A Zero- ohm grounding System

A grounding system, zero-ohm technology, applied in the direction of connection, connection contact material, circuit/collector parts, etc., can solve the problems of low resistivity, graphite grounding grid interruption and failure, etc., and achieves low resistivity and low volume density. , the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

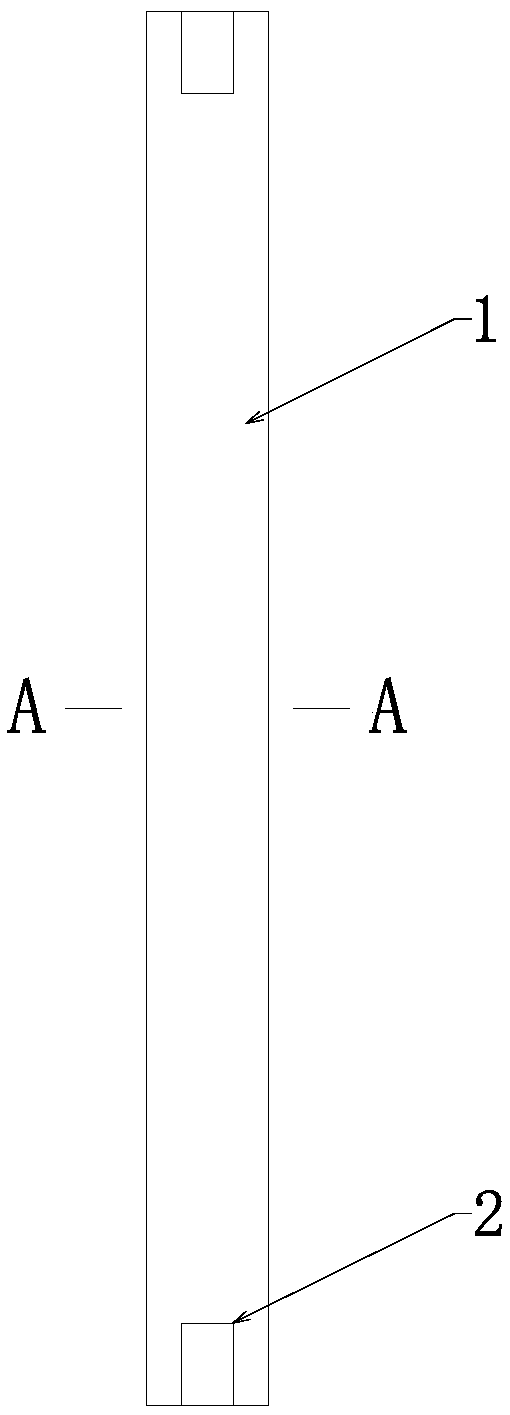

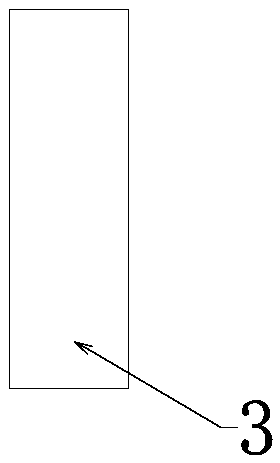

[0036] See attached figure 1 , 2 , 4 and 7, the present embodiment provides a zero-ohm grounding system, including 100 graphite bodies 1 connected end to end, the graphite bodies 1 are connected into a strip-shaped grounding system, and the adjacent graphite bodies 1 are connected by threads, and the threads The connection structure of the connection includes a graphite stud 3 and a threaded hole 2, and the end of the graphite body 1 is provided with the threaded hole 2.

[0037] The cross-sectional shape of the graphite body 1 is circular.

[0038] Adjacent graphite bodies 1 of the strip-shaped grounding system are connected through graphite studs 3 matched with threaded holes 2 at ends of graphite bodies 1 .

[0039] A preparation method of a zero-ohm grounding system, said preparation method comprising the following steps:

[0040] Step 1: Mix graphite, conductive carbon black, sodium silicate, and cement evenly in a weight ratio of 10:1:1:1, add water, mix and extrude, ...

Embodiment 2

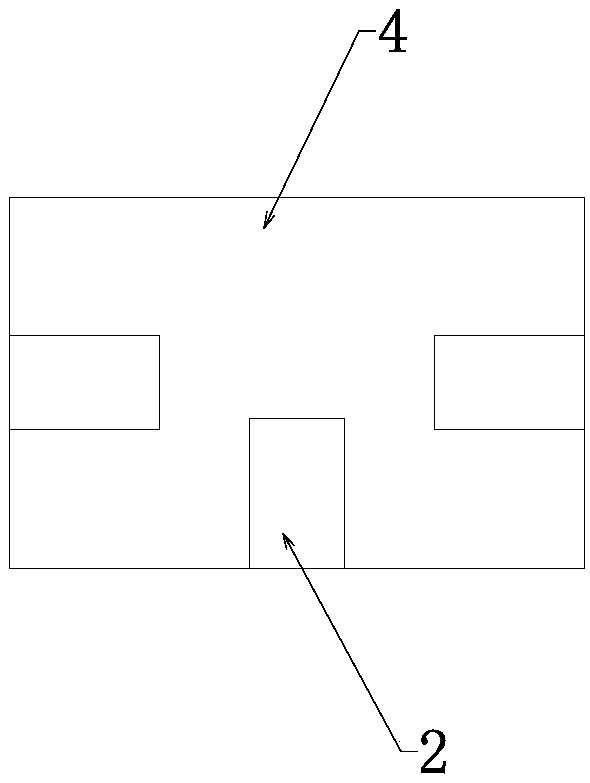

[0047] See attached figure 1 , 2 , 3, 5 and 7, the present embodiment provides a zero-ohm grounding system, including a number of graphite bodies 1 connected end to end, the graphite bodies 1 are connected into a plane mesh grounding system, and the adjacent graphite bodies 1 are connected by threads, so The connection structure of the threaded connection includes a graphite stud 3 and a threaded hole 2, and the end of the graphite body 1 is provided with the threaded hole 2.

[0048] The cross-sectional shape of the graphite body 1 is circular.

[0049] The planar net-like grounding system also includes a corner connector 4 with steering connection, the material of the corner connector 4 is the same as that of the graphite body 1, and the corner connector 4 is provided with not less than two threaded holes 2, and the corner The centerlines of the threaded holes 2 of the connector 4 have at least one pair of different directions.

[0050] A preparation method of a zero-ohm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com