milling process is set as: the ball milling speed is 800r / min, and the ball milling time is 40h. After ball milling is finished, treat that ball mill tank is cooled, take powder in the glove box that argon gas atmosphere protects, ...

Embodiment 3

[0057] The particle size of pure magnesium powder is 160-200nm, and the particle size of pure titanium powder is 60-80nm;

[0058] FeCl 3 The particle size of the powder is 1.0-1.5 μm.

[0059] Multi-walled carbon nanotubes have a diameter of 25-30 nm. In addition, the multi-walled carbon nanotubes are doped with nitrogen element, and the doping amount of nitrogen element is 3.5 at%.

[0060] Organic solvent, dehydrated alcohol by mass ratio: butane: pentane=100:10:2.

[0061] Powder mixing: Weigh the element powder according to the mass ratio of pure magnesium powder: titanium powder = 70:30 (converted atomic ratio 82:18) and put it into the ball mill jar, inject alcohol into the ball mill jar, and ensure that the alcohol fills the entire ball mill tank, no air remains. Add ZrO at a ball-to-material ratio of 15:1 2 Grinding balls, the ball milling process is set as: the ball milling speed is 800r / min, and the ball milling time is 30h. After the ball milling is completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com