Patents

Literature

97results about How to "Improve ferromagnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and preparation method thereof

InactiveCN105837196AReduce contentHigh polarizationCeramic layered productsMagnetic layerMagnetic composite

The invention provides a Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and a preparation method thereof. The ferromagnetic composite film comprises a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 crystalline film and a Zn1-yNiyFe2O4 crystalline film, which are compounded together. The preparation method is as below: first respectively preparing a Zn1-yNiyFe2O4 precursor solution and a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 precursor solution, wherein AE is Sr, Ca, Ba or Pb, x equals to 0.01-0.04, and y equals to 0.1-0.9; preparing a plurality of Zn1-yNiyFe2O4 films on a substrate by spin coating; and then preparing plurality of Bi0.92-xHo0.08AExFe0.97Mn0.03O3 films on the Zn1-yNiyFe2O4 films by spin coating, so as to obtain the ferromagnetic composite film. The method regulates the crystal structure of BiFeO3 by doping, and uses ferromagnetic Zn1-yNiyFe2O4 as the magnetic layer, so as to substantially increase the ferroelectric and ferromagnetic properties of the film, and effectively reduce the leakage current density of the film.

Owner:SHAANXI UNIV OF SCI & TECH

Multiferroic Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3-NiFe2O4 composite film and preparation method thereof

The invention discloses a multiferroic Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3-NiFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 crystalline state film and a NiFe2O4 crystalline state film which are compounded together. The preparation method comprises the following steps: respectively preparing a Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 precursor solution and a NiFe2O4 precursor solution; and spinning on a substrate to prepare a multilayer NiFe2O4 film, and spinning on the NiFe2O4 film to prepare a multilayer Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 film, thereby obtaining the target product. The equipment requirement is simple, the prepared film is high in uniformity, the doping amount is easy to control, and the ferroelectric properties and ferromagnetic properties of the film are greatly improved. Meanwhile, the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

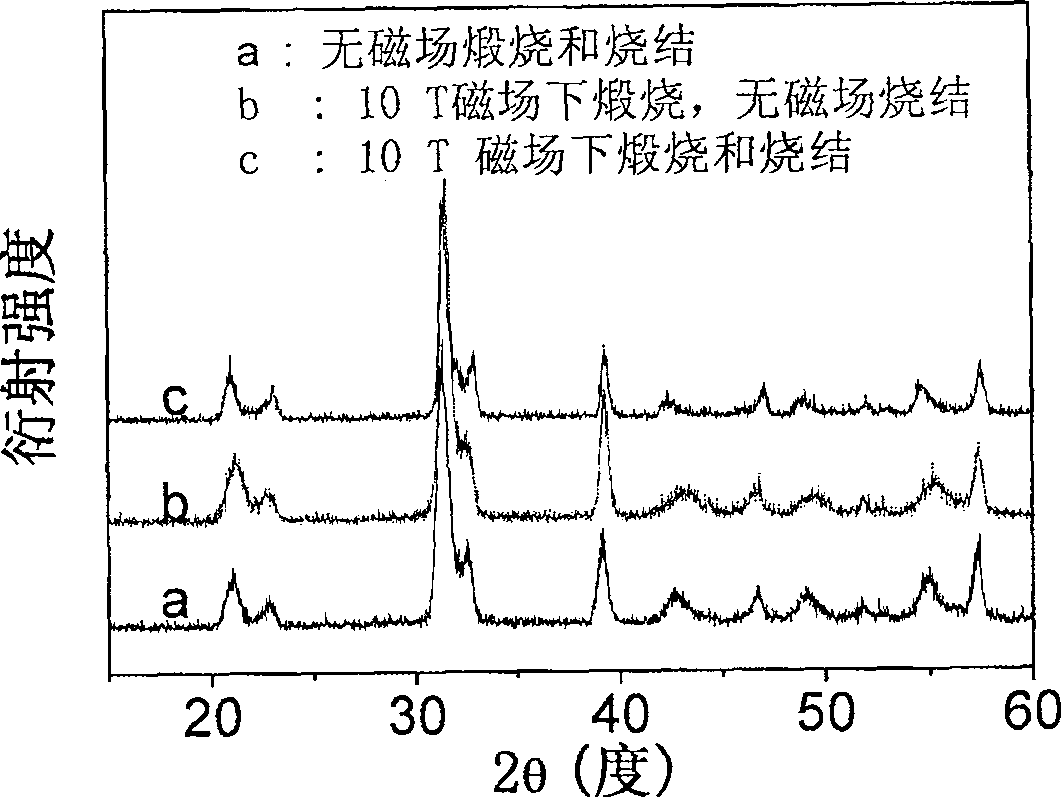

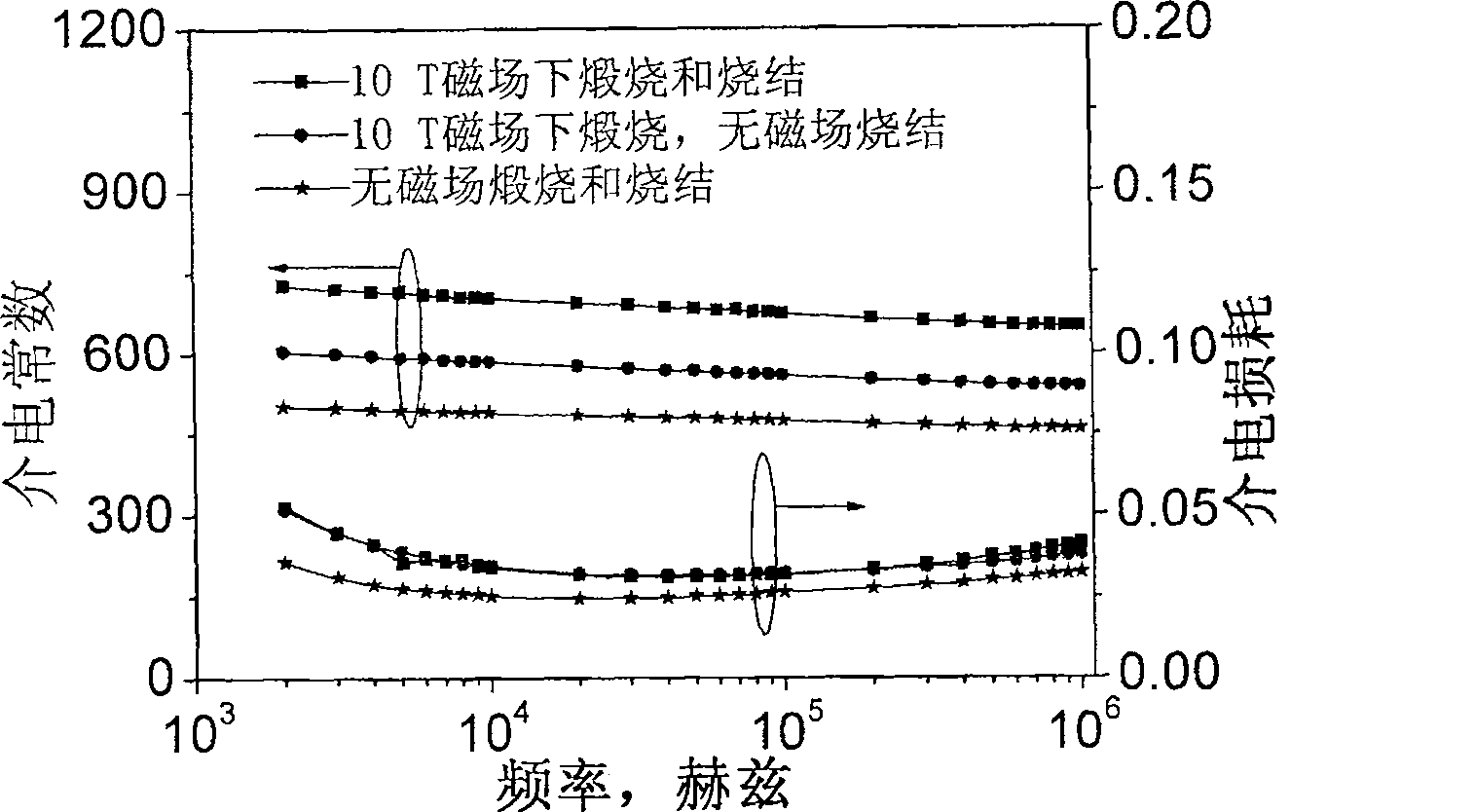

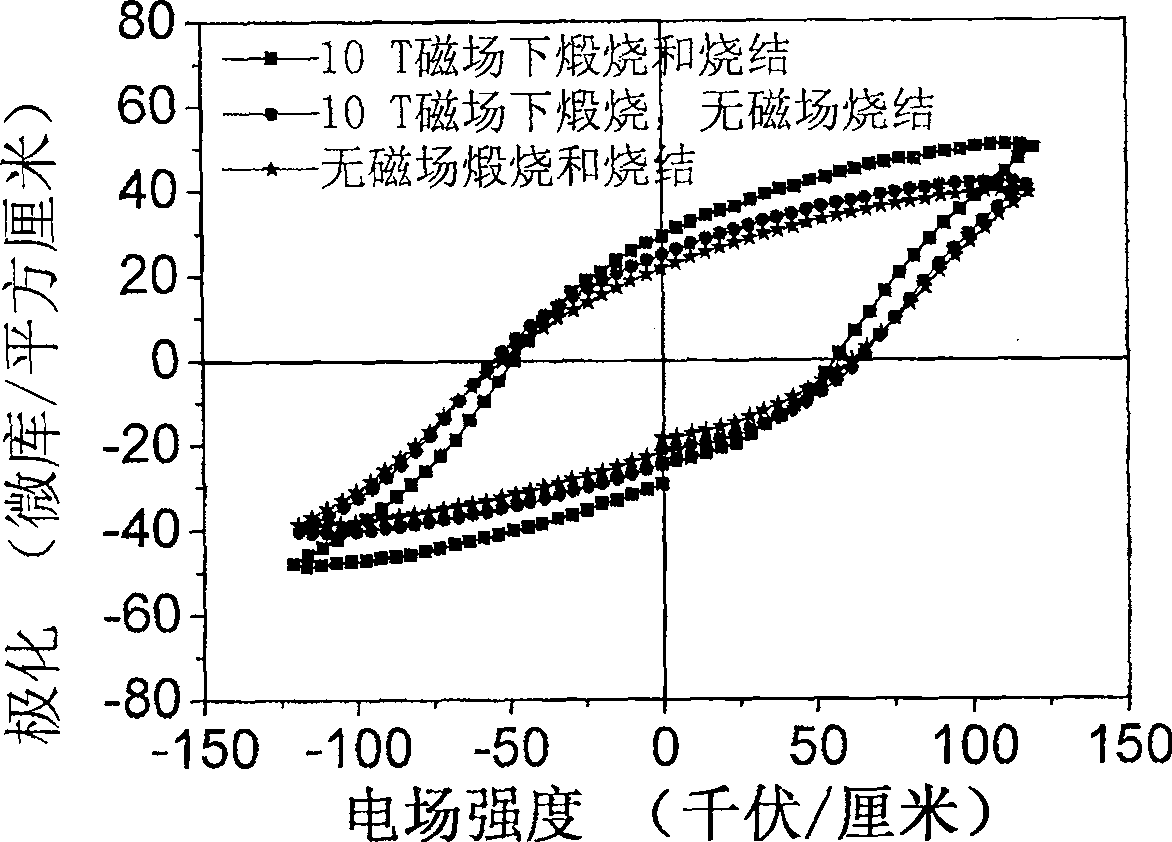

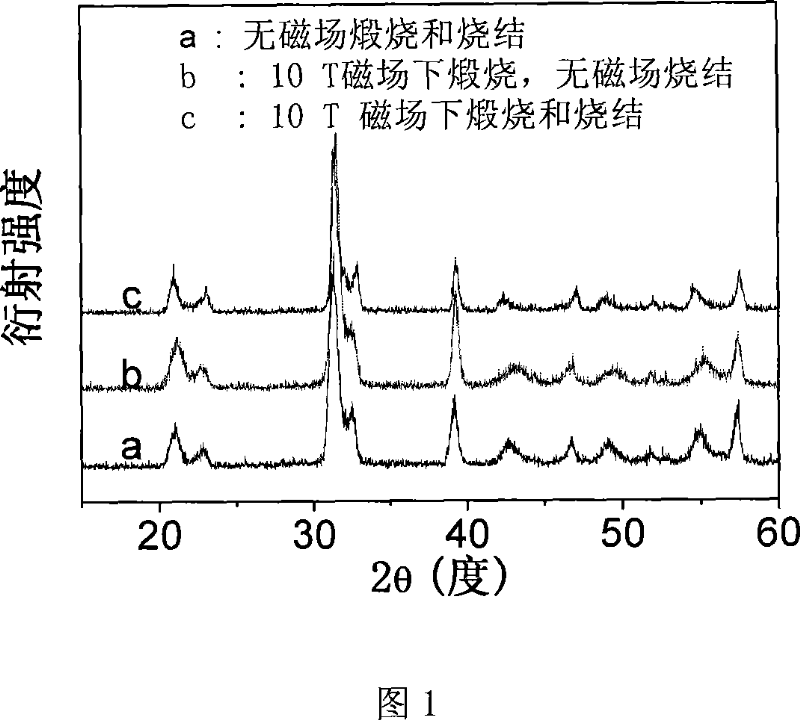

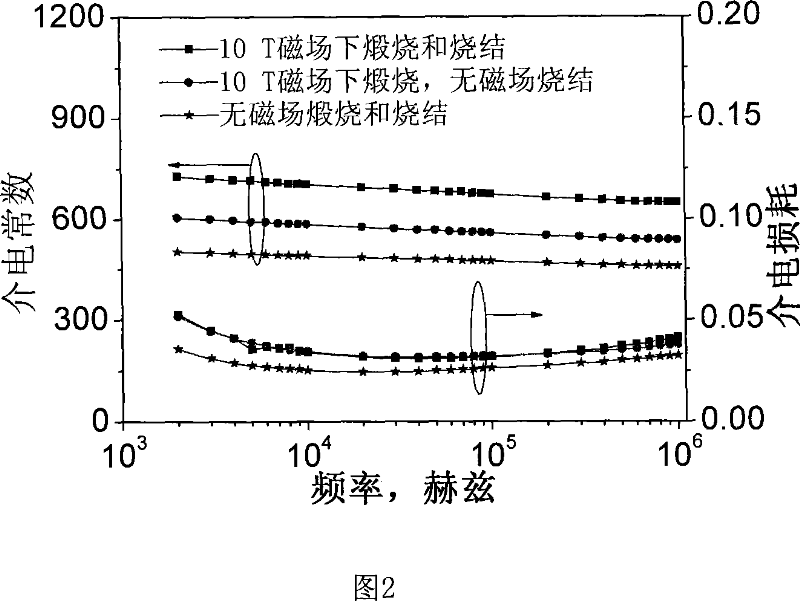

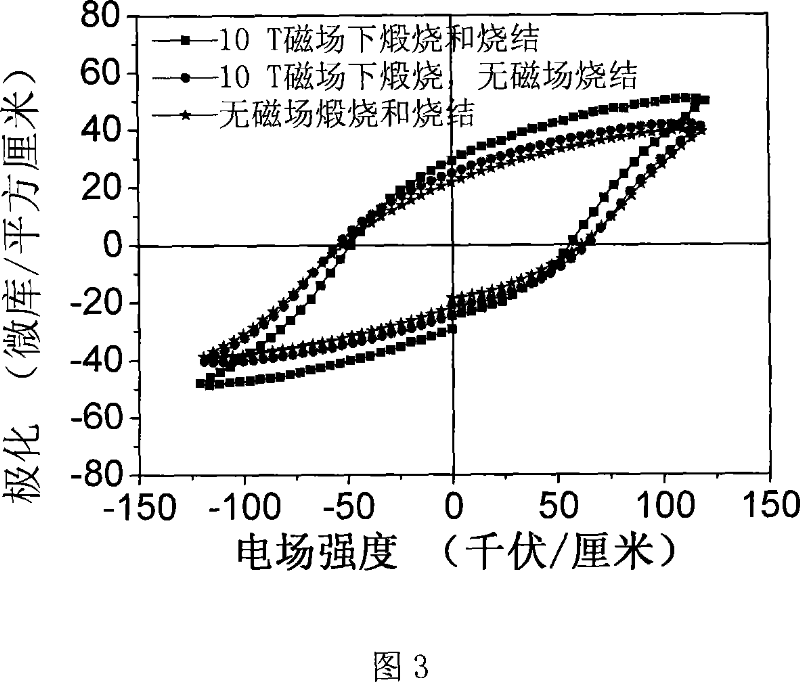

Method for preparing ferrite bismuth lanthanum-titanate lead solid solution ceramic under strong magnetic field action

The invention relates to a method for producing ferric acid bismuth lanthanum-lead titanate solid solution ceram in an intense magnetic field, belonging to the technical field of inorganic non-metal material and solid solution ceram material. The designed chemical formula of ferric acid bismuth lanthanum-lead titanate solid solution ceram is: (1-x)(Bil-yLay)FeO3-xPbTiO3; wherein: 0.2<=x<=0.6, y=0-0.4; weighing and preparing materials according to the chemical dosage rate of the chemical formula; weighing and mixing the Bi2O3, La2O3, Fe2O3, PbCO3 and TiO2 powder with a purity more than 99.9%, adding ethanol as abrasive, zirconia grain as abrasing medium; ball milling for 24 hours in the ball mill, mixing sufficiently and levigating; calcining and synthesizing in 750 DEG C in the magnetic intensity of 7-14T for 24 hours; ball milling for 24 hours; then doing a secondary ball milling; then prilling, tabletting; finally sintering the pressed compact in 1080-1100 DEG C, meanwhile introducing the intense magnetic field and obtaining the ferro-electricity ferromagnetism ceramic material.

Owner:SHANGHAI UNIV

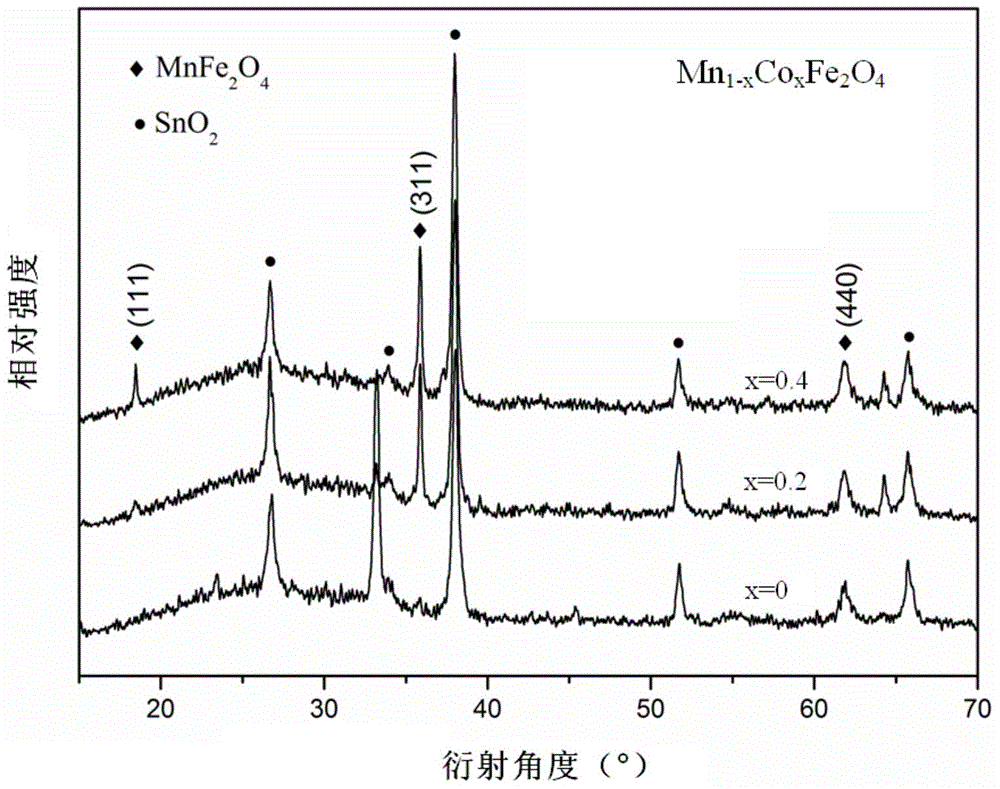

Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3/Mn(1-x)CoxFe2O4 composite film and preparation method thereof

The invention provides a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 / Mn(1-x)CoxFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 crystalline-state film and a Mn(1-x)CoxFe2O4 crystalline-state film which are compounded together. The preparation method comprises the following steps: respectively preparing a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 precursor solution and a Mn(1-x)CoxFe2O4 precursor solution; then spinning on a substrate to prepare a multi-layer Mn(1-x)CoxFe2O4 film; and spinning on the Mn(1-x)CoxFe2O4 film to prepare a multi-layer Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 film which is the target product. In the invention, the equipment requirements are simple, the prepared film has relatively good uniformity, the doping amount is easy to control, the ferroelectric property and ferromagnetic property of the film are remarkably improved, and the leak current density of the film is effectively reduced at the same time.

Owner:SHAANXI UNIV OF SCI & TECH

Multiferroic Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3-CuFe2O4 composite film and preparation method thereof

The invention discloses a multiferroic Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3-CuFe2O4 composite film and a preparation method thereof. The composite film comprises Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 crystal films and CuFe2O4 crystal films which are composited together. The preparation method comprises the following steps: firstly, preparing a Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 precursor solution and a CuFe2O4 precursor solution respectively; secondly, preparing multiple layers of CuFe2O4 films on a substrate by spin coating, and preparing multiple layers of Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 films on the CuFe2O4 films by spin coating to obtain a target product. The equipment requirement is simple, the uniformity of the prepared film is high, the doping amount is easy to control, the ferroelectric and ferromagnetic properties of the film are improved, and the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

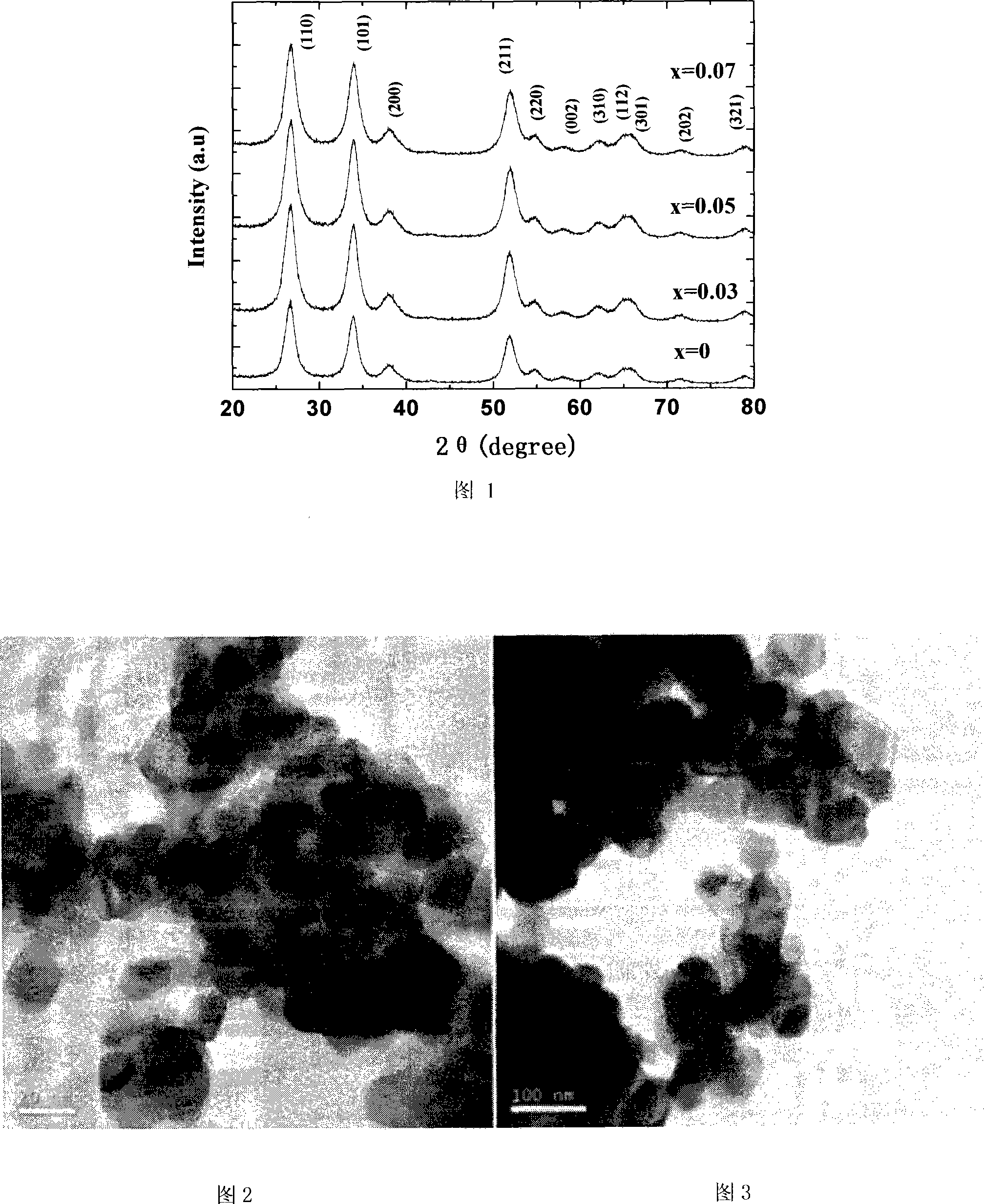

Dysprosium-doped BiFeO3 multi-ferroic ceramic block and preparation method thereof

