An iron-based rare earth oxygen storage composite solid solution adsorbent and its application in flue gas arsenic and mercury removal

An adsorbent and solid solution technology, which is applied in the field of iron-based rare earth oxygen storage composite solid solution adsorbent and its preparation, can solve the problems of strong chlorine or oxygen dependence, narrow temperature adaptation window of the adsorbent, and mismatched temperature window, etc., to achieve The effect of cost reduction, wide industry applicability, and improvement of denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

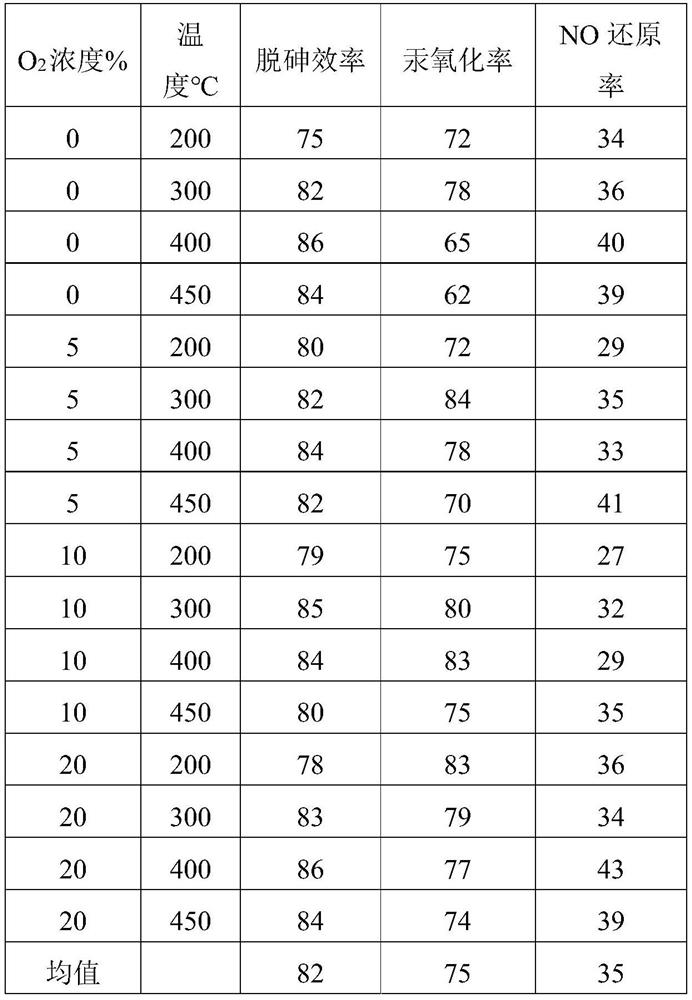

[0032] Fe prepared by co-precipitation 0.30 Ce 0.37 La 0.33 o 1.685 Adsorbent, according to the following steps: 0.5mol of Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water, and then 0.5 mol of H was added 2 o 2 , stirred for 30 minutes, weighed polyethylene glycol with a mass ratio of 1:1 to the theoretical yield of the adsorbent, added to the above solution and stirred to dissolve. Then weigh 0.3mol of La(NO 3 ) 3 ·6H 2 O and 1.2mol of Fe(NO 3 ) 3 9H 2 O was added to the above solution and stirred until dissolved to obtain a precursor solution. Will (NH 4 ) 2 CO 3 The mixed solution with a molar ratio of 1:1 to ammonia water was added dropwise to the precursor solution while stirring until the pH value of the mixed solution was 9.5. Stand at room temperature for aging, then centrifuge, and fully wash the filter cake with deionized water to obtain the precursor of the adsorbent. The precursor is dried in a constant temperature drying oven at 100°C, and th...

