Patents

Literature

60results about How to "Chemically inactive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant fiber starch fully-biodegradable material and preparation method thereof

The invention discloses a plant fiber starch fully-biodegradable material and a preparation method thereof. The material is a product prepared by melting, blending and extruding thermoplastic corn starch, 50 to 60 mesh needlebush fibers, polylactic acid, inorganic stuffing, a crosslinking agent and a solubilizer in a twin-screw extruder. The thermoplastic corn starch is a product prepared by extruding the corn starch and the solubilizer which are blended according to a ratio of 40 to 70: 2 to 5 in a single screw extruder. In the invention, dioctyl maleate (MOD) is grafted onto the polylactic acid to perform a hydroxylation reaction of MOD-functionalized polylactic acid and thermoplastic starch, so that PLA and TPS interfaces are soluble mutually and the binding force of the interfaces is improved. The product has high water resistance and high mechanical properties. Compared with the conventional thermoplastic corn starch composition packing material, the stretching strength of the material of the invention is improved by 30 to 60 percent, the rigidity is increased by 15 to 35 percent, the water absorption is reduced by 13 to 40 percent, and the material is nontoxic and low in cost.

Owner:HUNAN UNIV OF TECH

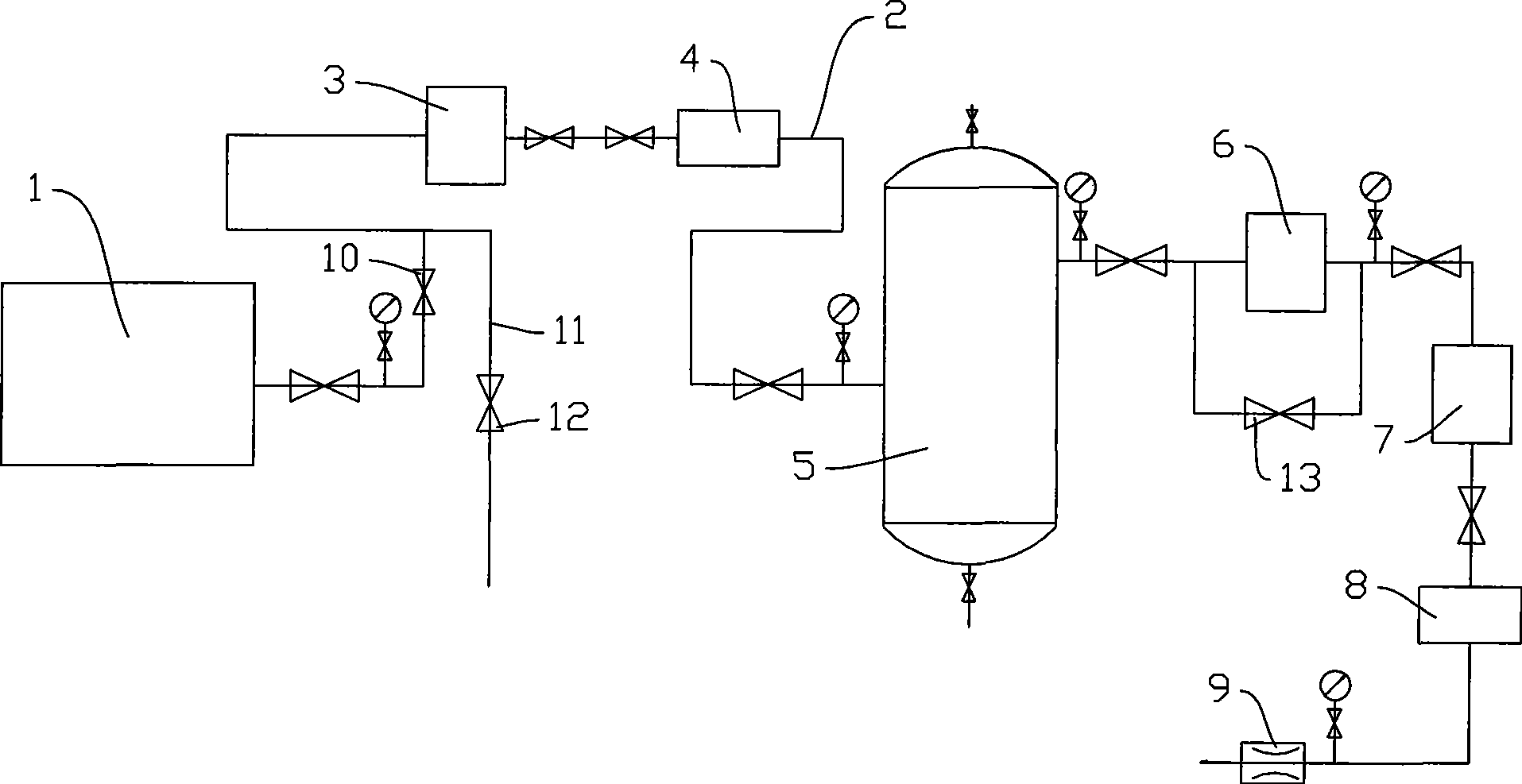

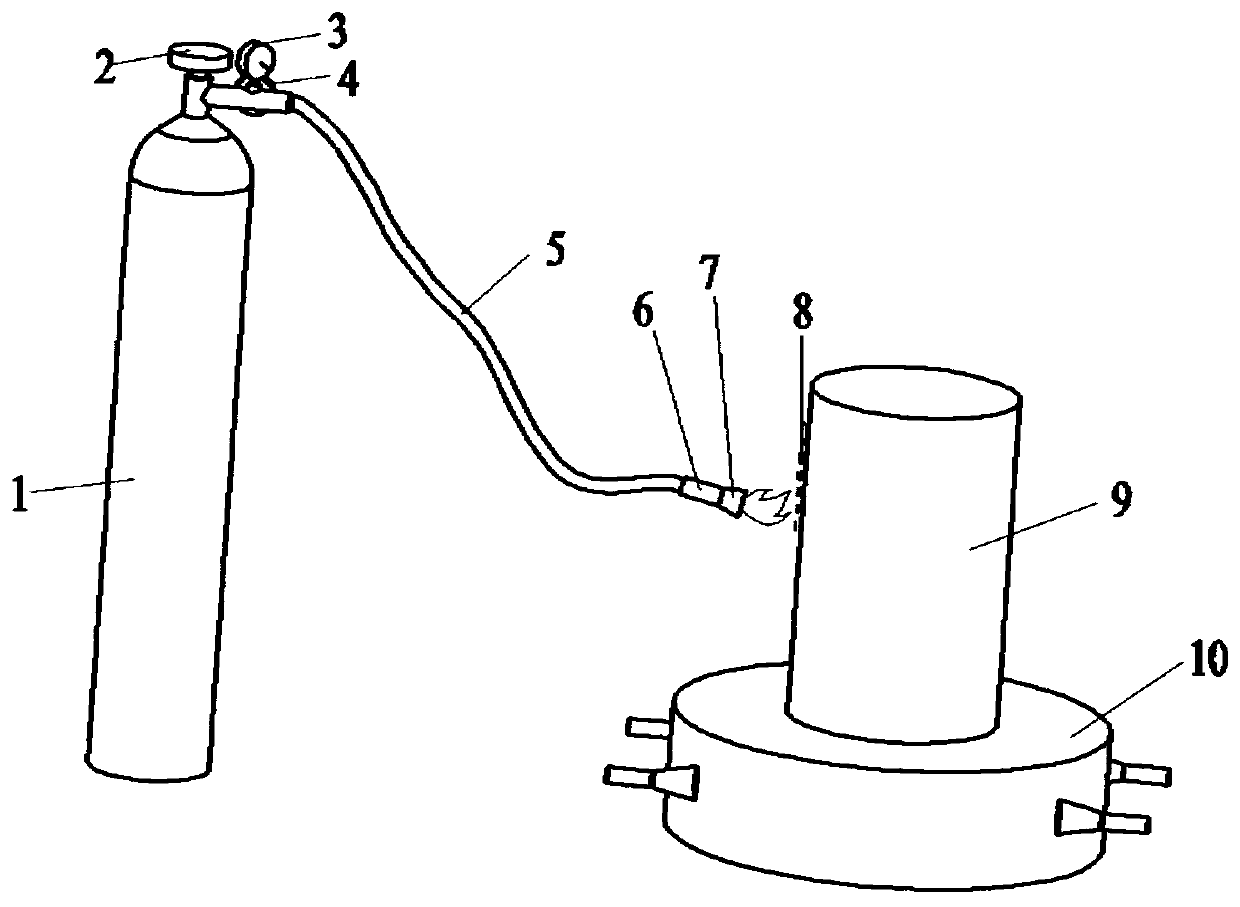

Nitrogen purging device of hydraulic line and method for cleaning hydraulic line

InactiveCN101480653AReduce adhesionEasy to useHollow article cleaningProcess engineeringNitrogen source

The invention provides a device and a method for cleaning hydraulic pipelines, in particular to a nitrogen purging device (cleaning device) for hydraulic pipelines, which has good cleaning effect, high efficiency and not pollution. The nitrogen purging device for hydraulic pipelines adopts the structure that a gas drier used for the drying treatment of nitrogen, a gas filter used for the filtering treatment of nitrogen and a flow control valve used for regulating the output flow of nitrogen are connected in series on an output pipeline which is connected with a nitrogen source. In addition, the cleaning method for hydraulic pipelines adopts nitrogen after being dried and filtered to purge the hydraulic pipelines.

Owner:CHINA 19TH METALLURGICAL CORP

Completely biodegradable food packing material and preparation method thereof

The invention discloses a completely biodegradable food packing material and a preparation method thereof. The completely biodegradable material of plant fiber and starch is a product obtained by melting, blending and extruding potato starch, bamboo fiber, polycaprolactone, a plasticizer, an inorganic filling agent and a cross linker through a double-screw extruder; and the molten blend comprises the following components in parts by weight: 40 to 60 parts of potato starch, 10 to 30 parts of bamboo fiber, 5 to 10 parts of polycaprolactone, 2 to 10 parts of inorganic filling agent, 2 to 8 parts of cross linker, 5 to 20 parts of plasticizer and 2 to 10 parts of solubilizing agent. Compared with the traditional starch-based plastic degradable material, the tensile strength of the completely biodegradable material is improved by 20 to 40 percent; the stiffness is improved by 20 to 40 percent; the water absorption is reduced by 10 to 20 percent; and the completely biodegradable material has excellent properties of low cost, complete biodegradability and environmental friendliness, and can be widely used for packing food, particularly disposable instant snack boxes.

Owner:HUNAN UNIV OF TECH

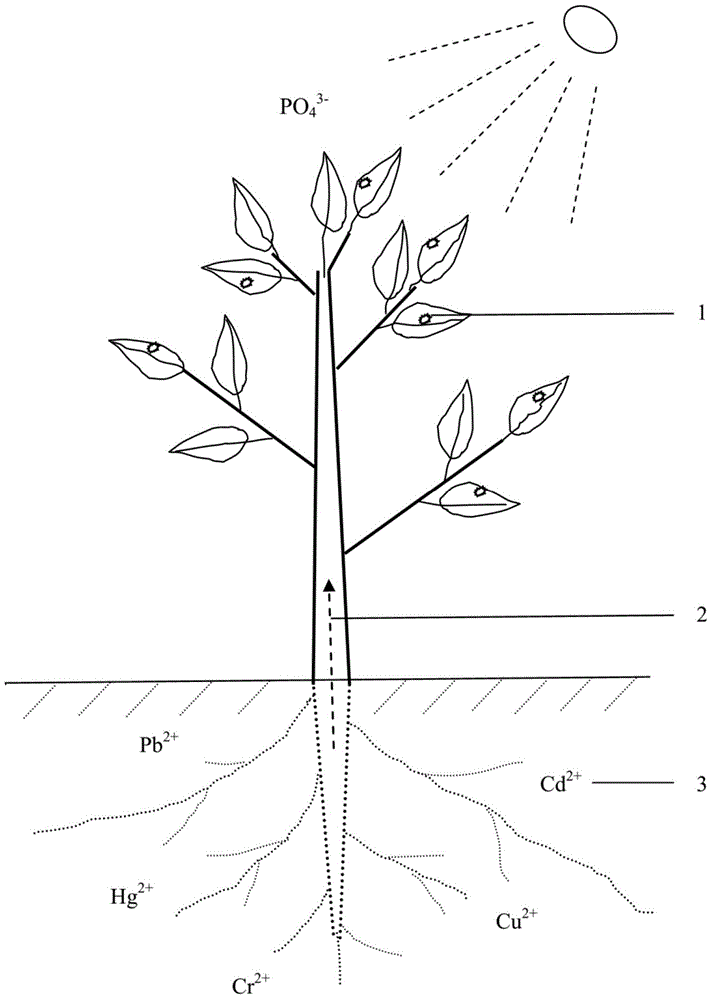

Method for improving repairing efficiency of heavy metal polluted plants

InactiveCN104871850ARemove or reduce toxic effectsEasy accessHorticulture methodsVegetative propogationGrowing seasonMetal contamination

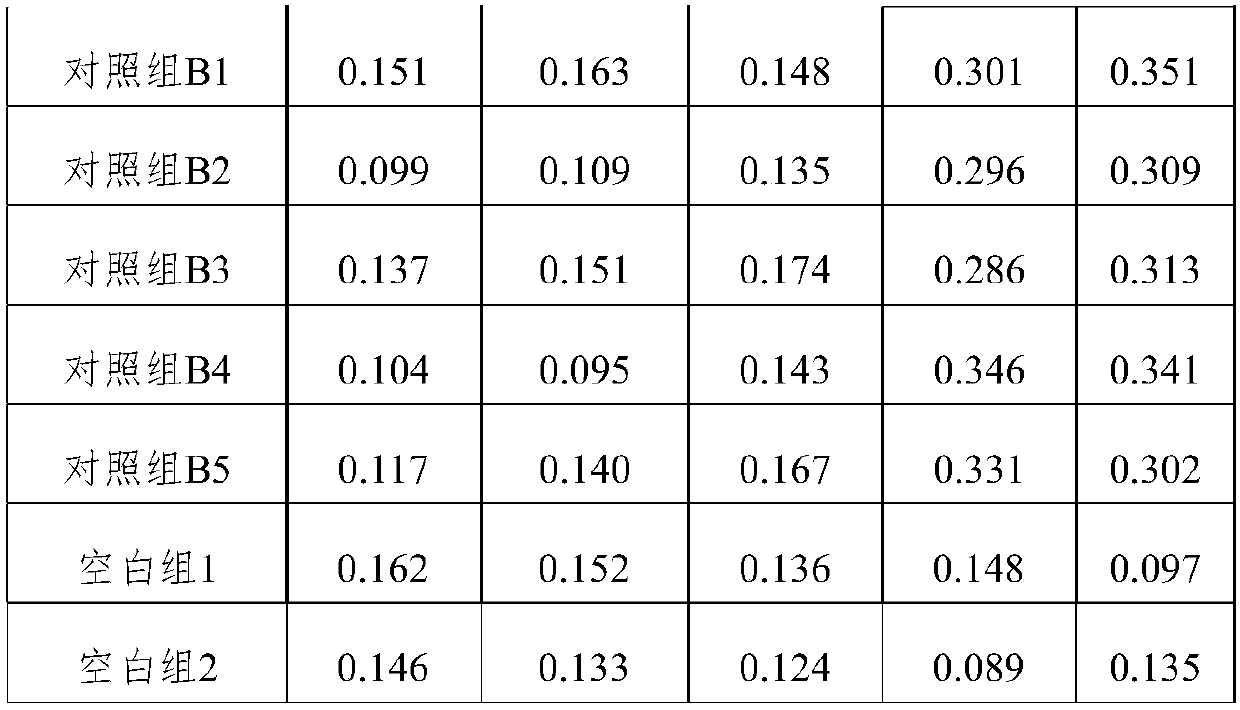

The invention discloses a method for improving the repairing efficiency of heavy metal polluted plants. The method comprises the following steps: growing plants with an enriching or super-enriching ability to heavy metal on heavy metal polluted soil or water; when the main stems of the plants grow leaves, spraying a heavy metal pollution repairing improver on the leaves; removing heavy metal pollutions by harvesting dead leaves of the plants in plant growing season. The method has the advantages that not only can the repairing efficiency of the heavy metal polluted plants be improved, but also heavy metal poisoning the plants can be reduced or removed, and the application range of heavy metal polluted plant repairing is extended.

