Preparation process of silicon nitride ceramic material for water seal of water pump

A silicon nitride ceramic and a preparation process technology are applied in the field of silicon nitride ceramic materials to achieve the effects of uniform structure, good wear resistance and improved toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

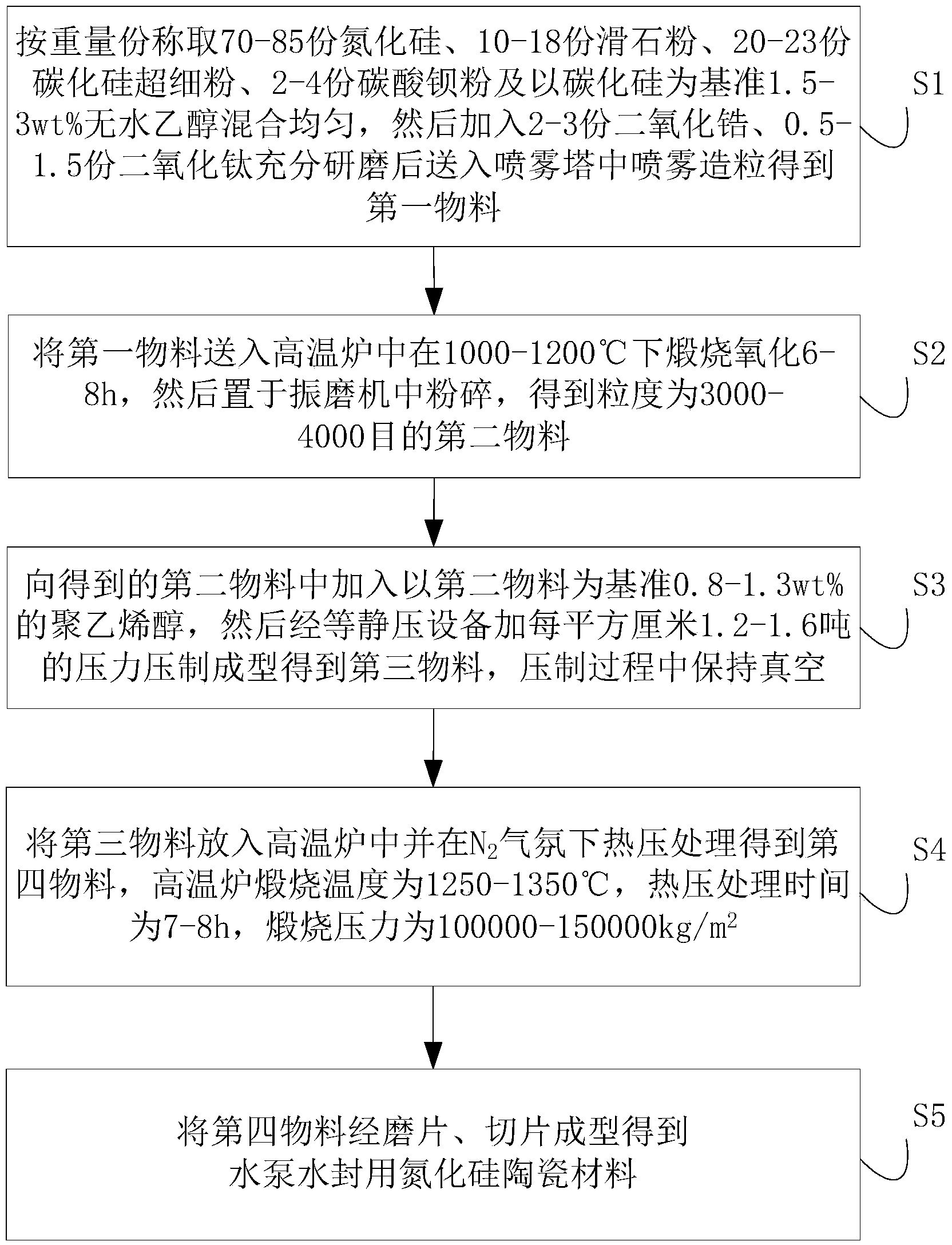

[0024] A preparation process of a silicon nitride ceramic material for a water pump water seal, comprising the steps of:

[0025] S1. Weigh 70 parts of silicon nitride, 18 parts of talc powder, 20 parts of silicon carbide superfine powder, 4 parts of barium carbonate powder and 1.5wt% absolute ethanol based on silicon carbide and mix evenly, then add 3 parts Zirconium dioxide and 0.5 parts of titanium dioxide are fully ground and sent to the spray tower for spray granulation to obtain the first material, wherein silicon carbide superfine powder includes silicon carbide superfine powder with a particle size of 5-10 μm, accounting for 85%, and a particle size of 15 μm. -30μm ultrafine silicon carbide powder accounts for 10%, and silicon carbide ultrafine powder with a particle size of 40-60μm accounts for 5%;

[0026] S2. Sending the first material into a high-temperature furnace for calcination and oxidation at 1200° C. for 6 hours, and then pulverizing it in a vibration mill t...

Embodiment 2

[0031] A preparation process of a silicon nitride ceramic material for a water pump water seal, comprising the steps of:

[0032] S1, take by weight 85 parts of silicon nitride, 10 parts of talcum powder, 23 parts of silicon carbide superfine powder, 2 parts of barium carbonate powder and 3wt% dehydrated alcohol based on silicon carbide and mix evenly, then add 2 parts of two Zirconia and 1.5 parts of titanium dioxide are fully ground and sent to the spray tower for spray granulation to obtain the first material, in which silicon carbide superfine powder includes silicon carbide superfine powder with a particle size of 5-10 μm, accounting for 70%, and a particle size of 15-10 μm. 30μm ultrafine silicon carbide powder accounts for 20%, and silicon carbide ultrafine powder with a particle size of 40-60μm accounts for 10%;

[0033] S2. Sending the first material into a high-temperature furnace for calcination and oxidation at 1000° C. for 8 hours, and then pulverizing it in a vib...

Embodiment 3

[0038] A preparation process of a silicon nitride ceramic material for a water pump water seal, comprising the steps of:

[0039] S1. Weigh 80 parts of silicon nitride, 15 parts of talc powder, 20 parts of silicon carbide superfine powder, 3 parts of barium carbonate powder and 2.5wt% absolute ethanol based on silicon carbide and mix them evenly, then add 2.8 parts Zirconium dioxide and 1.3 parts of titanium dioxide are fully ground and sent to the spray tower for spray granulation to obtain the first material, wherein the silicon carbide superfine powder comprises 80% of the silicon carbide superfine powder with a particle size of 5-10 μm, and the particle size is 15 μm. -30μm ultrafine silicon carbide powder accounts for 10%, and silicon carbide ultrafine powder with a particle size of 40-60μm accounts for 10%;

[0040] S2. Sending the first material into a high-temperature furnace for calcination and oxidation at 1100° C. for 7 hours, and then pulverizing it in a vibration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com