Embodiment 2

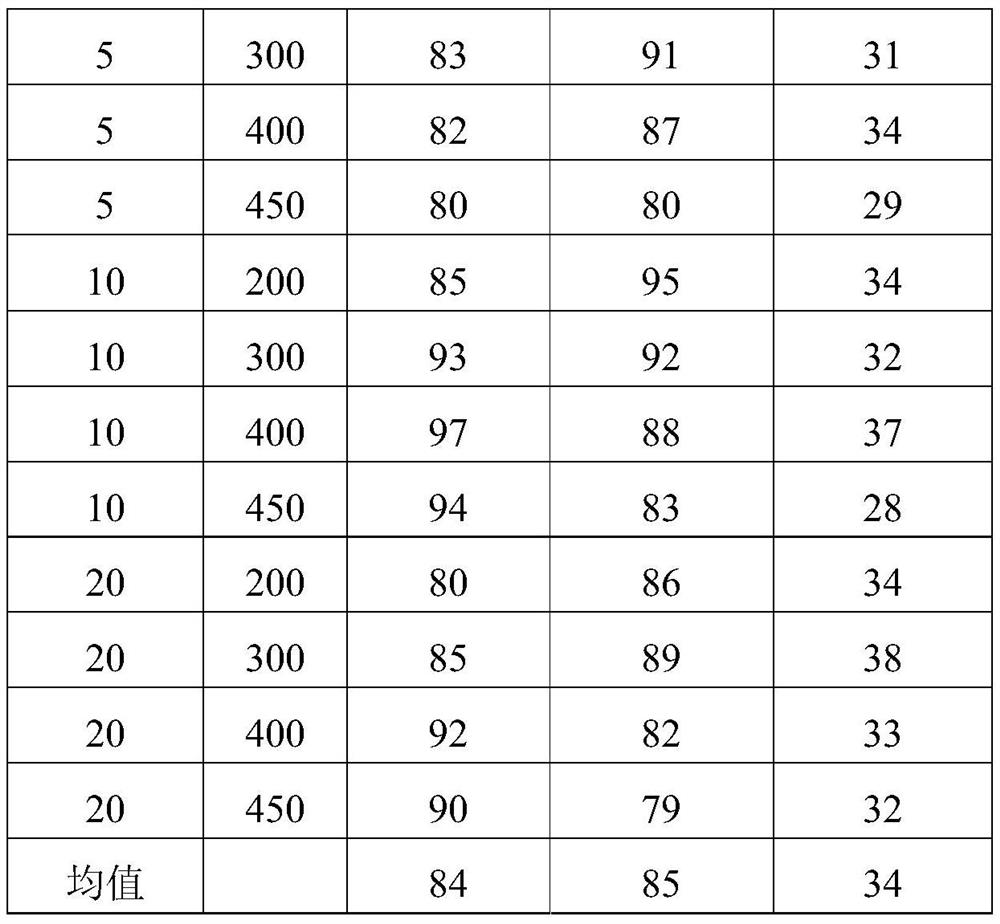

[0038] Preparation of Fe by co-precipitation method 0.44 Ce 0.25 La 0.23 PR 0.08 o 1.625 Adsorbent, according to the following steps: 0.4mol of Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water, and then 0.4 mol of H was added 2 o 2 , stirred for 30 minutes, weighed polyethylene glycol with a mass ratio of 1:1 to the theoretical yield of the adsorbent, added to the above solution and stirred to dissolve. Then weigh 0.3mol of La(NO 3 ) 3 ·6H 2 O, 0.1mol of Pr(NO 3 ) 3 ·6H 2 O and 0.8mol Fe(NO 3 ) 3 9H 2 O was added to the above solution and stirred until dissolved to obtain a precursor solution. Will (NH 4 ) 2 CO 3 The mixed solution with a molar ratio of 1:1 to ammonia water was added dropwise to the precursor solution while stirring until the pH value of the mixed solution was 8.5. Stand at room temperature for aging, then centrifuge, and fully wash the filter cake with deionized water to obtain the precursor of the adsorbent. The precursor is dried i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com