Owner:SHANGHAI JIAO TONG UNIV

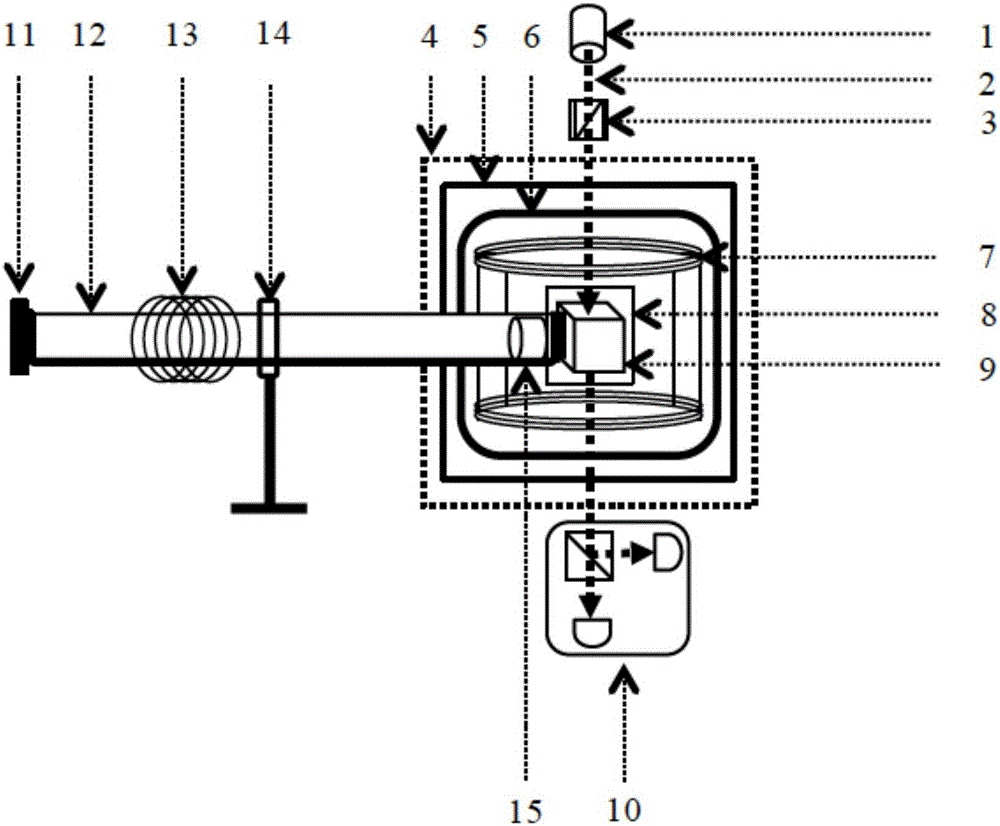

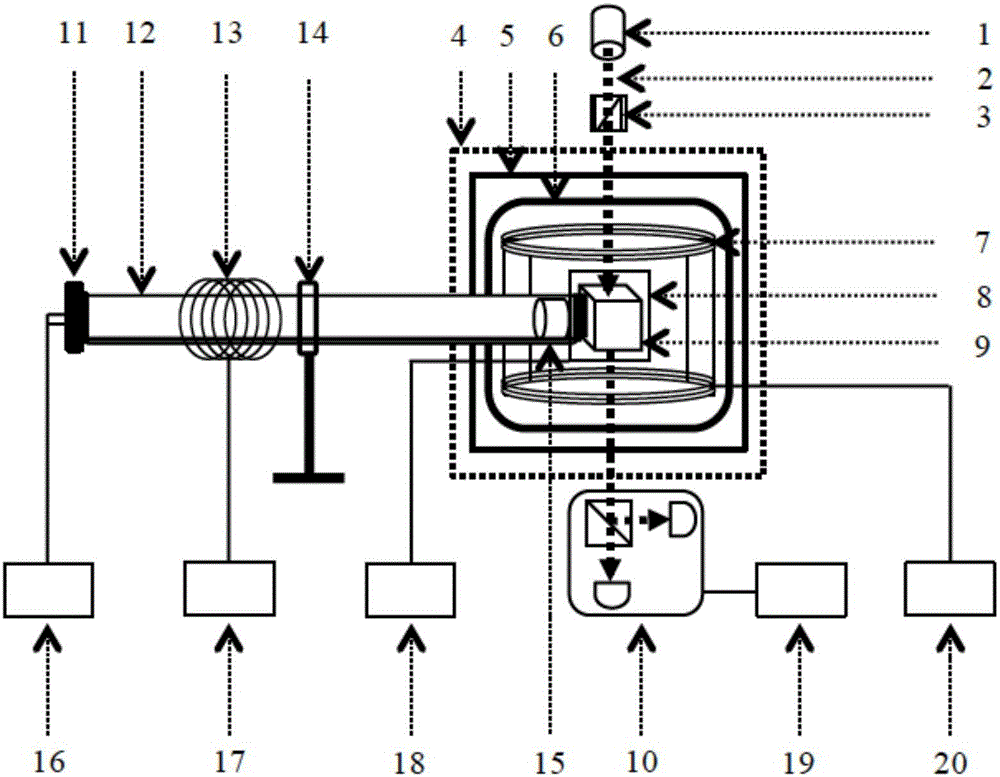

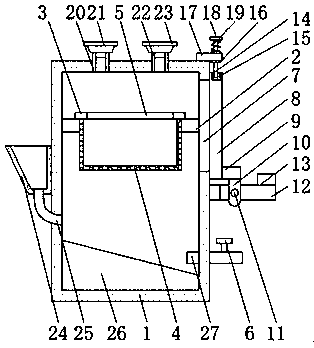

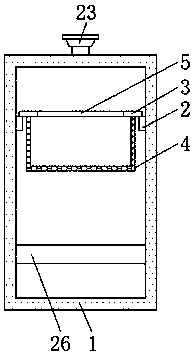

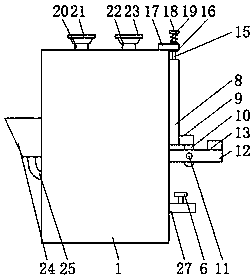

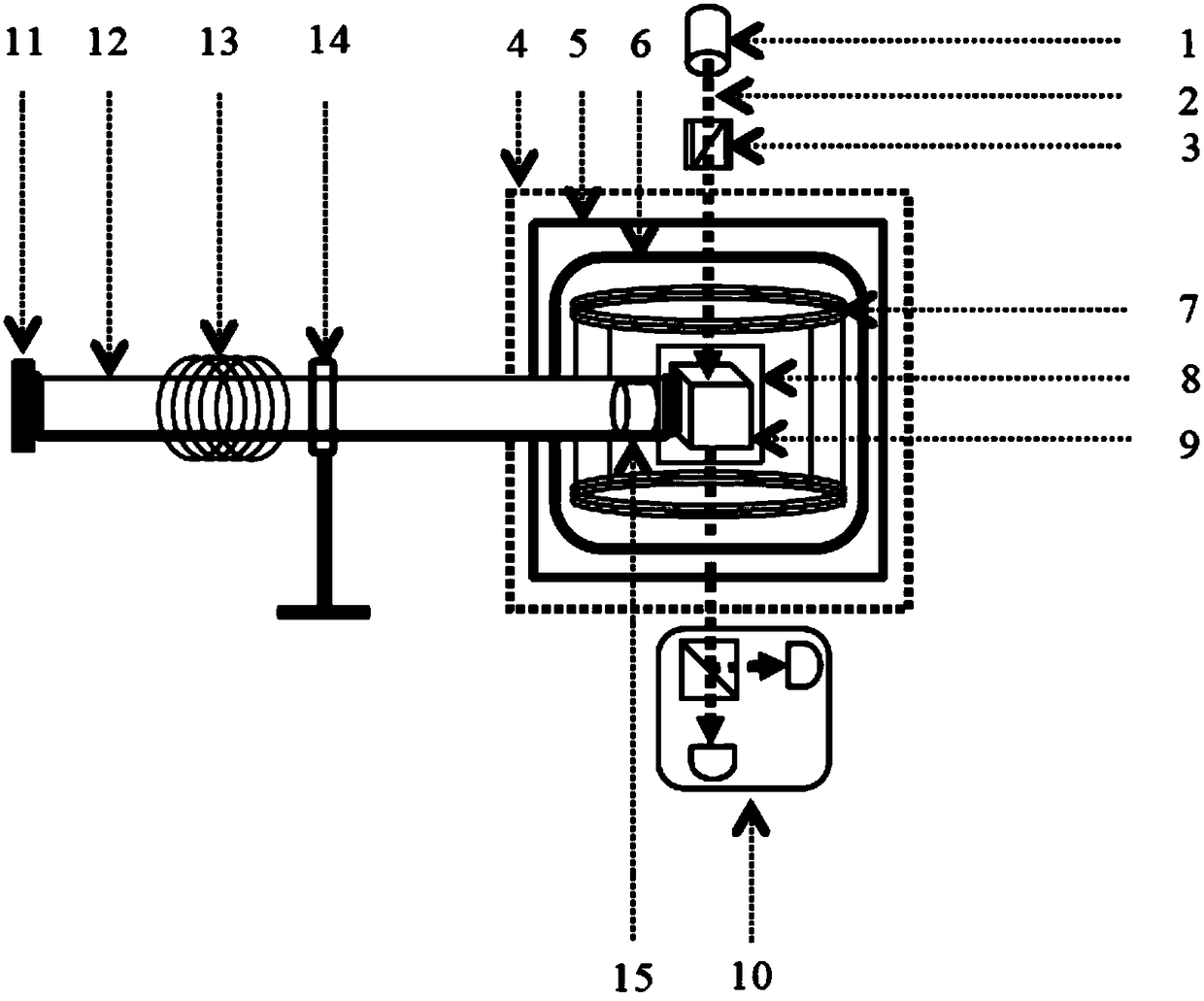

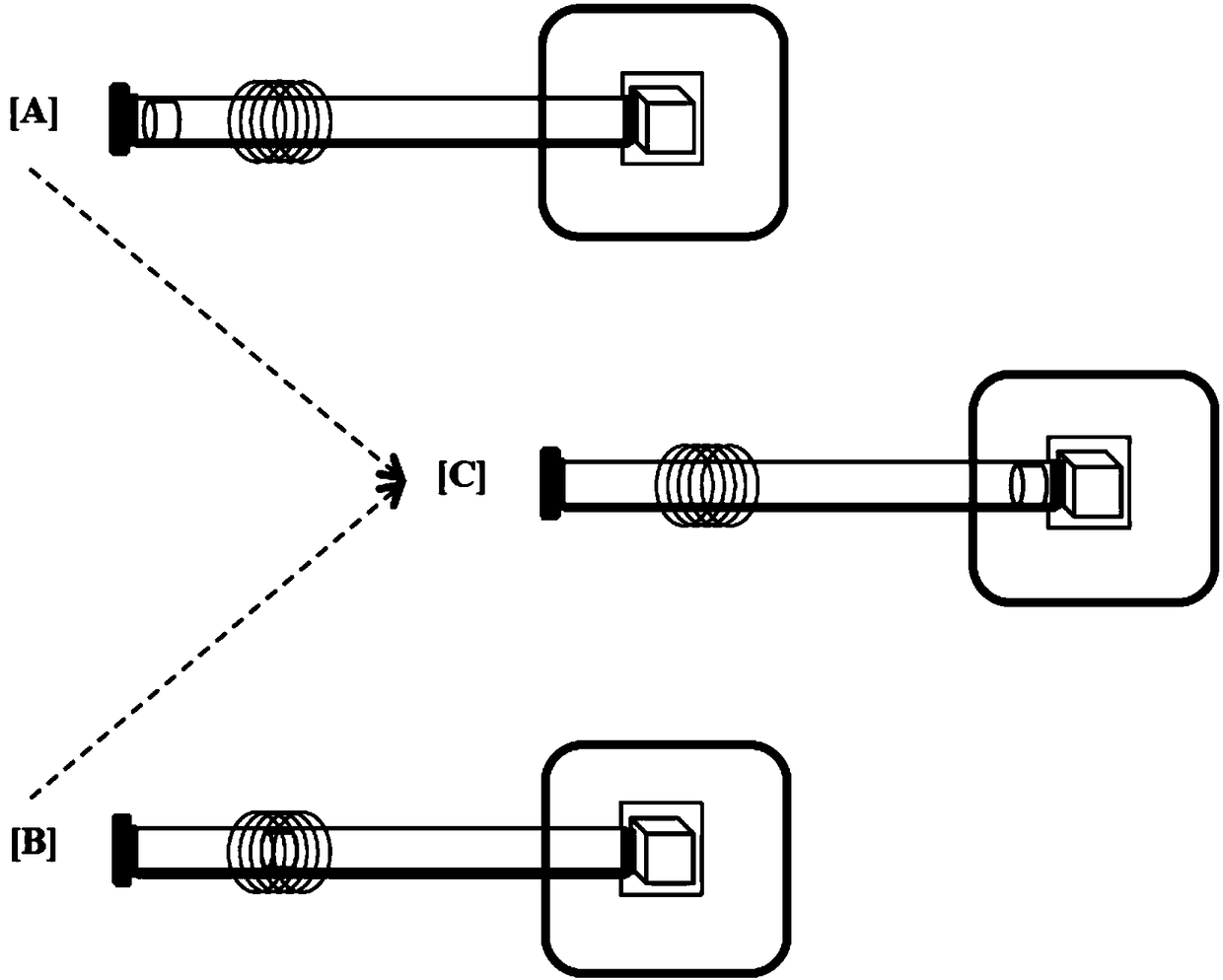

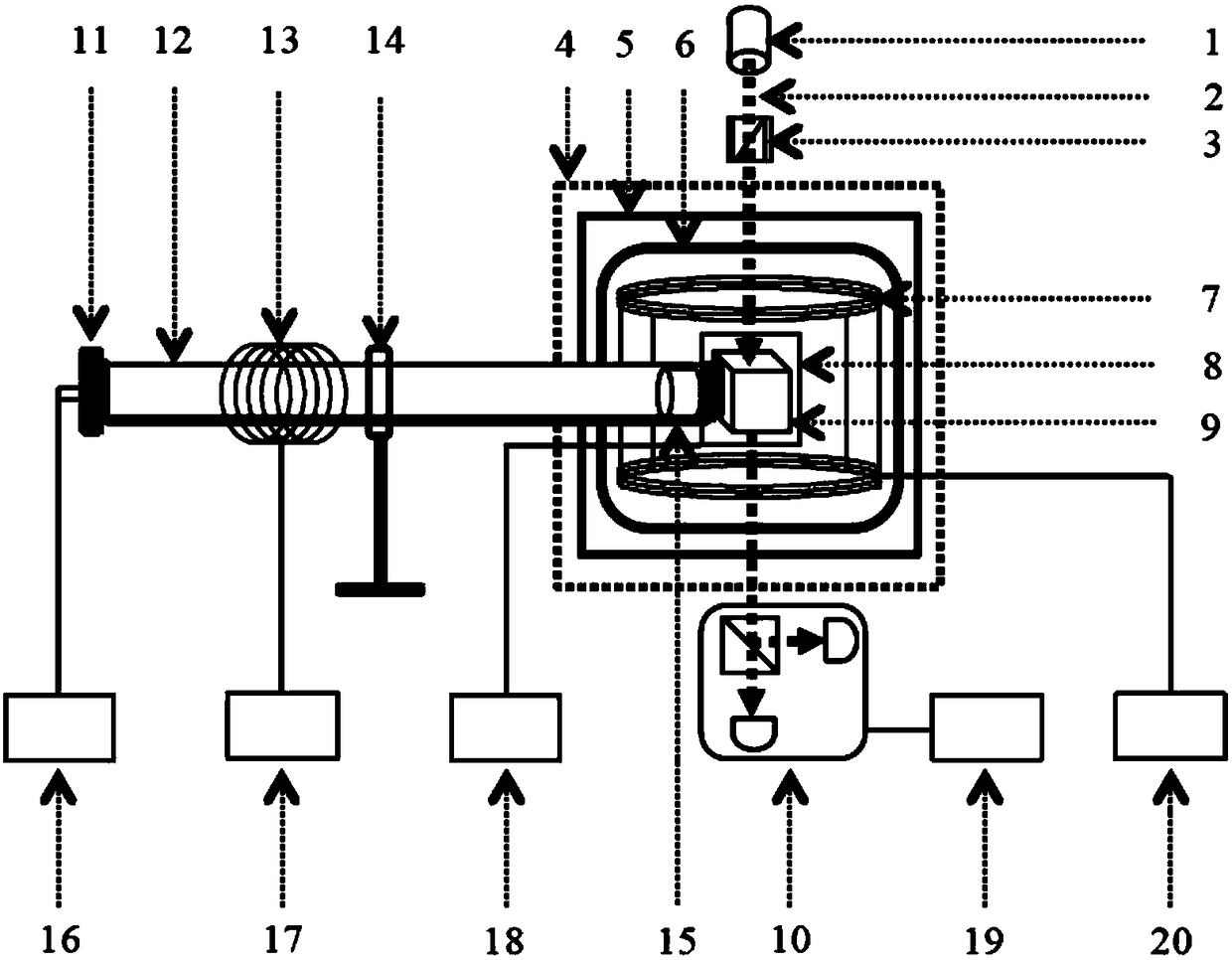

Device used for material ferromagnetism and magnetization performance detection and method thereof

ActiveCN106405457AHigh sensitivityImprove ferromagnetismMagnetisation measurementsMagnetic field measurement using magneto-optic devicesMagnetizationElectromagnetic shielding

The invention discloses a device used for material ferromagnetism and magnetization performance detection. The device comprises a laser device, linearly polarized light beams, a Glan-Thompson polarizer, an electromagnetic shielding cover, a radio frequency shielding box, a magnetic shielding cylinder, an axial scanning field coil, a heating and heat preservation module, atomic vapor bubbles, a light amplification detection module, a conveying tube sealing block, a conveying tube, a solenoid coil, a positioning frame and a grooved loading warehouse. The invention also discloses a method used for material ferromagnetism and magnetization performance detection. The device is integrated in structure and convenient to operate, material ferromagnetism and magnetization performance detection is acquired through nonlinear magneto-optical resonance dispersion signals, and the device has the characteristic of ultrahigh-sensitivity magnetic measurement and practical value in material selection of atomic frequency standards, atomic magnetometers and laser detection magnetic resonance instruments.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

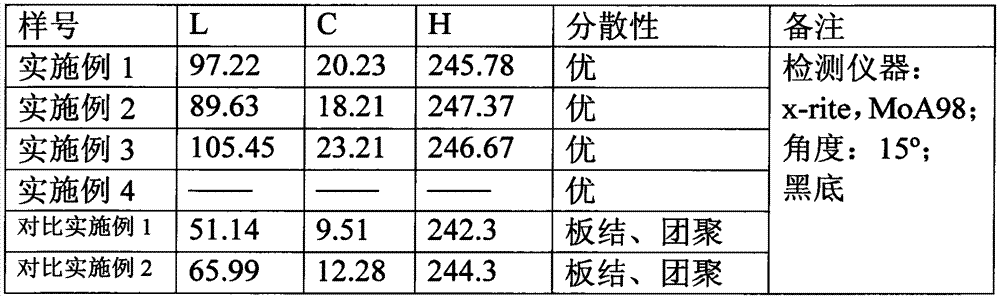

High temperature resistant pearlescent pigment and preparation method thereof

ActiveCN104327552AChemically activeSmall thermal expansionInorganic pigment treatmentColor ScaleHot Temperature

The invention relates to a high temperature resistant pearlescent pigment including a synthetic mica substrate, one layer or multi layers of metal oxide layer coating the synthetic mica substrate, and a zirconia high temperature resistant layer coating the metal oxide layer. The high temperature resistant pearlescent pigment using high temperature is up to 1150 DEG C, the high temperature resistant pearlescent pigment can be stably and well dispersed at high temperature, and can be widely used in underglaze color, in-glaze color, overglaze color, enamel, enamel paper transfers, architectural enamel plates, permanent color scales, high temperature resistant paints and other industries, and the usage amount is 0.5 ~ 50% of that of a glaze or a coating.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

