Method for introducing rare metal Hf element into coating

A rare metal and coating technology, applied in the field of composite electroplating, can solve the problems of difficult dispersion of Hf layer, difficulty in popularization and application, and high cost, and achieve the effect of low preparation cost, simple equipment requirements, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

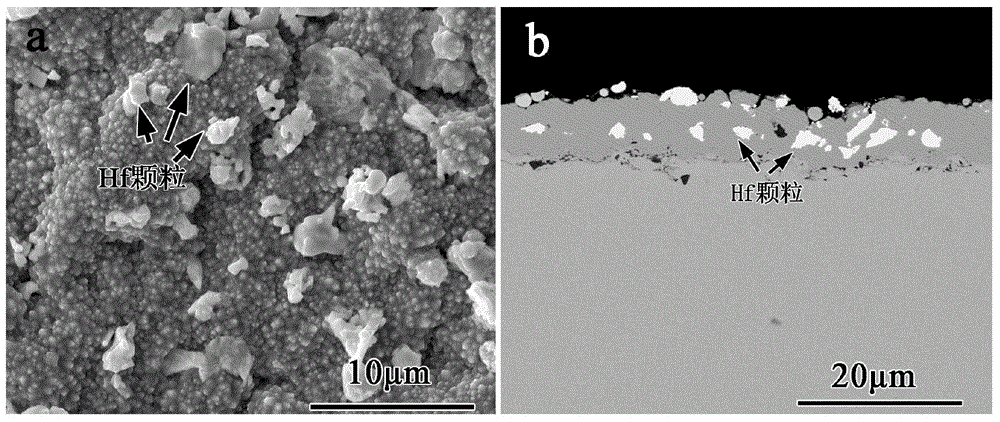

[0032]Ni-Hf composite electroplating: Nickel plating adopts traditional Watt-type nickel plating solution. The composition of the plating solution and the nickel plating process are shown in Table 1. Take an appropriate amount of Hf powder after grinding (with a particle size of 0.1-10 μm) and place it in the nickel plating solution, and fully mix the powder with the electroplating solution under the stirring of a magnetic stirrer. The sample used is nickel-based single crystal superalloy DD413, and the sample size is Φ15×2mm. Before electroplating, the sample needs to be polished with 150#, 240#, 400# SiC sandpaper in sequence, and then subjected to water blasting treatment, followed by ultrasonic degreasing with acetone 30min, and ultrasonically cleaned with alcohol and deionized water for 15min, respectively, and finally soaked the sample in 50g / L NaOH and heated to boiling to remove excess oil on the surface of the sample. The degreased samples were ultrasonically cleaned...