The invention relates to a dysprosium-doped BiFeO3 multi-ferroic ceramic block and a preparation method thereof and belongs to the field of functional ceramic. The preparation method comprises the following steps: weighting Bi(NO3)3.5H2O, Dy2O3 and Fe(NO3)3.9H2O at a ratio of (1-x):x:1; respectively dissolving in glacial acetic acid, diluted nitric acid and water, heating and stirring; mixing thethree solutions, and then adding citric acid, heating and stirring; after adjusting PH, continuously heating and stirring, thereby obtaining gel; foaming the gel, thereby obtaining aerogel; crushing the aerogel, thereby obtaining powder; pre-processing the powder; making the pre-processed powder into block and sintering; and removing a surface oxide layer, thereby obtaining the B(i1-x)DyxFeO3 multi-ferroic ceramic block, wherein x is equal to 0.03-0.20. The Bi(1-x)DyxFeO3 multi-ferroic ceramic block is single-phase ceramic; the ferroelectricity is enhanced; and when x is equal to 0.05 and 0.07, the ceramic block has ferromagnetism at room temperature.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and making method thereof

The invention provides a Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and a making method thereof. The method comprises the following steps: preparing a Bi0.9Er0.1Fe1-xCoxO3 precursor solution from bismuth nitrate, iron nitrate, cobalt nitrate and erbium nitrate, spin-coating a substrate with the Bi0.9Er0.1Fe1-xCoxO3 (x is 0.01-0.03) precursor solution, uniformly sizing, drying, and annealing to obtain the Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity. The method has the advantages of simple device requirements, easy reaching of experiment conditions, easy control of the doping amount, and great improvement of the ferromagnetism of a BiFeO3 film, and the Bi0.9Er0.1Fe1-xCoxO3 film made in the invention has the advantages of good uniformity, high magnetic intensity and high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

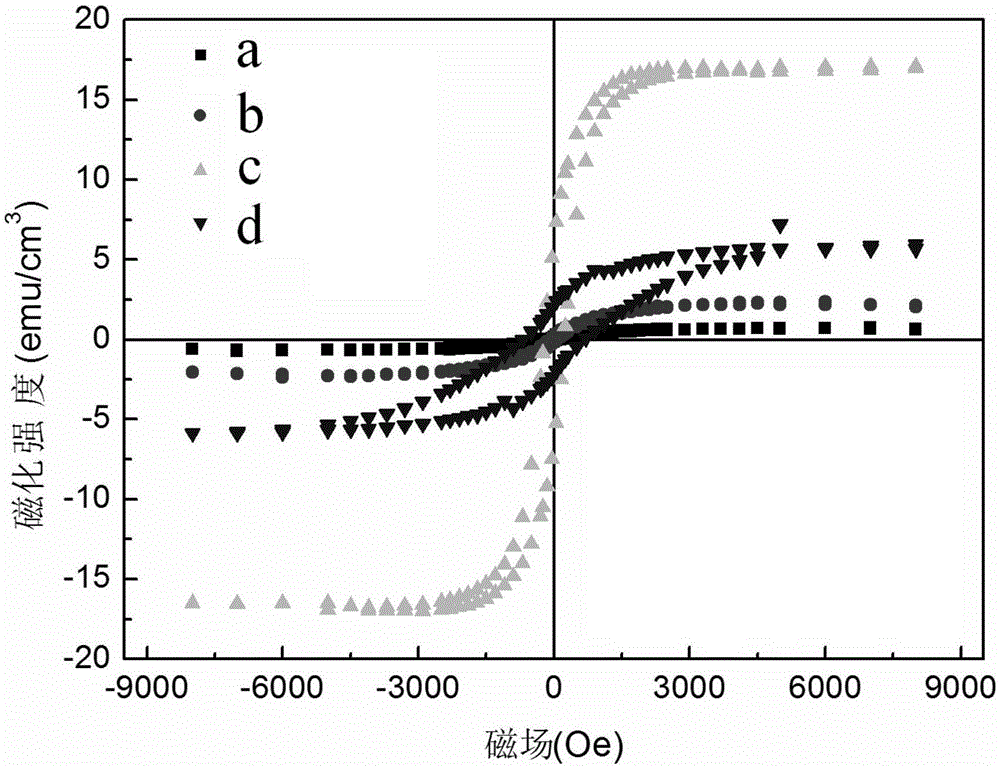

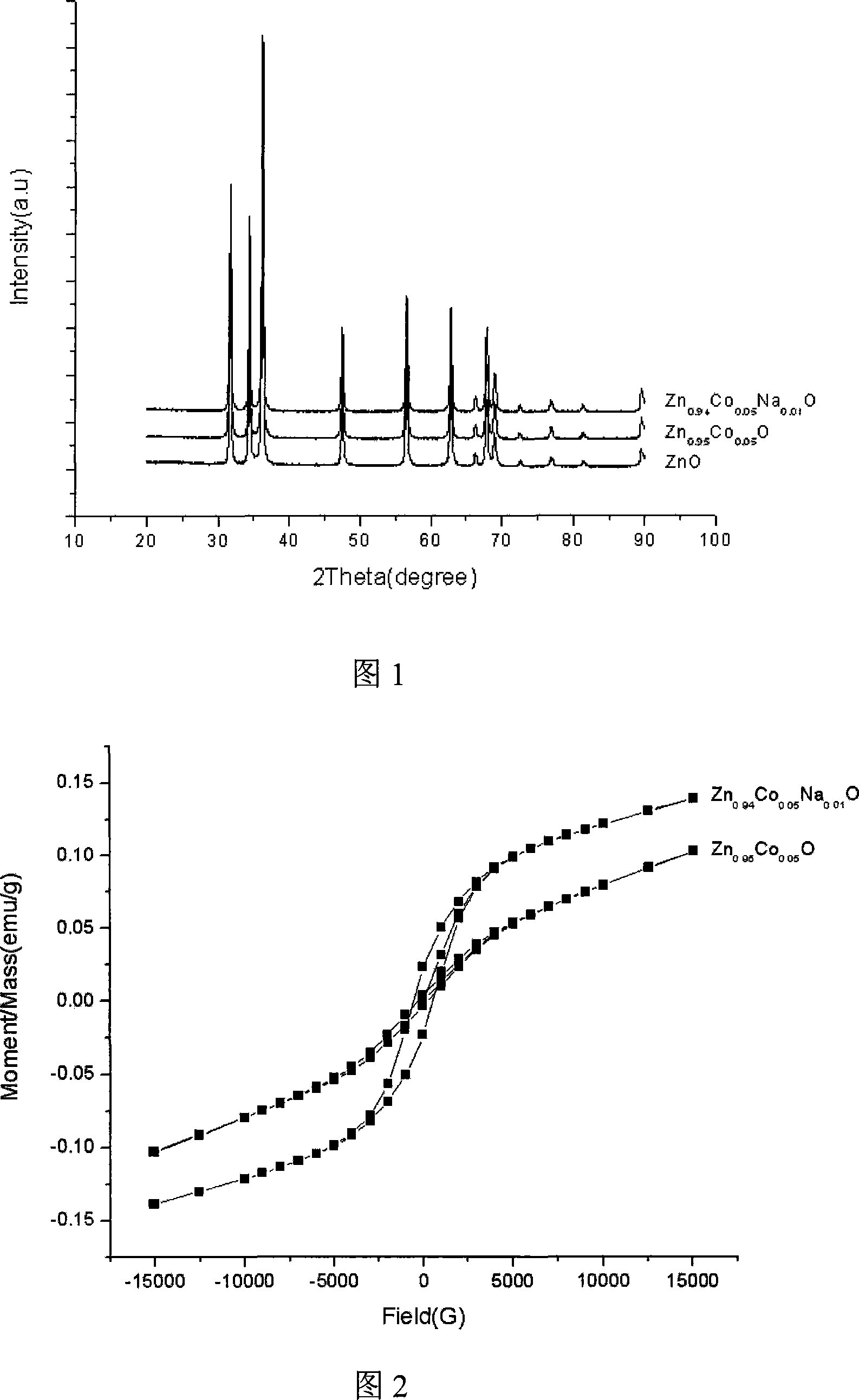

P type doping ZnO based rare magnetic semiconductor material and method of producing the same

ActiveCN101183595AEasy to getSimple technologyZinc oxides/hydroxidesGalvano-magnetic material selectionSodium acetateZinc Acetate Dihydrate

The invention discloses a p-type doped ZnO-based diluted magnetic semiconductor material and the preparation method. The material molecular structure formula is ZnTMyxO, in which Tm represents transition metal element, Co, Ni, Mn and other elements, x=0-10%, y=0-20%. Method is that zinc acetate, sodium acetate and transition metal salt are dissolved in ethylene glycol monomethyl ether as precursor; then ethanol is added as stabilizer; after stirring, the stable sol is formed. After the sol being dried and heat treated, the power sample is obtained; or by spin coating, the sol is coated uniformly on the Si wafer cleaned in advance or other substrates (quartz glass, sapphire, SiC and other materials), after being dried and heat treated, the thin film sample is obtained. The sol-gel method of preparing material has the advantage of simple technology, low cost, and obtaining easily large area thin films; based on the preparation of the room-temperature ferromagnetic ZnO-based diluted magnetic semiconductor, the Na ion is introduced successfully to obtain the p-type doping; therefore the magnetic property is improved, and by regulating concentration of the Na ion, the magnetic property is controlled.

Owner:ZHEJIANG UNIV +1

Low-cobalt nickel nanocrystalline iron-base magnetically soft alloy material and preparation method thereof

InactiveCN102828110AExpand the range of amorphous formationHigh Curie temperatureMagnetic materialsCobalt metalAlloy

The invention provides a low-cobalt nickel nanocrystalline iron-base magnetically soft alloy material and a preparation method thereof. Under the condition of ensuring better soft magnetic property, the material not only reduces the high-price metal cobalt but also has good magnetic property. The preparation method has simple process and low production cost and is suitable for industrial production. The material comprises the following components by weight percent: 4-6.5% of Co, 5-8% of Ni, 3-5% of Gd, 0.01-0.05% of Ir, 0.1-0.5% of Tm, 0.1-0.5% of Dy, 2-4% of Al, 0.1-0.5% of P, 1-3% of B and the balance of Fe.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

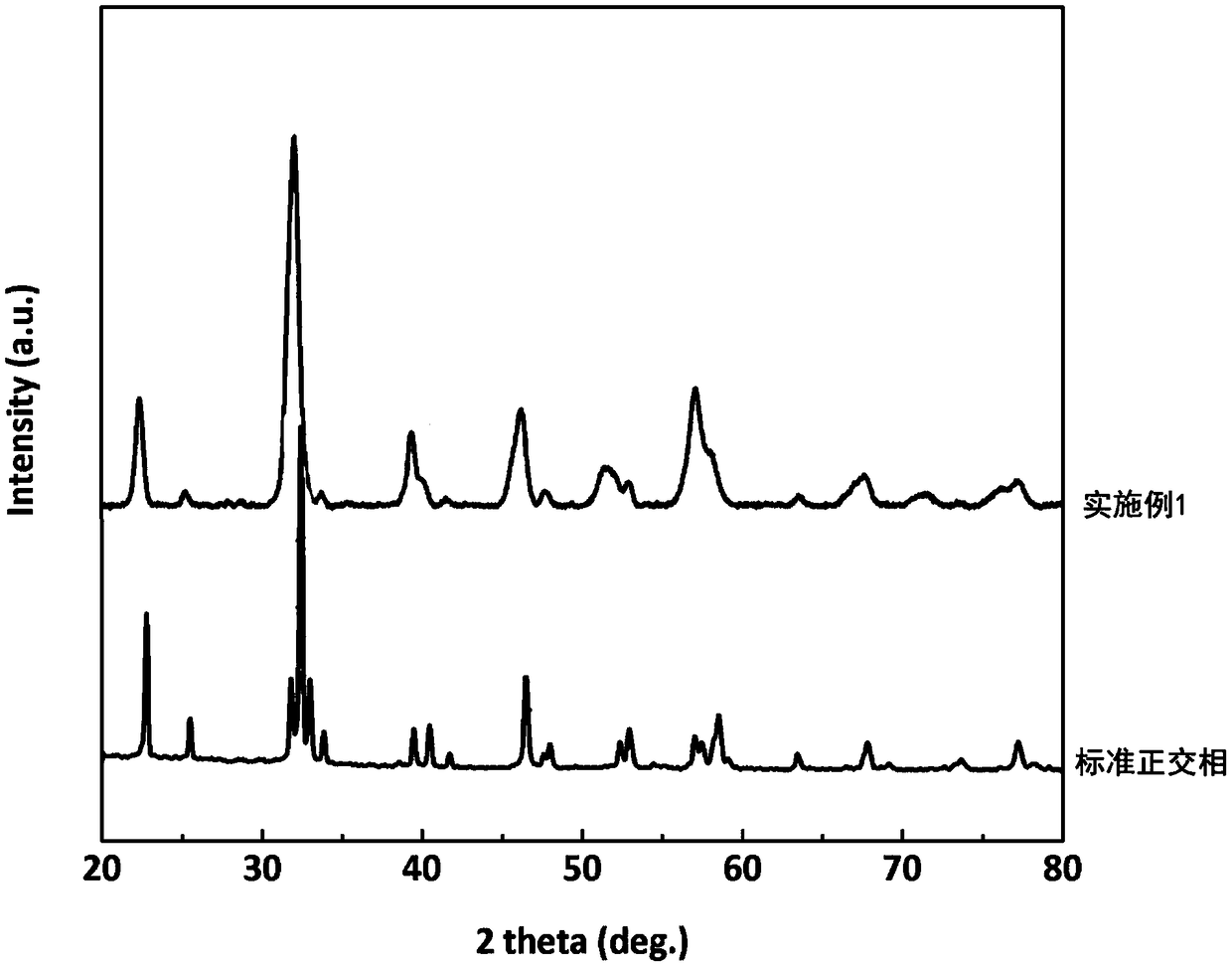

Bismuth ferrite based nano ceramic and preparation method

InactiveCN109354487AImprove ferromagnetism and ferroelectricityReduce dielectric loss and leakage currentFerroelectricityFerromagnetism

The invention discloses bismuth ferrite based nano ceramic. A main composition of the nano ceramic is Bi0.8Gd0.2Fe1-xTixO3, wherein value of x is doping proportion of Ti4+, x is greater than or equalto 0.01 and smaller than or equal to 0.1, and phase of Bi0.8Gd0.2Fe1-xTixO3 is orthogonal phase. Spiral cycle of bismuth ferrite based ceramic is broken through, ferromagnetism and ferroelectricity ofthe bismuth ferrite based nano ceramic are improved, and dielectric loss and leaking current are reduced. The invention further discloses a preparation method of the bismuth ferrite based nano ceramic. The preparation method includes following steps: weighing a bismuth source, an iron source, a gadolinium source and a titanium source, mixing and dissolving in an organic solvent to preparing a mixed solution, adding an additive, and stirring to obtain sol; drying the sol, and finely grinding to obtain nano powder; filling a graphite die with the nano powder, performing plasma sintering, polishing and grinding to remove carbon paper on the surface, and annealing to obtain the bismuth ferrite based nano ceramic. By adopting plasma sintering, compactness of the bismuth ferrite based nano ceramic is improved, so that ferromagnetism is enhanced, and generation of the orthogonal phase in the bismuth ferrite based nano ceramic is promoted.

Owner:JIANGXI UNIV OF TECH

High-effective-magnetic-permeability cobalt-nickel based microcrystalline magnetic material and preparation method thereof

InactiveCN102832006ALow coercivityHigh saturation magnetic inductionMagnetic materialsCobaltNickel based

The invention provides a high-effective-magnetic-permeability cobalt-nickel based microcrystalline magnetic material and a preparation method thereof. The material reduces the cobalt content under the condition of guaranteeing better soft magnetic properties. The preparation method is simple in process, low in production cost and suitable for industrial production. The material comprises the following components in percentage by weight: 18-22% of Fe, 30-35% of Ni, 4-7% of Gd, 0.01-0.05% of Ho, 0.1-0.5% of V, 0.01-0.05% of Ru, 6-9% of Al, 1-3% of P1, and the balance of Co.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

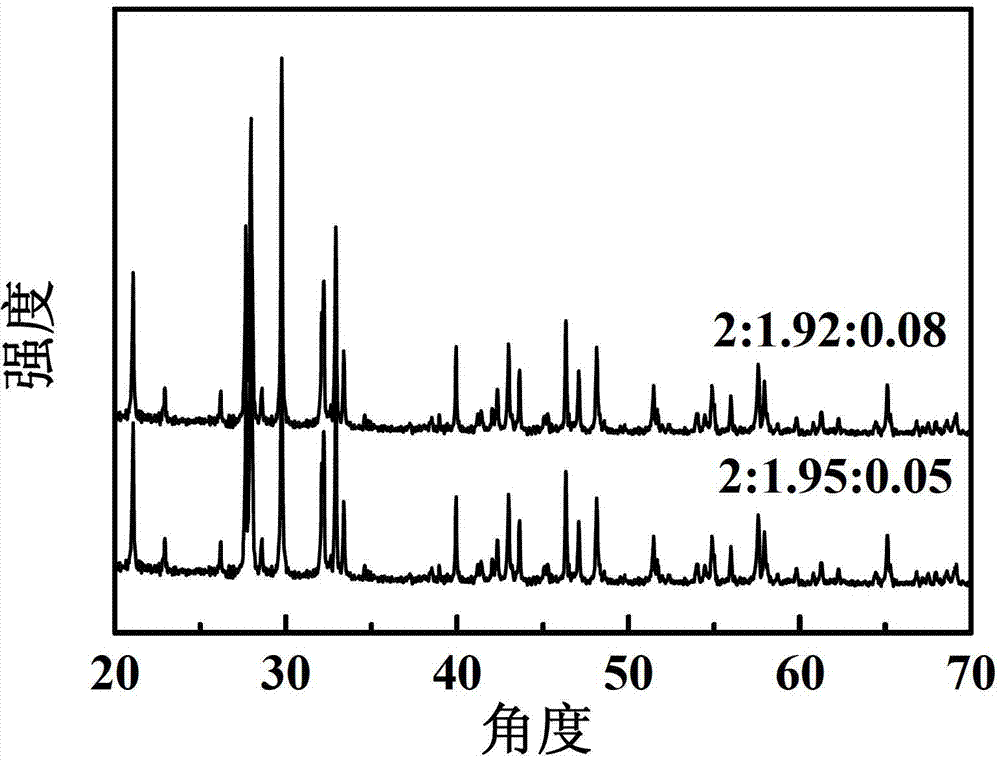

La2Ti2O7:Mn<4+> multiferroic ceramic and preparation method thereof

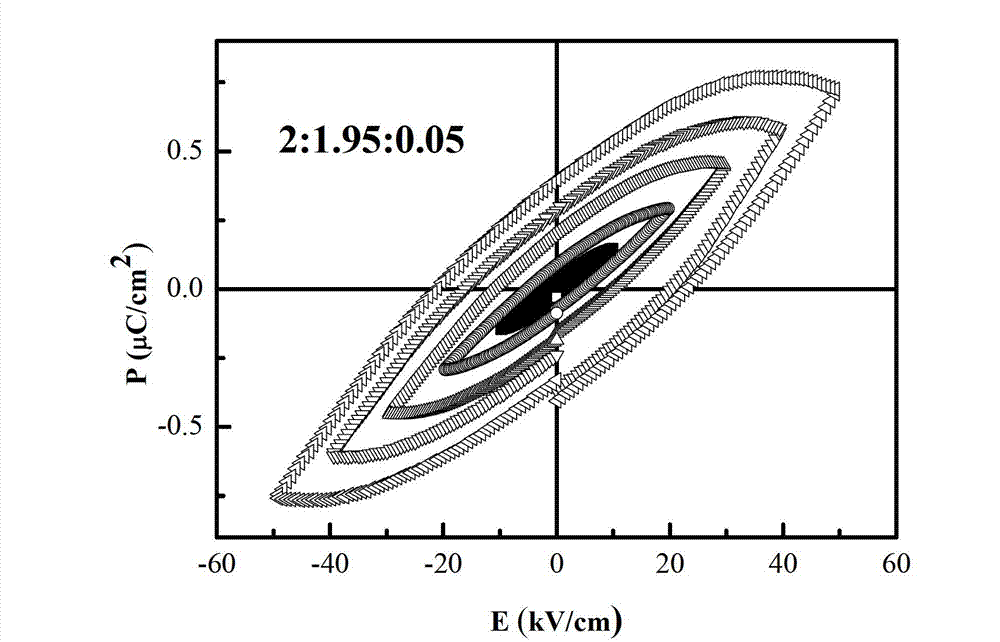

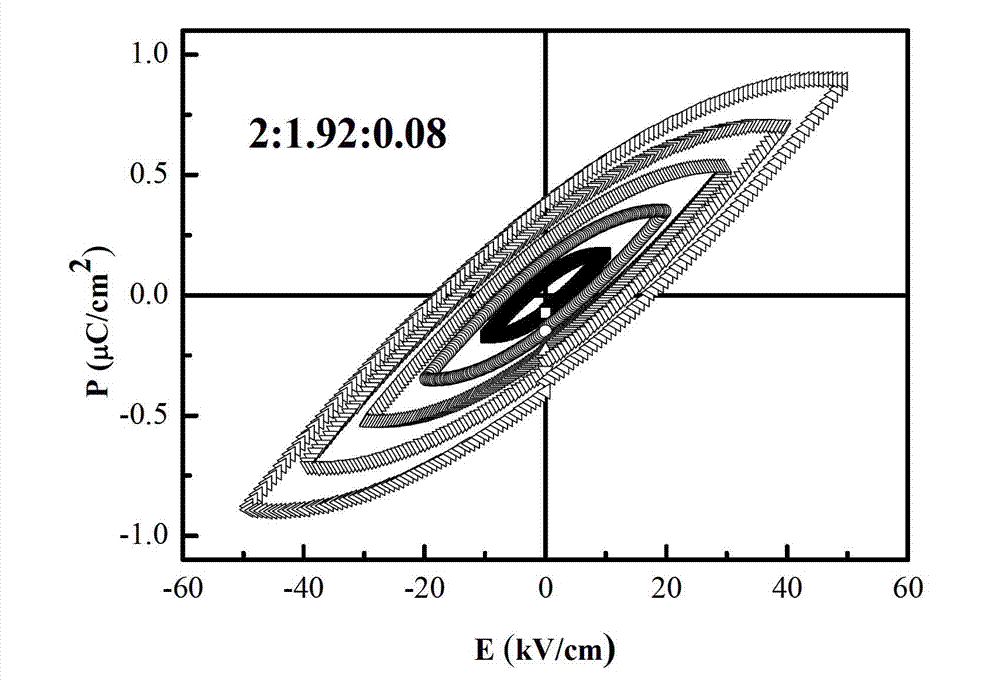

The invention relates to a preparation method of La2Ti2O7:Mn<4+> multiferroic ceramic, which comprises the following steps: (1) preparing high-purity La2O3, TiO2 and MnO2 according to a lanthanum-titanium-manganese mol ratio of 2:1.95:0.05 or 2:1.92:0.08; (2) adding anhydrous ethanol into the prepared materials in the step (1), uniformly mixing, and sufficiently performing ball milling; (3) drying the sample subjected to ball milling, further performing ball milling, placing the sufficiently mixed powder in an Al2O3 crucible, and presintering in an air atmosphere; and (4) dissolving the presintered powder with a nitric acid solution, drying the sample, performing ball milling, pressing into discs in a mold, placing the discs in the Al2O3 crucible, and sintering in an air atmosphere to obtain the ceramic. According to the invention, the La2Ti2O7:Mn<4+> ceramic prepared by the method has high purity and does not contain any impurity phase, the room-temperature multiferroic characteristic is greatly improved, and the Curie temperature is very high.