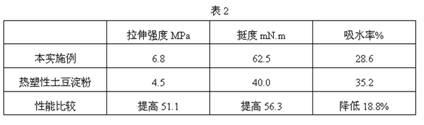

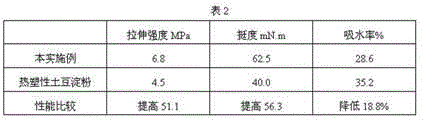

Plant fiber enhanced starch composite packaging material and preparation method thereof

The invention discloses a plant fiber enhanced starch composite packaging material and a preparation method thereof. The plant fiber enhanced starch composite packaging material is prepared by the steps of mixing 40 to 60 weight parts of cation modified potato starch, 10 to 20 weight parts of straw fiber, 5 to 10 weight parts of polyvinyl alcohol, 5 to 10 weight parts of inorganic filler, 5 to 10 weight parts of cross-linking agent, and 5 to 10 weight parts of plasticizer, and melting, mixing and extruding by using a double-screw extruder. Compared with the conventional thermoplastic potato starch composite packaging material, the plant fiber enhanced starch composite packaging material has the advantages that: the tensile strength is improved by 40 to 60 percent, the deflection is improved by 40 to 60 percent, and the water absorption rate is reduced by 15 to 30 percent.

Owner:广东普科特粉末涂料有限公司

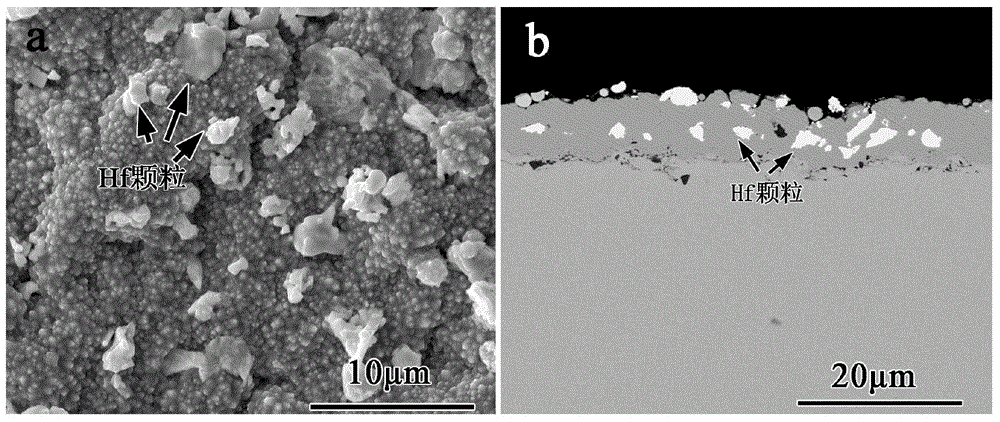

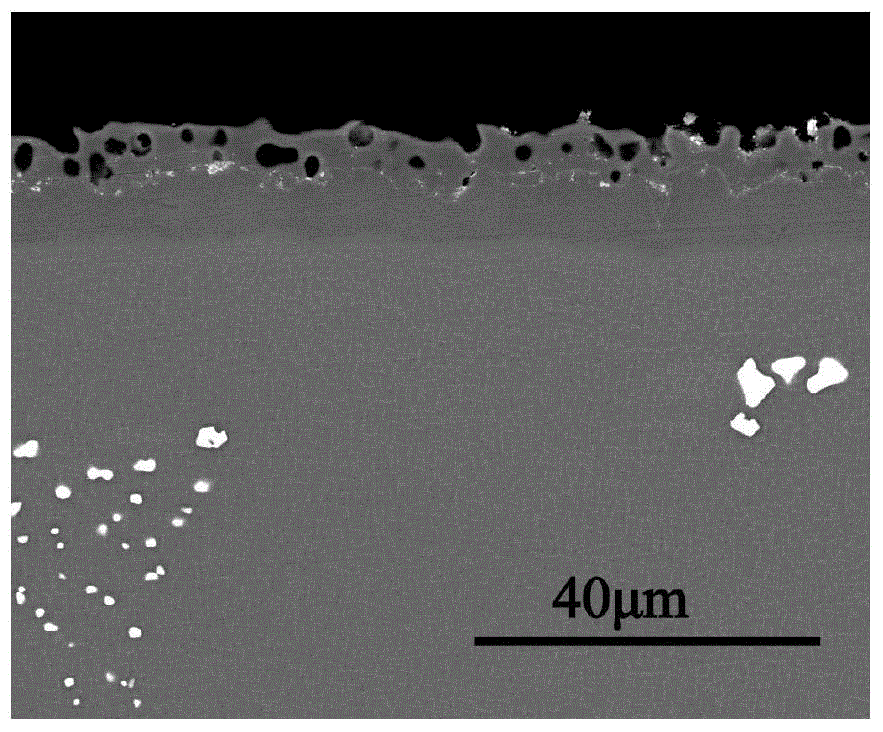

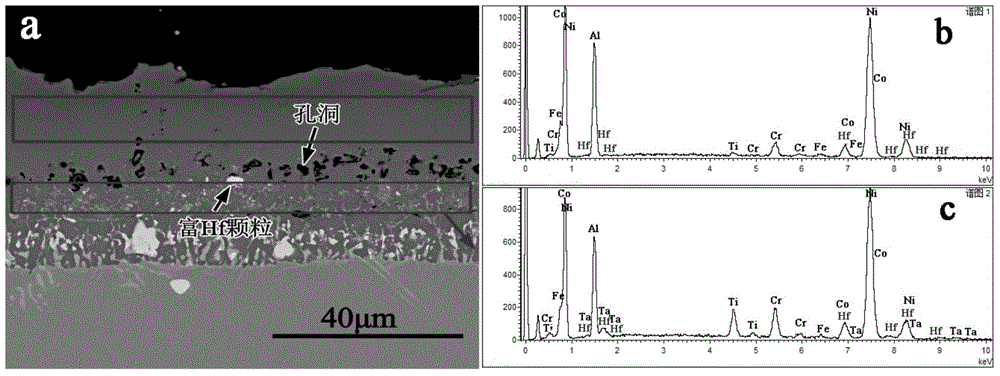

Method for introducing rare metal Hf element into coating

InactiveCN106283135AEasy to prepareImprove controllabilityElectrolytic coatingsSurface finishingAluminide

The invention relates to a method for introducing a rare metal Hf element into a coating. The method comprises: surface treatment, wherein a metal sample is burnished, a sand spraying treatment is performed after the original surface of the metal is grinded out, and a two-step oil removing treatment is performed; Hf particle suspended plating liquid preparation; electroplating condition setting, wherein the Hf element is introduced into the coating by using a composite electroplating method; electroplating liquid maintenance, wherein the characteristics of the plating liquid is basically unchanged by using the regular plating liquid maintenance way; diffusion annealing, wherein the composite plating layer obtained after the electroplating is annealed in a vacuum annealing furnace, the air pressure of the vacuum annealing furnace is less than 1*10<-2> Pa, and the heating rate is less than 10 DEG C / min; and coating preparation, wherein aluminizing is performed by using embedding, slurry and CVD chemical vapor phase method to obtain the high temperature protection aluminide coating. The method of the present invention has advantages of simple preparation process, high controllability, low cost, uniform Hf element distribution, wide plating layer application range, and strong universality.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

