Size-adjustable combined crucible thermal field

A combination and crucible technology, which is applied in the direction of condensed steam, single crystal growth, crystal growth, etc., can solve the problems that the thermal field cannot be adjusted, and the size of the crucible is single, so as to improve utilization rate, reduce production cost, location and number of uses Choose from flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

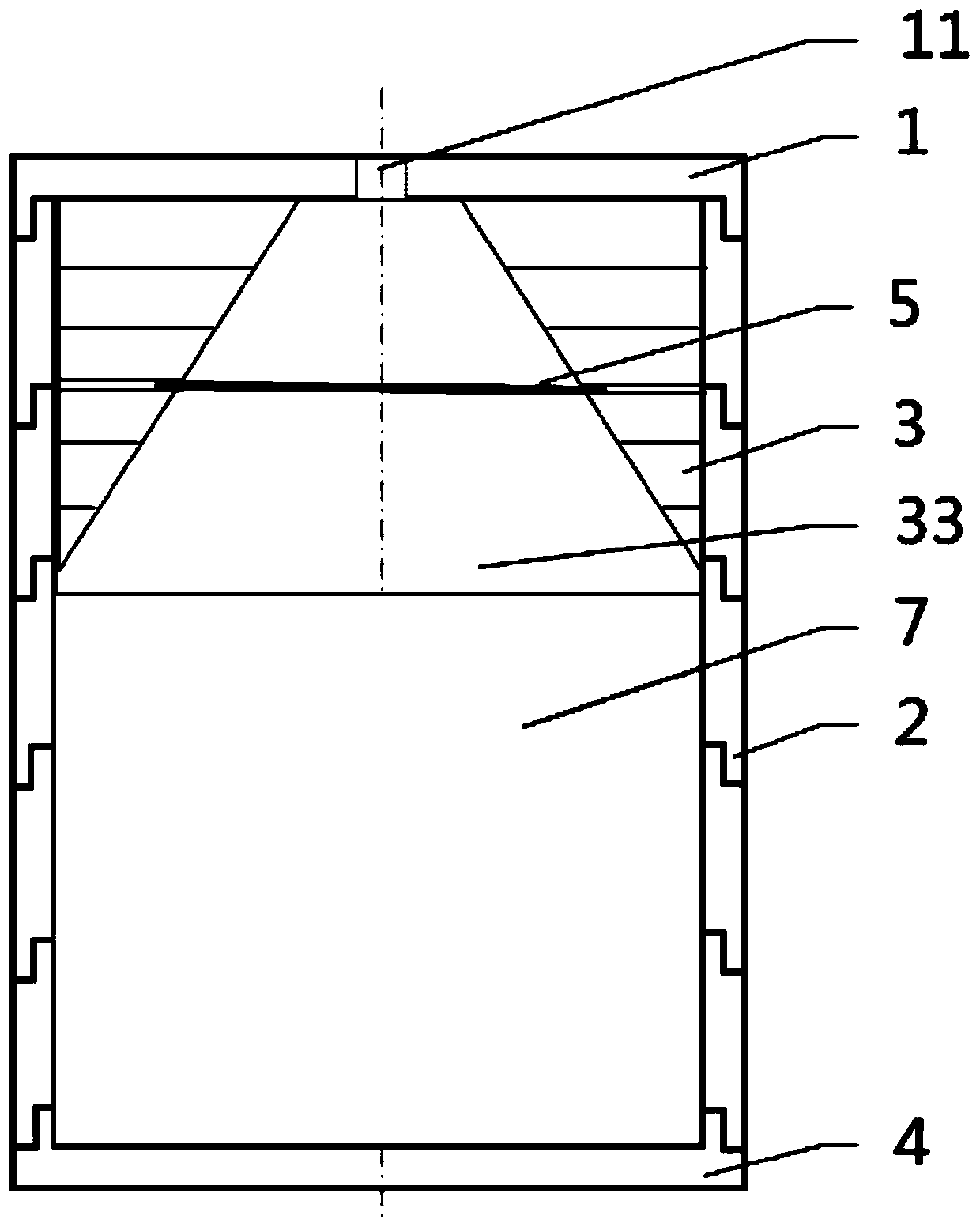

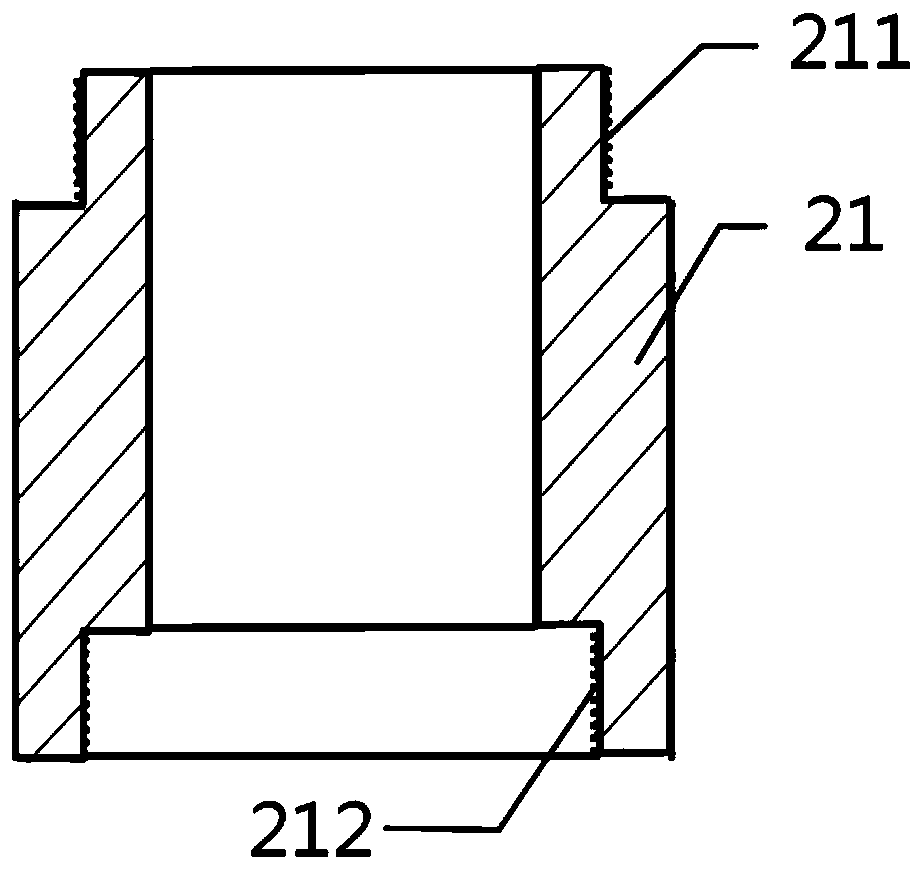

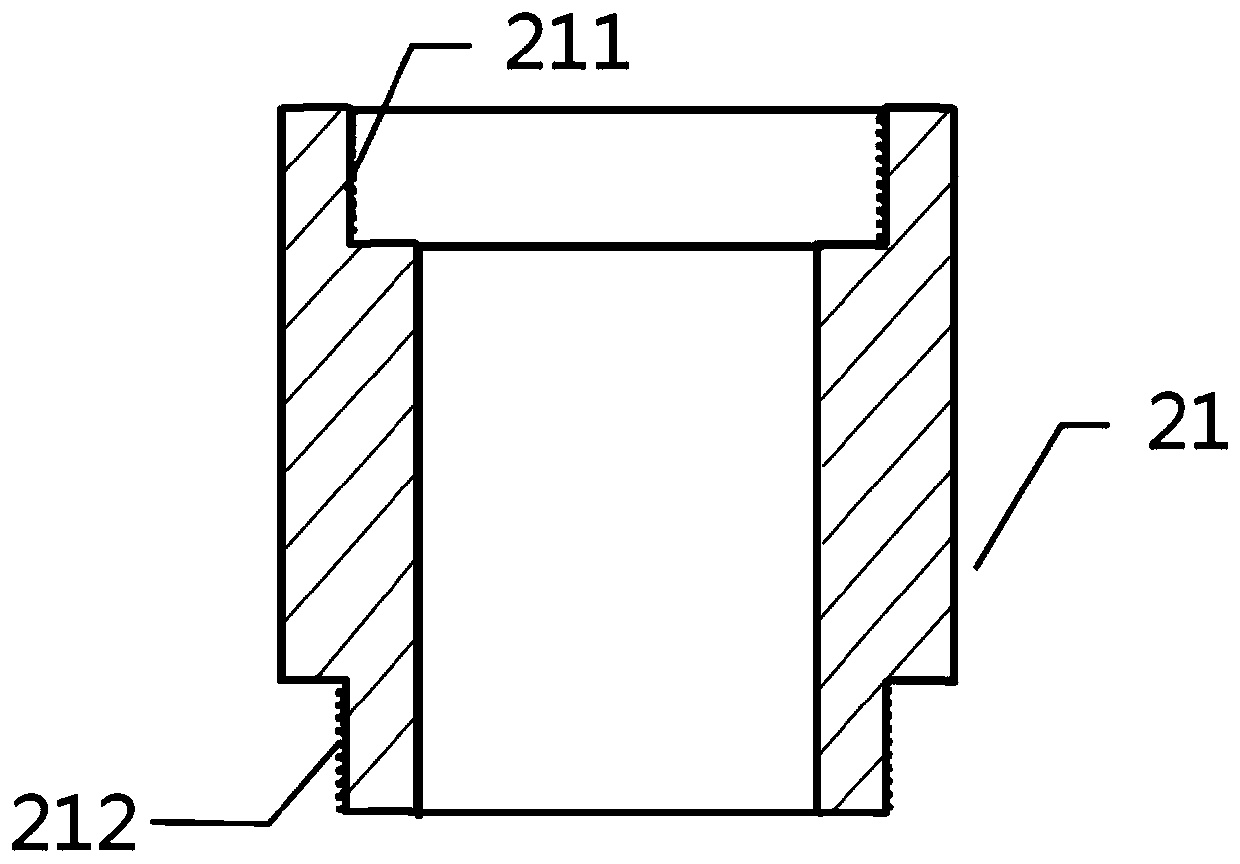

[0026] Such as figure 1 As shown, the present invention is a size-adjustable combined crucible thermal field, comprising: a crucible upper cover 1 , a combined crucible barrel 2 , side support components 3 and a crucible bottom 4 .