Owner:HUAZHONG UNIV OF SCI & TECH

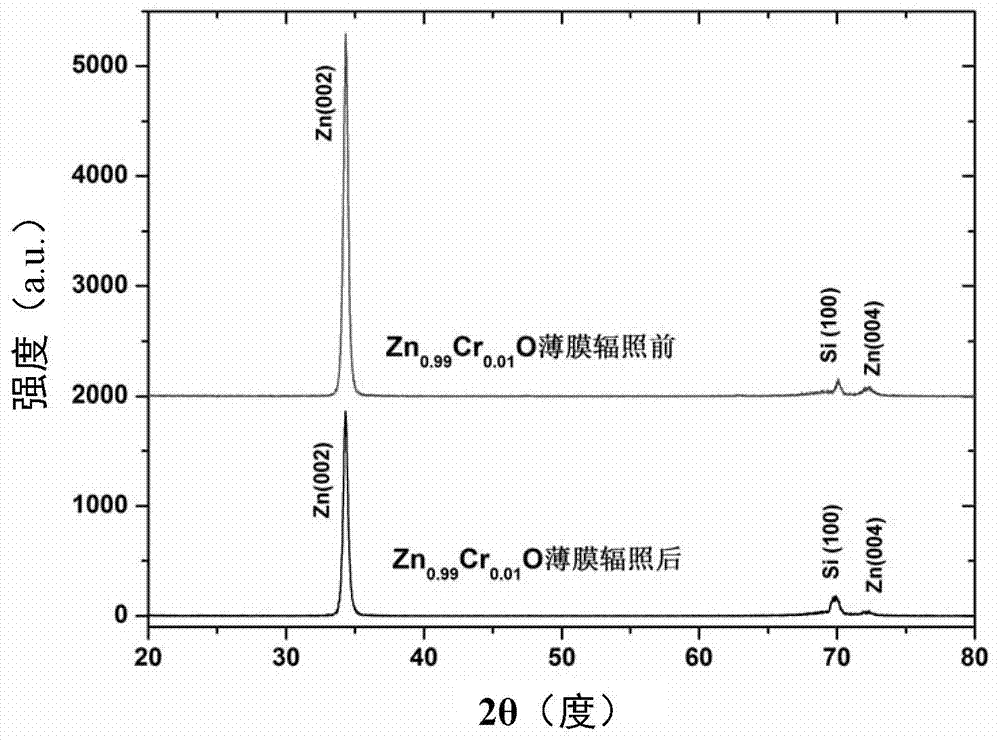

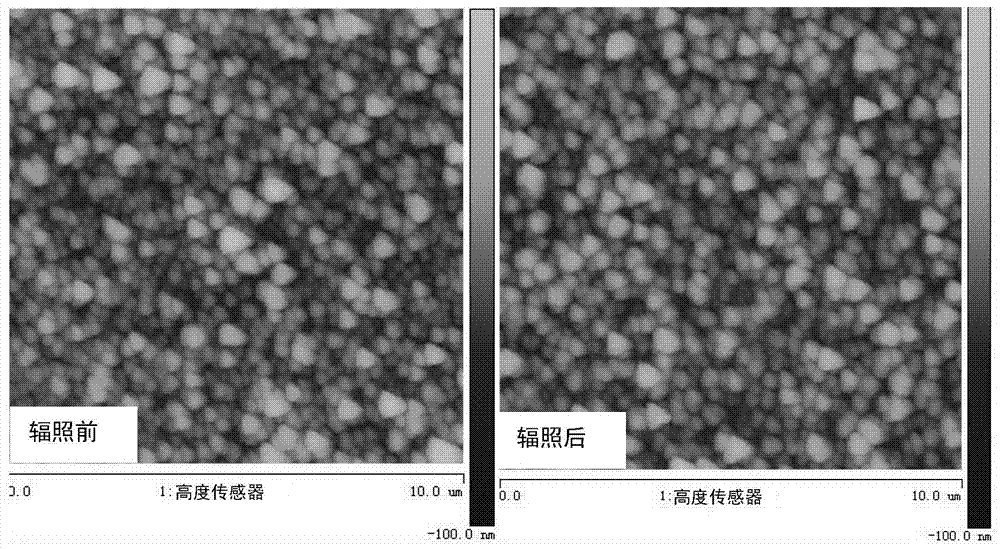

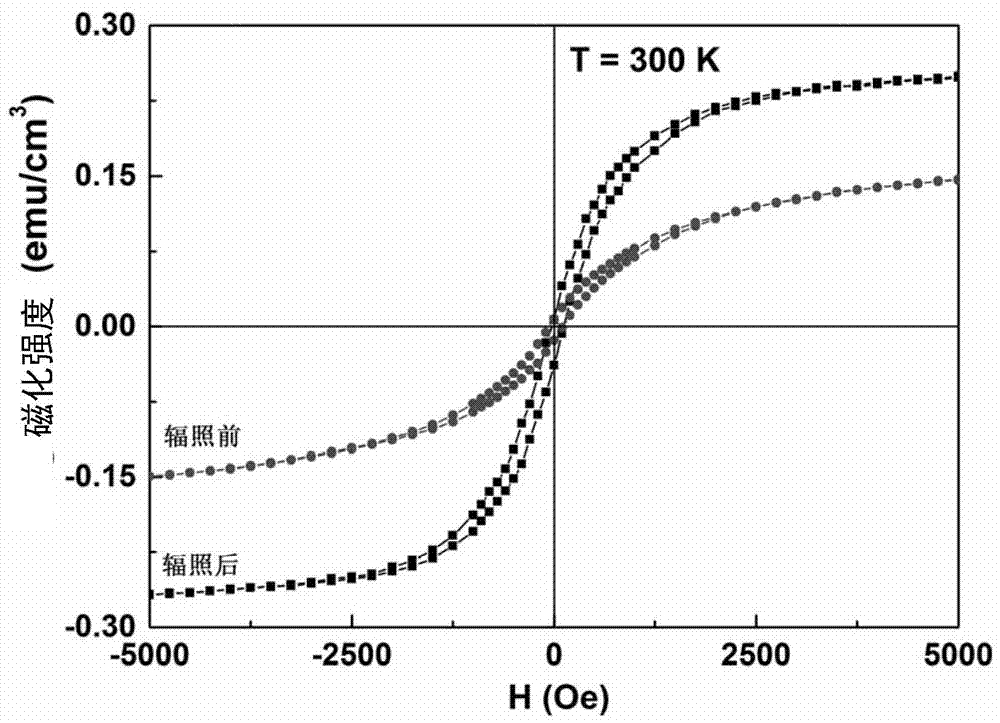

Method for strengthening Cr-doped ZnO thin film ferromagnetism through Ar particle irradiation

InactiveCN106920623AImprove ferromagnetismVacuum evaporation coatingSputtering coatingMagnetic semiconductorCr doped

The invention relates to a method for strengthening Cr-doped ZnO thin film ferromagnetism through Ar particle irradiation. A Cr-doped ZnO thin film is subjected to irradiation by a certain dosage of Ar particles; and the chemical formula of the Cr-doped ZnO thin film is Zn<1-x>Cr<x>O, wherein x is greater than 0 and less than or equal to 0.05. The method is stable and effective, and the ferromagnetism of a ZnO-based diluted magnetic semiconductor thin film can be obviously strengthened without damaging the material, so that development of a spinning electronic device based on a diluted magnetic semiconductor material can be facilitated.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

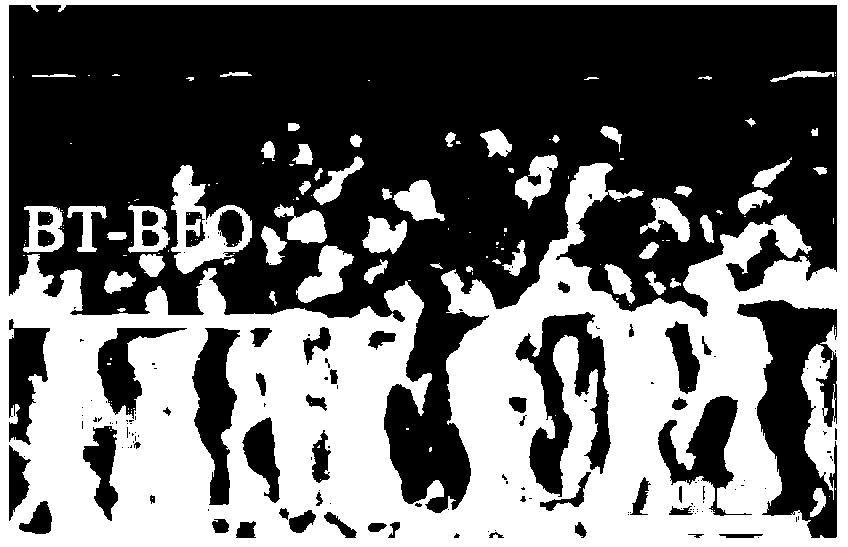

Chemical preparation method of multiferroic BiFeO3 doped film

ActiveCN103130281AIncrease resistanceImprove ferroelectric propertiesIron compoundsMetal layered productsTi dopingPropanoic acid

The invention discloses a chemical preparation method of a multiferroic BiFeO3 doped film. The method comprises the following eight steps of: firstly, preparing a basic solvent by using ethylene glycol monomethyl ether and propionic acid according to the volume ratio of 3:1; secondly, preparing parent-phase BiFeO3 (BFO) sol; thirdly, preparing doping phase BaTiO3 (BTO) sol; fourthly, cleaning and treating a Pt / Ti / SiO2 / Si substrate; fifthly, placing the Pt / Ti / SiO2 / Si substrate on a uniform sol coating machine, spin-coating a layer of BFO sol and drying; sixthly, spin-coating a layer of BTO sol on a wet BFO film and drying; seventhly, repeating the fifth and sixth steps to obtain BFO films with different Ba and Ti doping contents; and eighthly, sputtering platinum poles on the BFO films with different Ba and Ti doping contents. The way that cation salt of a doped element is directly added into a parent-phase solution to form entire sol to be spin-coated to form a film is not adopted; but the way that a dopant phase and a parent are respectively prepared into the sols, the sols are separately spin-coated, and solid solution doping is formed through the mutual movement of ions in the thermal treatment process. The chemical preparation method has a better application prospect in the technical field of new materials.