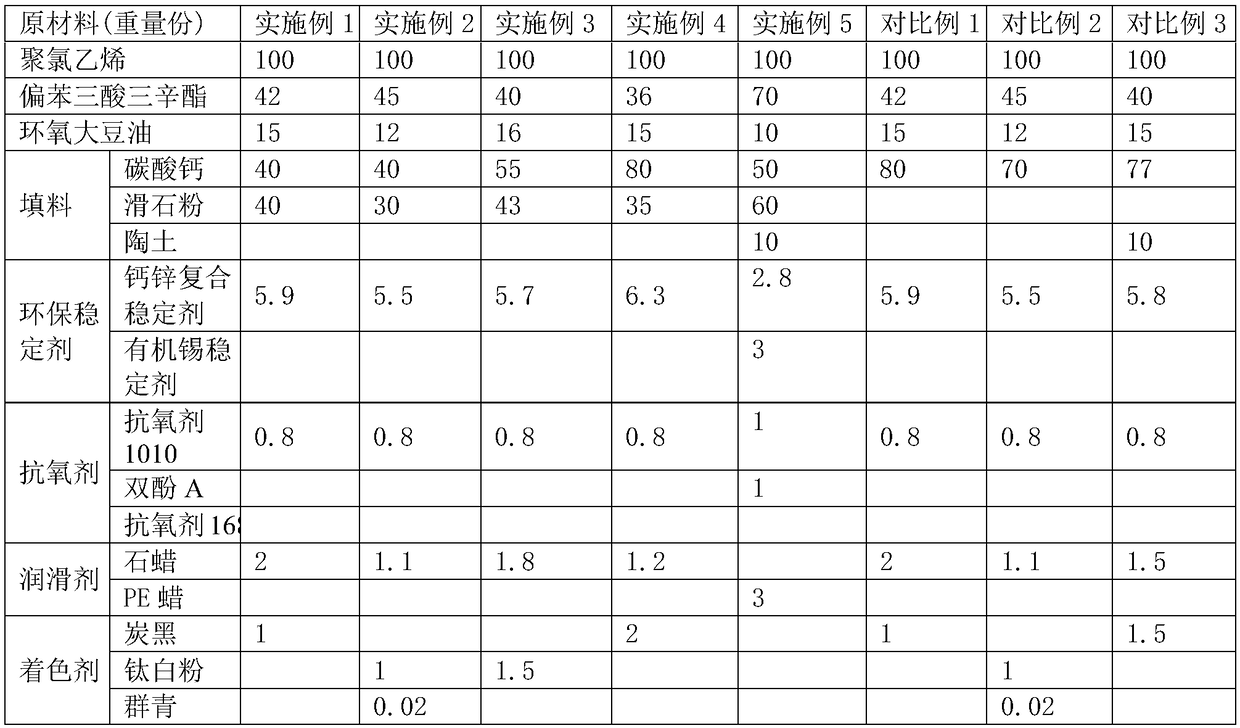

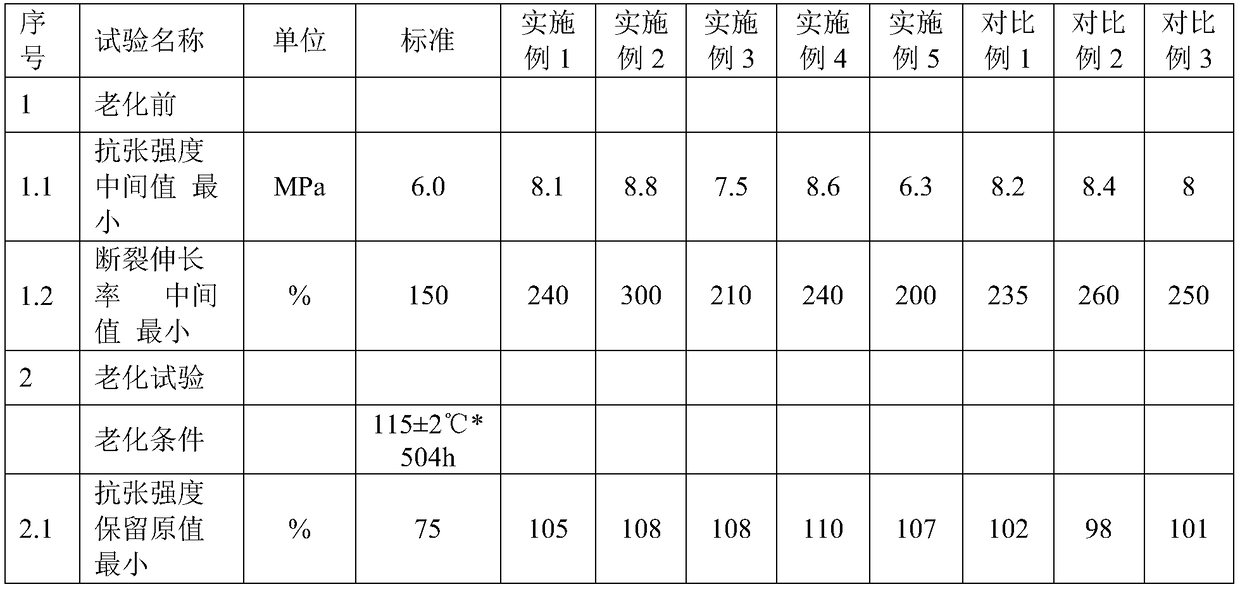

High-temperature-resistant environmentally-friendly easy-to-tear PVC protective jacket cable material and preparation method thereof

InactiveCN108727741AExcellent peelabilityAnti-adhesivePlastic/resin/waxes insulatorsAntioxidantPolyvinyl chloride

The invention discloses a high-temperature-resistant environmentally-friendly easy-to-tear PVC protective jacket cable material and a preparation method thereof. The PVC protective jacket cable material is prepared from the following components in parts by weight: 100 parts of polyvinyl chloride resin, 30 to 70 parts of trioctyl tribenzoate, 10 to 20 parts of epoxidized soybean oil, 70 to 120 parts of filler, 3 to 8 parts of environmentally-friendly stabilizer, 0.5 to 2 parts of antioxidant, 1 to 3 parts of lubricant and 0 to 2 parts of coloring agent, wherein the filler consists of 40 to 80 parts of calcium carbonate, 30 to 60 parts of talcum powder and 0 to 25 parts of argil. The PVC protective jacket cable material meets the requirement of a table 6 in Australian AS / NZS3808:2000 standard, meets various requirements in European Unit ROHS instruction, and is low in cost and high in stripping property.

Owner:GUILIN INT ELECTRIC WIRE & CABLE GROUP

Wear-resistant and high-temperature-resistant powder coating for oil well pipe

InactiveCN110105849AIncrease elasticityImprove toughnessFireproof paintsAnti-corrosive paintsEpoxyWear resistant

The invention discloses a wear-resistant and high-temperature-resistant powder coating for an oil well pipe, and belongs to the field of coatings. According to the technical scheme, the coating is prepared from, by weight, 100 parts of epoxy resin, 40-60 parts of phenolic resin, 10-16 parts of a curing agent, 10-20 parts of graphene oxide, 15-30 parts of a silane coupling agent, 1-5 parts of an anti-caking agent, 20-40 parts of talcum powder, 18-38 parts of mica powder and 10-30 parts of an antioxidant. The effect of improving high temperature resistance of the coating is achieved.

Owner:TIANJIN PRIMARY SECONDARY JIAHE CHEM CO LTD

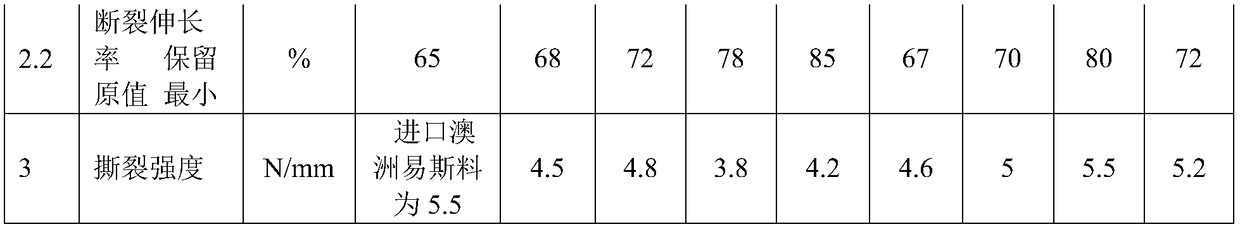

Vaccine diluent, and preparation method and application thereof

ActiveCN109620962AGood immune effectHas an immune boosting effectAntibody medical ingredientsMacromolecular non-active ingredientsAntigenWater baths

The invention relates to the field of immunology, and in particular, relates to a vaccine diluent, wherein the vaccine diluent comprises the raw materials: water for injection, a polymer, and an immunoenhancer optionally added. The preparation method of the vaccine diluent comprises the steps: weighing the raw materials, putting to the bottom of a stainless steel high-pressure reactor, putting a magneton, sealing, and putting the reactor into a water bath with magnetic stirring; setting the water bath temperature, starting up a single-cylinder injection pump, charging carbon dioxide to the pressure required in an experiment, stopping stamping, closing a reactor valve, keeping the internal pressure unchanged, and setting the stirring rate; and after placing at constant temperature in waterbath for a certain time and reaction is performed, relieving the pressure, and thus obtaining the vaccine diluent. The diluent combination after supercritical carbon dioxide treatment is easy for industrialized production of vaccines, and is safe and effective. The prepared diluent can be applied not only to an antigen of a live vaccine, but also to an antigen of an inactivated vaccine or an antigen of a synthetic peptide vaccine.

Owner:CHINA ANIMAL HUSBANDRY IND

Calcium sulfate modified ethylene-vinyl acetate copolymer and preparation method of calcium sulfate modified ethylene-vinyl acetate copolymer

ActiveCN102219954AHigh tensile strengthDimensionally stablePigment treatment with non-polymer organic compoundsSulfateEthylene

The invention relates to a calcium sulfate modified ethylene-vinyl acetate copolymer and a preparation method of the calcium sulfate modified ethylene-vinyl acetate copolymer. The calcium sulfate modified ethylene-vinyl acetate copolymer is prepared by the following raw materials according to parts by weight: 55-75 parts of ethylene-vinyl acetate copolymer, 10-30 parts of calcium sulfate and 10-30 parts of titanate coupling agents. The invention also comprises a preparation method of the calcium sulfate modified ethylene-vinyl acetate copolymer. The calcium sulfate modified ethylene-vinyl acetate copolymer has high tensile strength, is not easy to adsorb water, and has stable size, therefore, the calcium sulfate modified ethylene-vinyl acetate copolymer is particularly suitable for producing a transport packing material, a electronics shell, a life tool, a car instrument panel and the like.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

Environmentally-friendly metal primer

InactiveCN108795240AImprove acid resistanceAccelerated corrosionFireproof paintsAnti-corrosive paintsEpoxyDispersion stability

The invention discloses an environmentally-friendly metal primer. A preparation method of the metal primer includes: (1) adding graphite to water, stirring at 1200-1500r / min, adding sodium carboxymethyl cellulose and continuing to stir to prepare a graphite solution A; (2) adding epoxy resin, polyethylene glycol modified amino resin and polyacrylic acid polydimethylsiloxane to ethanol, stirring at1000r / min till the solid dissolves, then adding zinc yellow, carbon black and fumed silica and continuing stirring evenly to prepare a solution B; (3) adding the solution A slowly to the solution B under the stirring condition of 1500r / min and stirring uniformly to prepare slurry; (4) grinding and filtering the slurry to obtain the primer. The primer has simple process, the adopted solvents are environmentally friendly, the graphite and the zinc yellow in the process formula achieve an anti-corrosive effect, and the graphite has good dispersion stability. The prepared primer is an effective anti-corrosive primer, and can be widely applied to the field of metal corrosion prevention.

Owner:合肥炫升环保材料科技有限公司

Wastewater recycling apparatus for Huizhou ink production

PendingCN108383287ADoes not affect reuseChemically activeTreatment involving filtrationMultistage water/sewage treatmentLiquid wasteWastewater

The invention discloses a wastewater recycling apparatus for Huizhou ink production, comprising a neutralizing reaction container; a slide plate is fixedly connected to each of the front and back of the inner wall of the neutralizing reaction container; the upper surface of every slide plate is lapped to the lower surface of a connection plate; the lower surface of the connection plate is fixedlyconnected to the upper surface of a net cage; the upper surface of the connection plate is provided with first through holes corresponding to the net cage; the right side of the inner wall of the neutralizing reaction container is provided with second through holes corresponding to the net cage. The wastewater recycling apparatus for Huizhou ink production has the advantages that wastewater is filtered by the net cage, ink mud mixed in the wastewater can be blocked in the net cage, purified water is injected into the net cage via a purifying funnel, and acid matters attached to the surface ofthe ink mud in the net cage are removed under scouring of the purified water; the ink mud mainly includes ash, chemical properties of the ink mud are inactive, and therefore, purer ink mud can be acquired without affecting reuse of the ink mud; the treatment steps are simple, so that people's working is facilitated.

Owner:HUANGSHAN GUCHENG SHEZHOU INKSTONE CO LTD

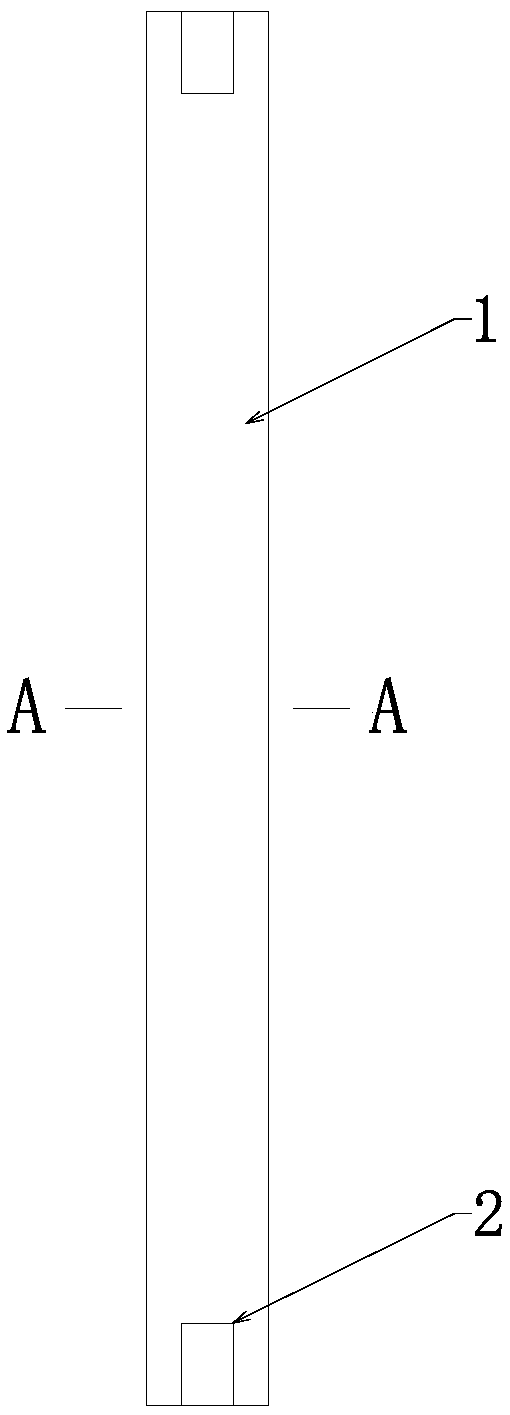

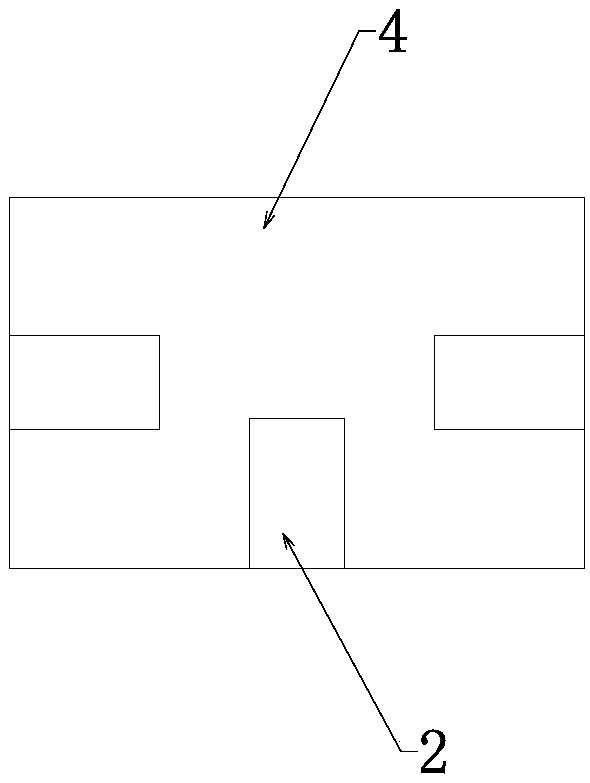

A Zero- ohm grounding System

PendingCN109004386AEasy constructionImprove qualityLine/current collector detailsConnection contact member materialTurn angleGround system

The invention discloses a zero-ohm grounding system, comprises a plurality of graphite bodies connected end to end, wherein the graphite bodies are connected into a strip-shaped or planar reticulatedor stereoscopic reticulated grounding system, adjacent graphite bodies are connected through threads, the threaded connection structure comprises graphite studs and threaded holes, and the end parts of the graphite bodies are provided with threaded holes; The cross-sectional shapes of the graphite bodies include polygonal shapes, circular shapes and plum blossom shapes; The adjacent graphite bodies of the strip-shaped grounding system are connected through a graphite screw post matched with a threaded hole of an end part of the graphite body; The planar mesh and the three-dimensional mesh grounding system further comprises a turning angle connector of a steering connection, wherein the turning angle connector is provided with not less than two threaded holes, and the centerline of the threaded holes of the turning angle connector is at least provided with a pair of different directions; The invention has the advantages of light weight, low resistivity, excellent mechanical properties,good corrosion resistance, environmental protection and no pollution, long service life and wide application range.

