Vaccine diluent, and preparation method and application thereof

A diluent and vaccine technology, applied in the field of immunology, can solve the problems of adverse reactions, immunization failure, unsatisfactory immunization effect, etc., and achieve the effect of improving the immunization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

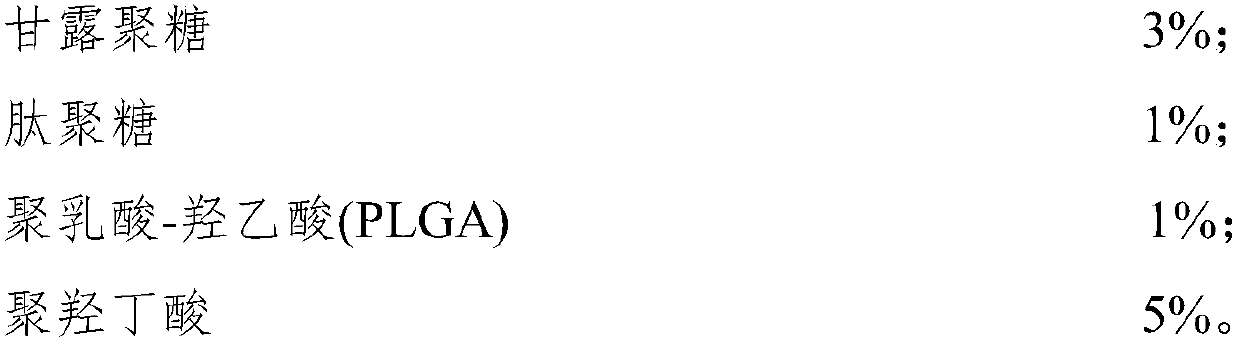

[0045] Raw materials and mass percentages are as follows:

[0046] 1. 90% aqueous solution for injection;

[0047] 2. Polymer combination:

[0048] Cyclodextrin 4%;

[0049] Chitosan 4%;

[0050] Macrogol 4000 2%.

[0051] Preparation:

[0052]Weigh the combination of the above-mentioned aqueous solution for injection and polymer into the bottom of the stainless steel high-pressure reactor, put in a magnet, and after sealing, put the reactor into a water bath with magnetic stirring, set the temperature of the water bath to 32 to 50°C, and turn on the single cylinder Fill the syringe pump with carbon dioxide to the required pressure of 7.3 to 15 MPa for the experiment, stop punching, close the reactor valve, keep the internal pressure constant, and set the stirring rate at 200 to 2000 rpm. Apply supercritical carbon dioxide to treat and react at a constant temperature in a water bath for 10 to 120 minutes, release the pressure, open the reactor, and take out to obtain the ...

Embodiment 2

[0054] The difference between this embodiment and embodiment 1 is:

[0055] Raw materials and mass percentages are as follows:

[0056] 1. 90% aqueous solution for injection;

[0057] 2. Polymer combination:

[0058] Polycaprolactone 3%;

[0059] Polyfumarate-Sebacic Acid 3%;

[0060] Water soluble starch 4%.

Embodiment 3

[0062] The difference between this embodiment and embodiment 1 is:

[0063] Raw materials and mass percentages are as follows:

[0064] 1. 90% aqueous solution for injection;

[0065] 2. Polymer combination:

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com