Owner:BEIHANG UNIV

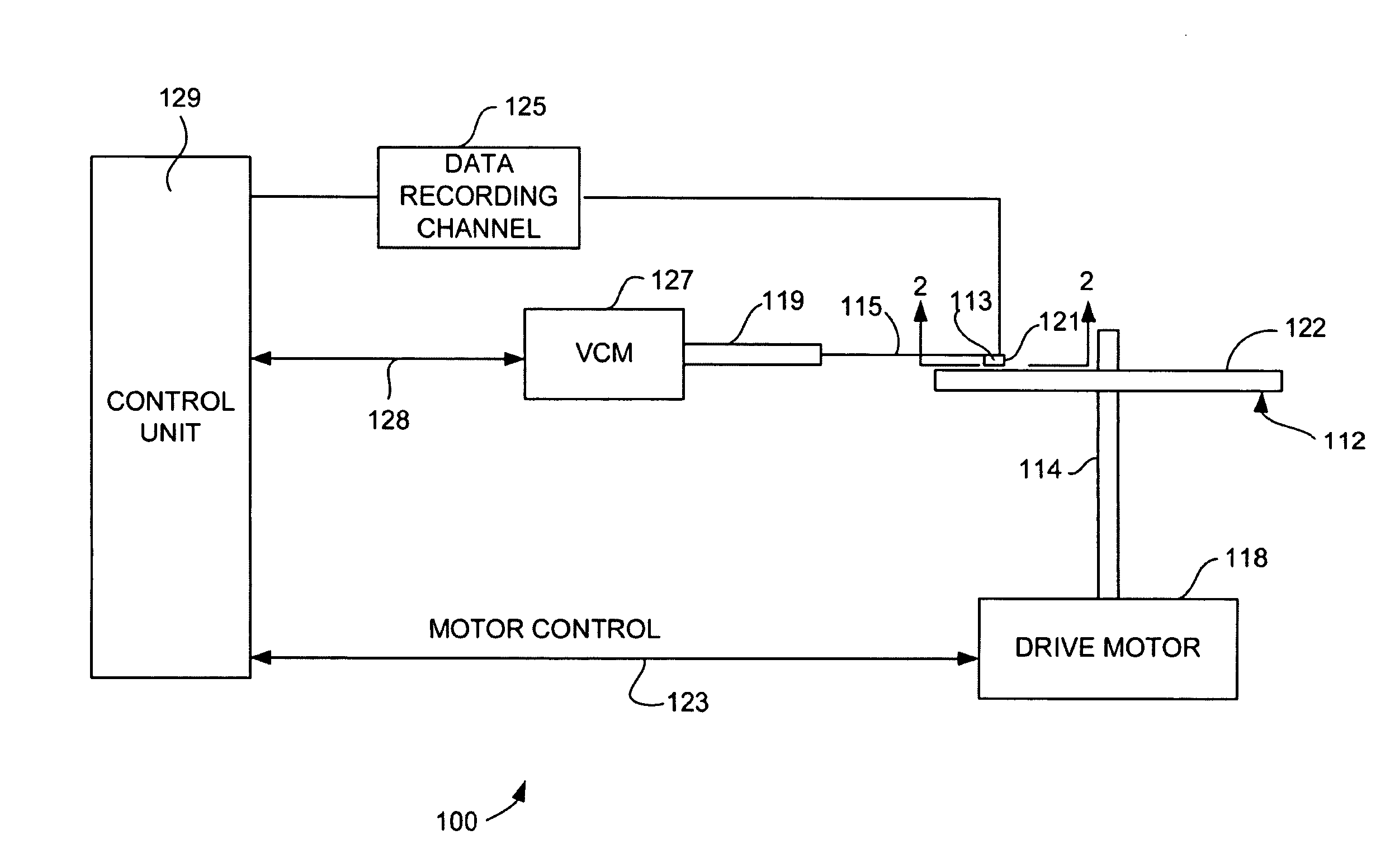

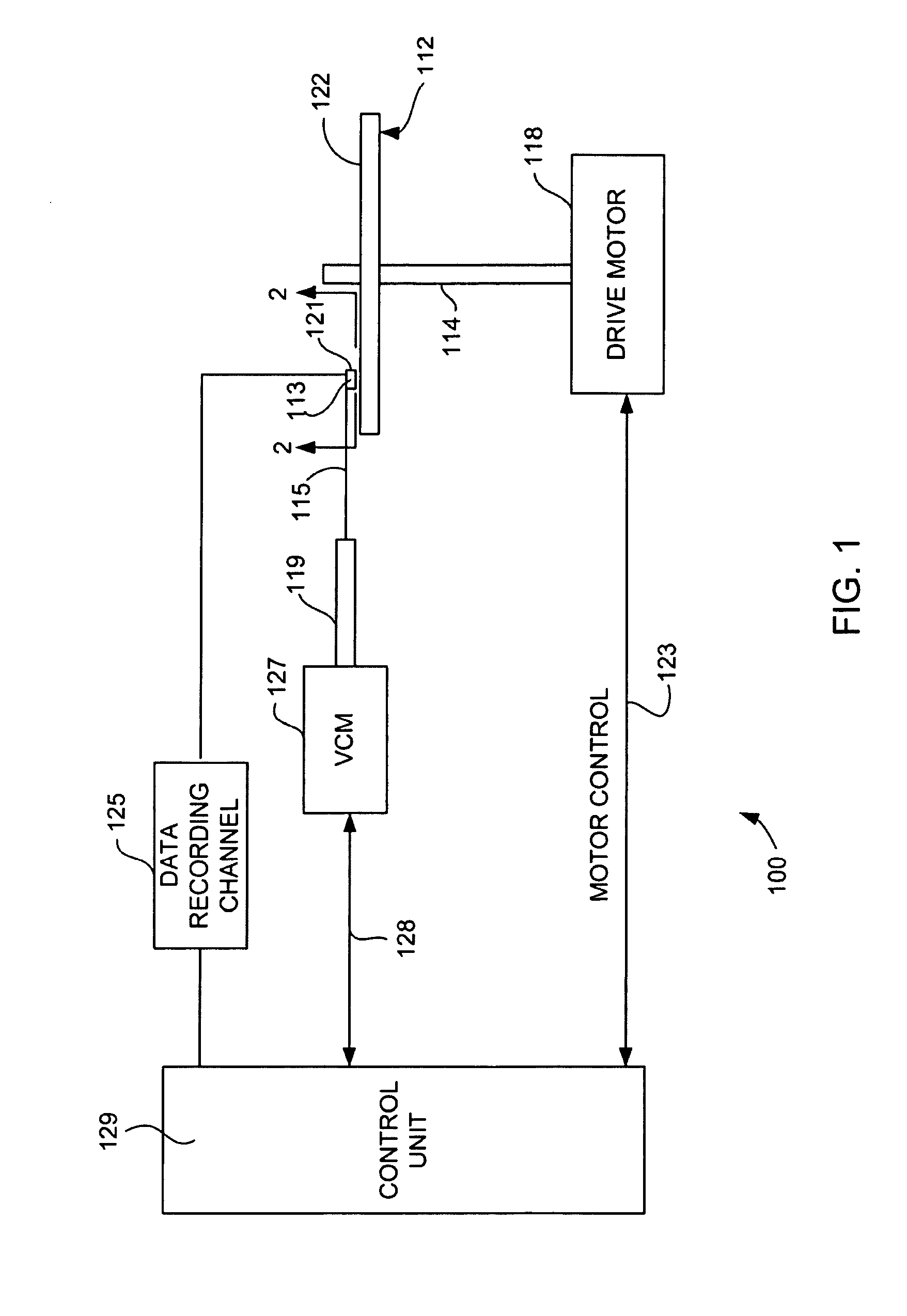

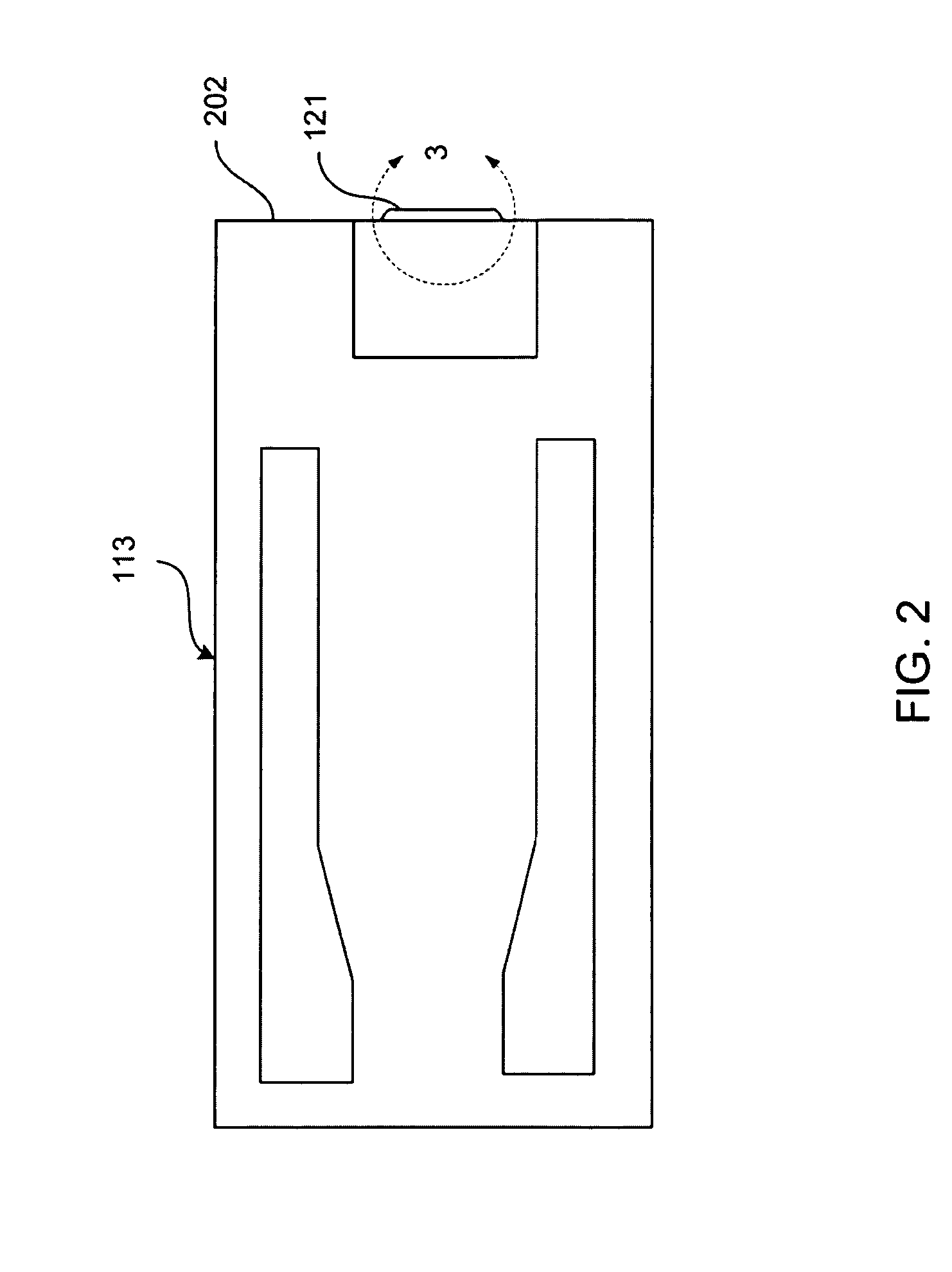

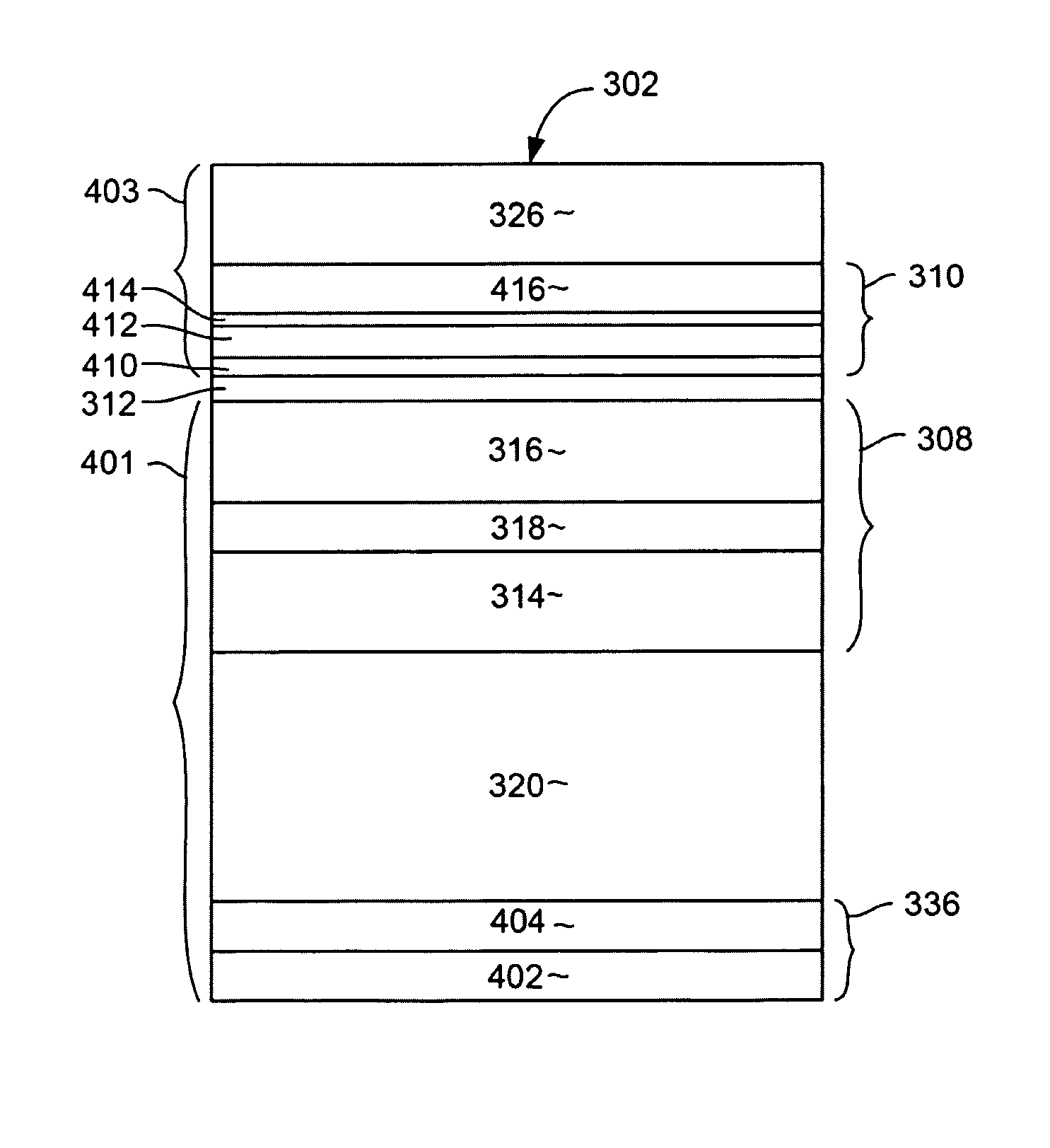

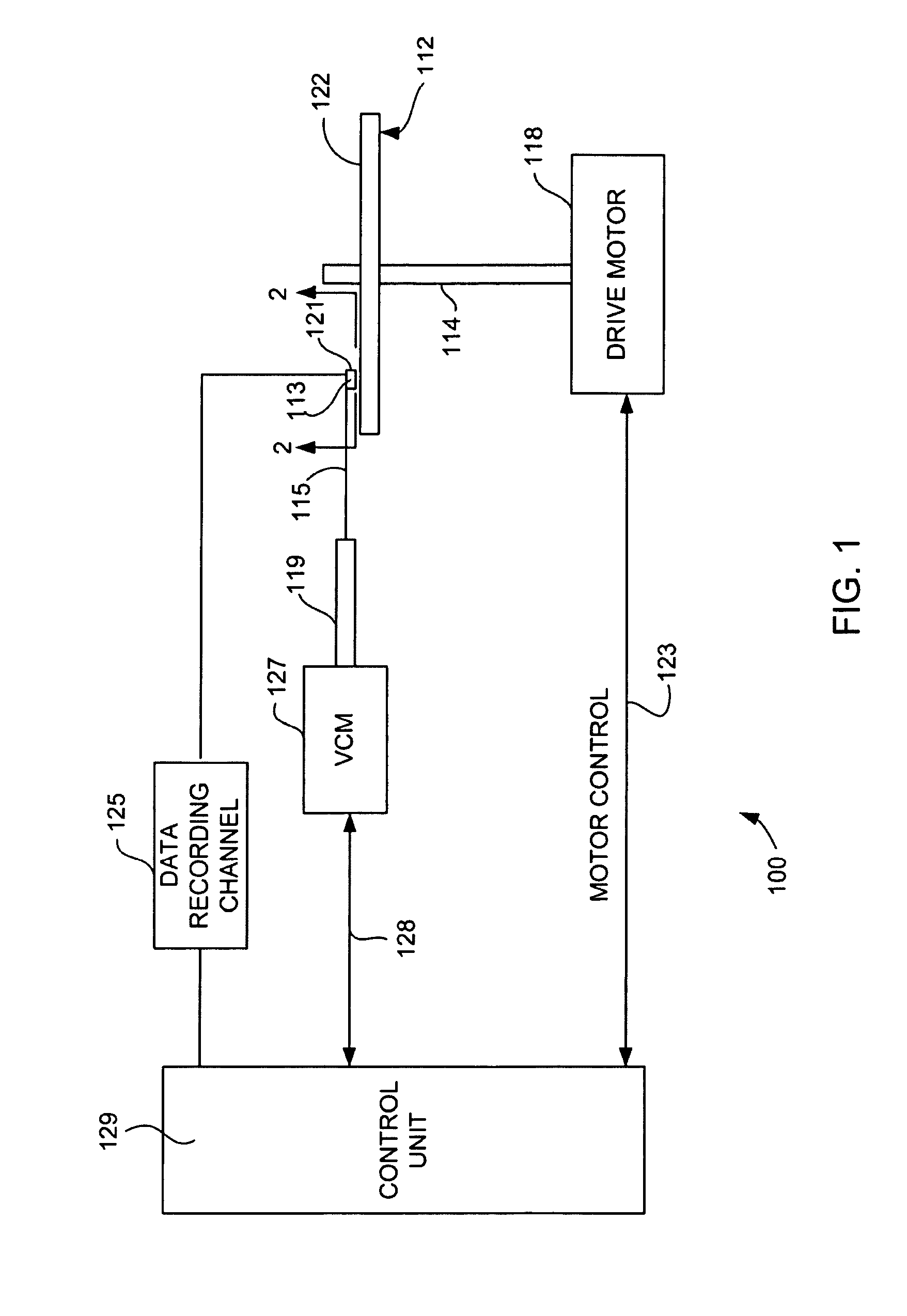

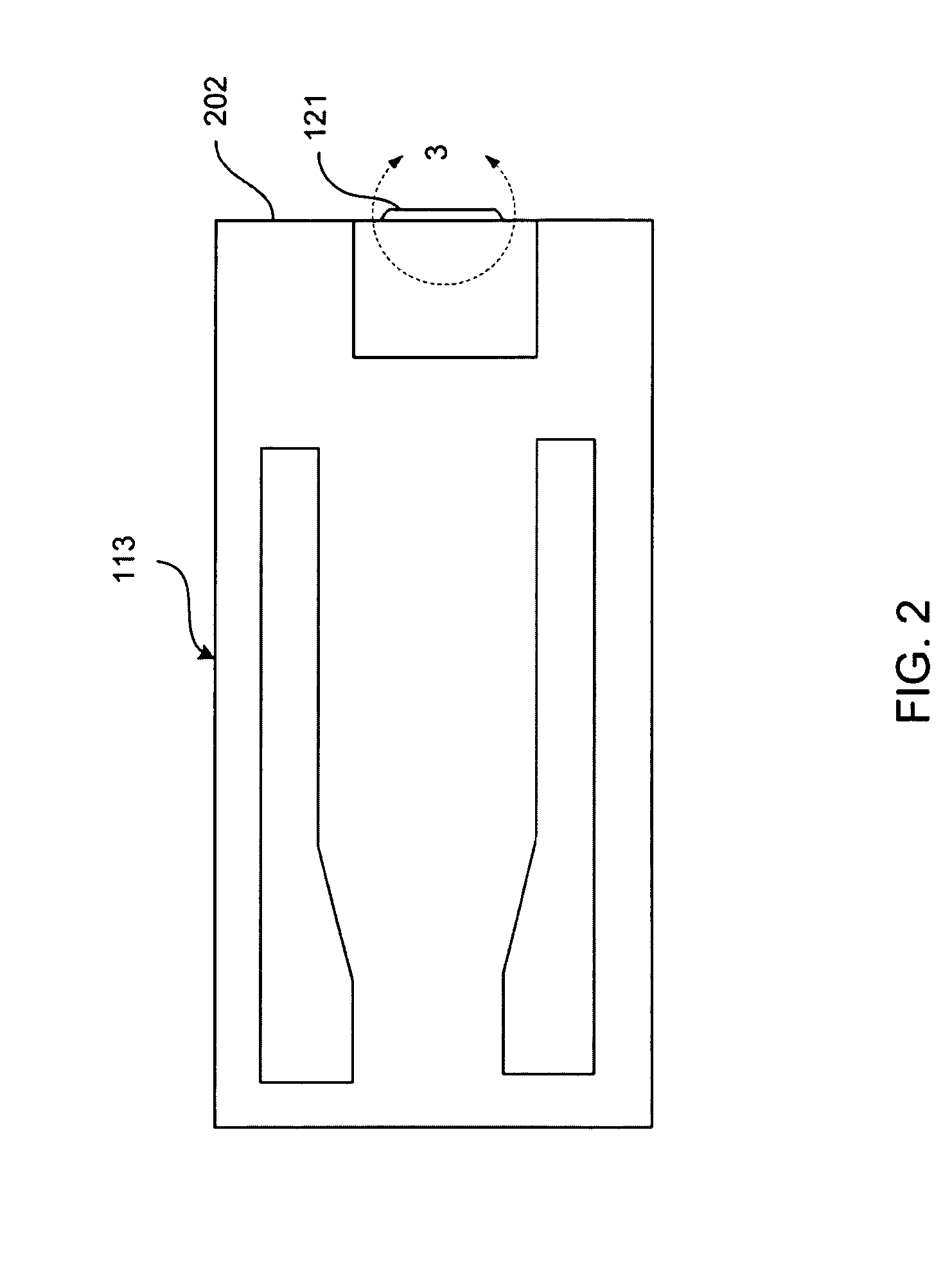

Current-perpendicular-to-plane (CPP) read sensor with multiple ferromagnetic sense layers

ActiveUS20090244791A1Strong effectImprove ferromagnetismNanomagnetismMagnetic measurementsTunnel magnetoresistanceDiffusion barrier

The invention provides a current-perpendicular-to-plane (CPP) tunneling magnetoresistance (TMR) or giant magnetoresistance (GMR) read sensor with multiple ferromagnetic sense layers. In one embodiment of the invention, a CPP TMR read sensor comprises a first sense layer formed by a ferromagnetic polycrystalline Co—Fe film, a second sense layer formed by a ferromagnetic interstitial-type amorphous Co—Fe— B film, a third sense layer formed by a ferromagnetic substitute-type amorphous Co—Fe—X film where X is Hf, Zr or Y, and a fourth sense layer formed by a ferromagnetic Ni—Fe film. The third sense layer acts as a diffusion barrier layer to suppress Ni diffusion, thus allowing the incorporation of the Ni—Fe fourth sense layer for improving ferromagnetic properties of the multiple sense layers. The multiple sense layers induce spin-dependent scattering, thus facilitating the CPP TMR read sensor to exhibit a strong TMR effect.

Owner:WESTERN DIGITAL TECH INC

Ni-Ni2O3 nano composite material and preparation

ActiveCN103990795AImprove utilization efficiencyPromote degradationInorganic material magnetismNanotechnologyNanowirePhoto catalysis

The invention relates to a Ni-Ni2O3 nano composite material, in particular to a ferro-magnetic Ni-Ni2O3 nano composite material and a method for hydrothermal one-step synthesis of the Ni-Ni2O3 nano composite material. Ni is in a nanowire form, and Ni2O3 is in a particle shape. Due to the joint effect of the Ni and the Ni2O3, the optical performance, the photocatalysis performance, the magnetic performance and the other performances of the Ni-Ni2O3 nano composite material are greatly improved.

Owner:NANKAI UNIV

Process for producing Mn doping SnO2 room temperature diluted magnetic semiconductor nano-powder

The invention relates to a preparation method for nano-powder of room temperature dilute magnetic semiconductor of Mn dozed SnO2, which is produced by adopting chemical precipitation method. The preparation method comprises that: A. Mixed solution of stannous chloride and manganese acetate and anhydrous ethyl alcohol solution of ammonium hydrogencarbonate are prepared first; B. under the condition of ultrasonic vibration and water bath, the mixed solution of stannous chloride and manganese acetate and anhydrous ethyl alcohol solution of ammonium hydrogencarbonate are mixed; C. the obtained solution is aged, deposited, filtrated and washed by deionized water for many times until the pH value of the solution is 7, to get settlement dried in a drying oven and ground to obtain primary powder; D. anneal treatment is carried out to the primary powder in the air; therefore, the nano-powder of room temperature dilute magnetic semiconductor of Mn dozed SnO2 is obtained. The invention can prepare room temperature ferromagnetism and Mn dosed SnO2 nano powder in the condition of low temperature.

Owner:HUAZHONG UNIV OF SCI & TECH

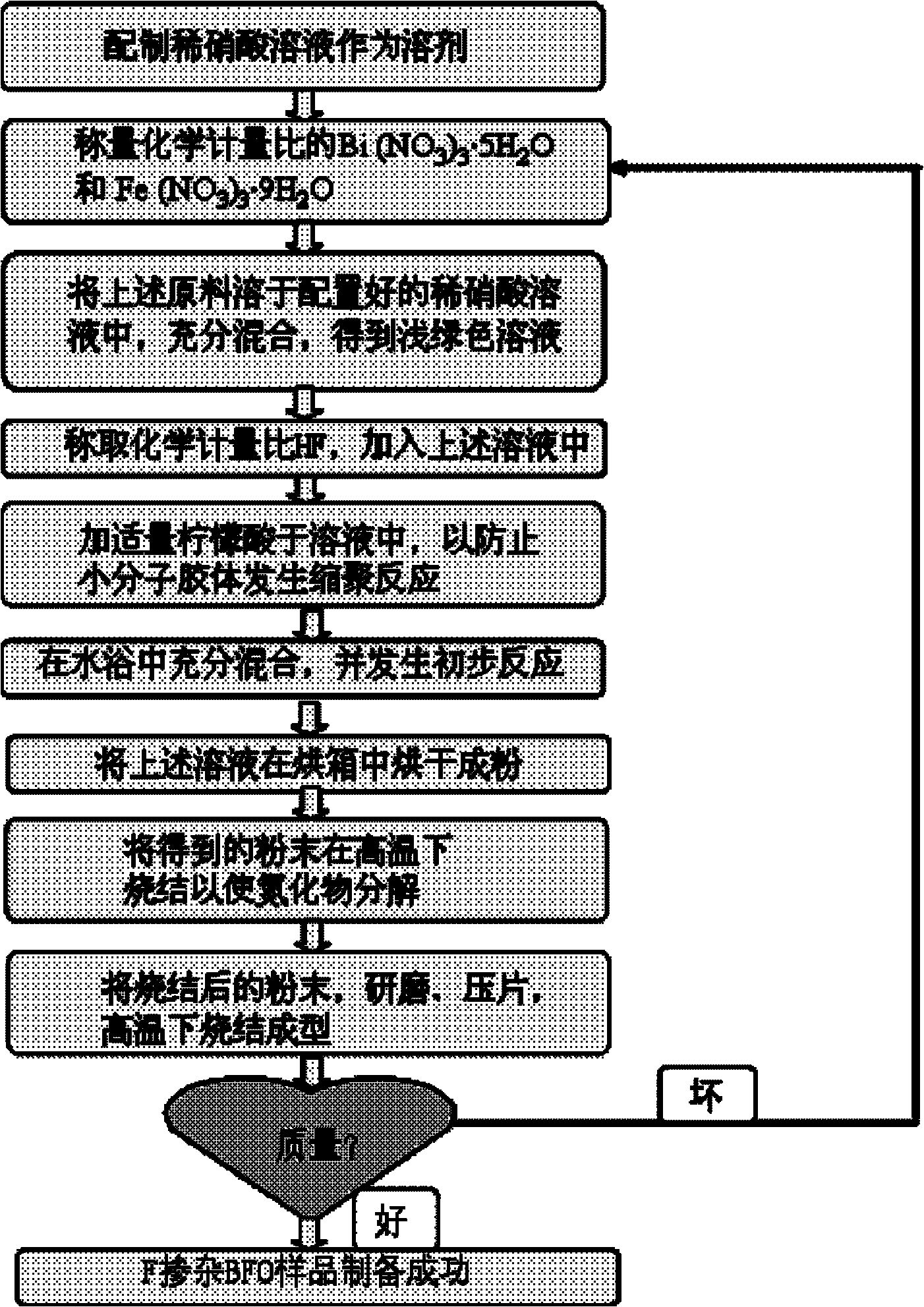

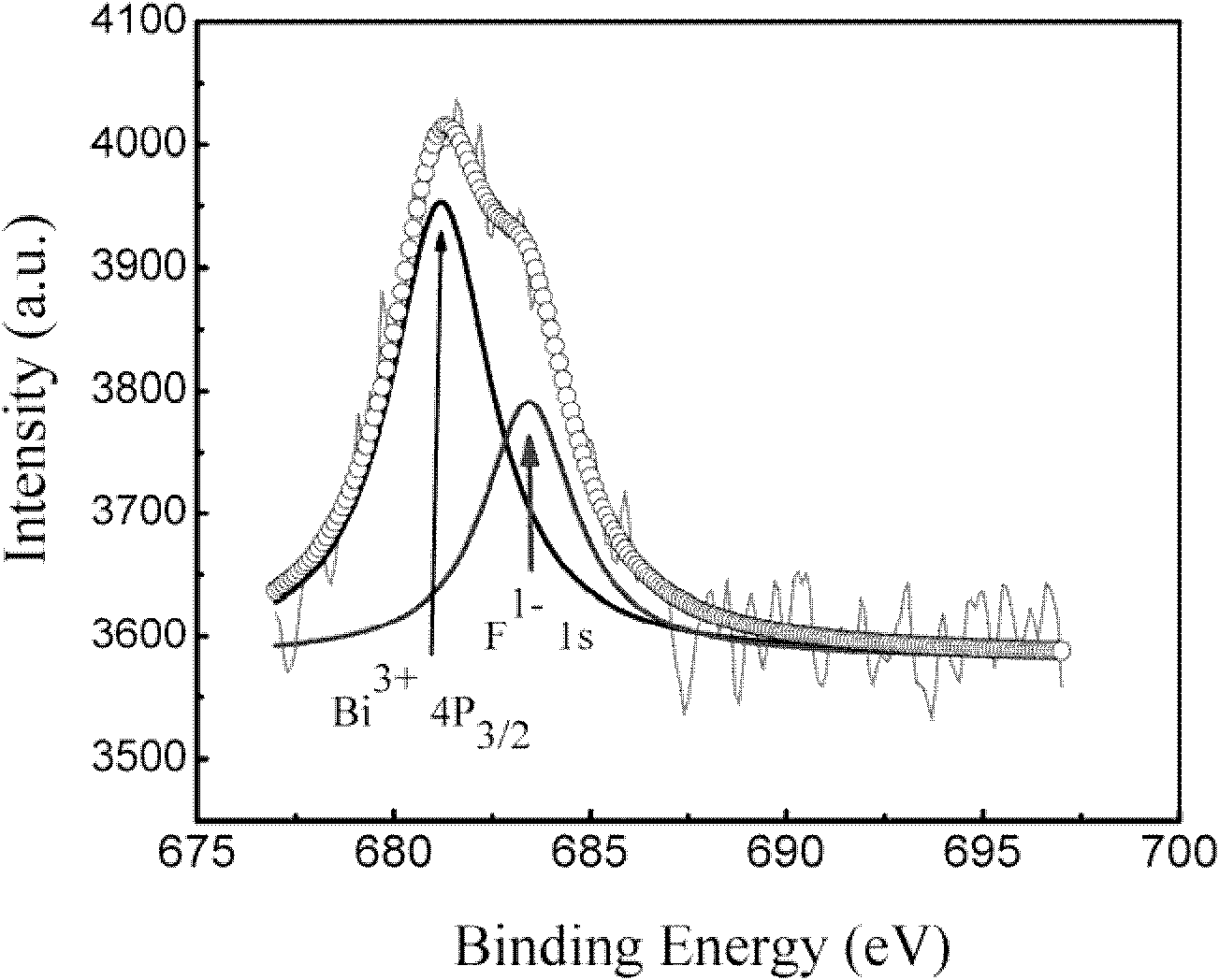

Preparation method for substituting fluorine for oxygen in bismuth ferrite crystal lattices

InactiveCN102320666AImprove ferromagnetismFerroelectricNanotechnologyIron compoundsWater bathsSolvent

The invention discloses a preparation method for substituting fluorine for oxygen in bismuth ferrite crystal lattices. The method comprises the following steps of: 1, selecting a utensil made of anticorrosive material as a container, selecting diluted acid as a solvent, weighing nitride of Bi and nitride of Fe in a stoichiometric ratio, adding the nitrides into the solvent in a molar ratio of 1:1, preparing a proper amount of fluorine-containing salt, and adding citric acid into the solution; 2, performing initial reaction on the prepared solution in a water bath for (2.5+ / -0.5) hours with uniform stirring, and drying the reaction product in an oven to obtain powder; and 3, performing decomposition reaction on the obtained powder at the high temperature of 780+ / -15 DEG C for 30+ / -3 minutes, removing impurities, sheeting the decomposed powder, sintering the powder at the high temperature of 810+ / -15 DEG C for 10+ / -2 minutes, and thus obtaining a sample in which F-1 effectively enters BFO crystal lattices. The sample in which the fluorine effectively enters the bismuth ferrite crystal lattices and substitutes the oxygen has ferro-electricity and ferromagnetism, and the other path isprovided for realizing the development of multifunctional electronic devices.

Owner:NANJING UNIV

Current-perpendicular-to-plane (CPP) read sensor with multiple ferromagnetic sense layers

ActiveUS8164863B2Improve ferromagnetismGood effectNanomagnetismMagnetic measurementsGiant magnetoresistancePower flow

The invention provides a current-perpendicular-to-plane (CPP) tunneling magnetoresistance (TMR) or giant magnetoresistance (GMR) read sensor with multiple ferromagnetic sense layers. In one embodiment of the invention, a CPP TMR read sensor comprises a first sense layer formed by a ferromagnetic polycrystalline Co—Fe film, a second sense layer formed by a ferromagnetic interstitial-type amorphous Co—Fe—B film, a third sense layer formed by a ferromagnetic substitute-type amorphous Co—Fe—X film where X is Hf, Zr or Y, and a fourth sense layer formed by a ferromagnetic Ni—Fe film. The third sense layer acts as a diffusion barrier layer to suppress Ni diffusion, thus allowing the incorporation of the Ni—Fe fourth sense layer for improving ferromagnetic properties of the multiple sense layers. The multiple sense layers induce spin-dependent scattering, thus facilitating the CPP TMR read sensor to exhibit a strong TMR effect.

Owner:WESTERN DIGITAL TECH INC

Titanium-iron-gadolinium cobaltate-bismuth ceramic material in layer structure and preparation method of titanium-iron-gadolinium cobaltate-bismuth ceramic material

InactiveCN102863211AImprove ferroelectric propertiesImprove ferromagnetic propertiesOxide ceramicsOctahedron

The invention provides a titanium-iron-gadolinium cobaltate-bismuth ceramic material in a layer structure. Gadolinium ions substitute for part of bismuth ions, and cobalt ions substitute for part of iron ions so that Bi7-xGdxFe1.5Co1.5Ti3O21 layered Aurivillius type multiferroic oxide ceramics are obtained. The titanium-iron-gadolinium cobaltate-bismuth ceramic material has the advantages that on one hand, an iron atomic structure and a cobalt atomic structure are approximate, and after part of the cobalt ions substitutes for part of iron ions in position, Fe-O octahedrons and Co-O octahedrons are arrayed in order, and Fe-O-Co coupling can be generated partially, so that ferroelectricity and ferromagnetism of the ceramic material can be improved; and on the other hand, since the gadolinium ions partially having magnetism substitute for part of bismuth ions, leakage current is effectively reduced while ferroelectricity of the ceramic material is enhanced, and partially existing coupling of Gd-O-Co / Fe enables the ferromagnetism of the ceramic material to be improved.

Owner:UNIV OF SCI & TECH OF CHINA

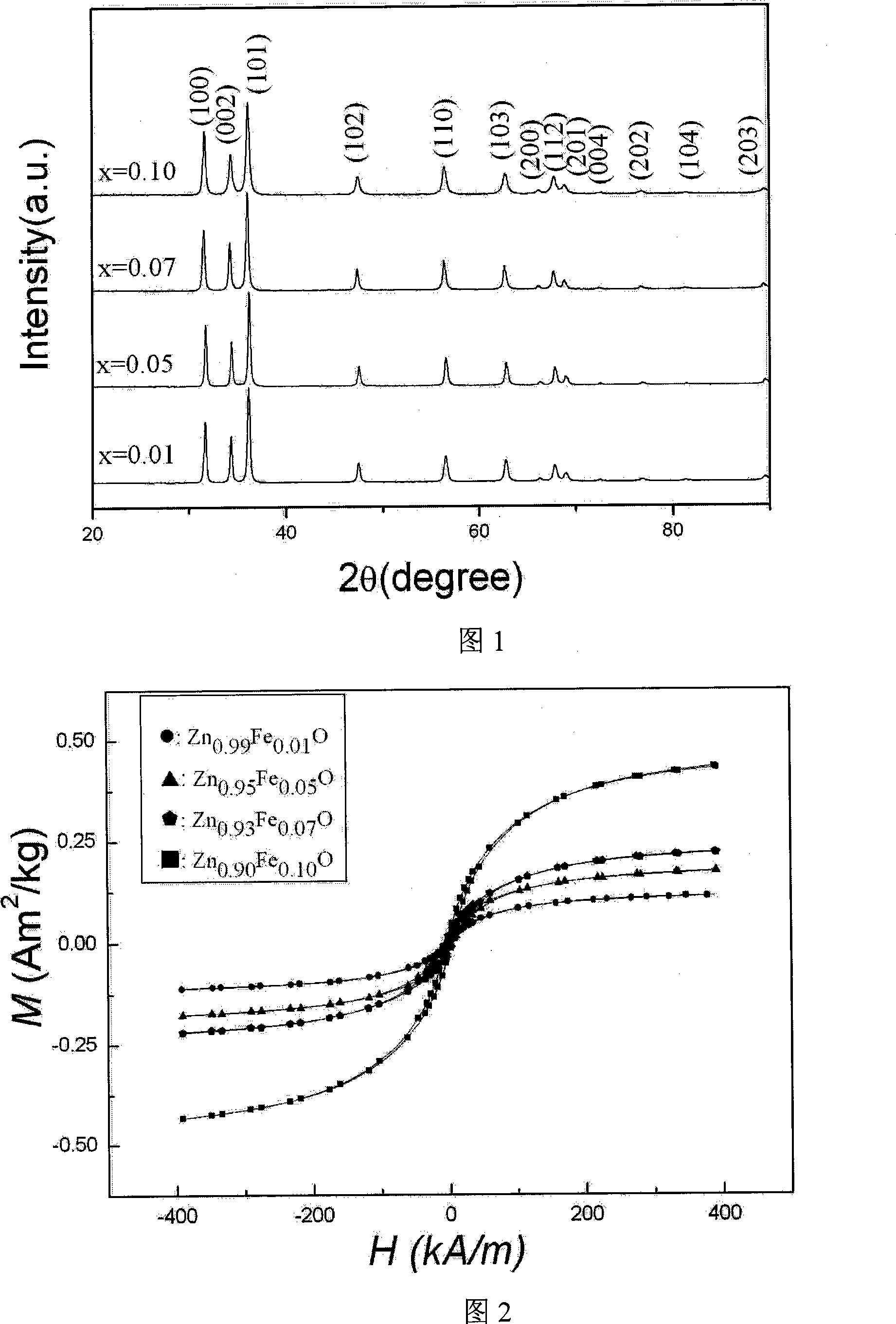

Method of producing zinc oxide Fe-doped rare magnetic semiconductor material

InactiveCN101183607AEasy to getSimple technologyZinc oxides/hydroxidesSemiconductor/solid-state device manufacturingAntioxidantHYDROSOL

The invention discloses a preparation method of the diluted magnetic semiconductor material of iron-doped zinc oxide, which adopts the technical proposal that zinc acetate and iron acetate are adopted as the precursor which is dissolved in ethylene glycol monomethyl ether with ethanolamine as a stabilizer and ascorbic acid as an antioxidant added into the solution, all of which are stirred to form a sol; after the processing of drying and heating, the diluted magnetic semiconductor material dust can be obtained from the sol, or the diluted magnetic semiconductor material film can be obtained by adding the sol in drops on a substrate and by a spin coating method. In the invention, ascorbic acid plays a key role during the sample preparation, which can protect significantly Fe <2+> ions from being oxidized in air environment and allow the ions to get into the ZnO lattices more easily to complete disordered substitution and increase the Fe doping content to 10% which is higher significantly than the most doping concentration 7% in traditional solution-sol preparation process. The sample keeps a single ZnO wurtzite structure and presents obvious room-temperature ferromagnetism.

