Wastewater recycling apparatus for Huizhou ink production

A waste liquid recycling and ink printing technology, which is applied in water/sludge/sewage treatment, filtration treatment, sedimentation treatment, etc., can solve the problems of affecting the reuse of ink mud, inconvenient work, complicated waste liquid treatment process, etc. The effect of waste, avoiding secondary pollution and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

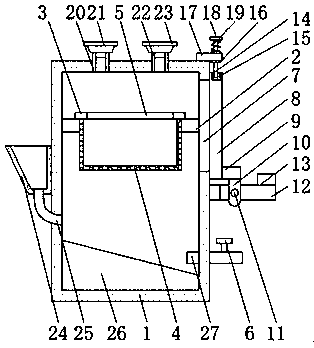

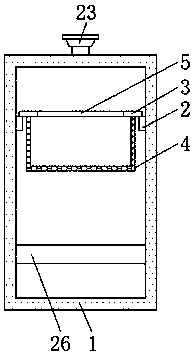

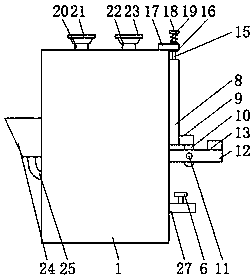

[0029] A waste liquid recovery device for Hui ink production and processing, including a neutralization reaction container, the front and back of the inner wall of the neutralization reaction container are fixedly connected with slide plates, and the upper surfaces of the two slide plates are overlapped with the lower surface of the connecting plate , the lower surface of the connecting plate is fixedly connected with the upper surface of the net cage, the position corresponding to the net cage on the upper surface of the connecting plate is provided with a first through hole, and the right side of the inner wall of the neutralization reaction vessel corresponds to the net cage A second through hole is opened at the position of the neutralization reaction vessel, and a cover plate is provided at the position corresponding to the second through hole on the right side of the neutralization reaction vessel.

[0030] The left side of the cover plate is overlapped with the right sid...

Embodiment 2

[0034] A waste liquid recovery device for Hui ink production and processing, including a neutralization reaction container, the front and back of the inner wall of the neutralization reaction container are fixedly connected with slide plates, and the upper surfaces of the two slide plates are overlapped with the lower surface of the connecting plate , the lower surface of the connecting plate is fixedly connected with the upper surface of the net cage, the position corresponding to the net cage on the upper surface of the connecting plate is provided with a first through hole, and the right side of the inner wall of the neutralization reaction vessel corresponds to the net cage A second through hole is opened at the position of the neutralization reaction vessel, and a cover plate is provided at the position corresponding to the second through hole on the right side of the neutralization reaction vessel.

[0035]The left side of the cover plate is overlapped with the right side...

Embodiment 3

[0042] A waste liquid recovery device for Hui ink production and processing, including a neutralization reaction container, the front and back of the inner wall of the neutralization reaction container are fixedly connected with slide plates, and the upper surfaces of the two slide plates are overlapped with the lower surface of the connecting plate , the lower surface of the connecting plate is fixedly connected with the upper surface of the net cage, the position corresponding to the net cage on the upper surface of the connecting plate is provided with a first through hole, and the right side of the inner wall of the neutralization reaction vessel corresponds to the net cage A second through hole is opened at the position of the neutralization reaction vessel, and a cover plate is provided at the position corresponding to the second through hole on the right side of the neutralization reaction vessel.

[0043] The left side of the cover plate is overlapped with the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com