Multifunctional integrated part and method for preparing same

A multifunctional, part technology, applied in the field of additive manufacturing, which can solve the problems of inability to customize local performance, complex structure, and inability to use, and achieve the effect of easy operation, obvious effect, and high-quality overall forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

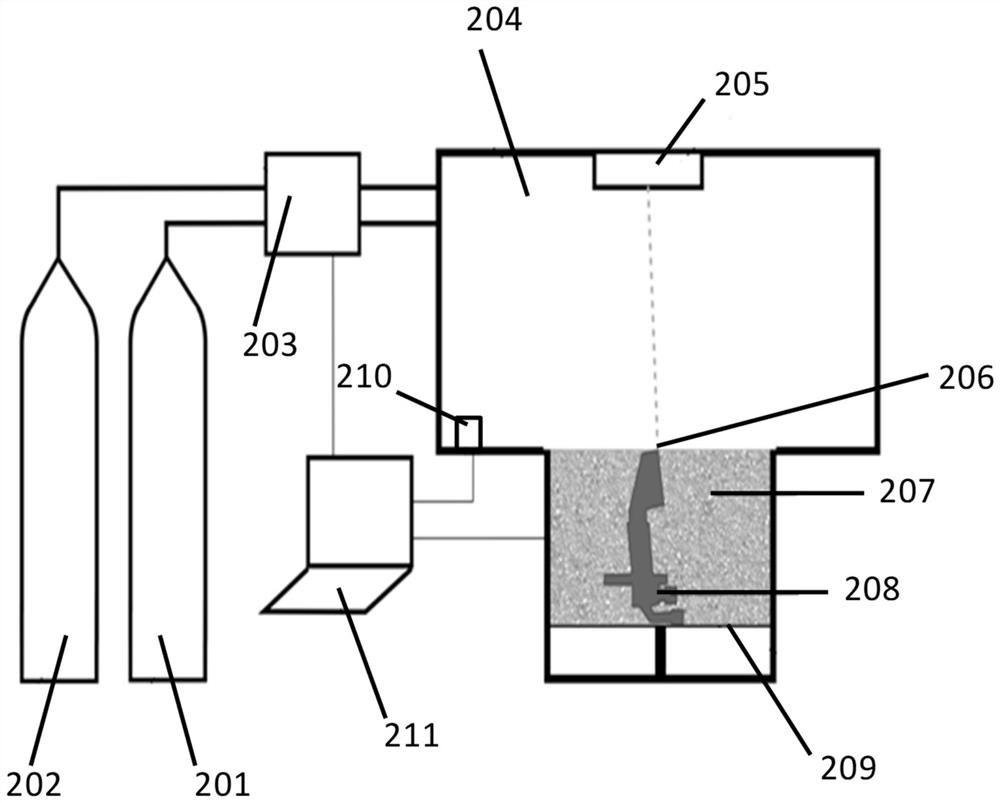

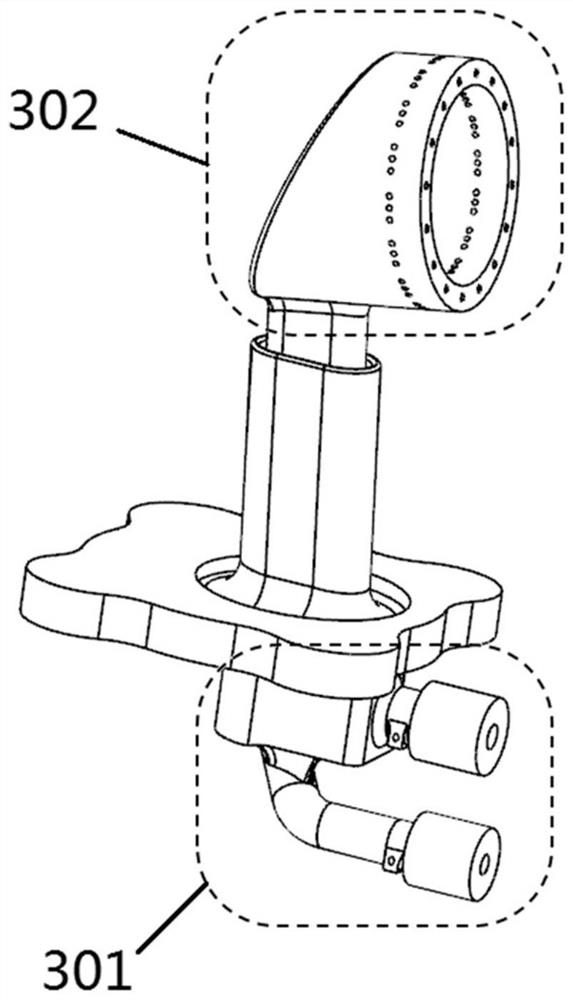

[0022] Selective Laser Melting (SLM) is considered to be one of the most potential metal additive manufacturing technologies. SLM technology mainly uses high-power or high-brightness laser as a heat source to melt metal powder layer by layer to directly manufacture parts with complex shapes. SLM technology uses a laser beam with a finely focused spot as the forming energy source, a high-speed and high-precision scanning galvanometer as the processing beam control unit, and adopts thinner layer thickness control technology. SLM technology has more advantages in obtaining high-density and high-precision formed parts. , can complete the direct forming of complex cavity, profile, thin wall and variable cross-section parts, such as aero-engine pre-swirl nozzles, fuel nozzles, turbine blades and other parts.

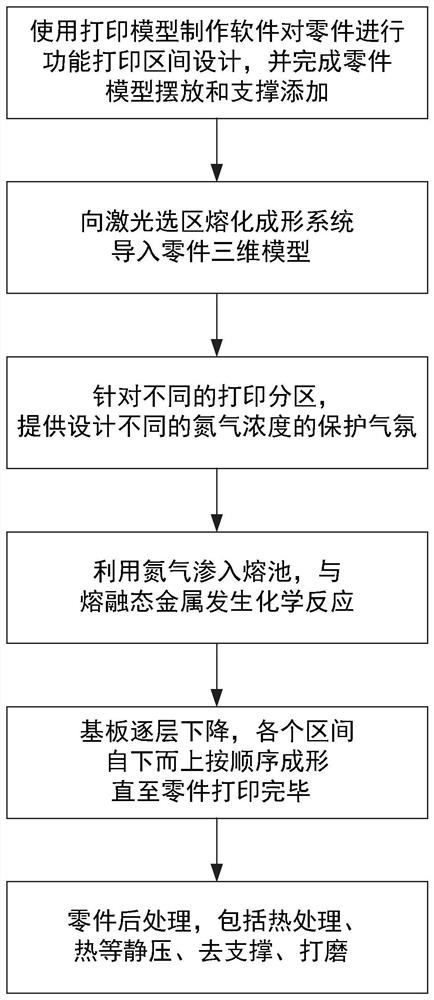

[0023] In view of the problem that the local performance of a single part cannot be customized in the existing part manufacturing process, the following embodiments provide a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com