Owner:ZHEJIANG UNIV +1

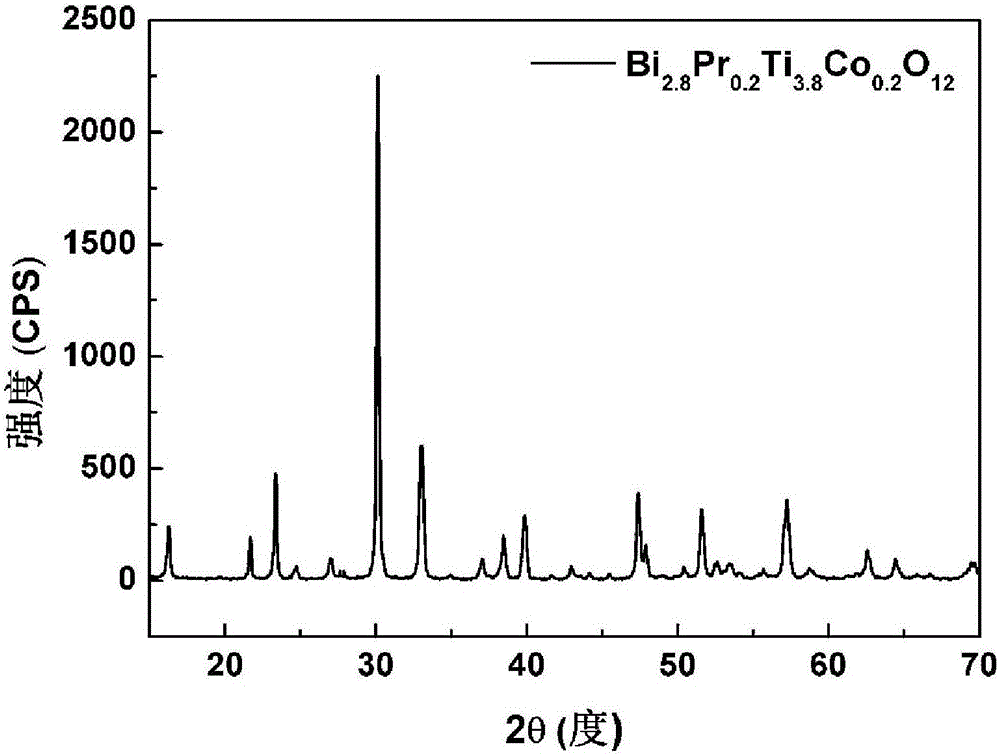

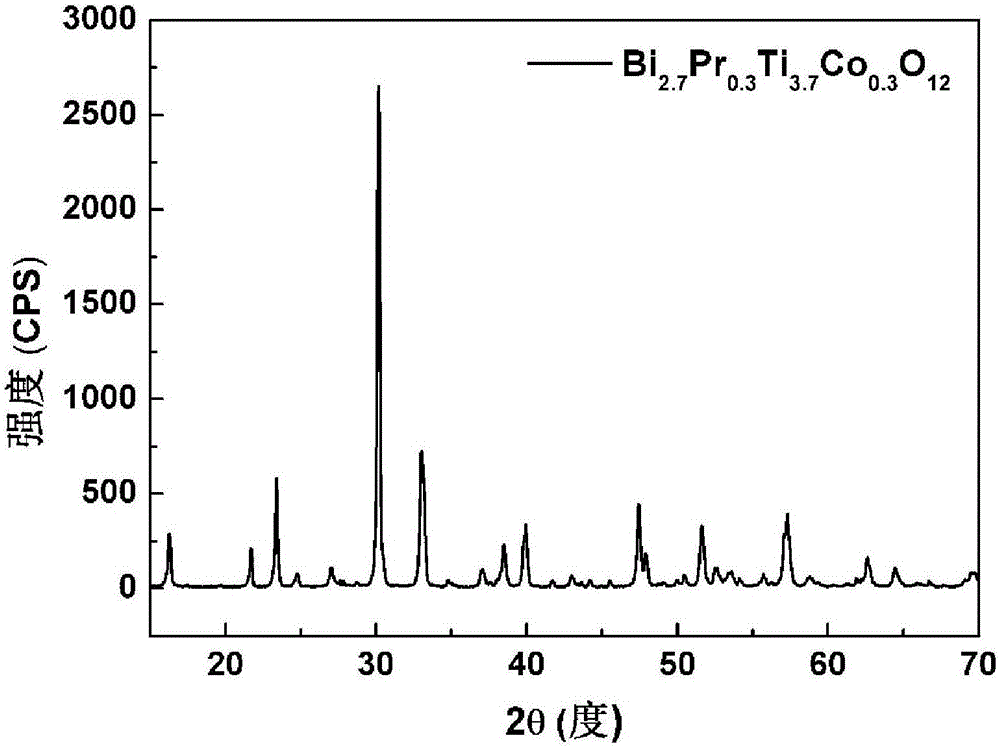

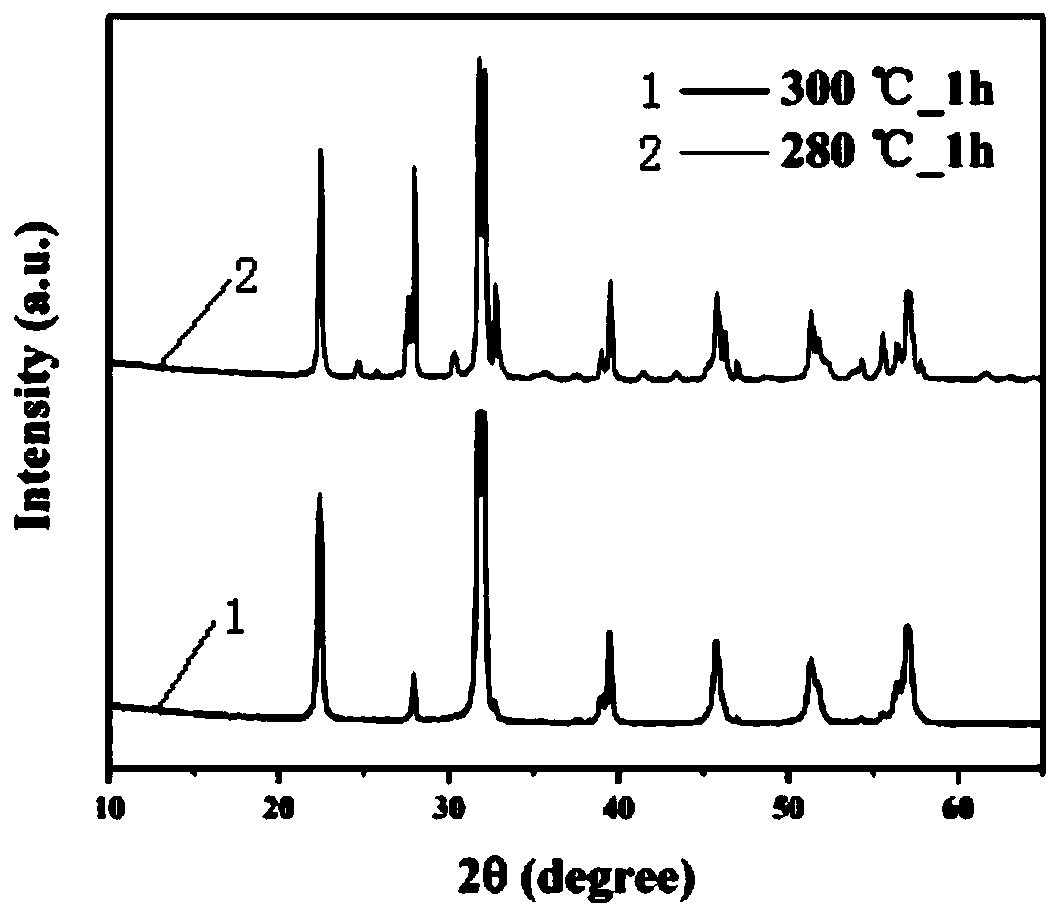

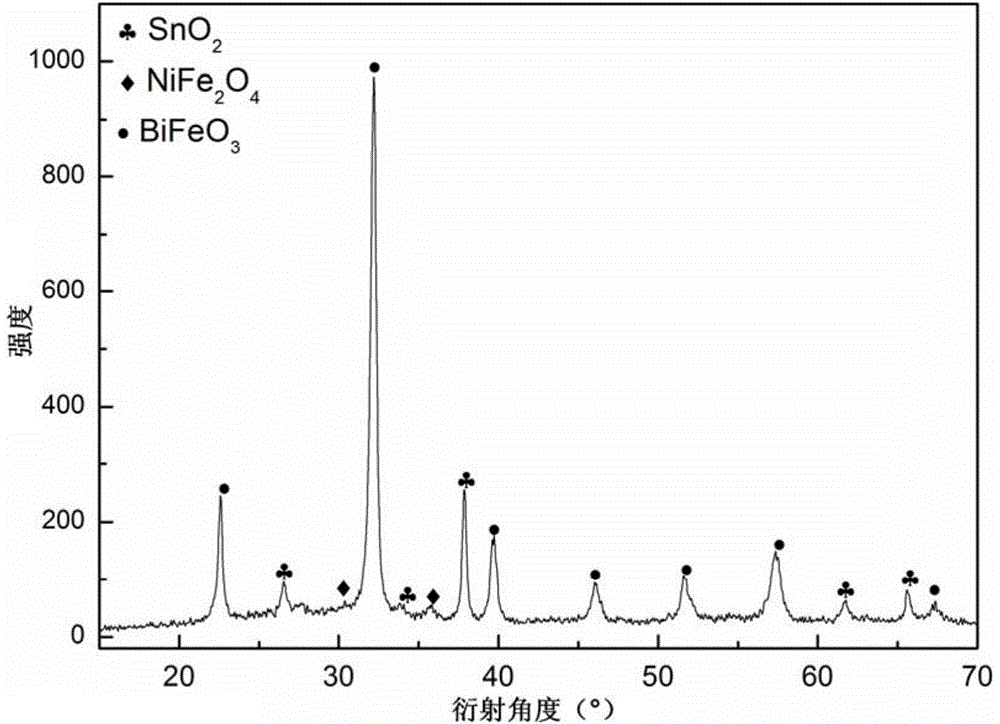

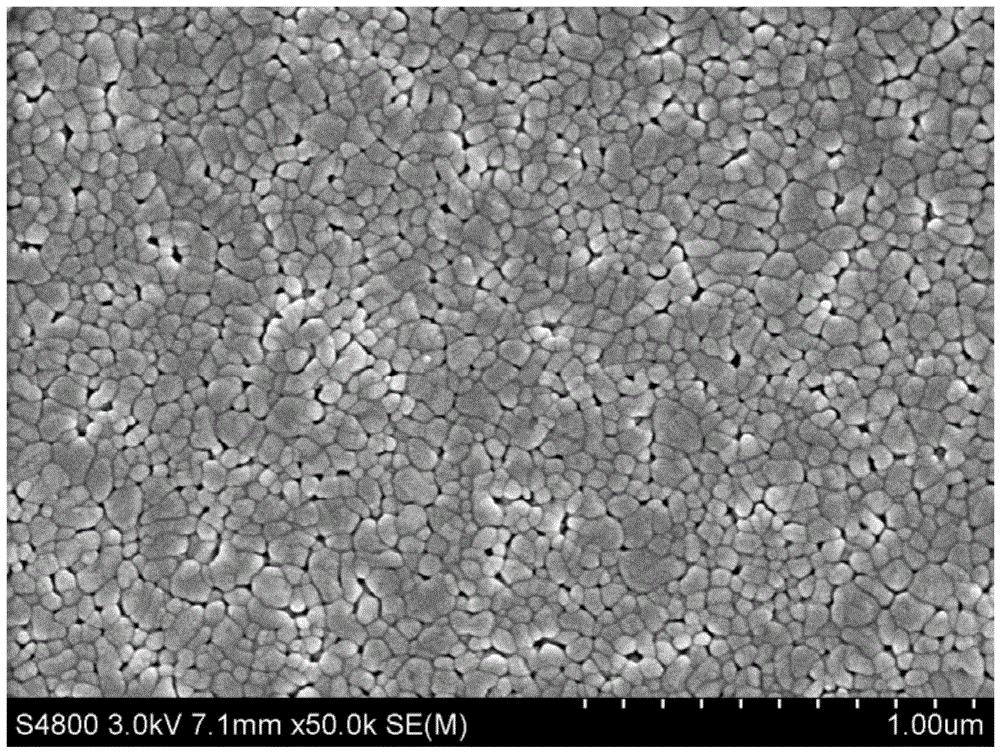

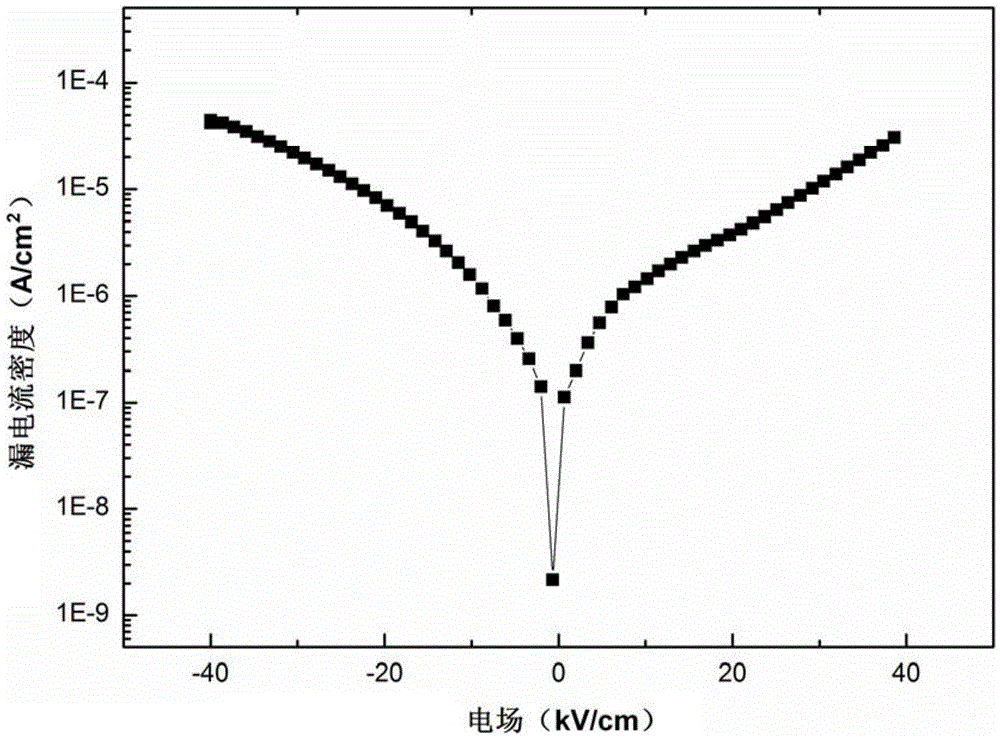

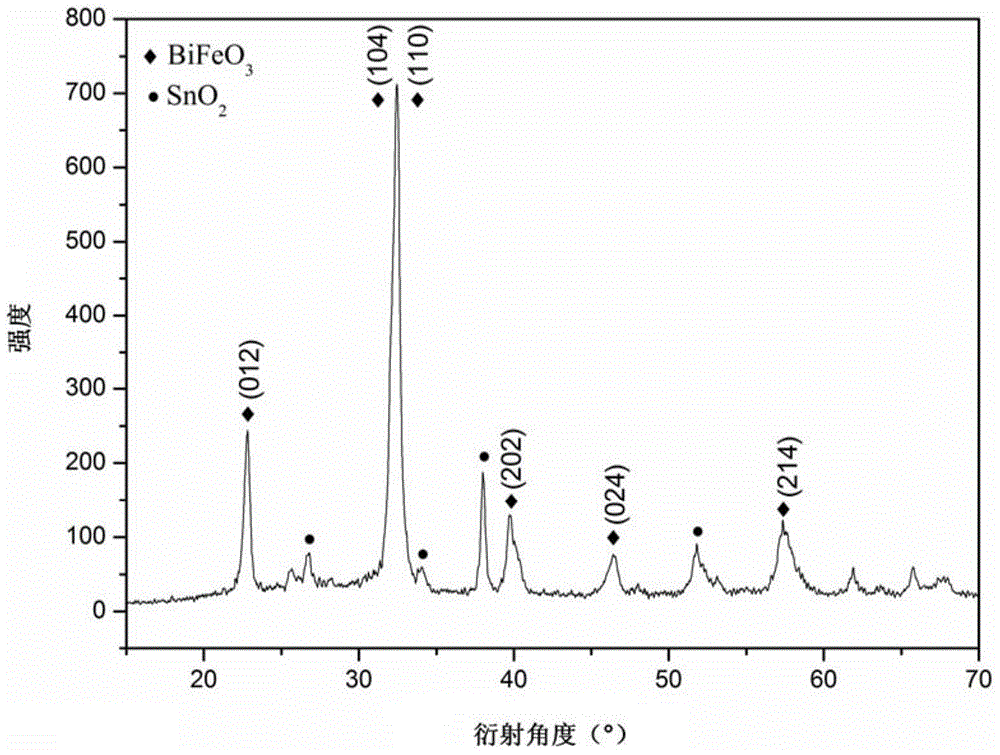

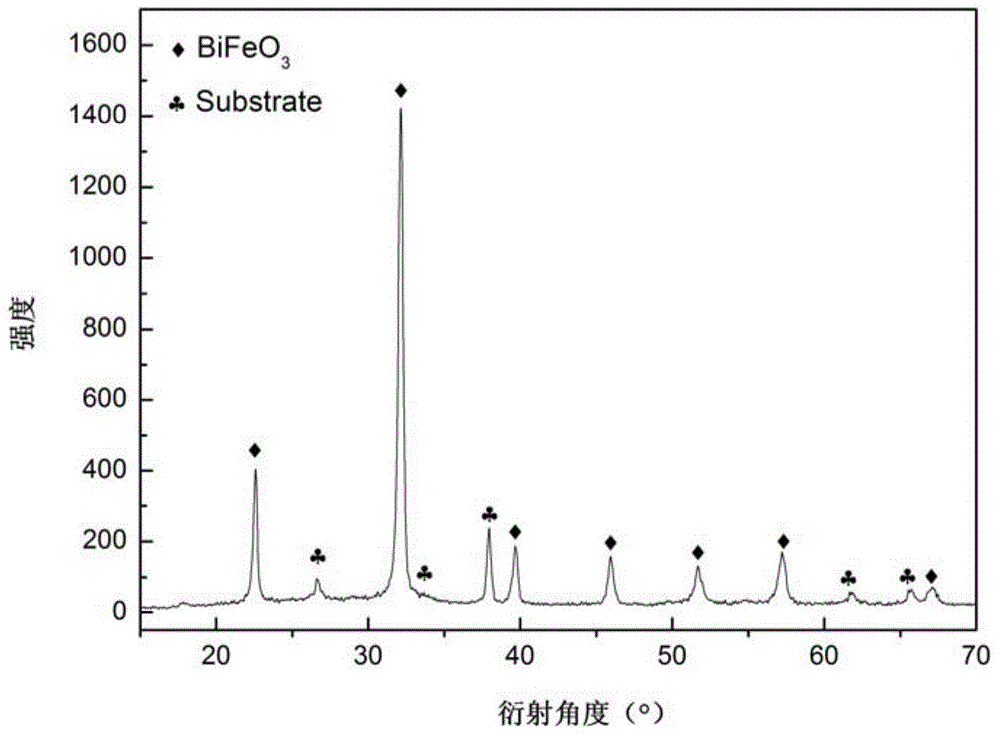

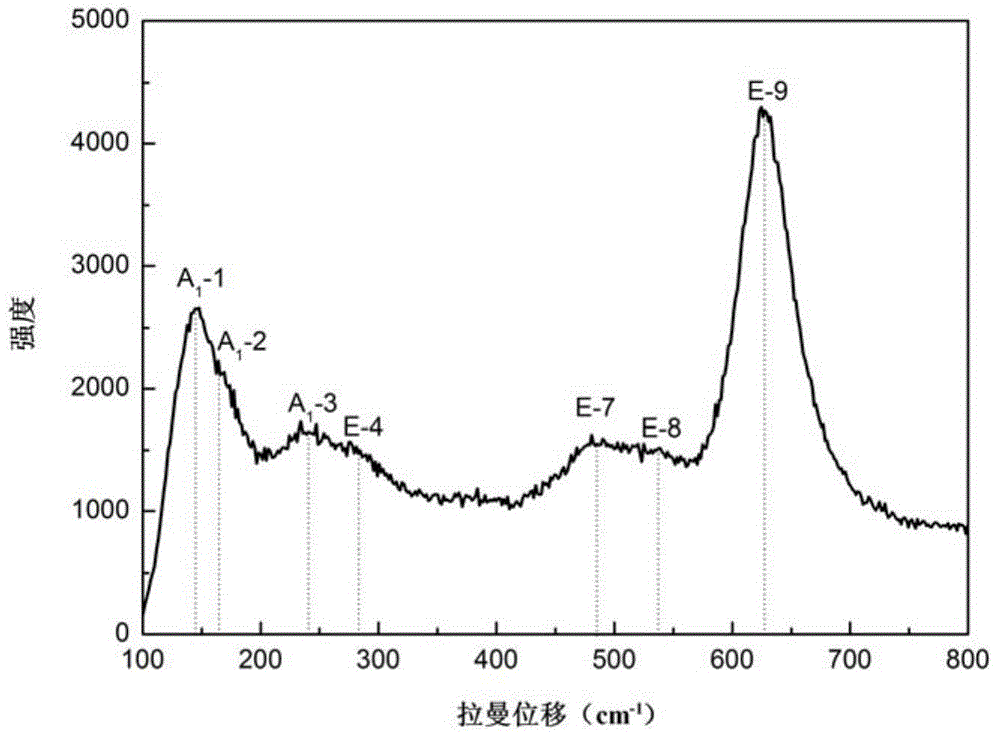

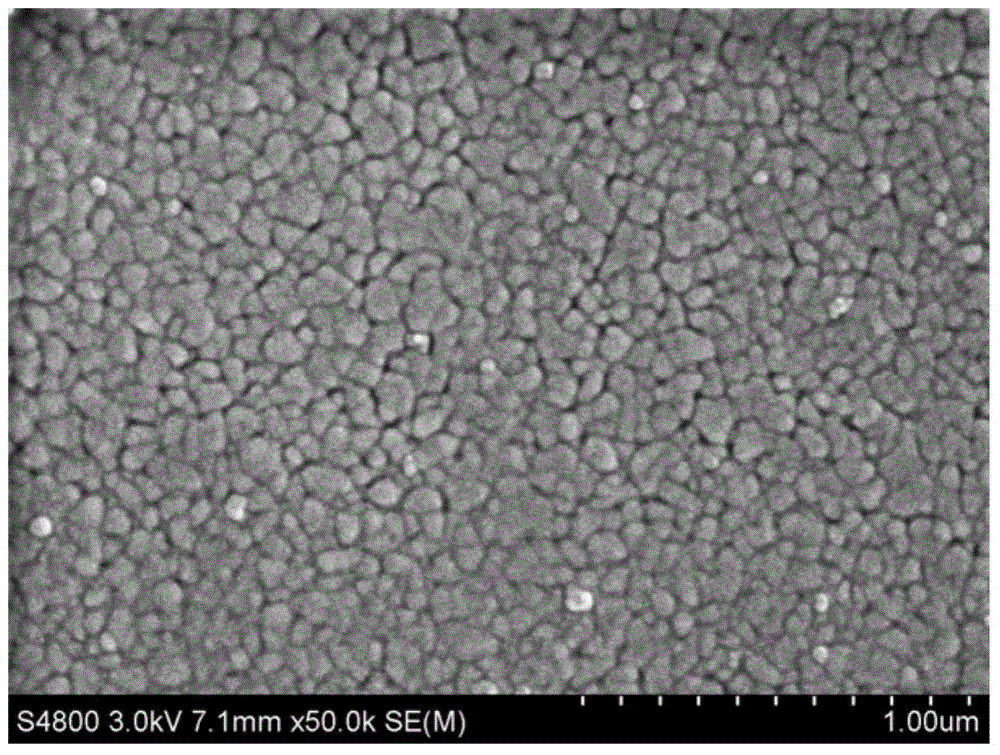

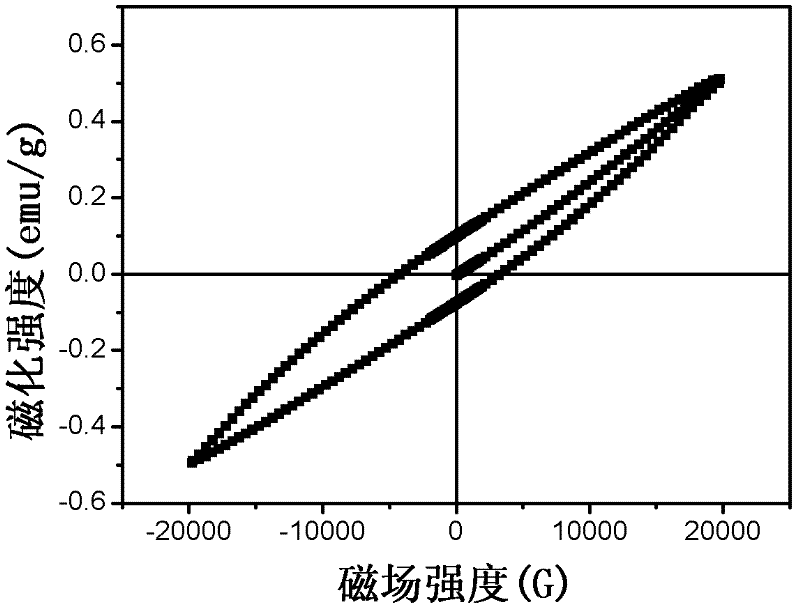

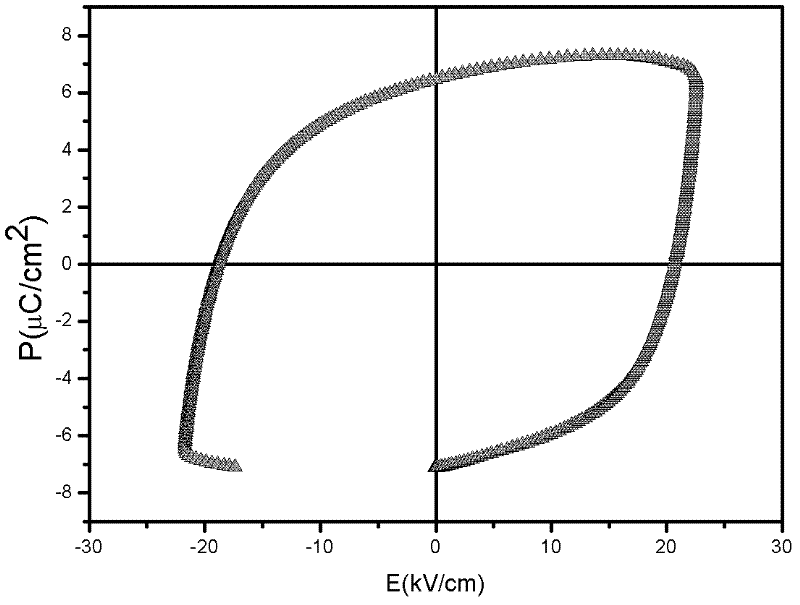

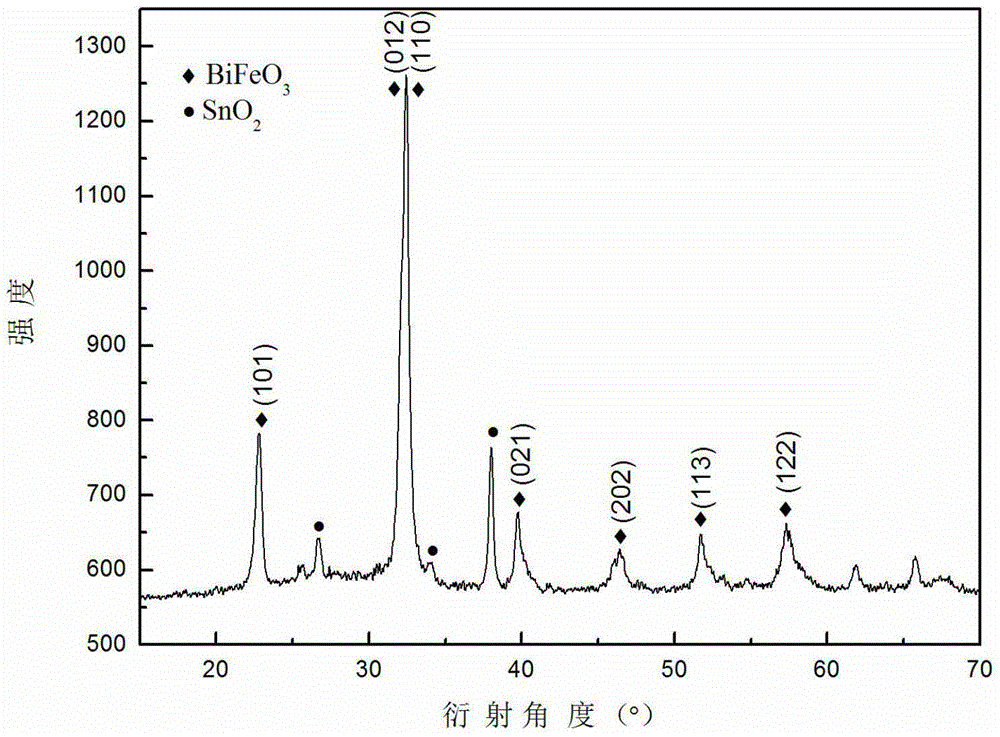

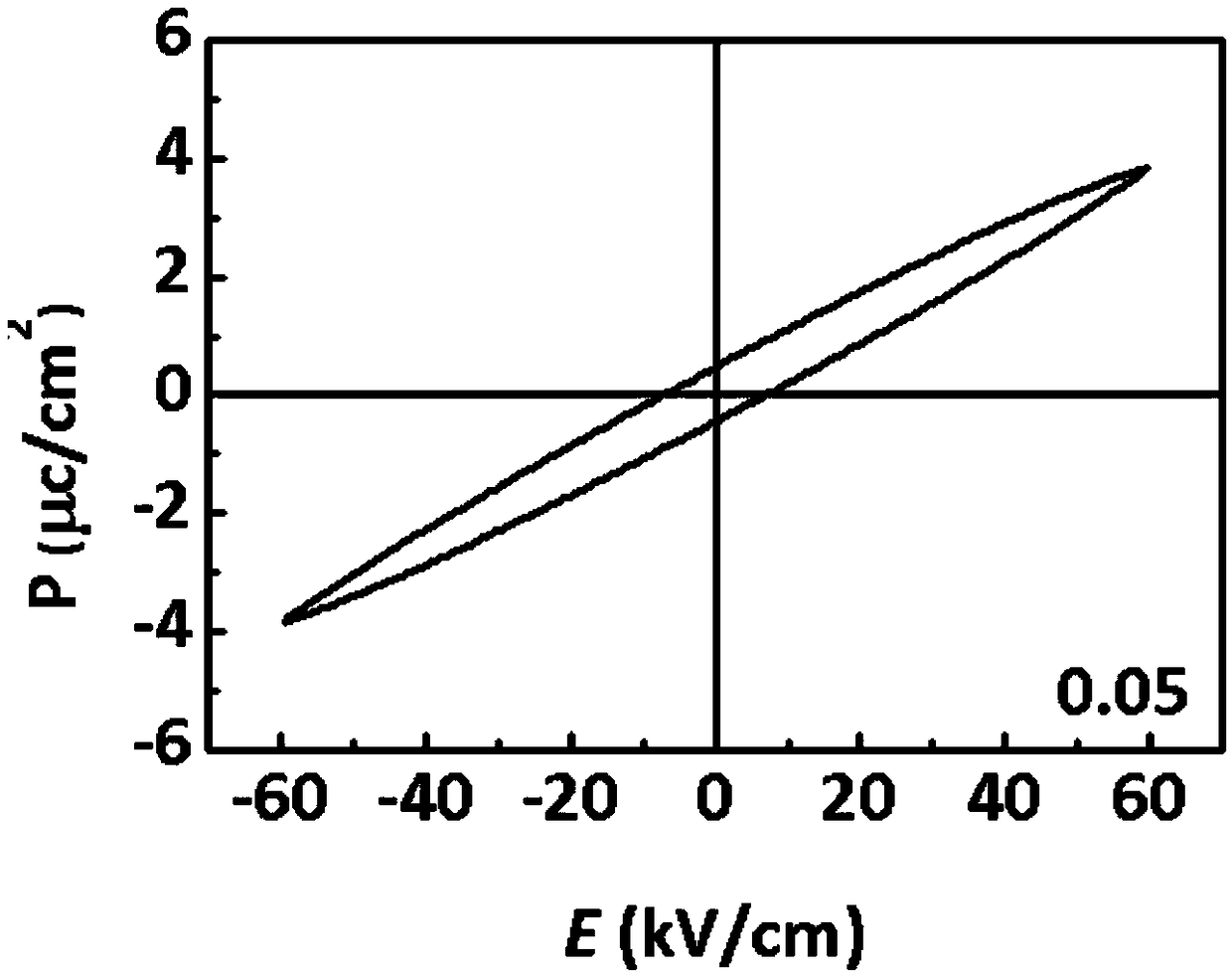

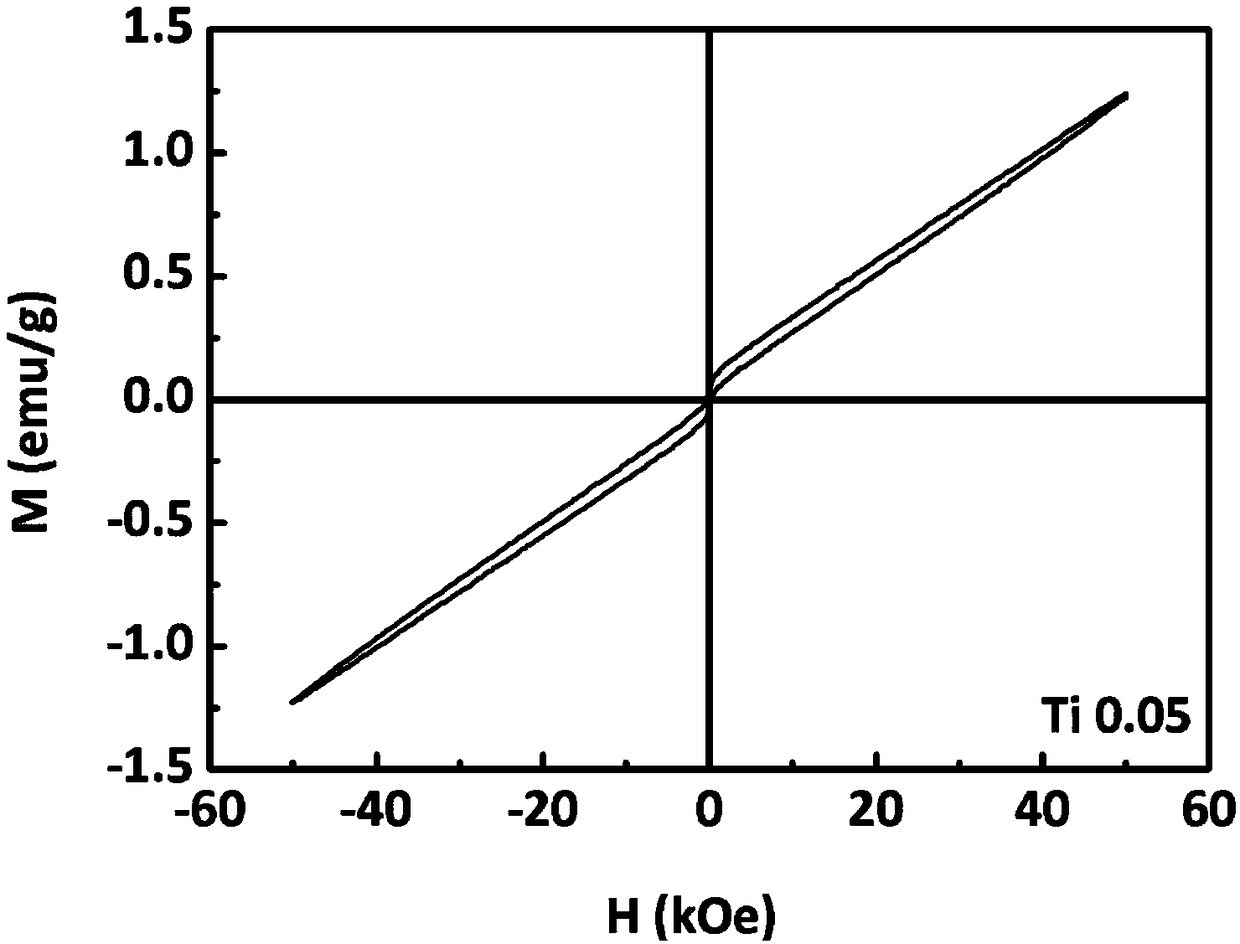

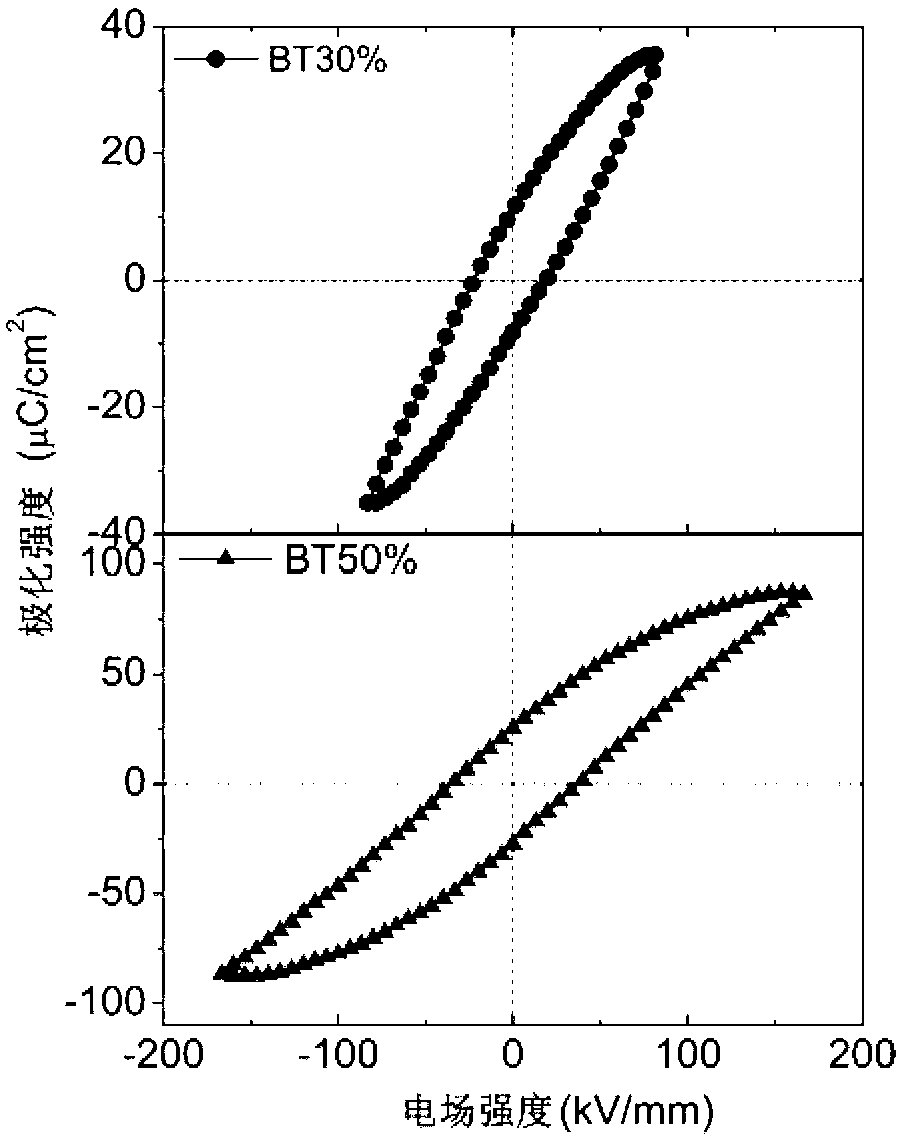

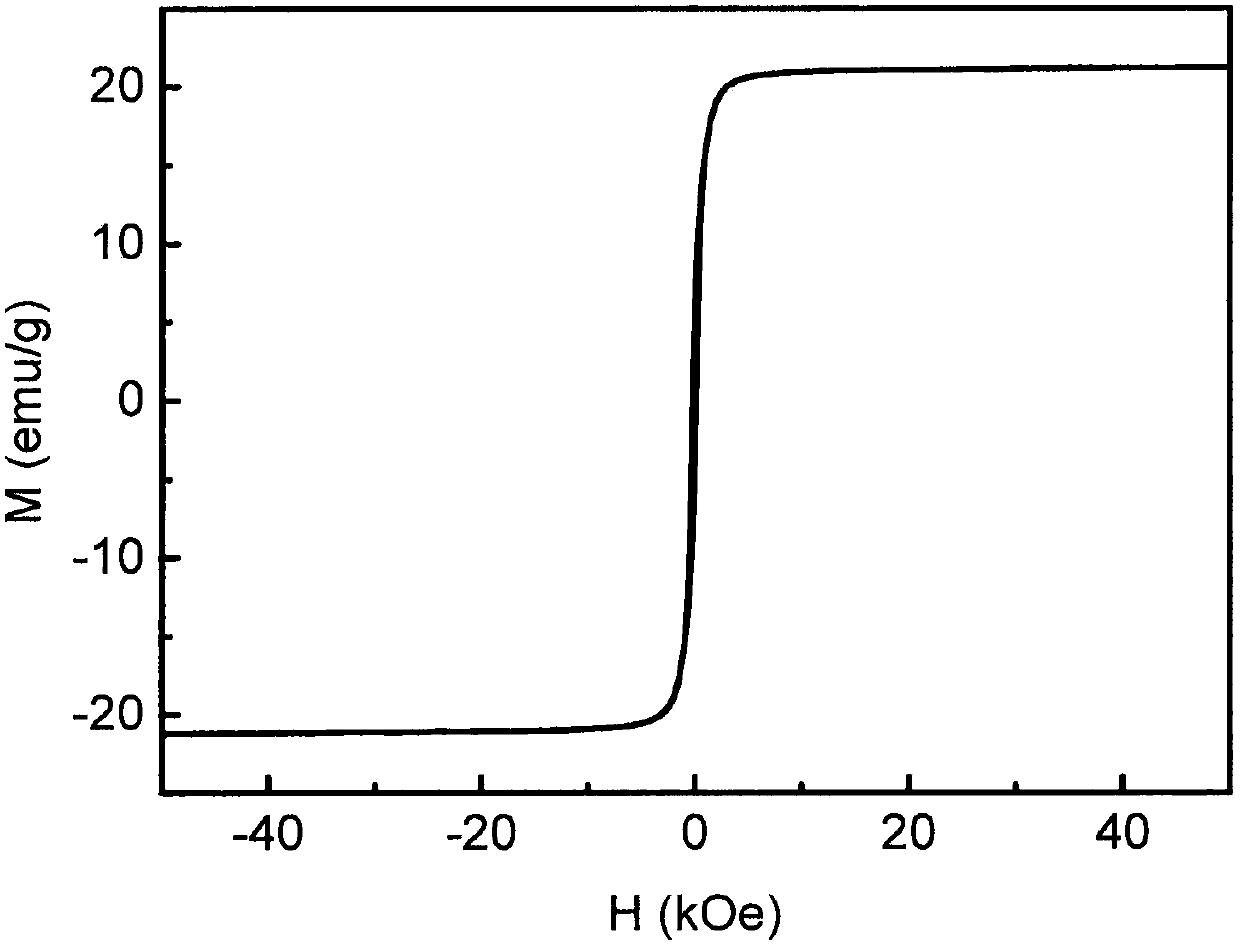

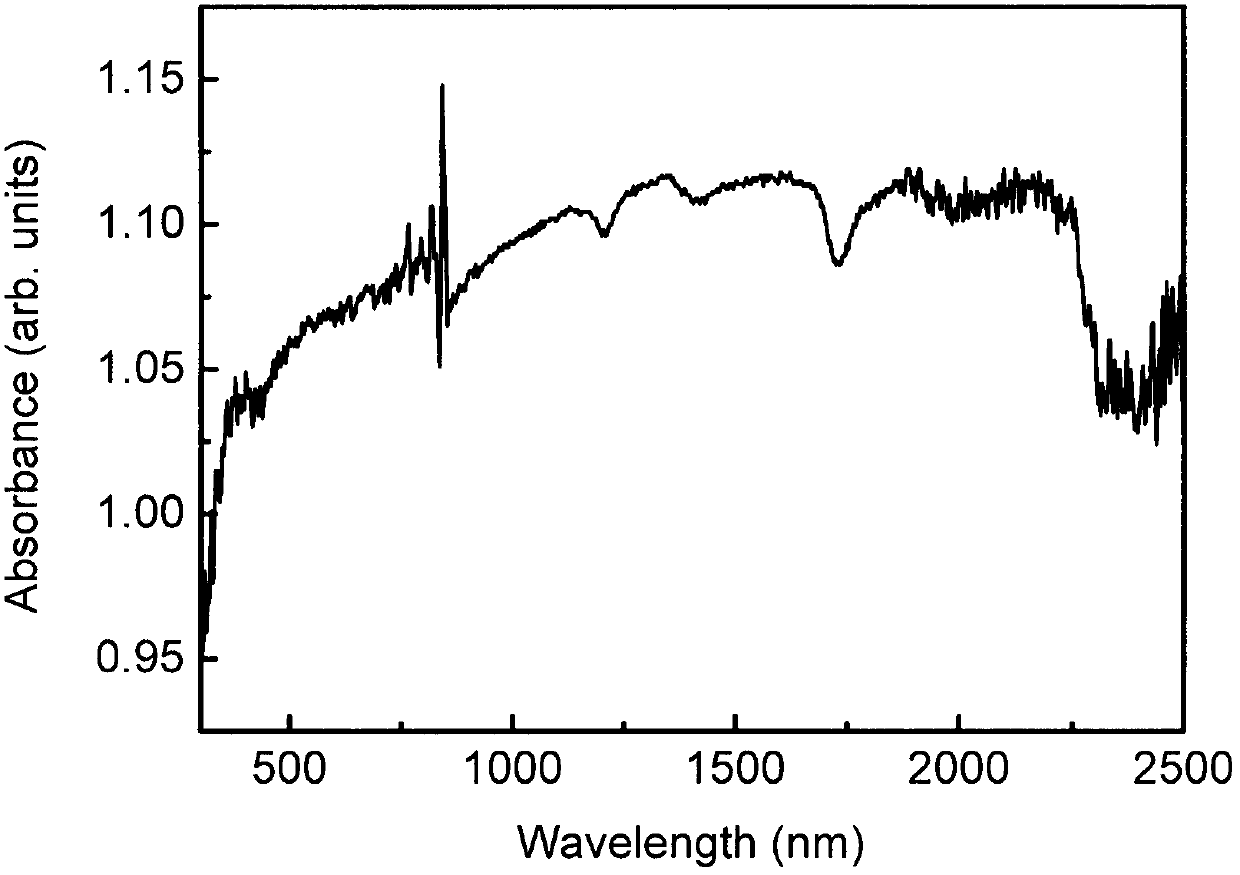

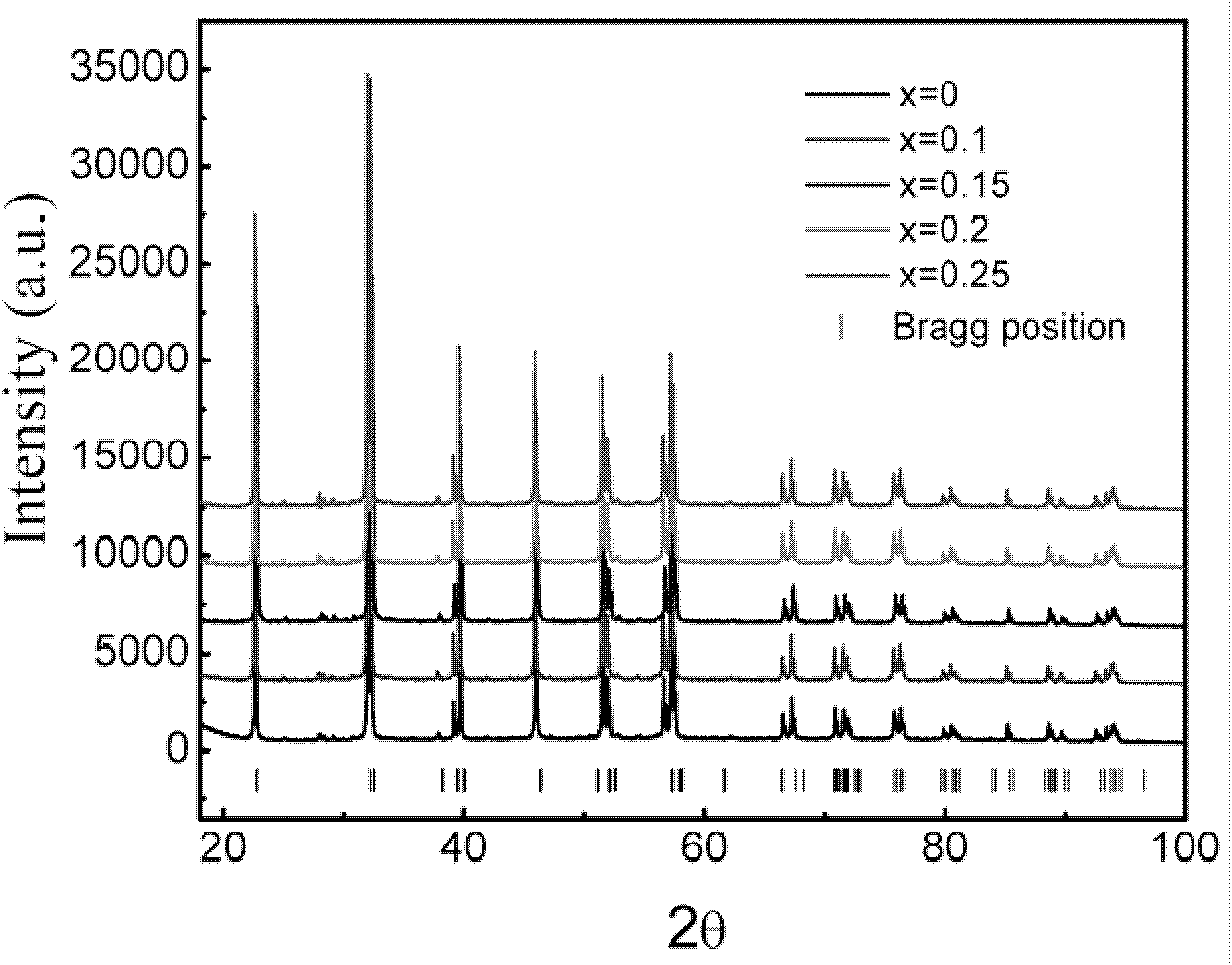

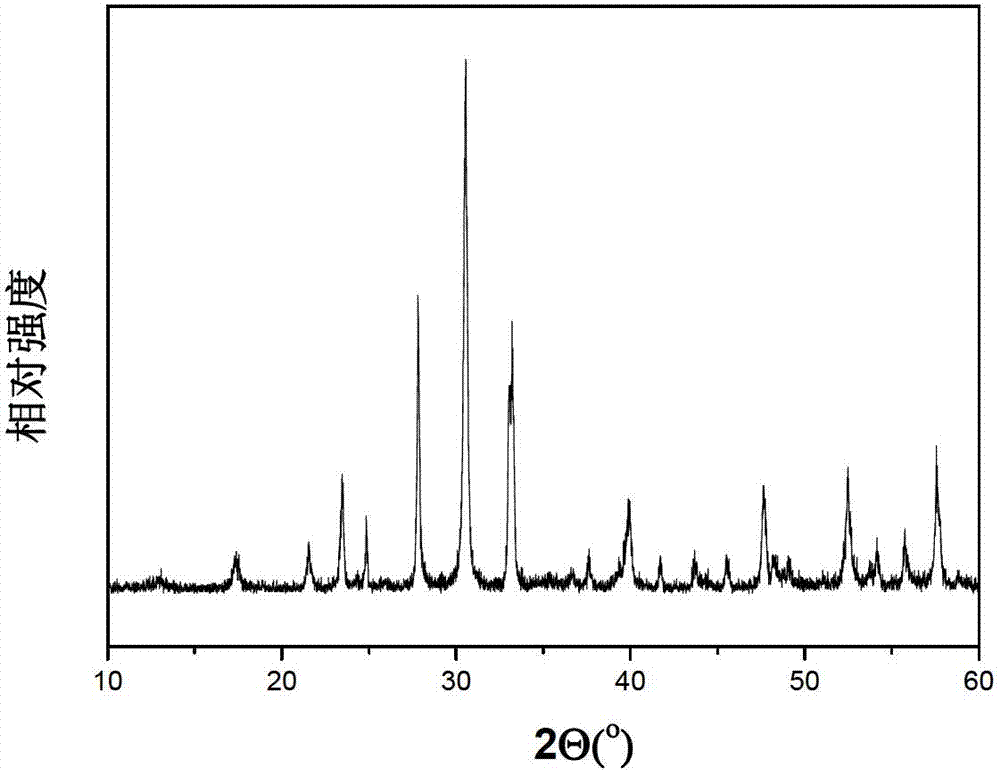

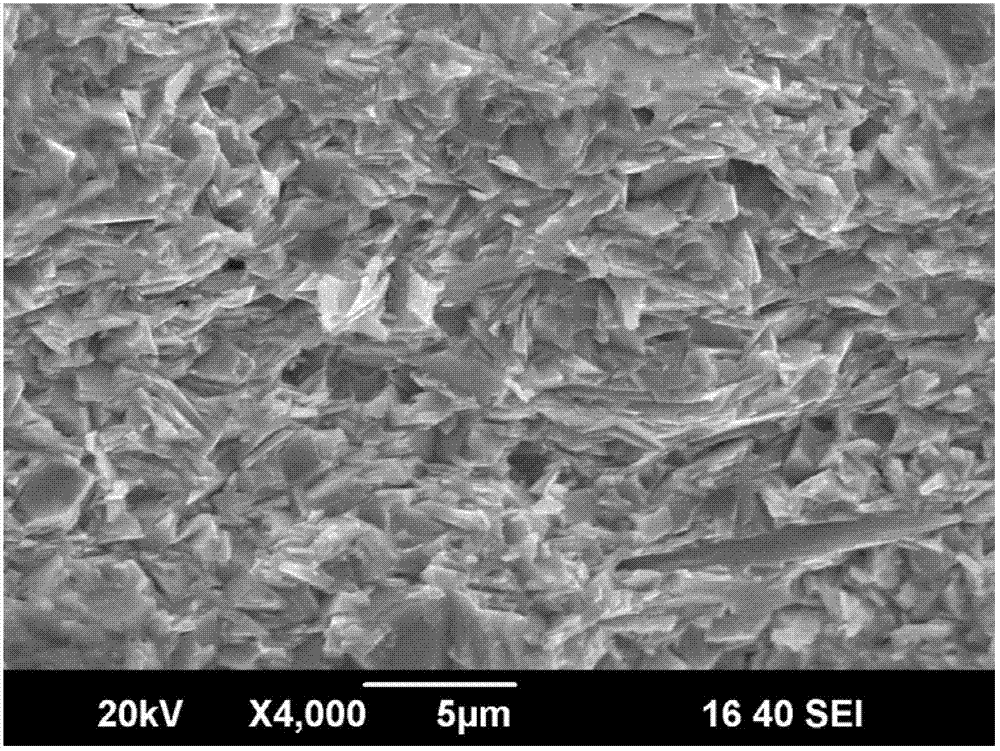

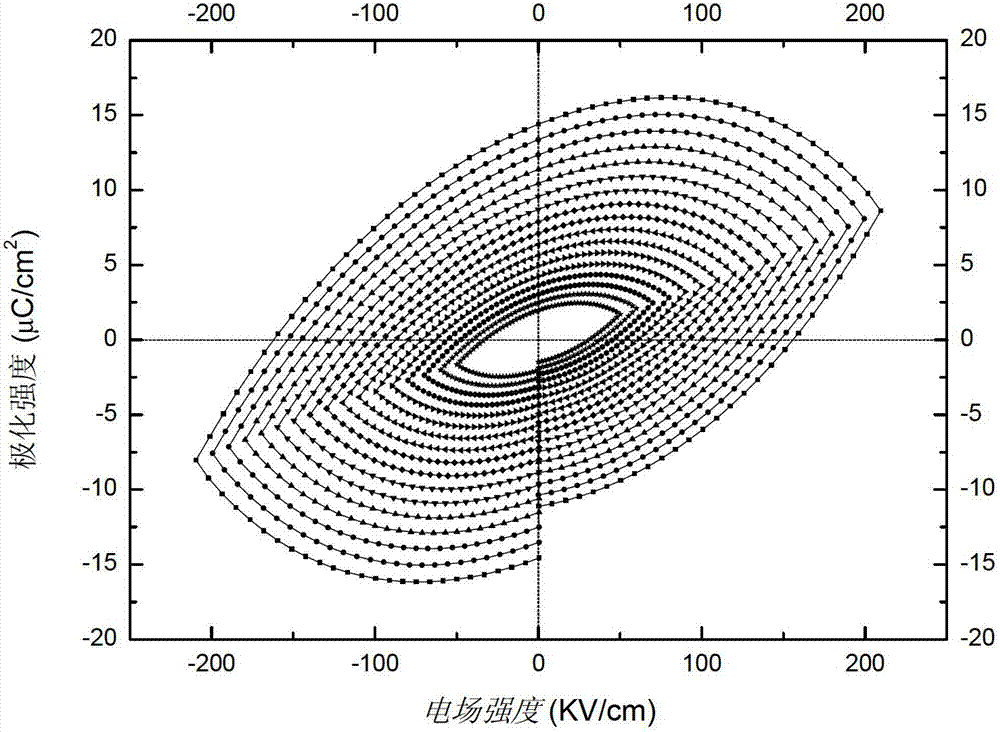

Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof

The invention provides a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and a preparation method thereof. The method comprises the following steps: preparing a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 precursor solution from bismuth