Owner:山西捷力通防雷科技有限公司

Calcium sulfate modified polylactic acid material and preparation method thereof

The invention discloses a calcium sulfate modified polylactic acid material and a preparation method thereof. The calcium sulfate modified polylactic acid material is prepared from the following raw materials in part by weight: 65 to 85 parts of polylactic acid, 5 to 20 parts of calcium sulfate, and 5 to 30 parts of vinyl triethoxysilane serving as a coupling agent. The invention also discloses the preparation method for the calcium sulfate modified polylactic acid material. The calcium sulfate modified polylactic acid material has high impact strength, good water resistance and good dimensional stability, and is particularly suitable for manufacturing biomedical products, packing products, living articles, electronic appliance shells, automobile instrument panels and the like.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

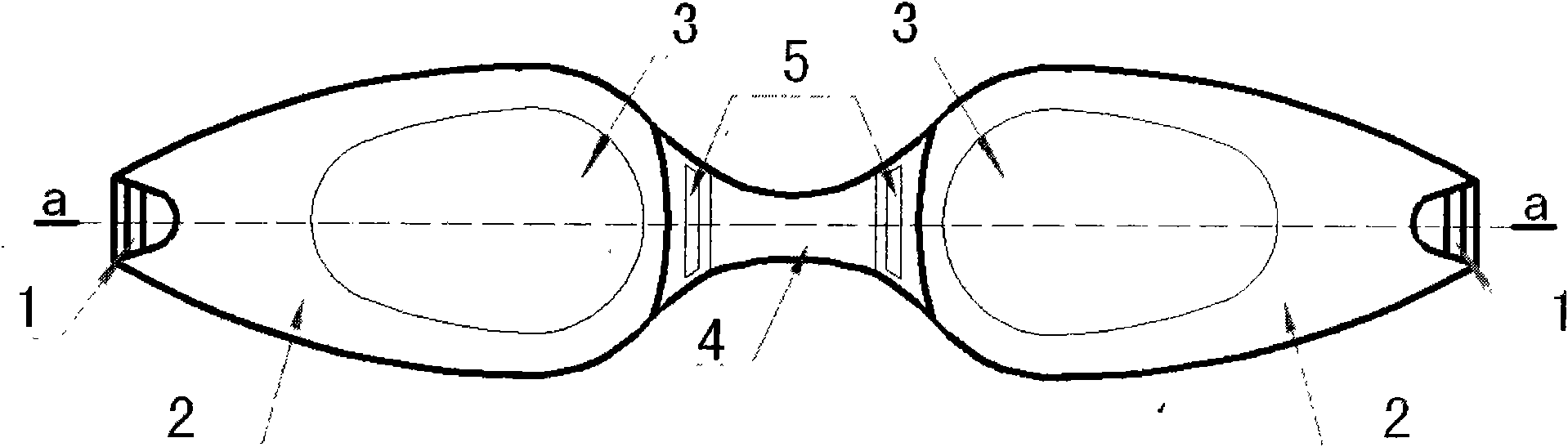

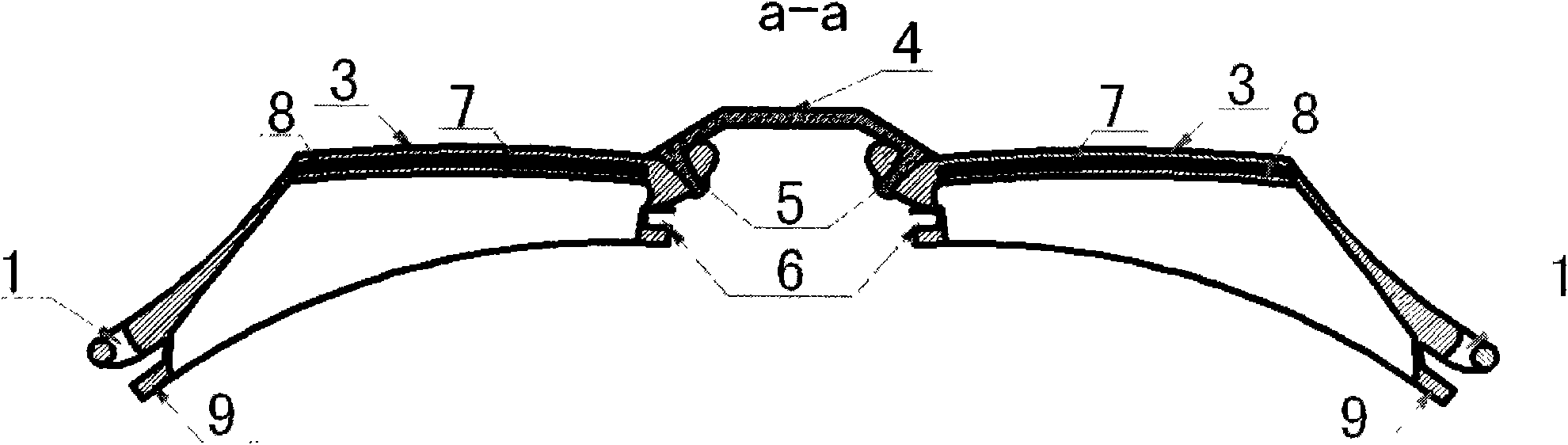

Safety permanent anti-fog swimming goggle

The invention relates to a safety permanent anti-fog swimming goggle mainly comprising a goggle frame, double layer lenses, a pad part, a head band and a nose bridge. The safety permanent anti-fog swimming goggle is mainly characterized in that the swimming goggle frame and the outer transparent lens are integrated into a whole; a ring-shaped sealing edge for sealing the inside lens is arranged inside the swimming goggle frame, and the edge thereof is subjected to waterproof sealing treatment by using waterproof sealing adhesive; nitrogen gas is charged in an interlayer between the swimming goggle frame and the lenses; and two edges of the outer side of the goggle frame are provided with splicing parts for realizing the combination with the head band and the nose bridge. The safety permanent anti-fog swimming goggle can guarantee long time underwater sports, improves the protection safety of eyes, has good anti-fog and waterproof effect, and is comfortable in wearing.

Owner:田艳民

Preparation method of antibacterial stainless steel cutter with nano titanium nitride coating

ActiveCN112251745AHigh melting pointHigh hardnessMaterial nanotechnologyNitrogen compoundsTitanium coatingSolution treatment

The invention discloses a preparation method of an antibacterial stainless steel cutter with a nano titanium nitride coating. The preparation method specifically comprises the following steps: firstly, preparing nano titanium nitride particles by using an ammonia gas reduction method; then adding a metal element with an antibacterial function into a stainless steel matrix, and carrying out solution treatment to obtain an antibacterial stainless steel matrix; and finally, compounding the nano titanium nitride particles onto an antibacterial stainless steel cutter material matrix by using a coldspraying technology to obtain the antibacterial stainless steel cutter with the nano titanium nitride coating. The titanium nitride coating reinforced antibacterial stainless steel cutter material prepared by combining the titanium nitride coating and the antibacterial stainless steel has the good characteristics of high hardness, high strength, high wear resistance, bacterial resistance and no rust.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Preparation method of dielectric wetting composite material

The invention relates to a preparation method of a dielectric wetting composite material, belonging to the technical field of dielectric wetting materials. According to the invention, tetraethoxysilane is used as a precursor, a sol-gel method is adopted to prepare nanometer silicon dioxide microspheres in situ in poly-p-xylene, and epoxy-terminated polydimethylsiloxane and perfluorosilane are separately used for hydrophobization treatment so as to prepare the dielectric wetting composite material; poly-p-xylylene is inactive in chemical properties and conformal in surface coating, and is a good polymer insulating layer; the dielectric constant of silicon dioxide is relatively high, so driving voltage can be effectively reduced; as the nanometer silicon dioxide microspheres are prepared insitu in poly-p-xylylene, so poly-p-xylylene has good hydrophobic property and a relatively high dielectric constant; the chemical state of polydimethylsiloxane is dimethyl silicone oil, and the dimethyl silicone oil is non-toxic and odorless, and has physiological inertness and good chemical stability, so the prepared dielectric wetting composite material has good hydrophobicity and weather resistance.

Owner:江苏海獭新材料科技有限公司

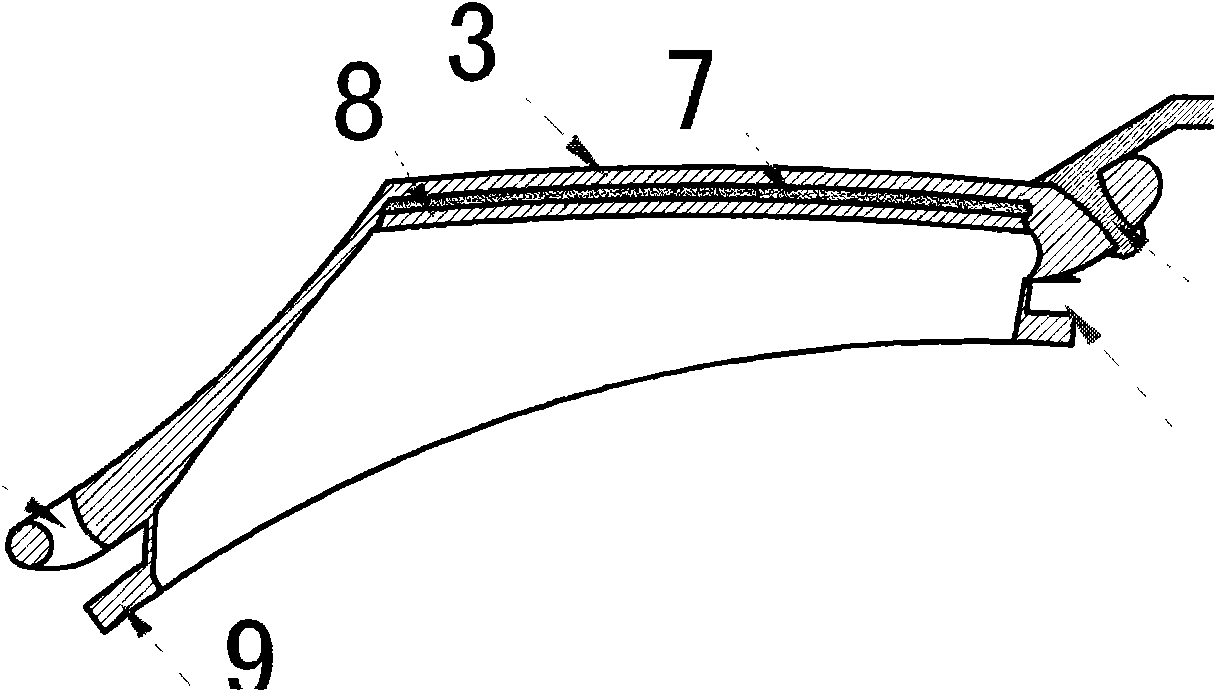

Converter gas flue gas conditioning system and flue gas conditioning method thereof

InactiveCN111593163AChemically inactiveLower acquisition costsIncreasing energy efficiencyManufacturing convertersParticulatesEvaporative cooler

The invention provides a converter gas flue gas conditioning system and a flue gas conditioning method thereof in order to solve the problems that in the prior art, pollution is heavy and the cost ishigh when a chemical agent is used for flue gas conditioning, and due to the fact that converter gas belongs to flammable and combustible gas, conditioning of the conductivity of flue gas and dust through atomization of compressed air and water is not suitable, and belongs to the technical field of converter gas dedusting systems. The system comprises a water inlet pipeline and a nitrogen pipeline, nitrogen and water or water vapor are mixed to atomize the water, the mixed and atomized water is introduced into an inlet of an evaporative cooler through a pipeline, the atomized water is furthervaporized in the evaporative cooler, water molecules are combined with particles in the flue gas, the conductivity of the dust particles in the flue gas is changed, the dust is easier to charge afterentering an electric precipitator, and the chemical property of the nitrogen is inactive, so that the risk of explosion when the nitrogen makes full contact with the flue gas is avoided.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