Embodiment 2

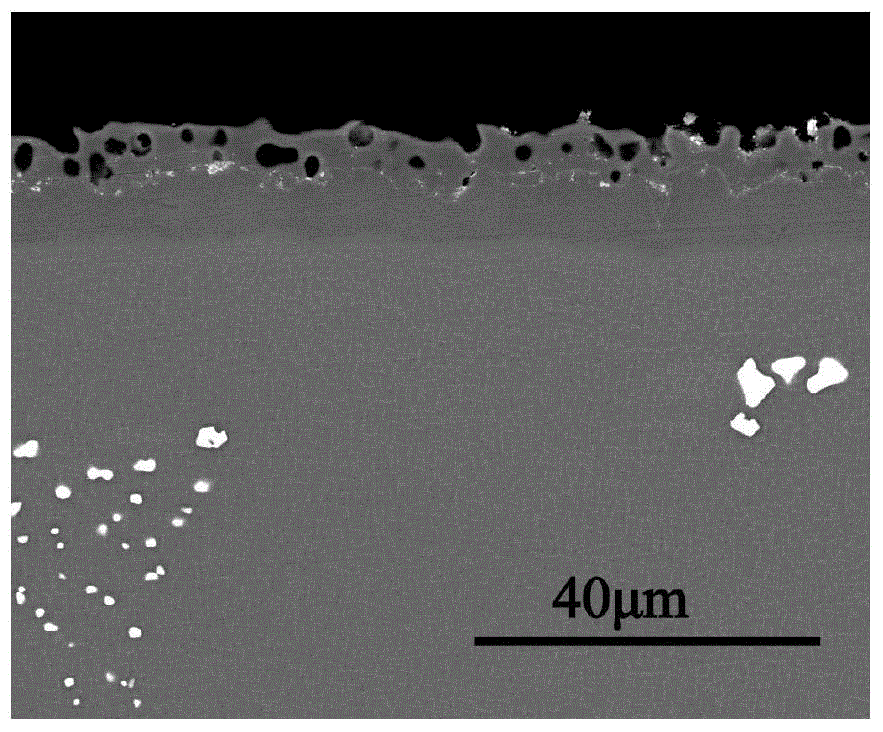

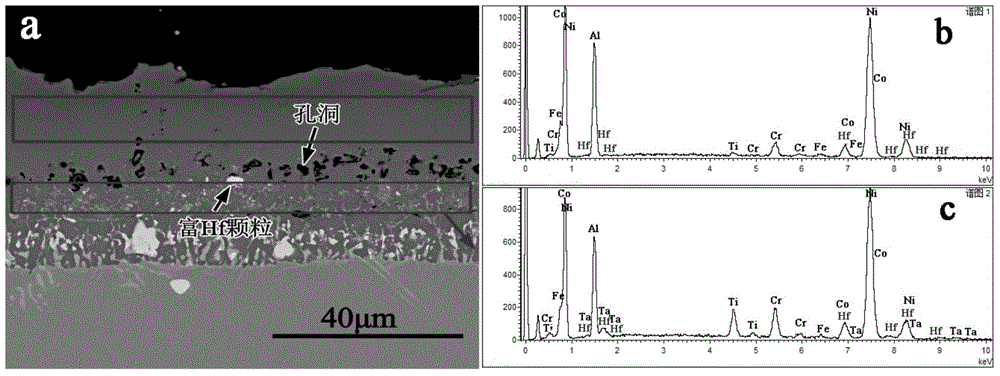

[0040] Considering that Hf element does not interact with water, dilute acid or strong alkali, and does not directly combine with oxygen, nitrogen and other gases at room temperature, and Hf as a metal element has good electrical conductivity and other characteristics, Hf powder with a certain particle size range is directly Mixed with metal plating solution (nickel plating solution, platinum plating solution, etc.) The metal Hf particles become part of the cathode together with the sample; with the continuous thickening of the coating, the electroplating deposition of the composite coating modified by rare metal Hf can be realized.

[0041] The concrete implementation process of above-mentioned composite electroplating is:

[0042] 1) The particle size range of the Hf powder used is 0.1-10 μm. The commercially available Hf powder (<500 mesh) can be ground with a planetary ball mill and dispersed with deionized water until the Hf powder particles in the above particle size ran...

Embodiment 3

[0047] The invention provides a method for introducing rare metal Hf elements in the coating, characterized in that: the method for introducing rare metal Hf elements in the coating comprises the following steps:

[0048] 1) Surface treatment method: grind the sample, grind off the original surface of the metal, then perform sandblasting treatment, and then perform two-step degreasing treatment: the first step is ultrasonic cleaning with acetone for 15-30min, and the second step is at 40 -Boil in 60g / L NaOH solution for 10min;

[0049] 2) Configuration of the suspension plating solution: add pure Hf particles with a particle size of 0.1-10 μm in the conventional metal plating solution, and use a magnetic stirrer to stir the mixed solution until a uniform suspension is formed; adjust the pH value of the solution, Keep it in the pH range of ordinary electroplating metal coating;

[0050] For example, when Ni-Hf composite electroplating is carried out with a Watt-type plating so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com