nitrate, praseodymium nitrate, hydrogen nitrate AE, ferric nitrate and manganous nitrate, wherein AE is Sr, Ca or Ba, and x=0.02-0.05; spinning the precursor solution on a substrate; and then spinning, drying and annealing, so as to obtain the Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film. The Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is simple in demands on equipment; the experiment condition is easy to achieve; the doping amount is easy to control; the ferroelectric property of the film can be greatly improved; and the prepared Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is good in uniformity, low in leakage current, and low in coercive field, and has relatively high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

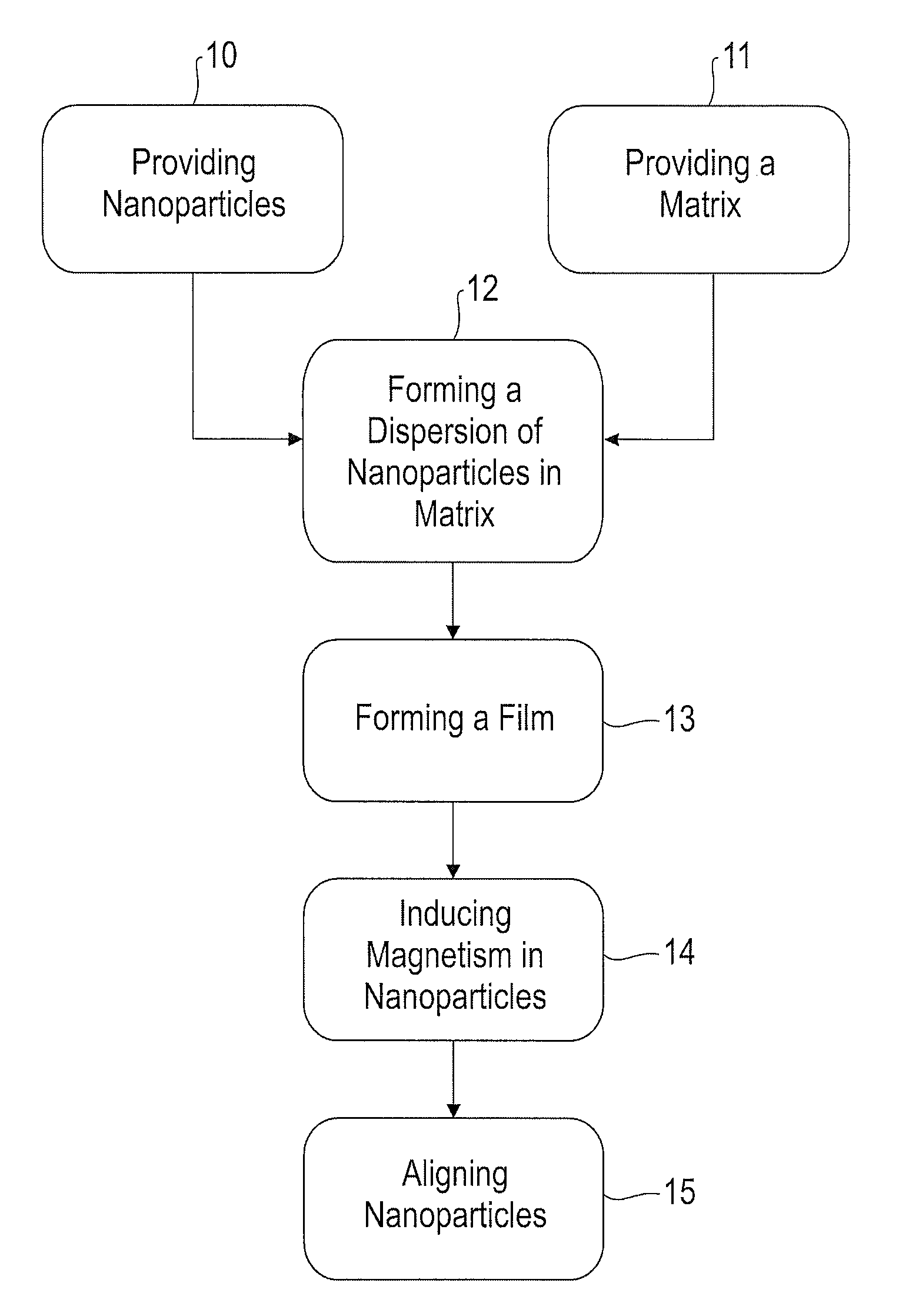

Method for forming and aligning chemically mediated dispersion of magnetic nanoparticles in a polymer

InactiveUS7854878B2Improve ferromagnetismMaterial nanotechnologyNanomagnetismMagnetite NanoparticlesSpins

A method including providing Au-doped Co nanoparticles. The nanoparticles include a combination of non-ferromagnetic nanoparticles and weakly ferromagnetic nanoparticles. The nanoparticles each have an exterior surface. The surfaces of the