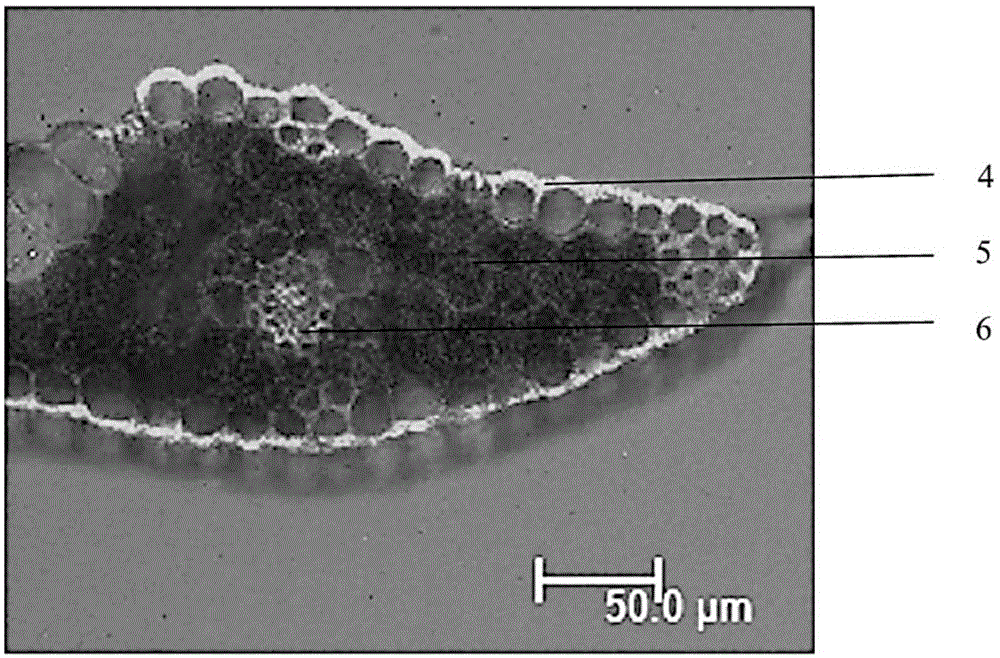

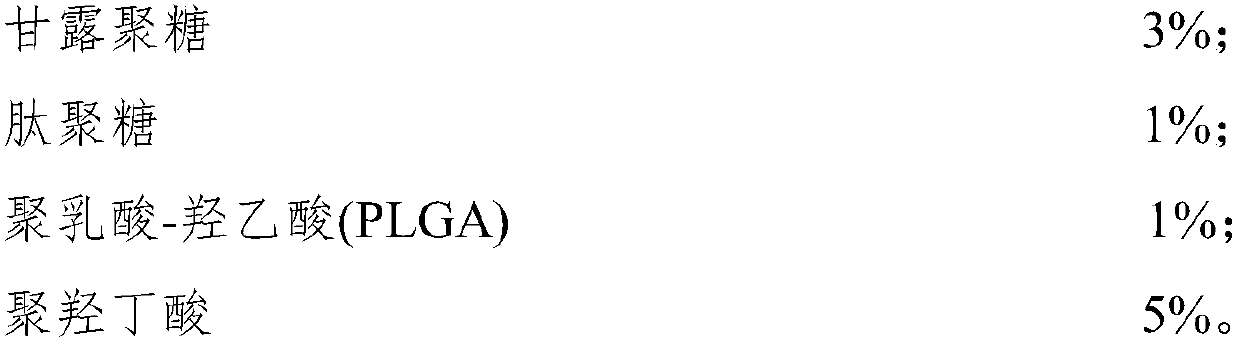

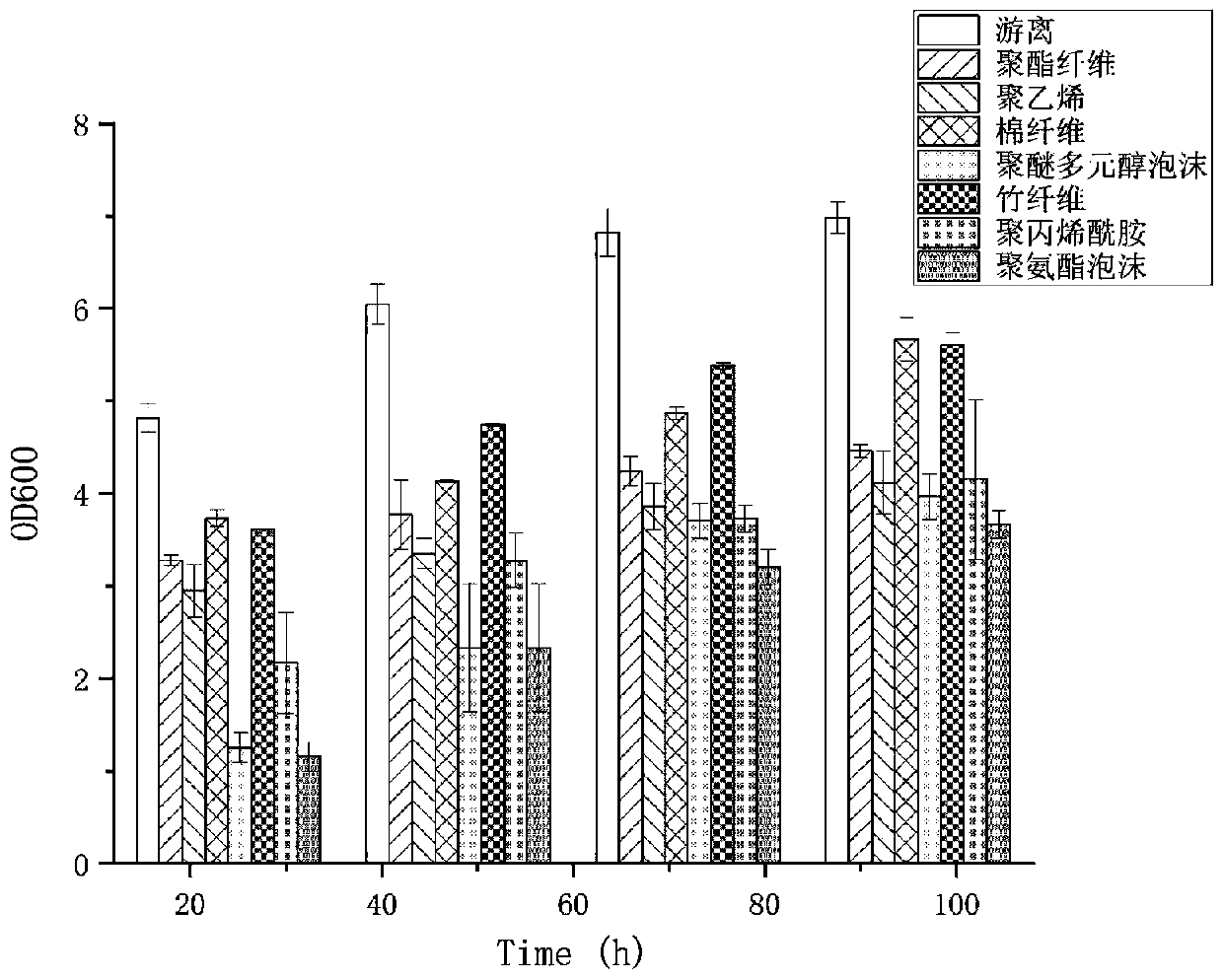

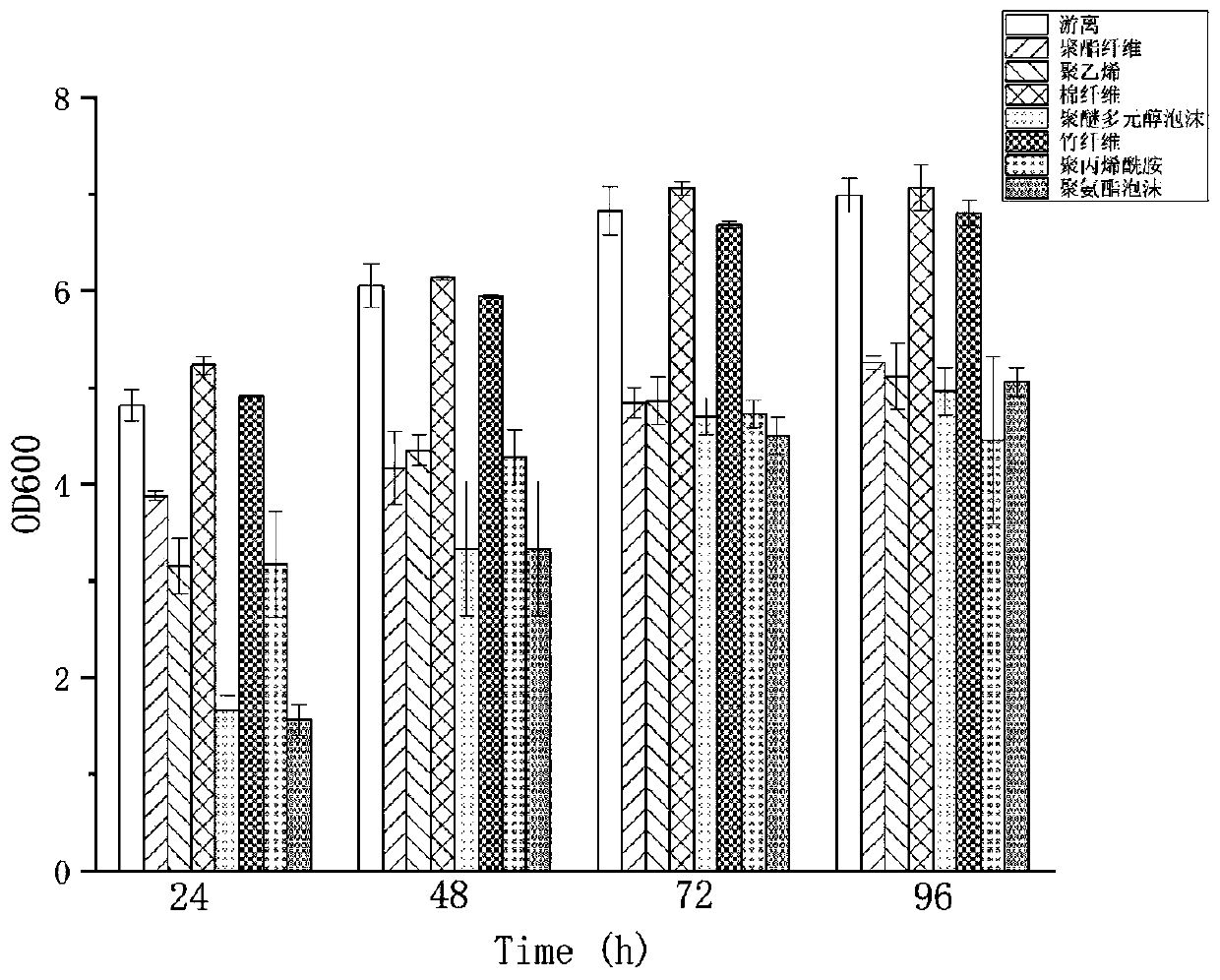

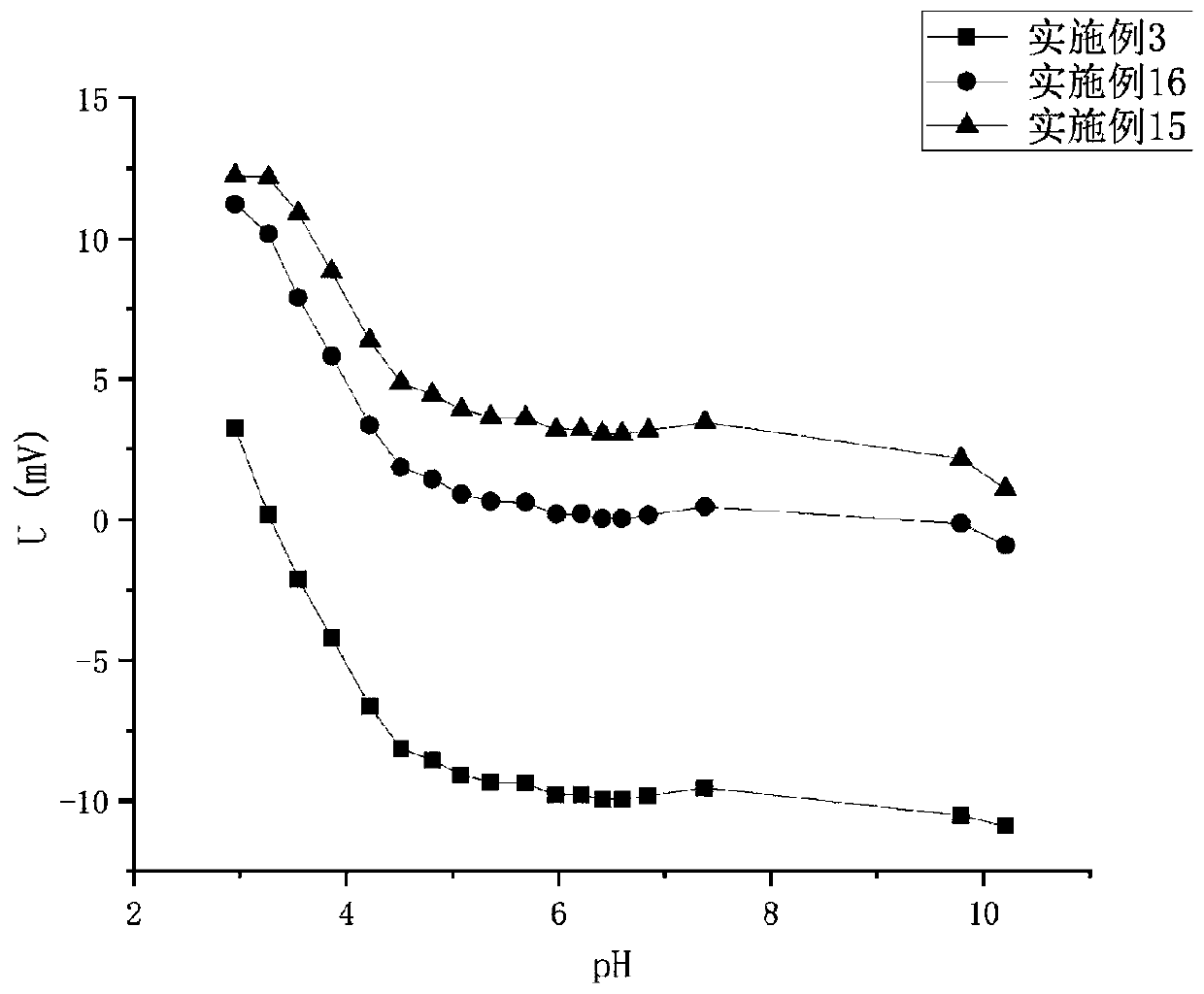

Immobilization method and application of pichia pastoris

ActiveCN111073880AChemically activeImprove material performanceHydrolasesMicroorganism based processesPhytaseCell adhesion

The invention discloses an immobilization method and application of pichia pastoris. Fibrous materials after being pretreated by plant glue are used as an immobilization carrier, the pichia pastoris is activated, then immobilization fermentation culture mediums are inoculated with the activated pichia pastoris, culture is performed, strains are adsorbed on the carrier in the culture process. In addition, the fibrous materials after being pretreated by the plant glue can be soaked in a methyl acryloxyethyl trimethyl ammonium chloride aqueous solution for secondary pretreatment, then washing anddrying are performed, so that the pichia pastoris is obtained. The immobilization method has the beneficial effects that through treatment with methyl acryloxyethyl trimethyl ammonium chloride, the surface of the carrier is provided with positive charges; the surfaces of materials are accessed with the positive charges of appropriate density, so that adsorption of proteins adhered on cell surfaces can be effectively strengthened, cell adhesion can be promoted, and besides, negative influence cannot be produced on the activity of cells; the enzyme activity of products is increased, the enzymeactivity of phytase produced through a fermenter is increased from 12326.85U / mL to 15221.85U / mL; and the whole fermentation cycle can be shortened.