[0027] The upper cover 1 of the crucible is circular, and threads are processed on the inner side wall of the upper cover 1 of the crucible, which is made of high temperature resistant material, and the high temperature resistant material is composed of graphite and high melting point metal.

[0028] Further, in order to facilitate the temperature measurement by the thermometer, a temperature measurement window 11 may also be provided at the center of the upper cover 1 of the crucible.

[0029] The bottom 4 of the crucible is circular, and the fourth upper surface of the crucible is provided with a connecting surface for threaded connection with the combined crucible barrel 2, and threads are processed on the side wall of the connecting surface. ...

Embodiment 2

[0038] Such as Figure 7 and Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that each single support 31 is spliced by two C-shaped structures, and the splicing surfaces of the two single supports 31 can be plugged or for surface contact. Insertion teeth 32 protruding toward the center of the circle are processed at intervals in the circumferential direction on the inner side wall of each single support member 31 , and the insertion teeth 32 are in a convex-concave structure.

[0039] A heat preservation component 6 is also added inside the combined crucible tube 2 . The upper heat preservation part 6 is in the shape of a truncated cone, and the outer wall of the upper heat preservation part 6 is provided with mating teeth 61 that match the insertion teeth 32 on the single support 31. Through the cooperation of the insertion teeth 32 and the mating teeth 61, the heat preservation The component 6 is clamped in the central through hole 30 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com