nanoparticles are functionalized with 7-(5-uracil-ylcarbamoyl)heptanoic acid. A polymer is provided having a general formula including a uracil group. A dispersion is formed by agitating a solution of the nanoparticles. The solution is spin cast into a film. The film is heated under vacuum at a first temperature, TFM, resulting in inducing ferromagnetism in the non-ferromagnetic nanoparticles and converting the non-ferromagnetic nanoparticles to ferromagnetic nanoparticles, and resulting in enhancing ferromagnetism in the weakly ferromagnetic nanoparticles. The nanoparticles are aligned such that magnetic easy axes of the nanoparticles are oriented by applying a magnetic field to the dispersion while at a second temperature less than TFM. The axes align in a plane parallel to a plane of the film.

Owner:GLOBALFOUNDRIES INC

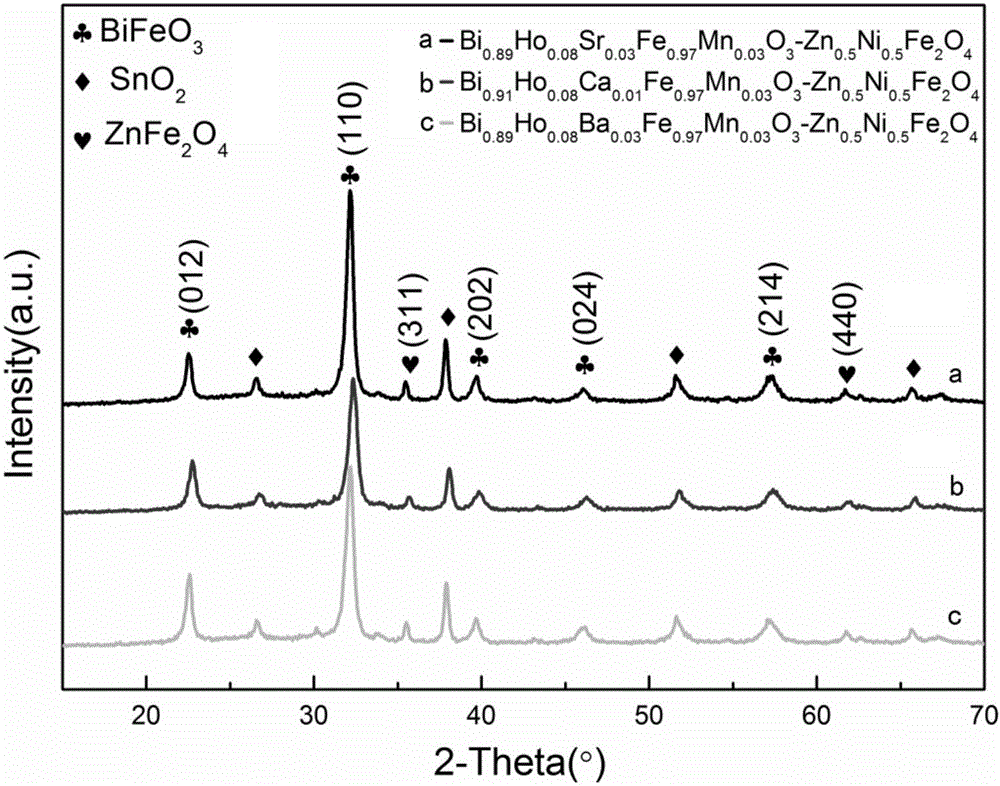

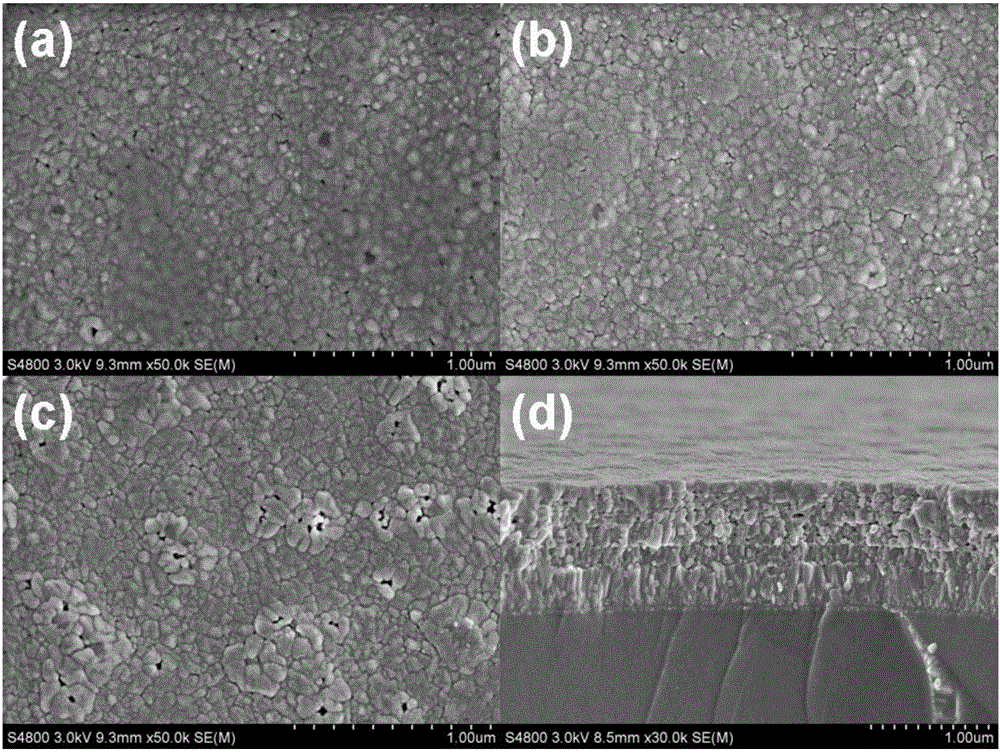

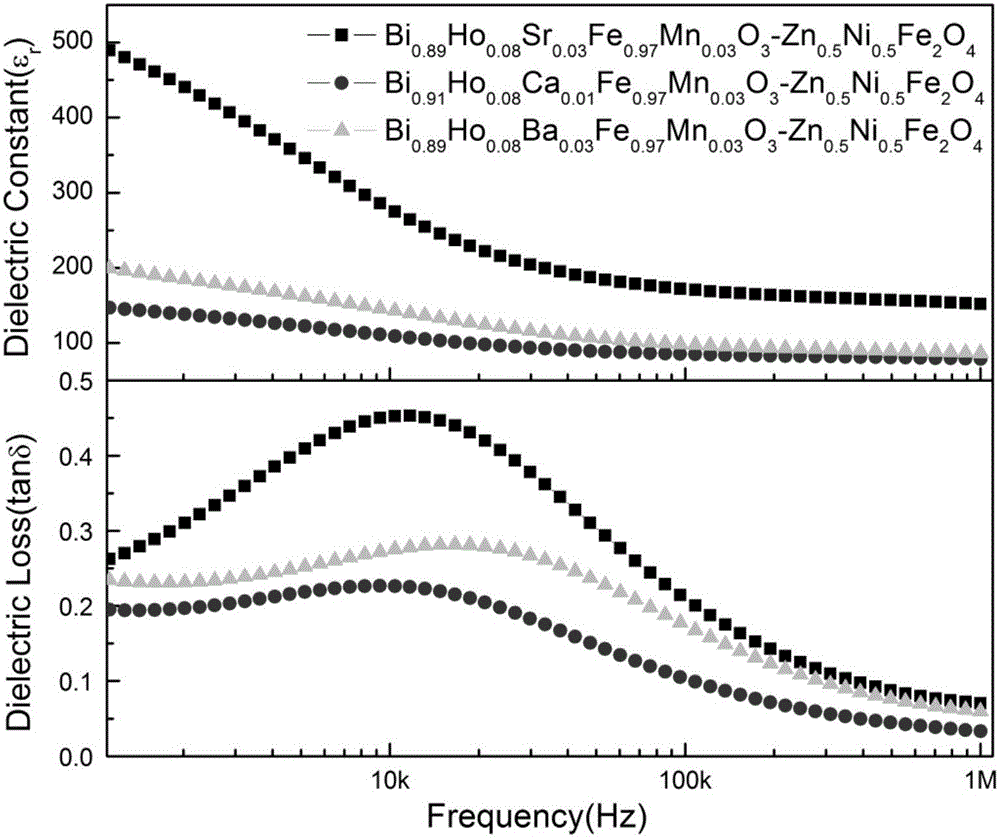

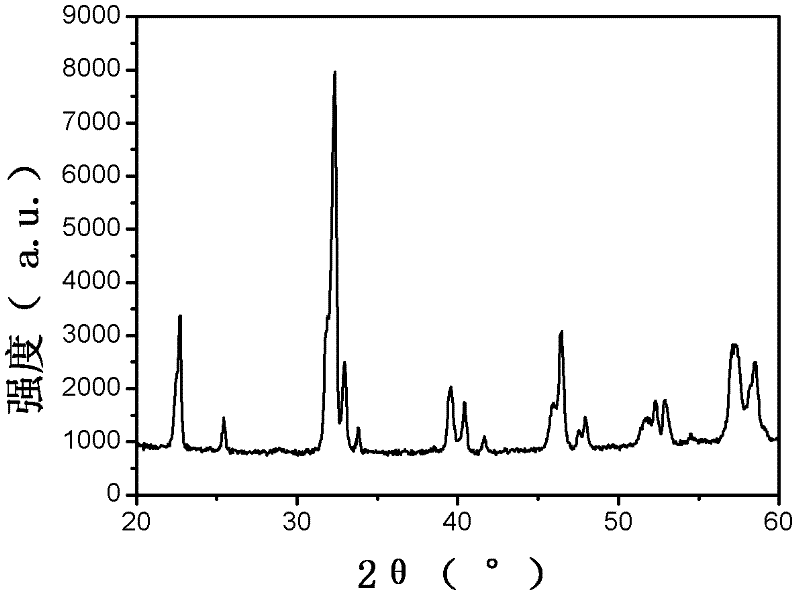

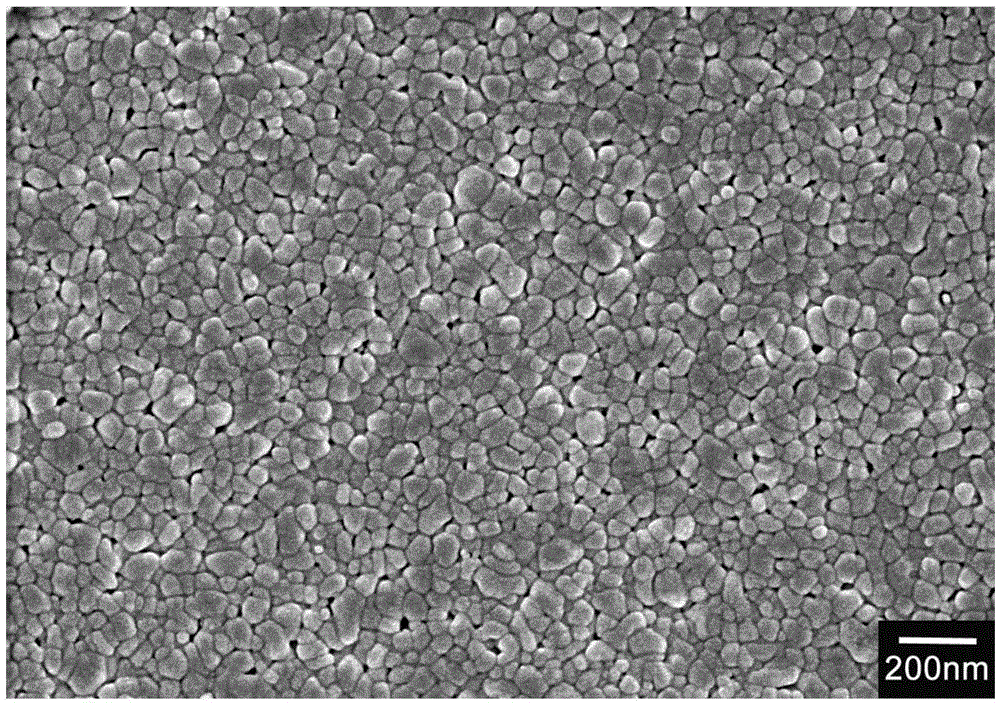

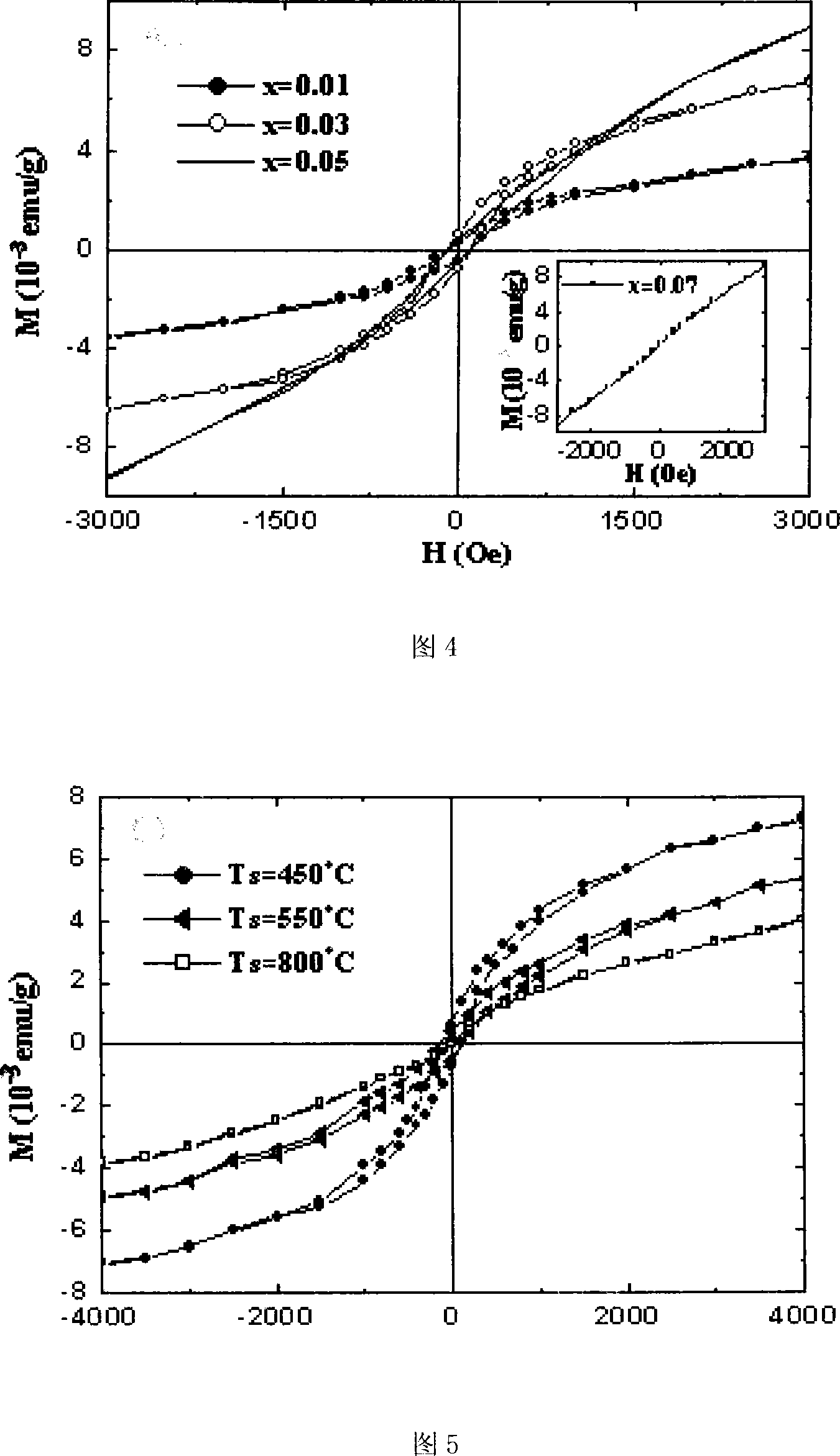

Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof

InactiveCN104478230AReduce defectsReduce leakage conduction currentCoatingsMANGANESE ACETATEMultiferroics