Owner:NANJING UNIV OF TECH

A device and method for detecting ferromagnetism and magnetization properties of materials

ActiveCN106405457BHigh sensitivityImprove ferromagnetismMagnetisation measurementsMagnetic field measurement using magneto-optic devicesMagnetizationElectromagnetic shielding

The invention discloses a device used for material ferromagnetism and magnetization performance detection. The device comprises a laser device, linearly polarized light beams, a Glan-Thompson polarizer, an electromagnetic shielding cover, a radio frequency shielding box, a magnetic shielding cylinder, an axial scanning field coil, a heating and heat preservation module, atomic vapor bubbles, a light amplification detection module, a conveying tube sealing block, a conveying tube, a solenoid coil, a positioning frame and a grooved loading warehouse. The invention also discloses a method used for material ferromagnetism and magnetization performance detection. The device is integrated in structure and convenient to operate, material ferromagnetism and magnetization performance detection is acquired through nonlinear magneto-optical resonance dispersion signals, and the device has the characteristic of ultrahigh-sensitivity magnetic measurement and practical value in material selection of atomic frequency standards, atomic magnetometers and laser detection magnetic resonance instruments.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

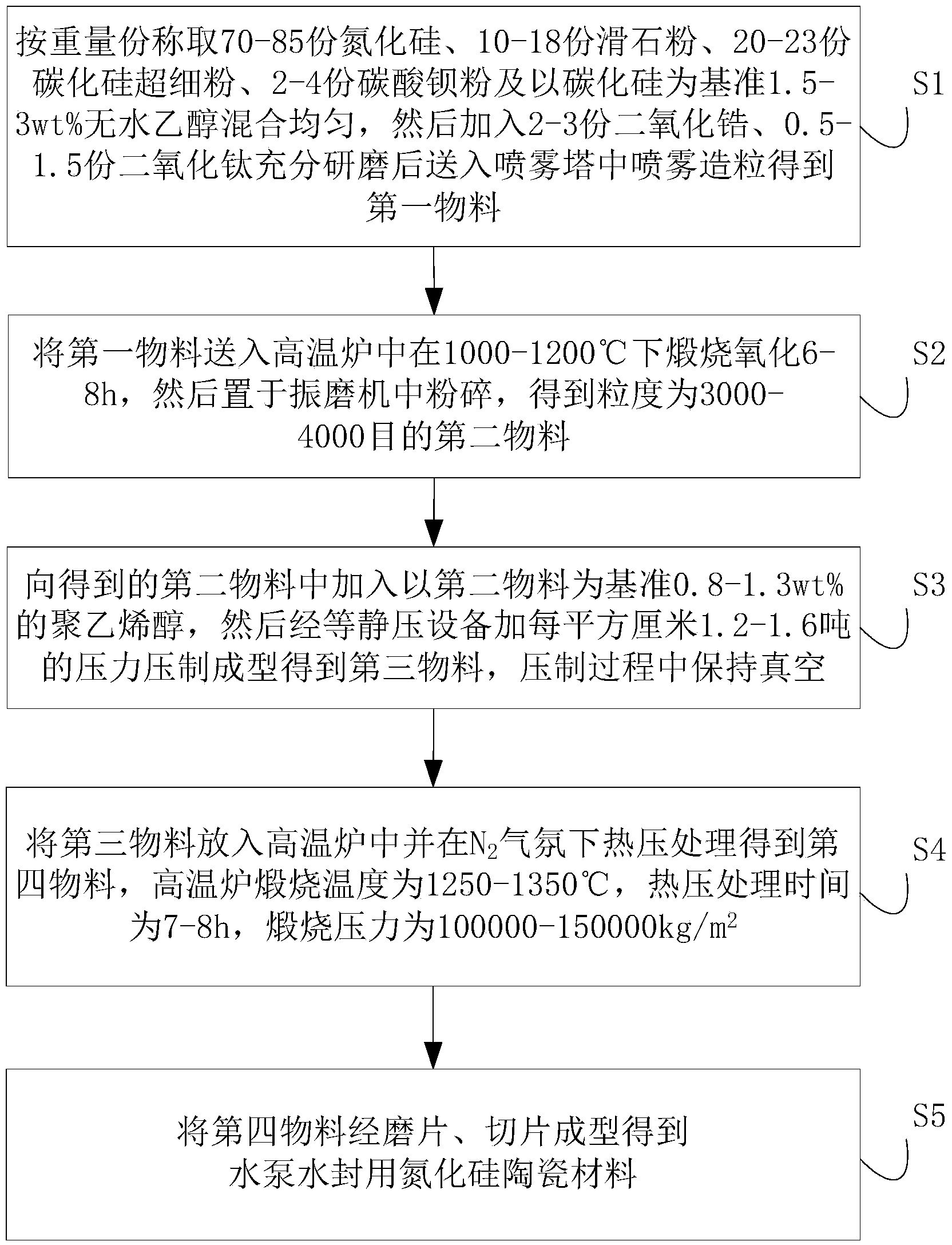

Preparation process of silicon nitride ceramic material for water seal of water pump

The invention discloses a preparation process of a silicon nitride ceramic material for water seal of a water pump. The preparation process comprises the following steps: uniformly mixing silicon nitride, talcum powder, silicon carbide superfine powder, barium carbonate powder and absolute ethyl alcohol, adding zirconium dioxide and titanium dioxide, completely grinding, and implementing spray granulation in a spray tower to obtain a first material; calcining and oxidizing in a high-temperature furnace at 1000-1200 DEG C for 6-8h, and grinding in a vibrating grinder to obtain a second material which is 3000-4000 meshes in granularity; adding polyvinyl alcohol to the second material obtained, and pressurizing and molding in isostatic pressing equipment under pressure of 1.2-1.6 tons per square meter to obtain a third material; implementing heat-pressing treatment to obtain a fourth material, wherein calcining temperature of the high-temperature furnace is 1250-1350 DEG C, heat-pressing treatment duration is 7-8h and calcining pressure is 100,000-150,000kg / m<2>; and grinding, slicing and shaping to obtain the silicon nitride ceramic material for water seal of the water pump.

Owner:安徽安尔达机电有限公司

Alkali-resistant porcelain glaze

The invention relates to alkali-resistant porcelain glaze. The porcelain glaze is prepared from raw materials in parts by weight as follows: 40-50 parts of silicon dioxide, 4-10 parts of diboron trioxide, 3-8 parts of lithium oxide, 2-8 parts of potassium oxide, 2-8 parts of sodium oxide, 10-15 parts of zinc oxide, 7-12 parts of titanium oxide, 1-2 parts of cobalt oxide, 4-7 parts of zirconium oxide, 4-7 parts of aluminum oxide, 3-8 parts of limestone and 3-8 parts of clay. In a word, the porcelain glaze has the advantages of alkali resistance and good glossiness, fineness and elasticity.

Owner:禹州市天宝钧瓷文化有限公司

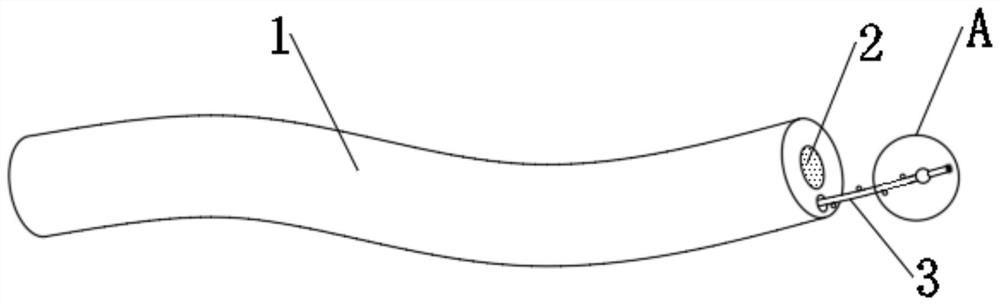

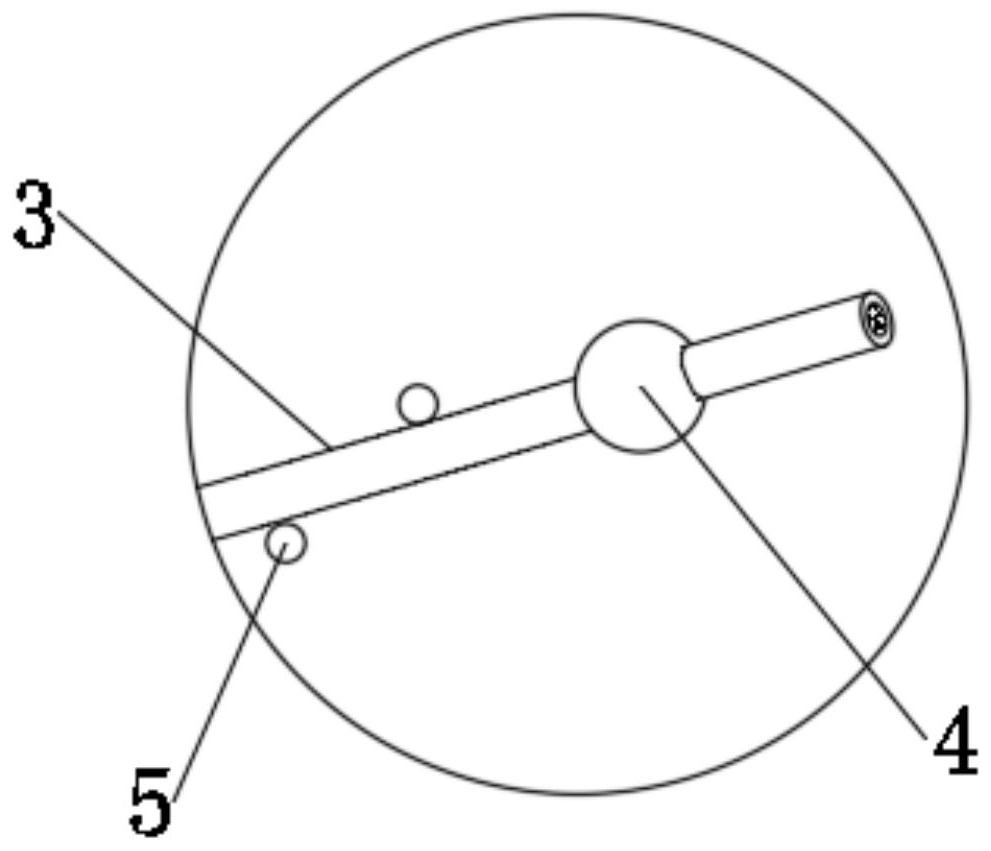

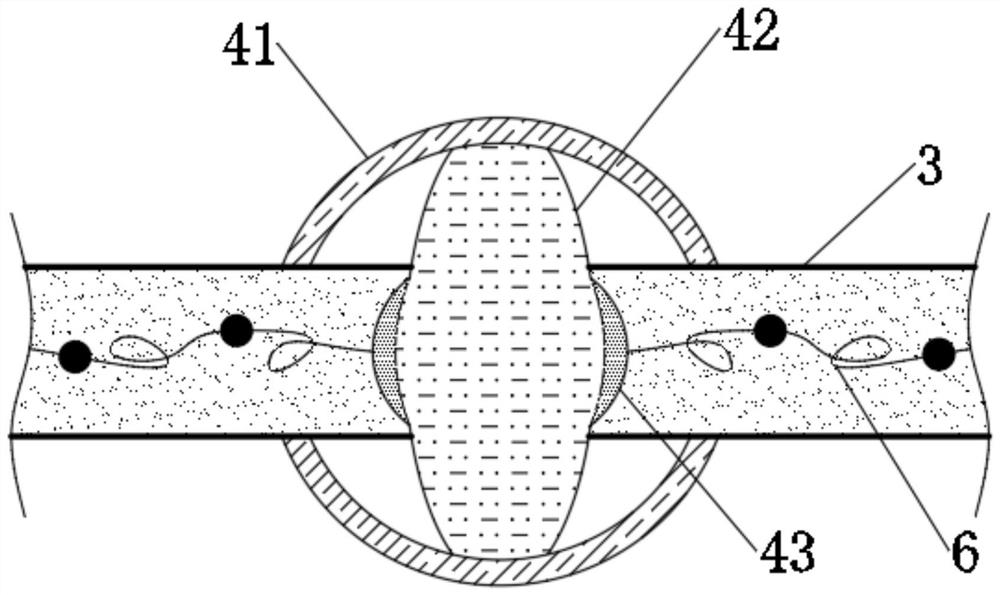

Self-hardening anti-breaking cable based on power grid power transmission

InactiveCN113506652AHigh strengthAvoid breakingClimate change adaptationPower cables with screens/conductive layersWater leakagePower grid

The invention discloses a self-hardening anti-breaking cable based on power grid power transmission, and belongs to the technical field of power grid power transmission, the self-hardening anti-breaking cable can reinforce an outer sheath by inlaying a middle embedded pipe and a node ball, and the middle embedded pipe can perform an extension compensation effect to a certain extent under the condition that normal stretching and bending actions of the cable are met; under the action of extreme stretching, the middle embedded pipe can generate an excessive compensation action, the water release action of the node ball is triggered by virtue of a trigger line in the middle embedded pipe, then water enters the middle embedded pipe and then is subjected to a hydraulic gelatinization reaction, the middle embedded pipe is promoted to generate a hardening action, and at the moment, the strength of the middle embedded pipe is greatly improved, and therefore, the cable is prevented from being continuously stretched and fractured; and through the water absorption magnetic balls absorbed on the middle embedded pipe, the water leakage phenomenon can be sensed in time, plugging is carried out, the influence of water penetration on the cable is avoided, and the power transmission safety of the cable is greatly ensured.

Owner:李孟

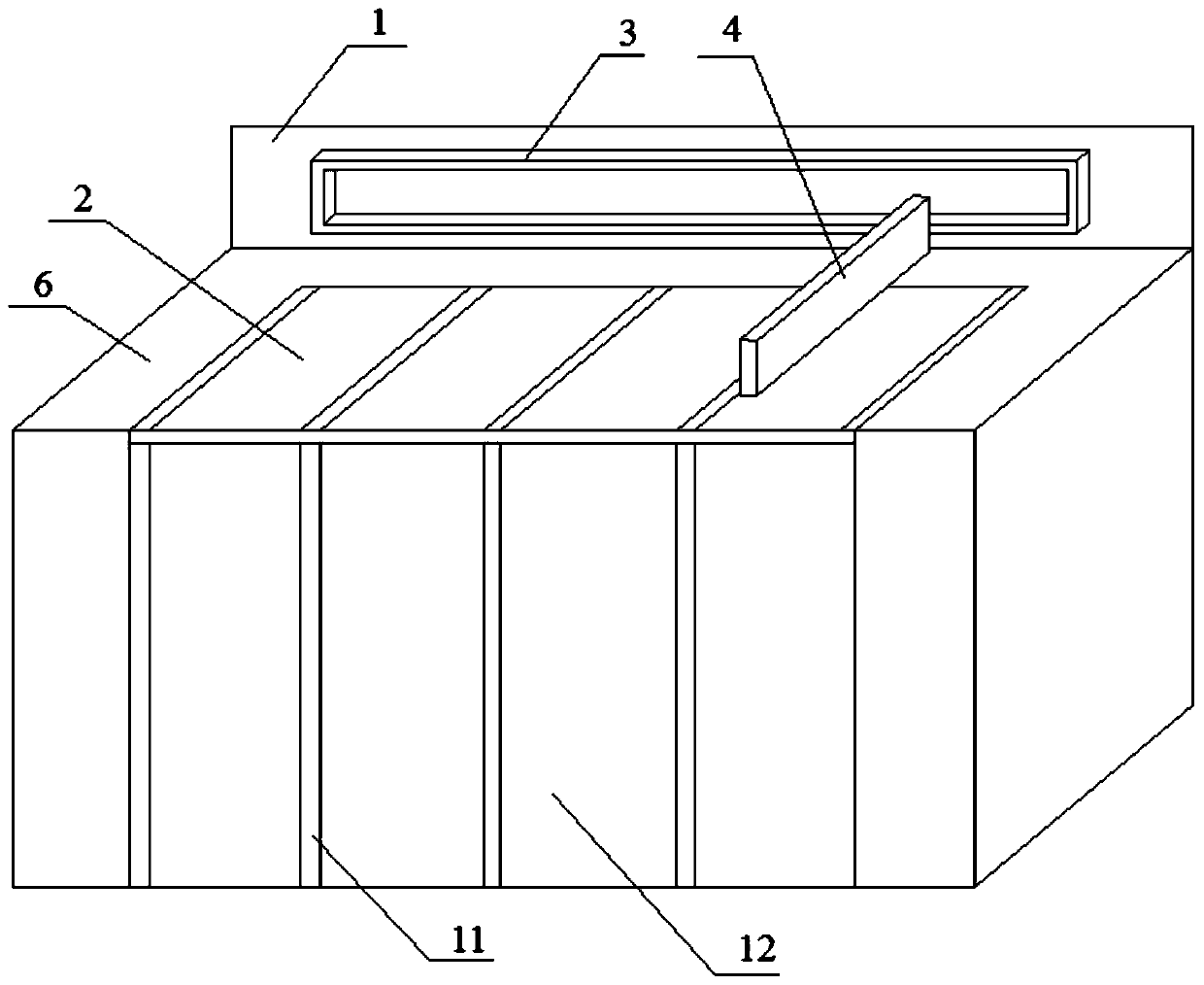

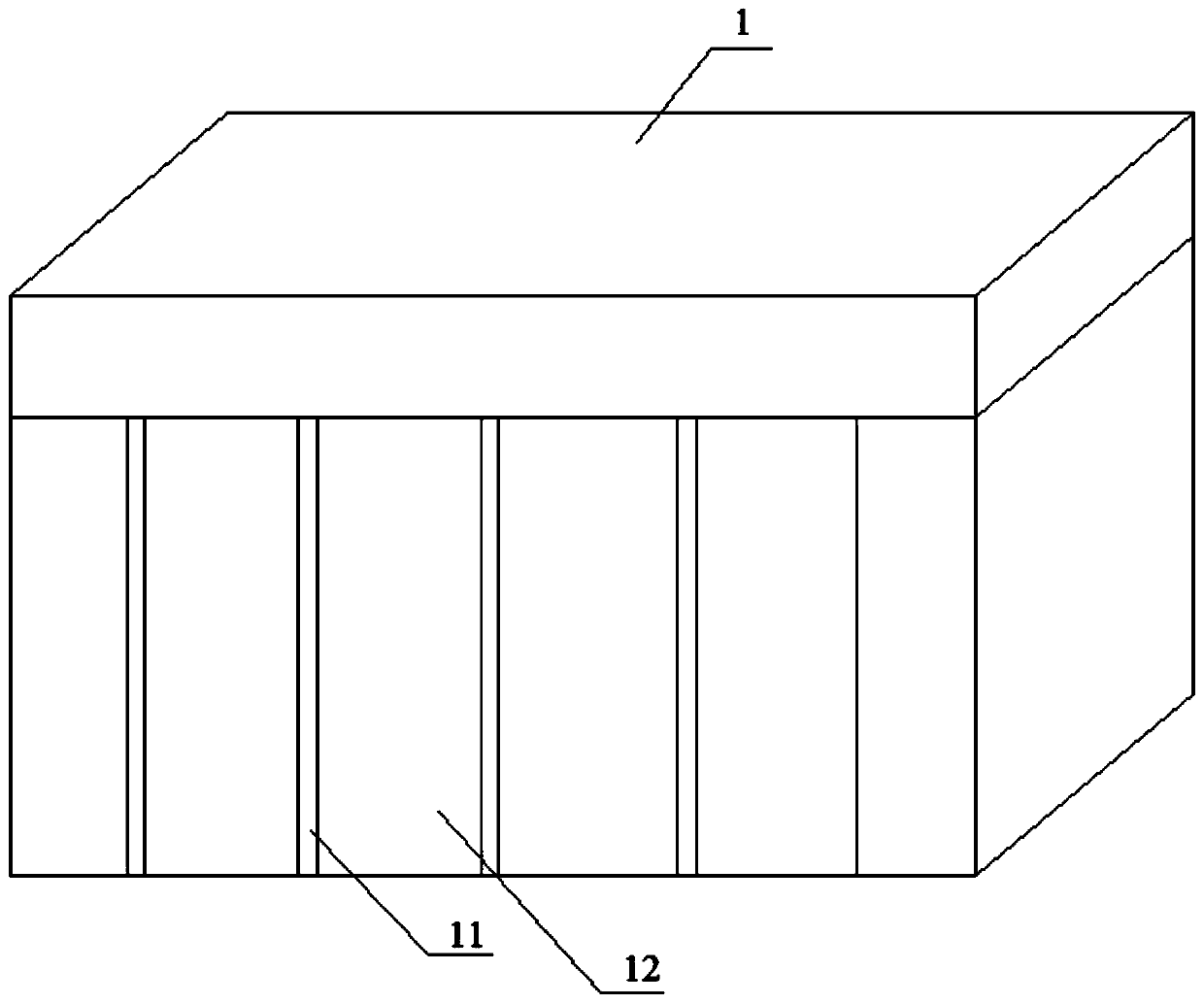

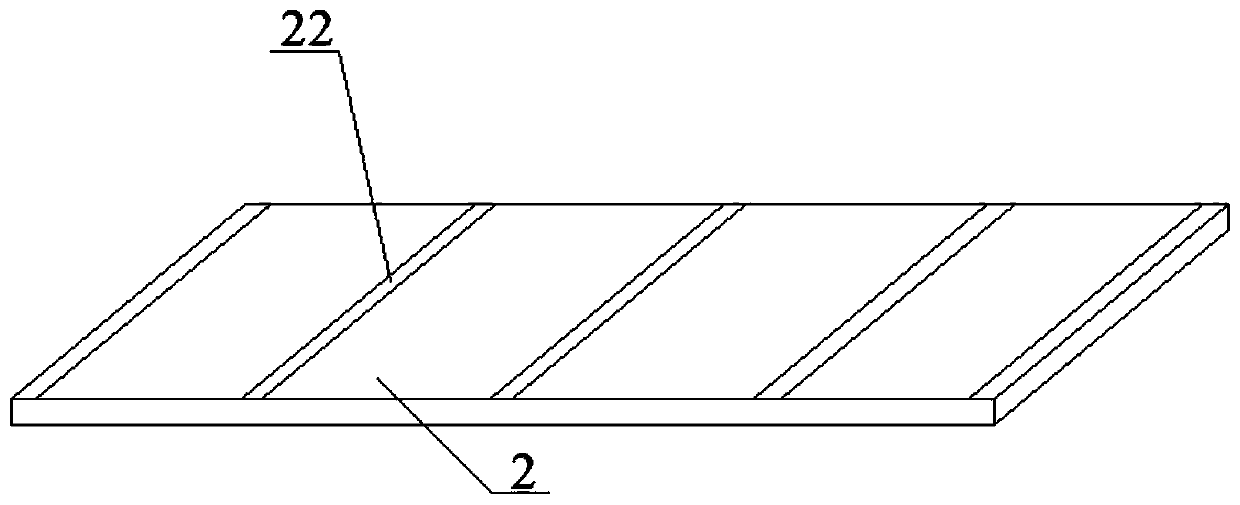

Granary capable of preventing mildewing during grain storage and anti-mildewing control method

ActiveCN110366964APrevent incomplete dryingPrevent mildewAgriculture tools and machinesAntifouling/underwater paintsEngineeringStorage area

The invention belongs to the technical field of grain storage, and particularly relates to a granary capable of preventing mildewing during grain storage and an anti-mildewing control method. The granary comprises a granary main body. The granary main body is separated into a plurality of storage areas by a plurality of partition walls. A drying platform is arranged in the granary main body and above all the storage areas, and comprises drying tabletops for drying grains, a tabletop lifter, a grain spreader and a controller. The controller can control the inclination angle of each drying tabletop to enable the dried grains to enter a certain storage area. The granary has the advantages that after the grains are transported and dried at a height in the drying process, grain positions insideand outside a grain pile can be exchanged to avoid non-thorough grain drying; the storage areas are dried, and accordingly, grain mildewing can be effectively prevented. The invention further provides a mildew-proof plate with a good anti-mildew effect.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

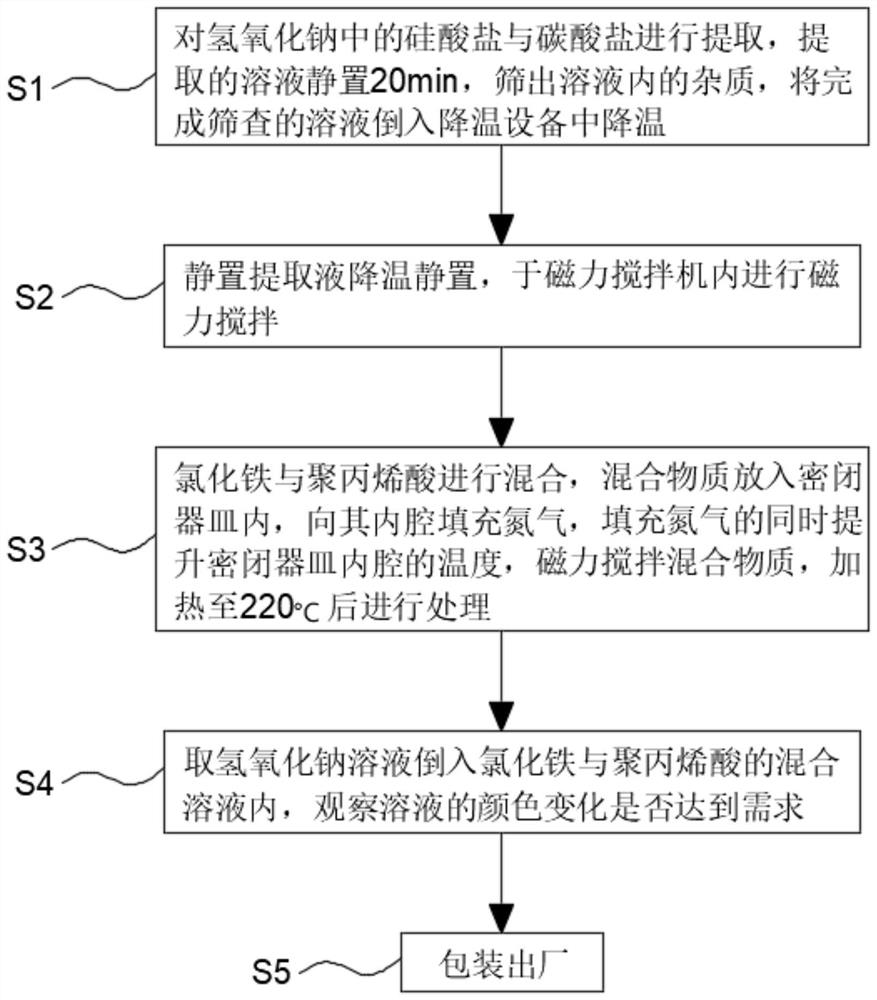

Magnetic particle preparation process

PendingCN114854054AChemically activeIncrease temperatureFerroso-ferric oxidesInductances/transformers/magnets manufactureMagnetic stirrerNitrogen gas

The invention discloses a magnetic particle preparation process, and belongs to the technical field of magnetic particle preparation. The method comprises the following steps: extracting silicate and carbonate in sodium hydroxide, standing the extracted solution for 20 minutes, screening out impurities in the solution, pouring the screened solution into cooling equipment for cooling, standing the standing extracting solution, cooling and standing, magnetically stirring in a magnetic stirrer, mixing ferric chloride and polyacrylic acid, putting the mixed substance into a closed vessel, and uniformly stirring. Filling the inner cavity of the closed vessel with nitrogen, increasing the temperature of the inner cavity of the closed vessel while filling the nitrogen, magnetically stirring the mixed substance, heating to 220 DEG C, treating, pouring a sodium hydroxide solution into a mixed solution of ferric chloride and polyacrylic acid, observing whether the color change of the solution meets the requirement, and packaging and leaving a factory. In the preparation process, the device is filled with nitrogen, the chemical property of the nitrogen is inactive, and the situation that the preparation result does not reach the preset standard due to the fact that the nitrogen reacts with external gas in the preparation process can be avoided.

Owner:阜阳德润磁材科技有限公司

Method for improving fluidity of cast magnesium alloy in casting mould

ActiveCN111360196ALow carbon particle sizeFine and smooth carbon particlesFoundry mouldsFoundry coresSodium silicateThin walled

The invention discloses a method for improving the fluidity of a cast magnesium alloy in a casting mould. The method specifically comprises the following steps of spraying an alkyl sodium sulfonate aqueous solution on the surface of the casting mould or a mud core first; coating and brushing sodium silicate after the casting mould or the mud core is dried; and then, igniting an organic matter withhigh carbon content; aligning a flame of the organic matter with a casting mould surface to perform roasting, so that carbon particles produced by incomplete combustion of the organic matter are uniformly adhered to the surface of a mould core in contact with a molten metal; and therefore, the roughness of the casting mould surface is reduced, and the fluidity of the molten metal in the casting mould is improved. According to the method disclosed by the invention, the fluidity of the cast magnesium alloy in the casting mould can be improved, so that the capacity of the cast magnesium alloy for forming a complex thin-walled casting is enhanced; meanwhile, the fluidity of the molten metal is enhanced; and under the same casting conditions, the alloy casting temperature is reduced, so that the defects of loosening and the like are reduced.

Owner:新江科技(江苏)有限公司

High-performance ceramic material for water seal of water pump

The invention discloses a high-performance ceramic material for a water seal of a water pump, which comprises the following raw materials in parts by weight: 50-60 parts of silicon nitride, 15-18 parts of talc powder, 28-34 parts of wollastonite, 2-5 parts of aluminum oxide, 2-4 parts of yttrium nitrate, 1-3 parts of zirconium dioxide, 2-3 parts of titanium dioxide, 1-1.5 parts of thermoplastic phenolic resin and 2-3 parts of absolute ethyl alcohol. The ceramic material disclosed by the invention has high mechanical strength, excellent wear resistance and excellent heat resistance; moreover, the preparation process is simple, and the cost is relatively low.

Owner:安徽安尔达机电有限公司

Plant fiber enhanced starch composite packaging material and preparation method thereof

The invention discloses a plant fiber enhanced starch composite packaging material and a preparation method thereof. The plant fiber enhanced starch composite packaging material is prepared by the steps of mixing 40 to 60 weight parts of cation modified potato starch, 10 to 20 weight parts of straw fiber, 5 to 10 weight parts of polyvinyl alcohol, 5 to 10 weight parts of inorganic filler, 5 to 10weight parts of cross-linking agent, and 5 to 10 weight parts of plasticizer, and melting, mixing and extruding by using a double-screw extruder. Compared with the conventional thermoplastic potato starch composite packaging material, the plant fiber enhanced starch composite packaging material has the advantages that: the tensile strength is improved by 40 to 60 percent, the deflection is improved by 40 to 60 percent, and the water absorption rate is reduced by 15 to 30 percent.

Owner:广东普科特粉末涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com