The invention provides a Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and a preparation method thereof. The method comprises the following steps: preparing a Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 precursor solution from bismuth nitrate, holmium nitrate, nitric acid AE, ferric nitrate and manganese acetate, wherein AE is Ca, Ba or Sr, and x=0.01-0.08; spinning the precursor solution on a substrate; and then spinning, drying and annealing, so as to obtain the Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film. The Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film is simple in demands on equipment; the experiment condition is easy to achieve; the doping amount is easy to control; the ferroelectric property of the film can be greatly improved; and the prepared Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film is good in uniformity, low in leakage current and low in coercive field, and has relatively high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

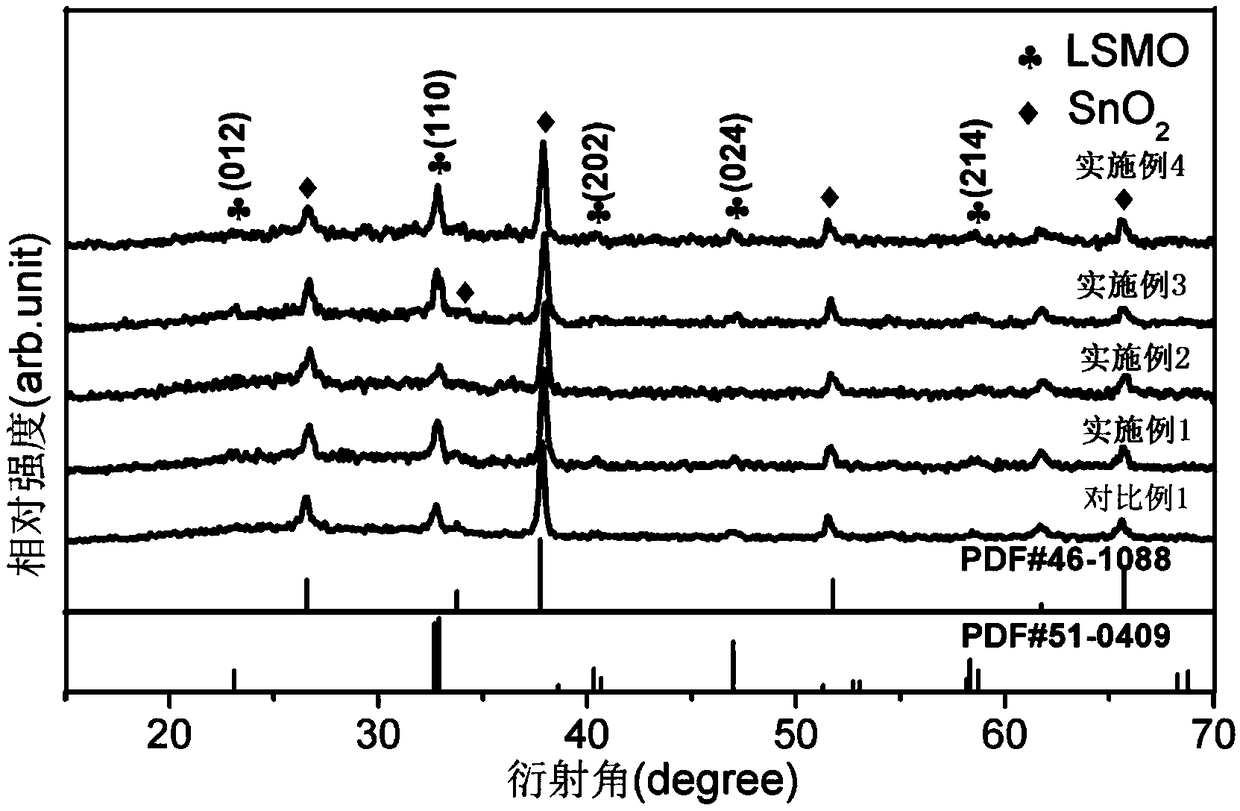

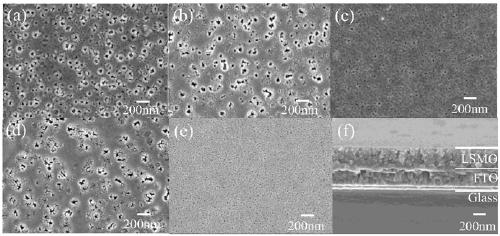

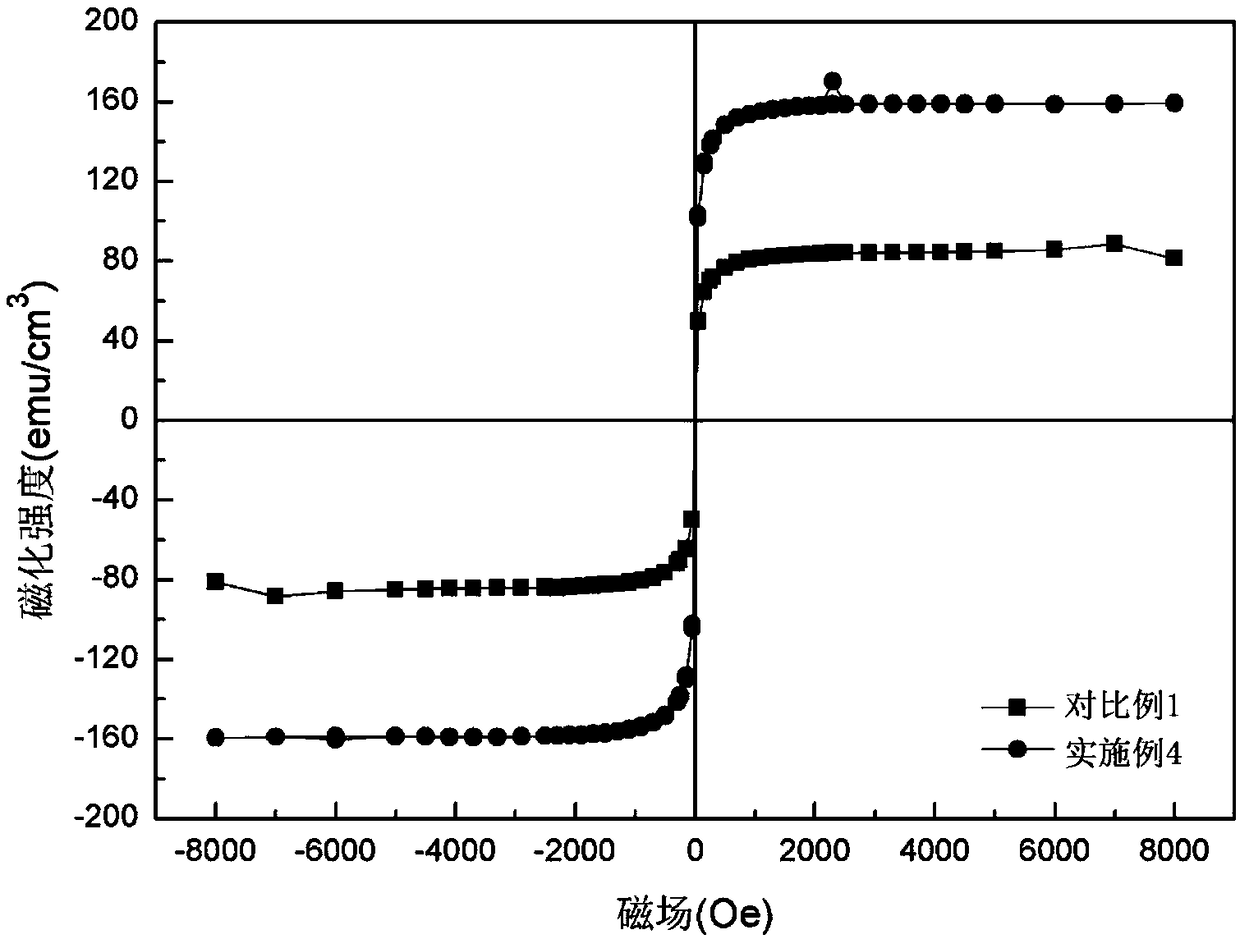

A ferromagnetic LSMO film and a preparation method thereof

ActiveCN109273255AHigh densityQuality improvementChemical vapor deposition applicationLiquid applicationOrganic solventMagnetization

The invention provides a LSMO thin film with high ferromagnetism and a preparation method thereof. A La0. 7Sr0. 3MnO3 wet film is prepare by a gel spin coating method, La_ (0.7) Sr_ (0.3) MnO_3 thin films were prepared by pre-annealing at the heating rate of 10 -20 DEG C / min to 350 -400DEG C and then annealing at 600 -620 DEG C at the heating rate of 10 -20 DEG C / min. The La_ (0.7) Sr_ (0.3) MnO_3 thin films are rhombohedral perovskite structure, space group R_3c, grown along (101) direction, and the saturation magnetization Ms is 160.12 emu / cm3. The results show that the La_ (0.7) Sr_ (0.3)MnO_3 thin films have a high saturation magnetization. The preparation method of the invention increases the pre-annealing process, which is beneficial to the volatilization of organic solvent and improves the ferromagnetism of the thin film; Adding polyethylene glycol can adjust the viscosity of the precursor and improve the quality of the film.

Owner:SHAANXI UNIV OF SCI & TECH

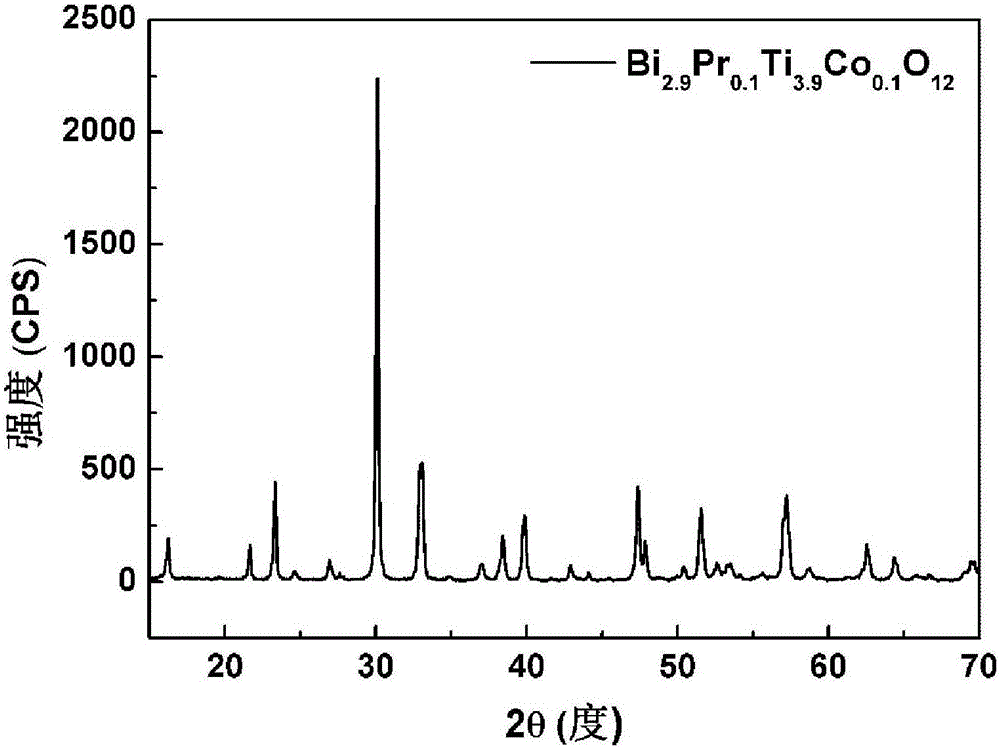

Bismuth titanate Bi4-XPrXTi3-XCoXO12 ceramic material and preparation method thereof

The invention provides a bismuth titanate Bi4-XPrXTi3-XCoXO12 ceramic material and a preparation method thereof. The bismuth titanate Bi4-XPrXTi3-XCoXO12 ceramic material is prepared by the following steps: mixing Bi2O3, TiO2, Pr2O3 and Co3O4 at a mol ratio through a solid-phase method, wherein x is a mole percent of doped ions Pr<3+> and Co<3+> ions; after mixing uniformly, pre-sintering a mixture at 700 DEG C to 800 DEG C for 4h to 8h, and then carrying out secondary ball milling and granulation; pressing and molding the mixture in a mold and discharging a PVC (Polyvinyl Chloride) adhesive; sintering by microwaves at 920 DEG C to 1000 DEG C and keeping the heat for 20min to 40min. By carrying out AB site doping of Pr<3+> and Co<3+> on bismuth titanate, the ferroelectric property is improved and the ferromagnetic property of the material is improved. By adopting a microwave sintering manner, low-temperature and rapid sintering is realized, and the bismuth titanate Bi4-XPrXTi3-XCoXO12 ceramic material with high ferroelectric property and high ferromagnetic property is prepared.

Owner:SHAANXI UNIV OF SCI & TECH

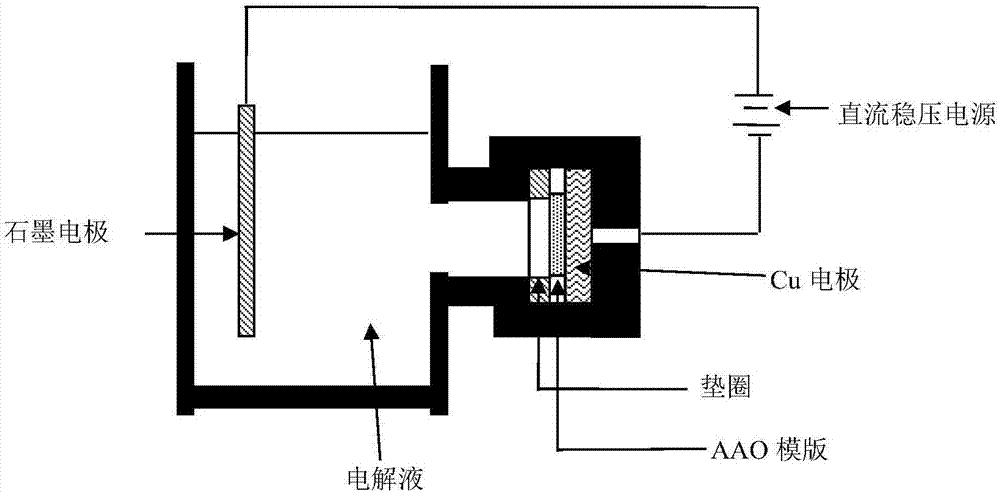

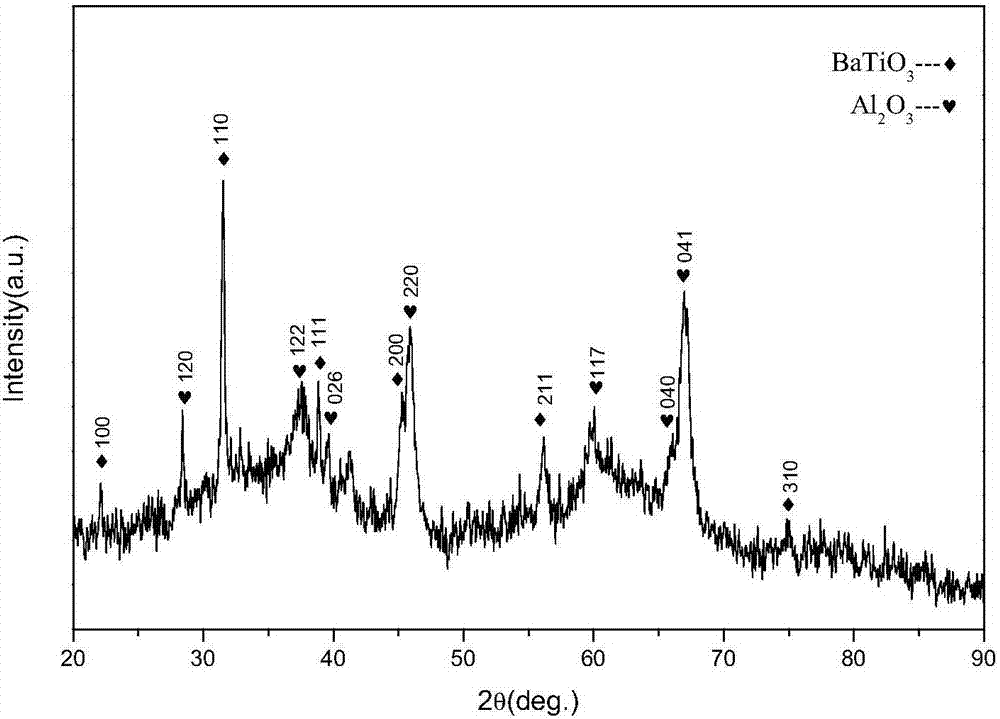

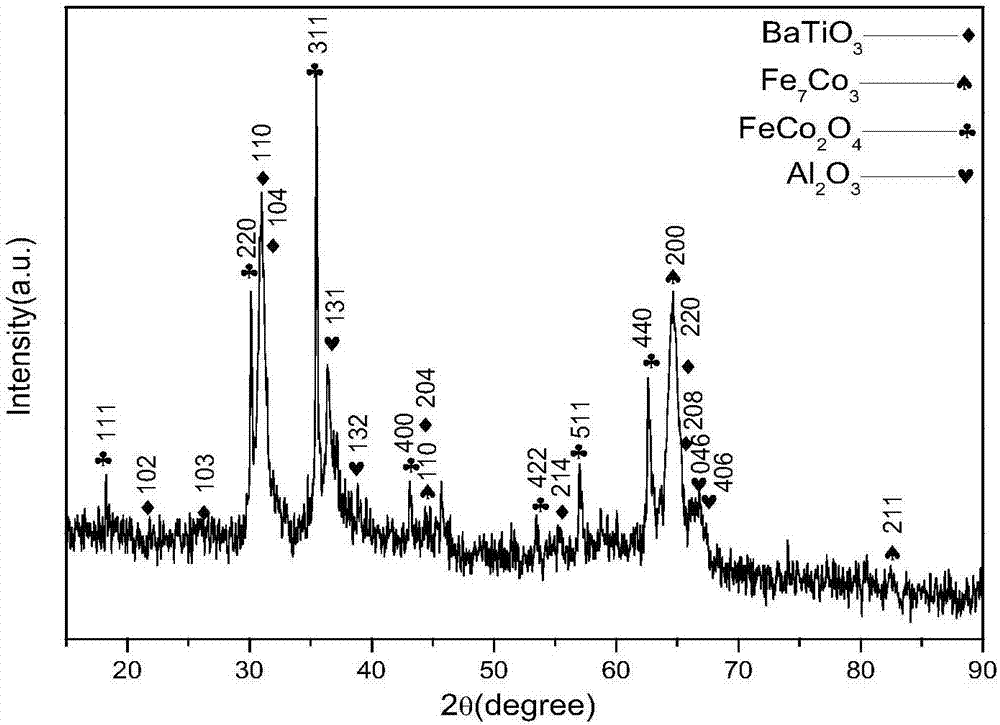

Preparing method for (Fe-Co)-BaTiO3 core-tube complex-phase multiferroic materials

ActiveCN107488839AHighlight substantive featuresRegular shapeMaterial nanotechnologyVacuum evaporation coatingCompound (substance)Ferromagnetism

The invention discloses a preparing method for (Fe-Co)-BaTiO3 core-tube complex-phase multiferroic materials. The technology of combination of the template method, the sol-gel method and the direct current chemical sedimentation method is adopted, before an Fe-Co nano wire is deposited on an AAO template, a BaTiO3 nano tube is prepared with the hole diameter of the AAO template as an attached body, then, the Fe-Co nano wire is deposited, the BaTiO3 nano tube is a ferroelectric phase, an Fe-Co nano core is a ferromagnetic phase, and the (Fe-Co)-BaTiO3 core-tube complex-phase multiferroic materials are prepared through the piezoelectric effect of the ferroelectric phase and the piezomagnetic effect of the ferromagnetic phase. The technology is simple, cost is low, and the success rate is high. Product hole structure parameters including the diameter, the length and the hole interval can be adjusted, the sintering quality is high, good ferroelectricity and ferromagnetism are achieved, and the (Fe-Co)-BaTiO3 core-tube complex-phase multiferroic materials are suitable for serving as novel complex-phase multiferroic materials.

Owner:HEBEI UNIV OF TECH

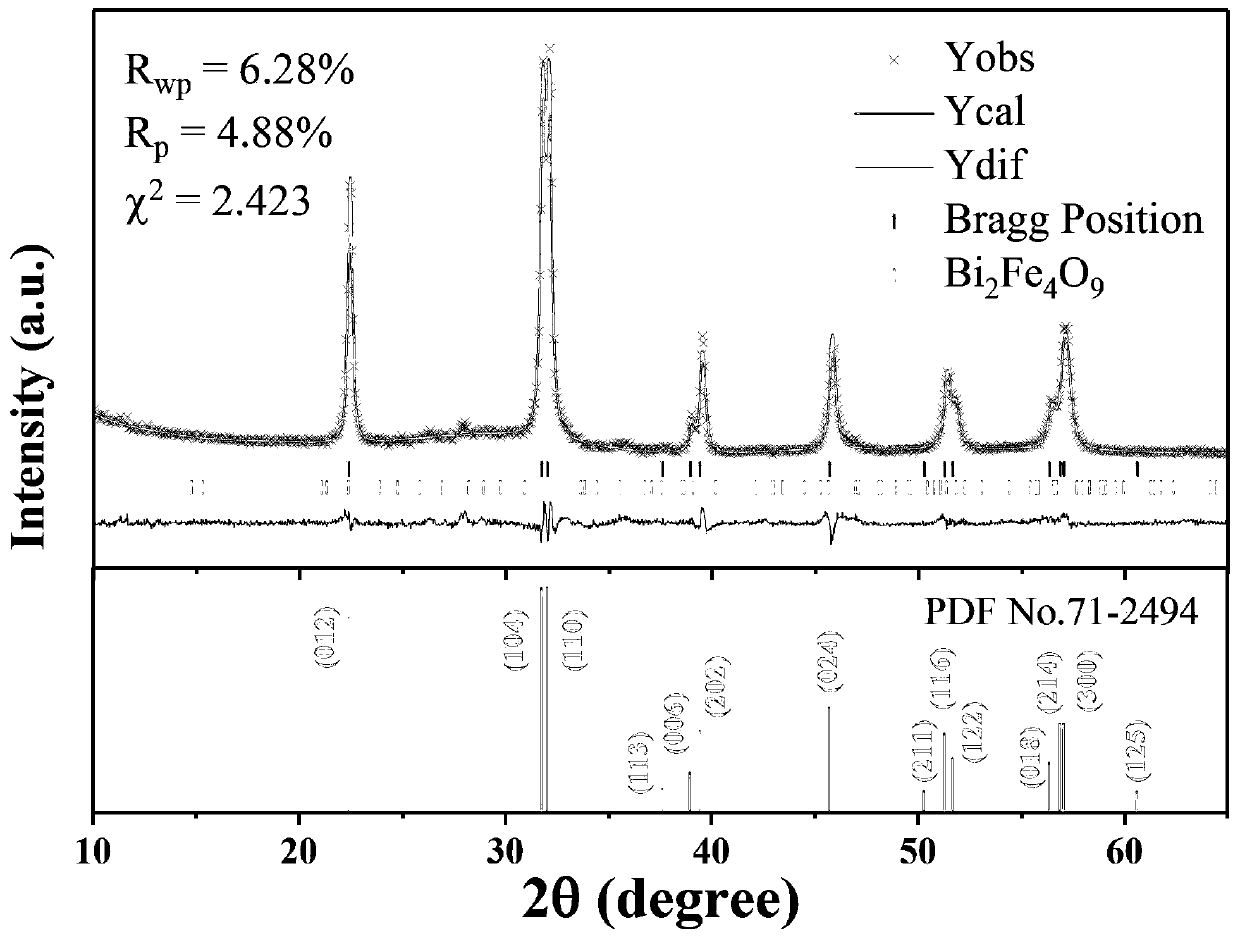

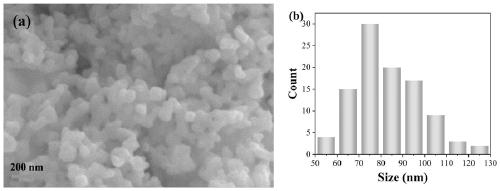

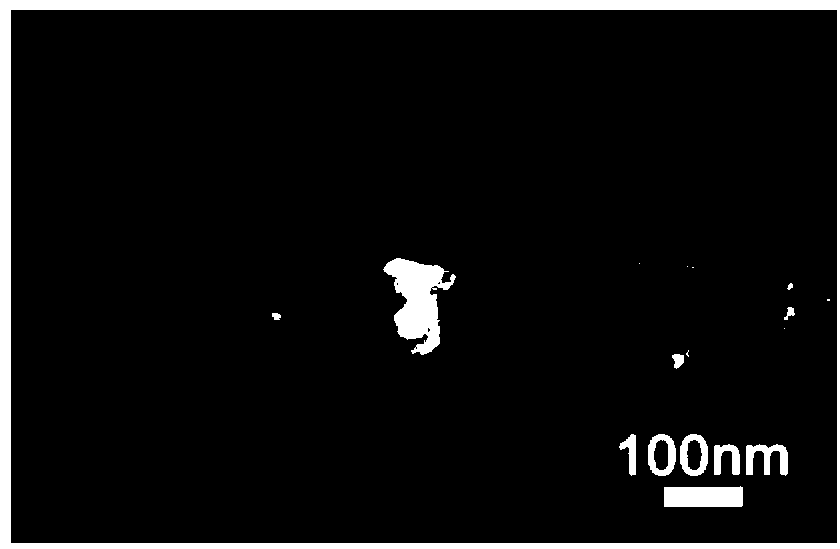

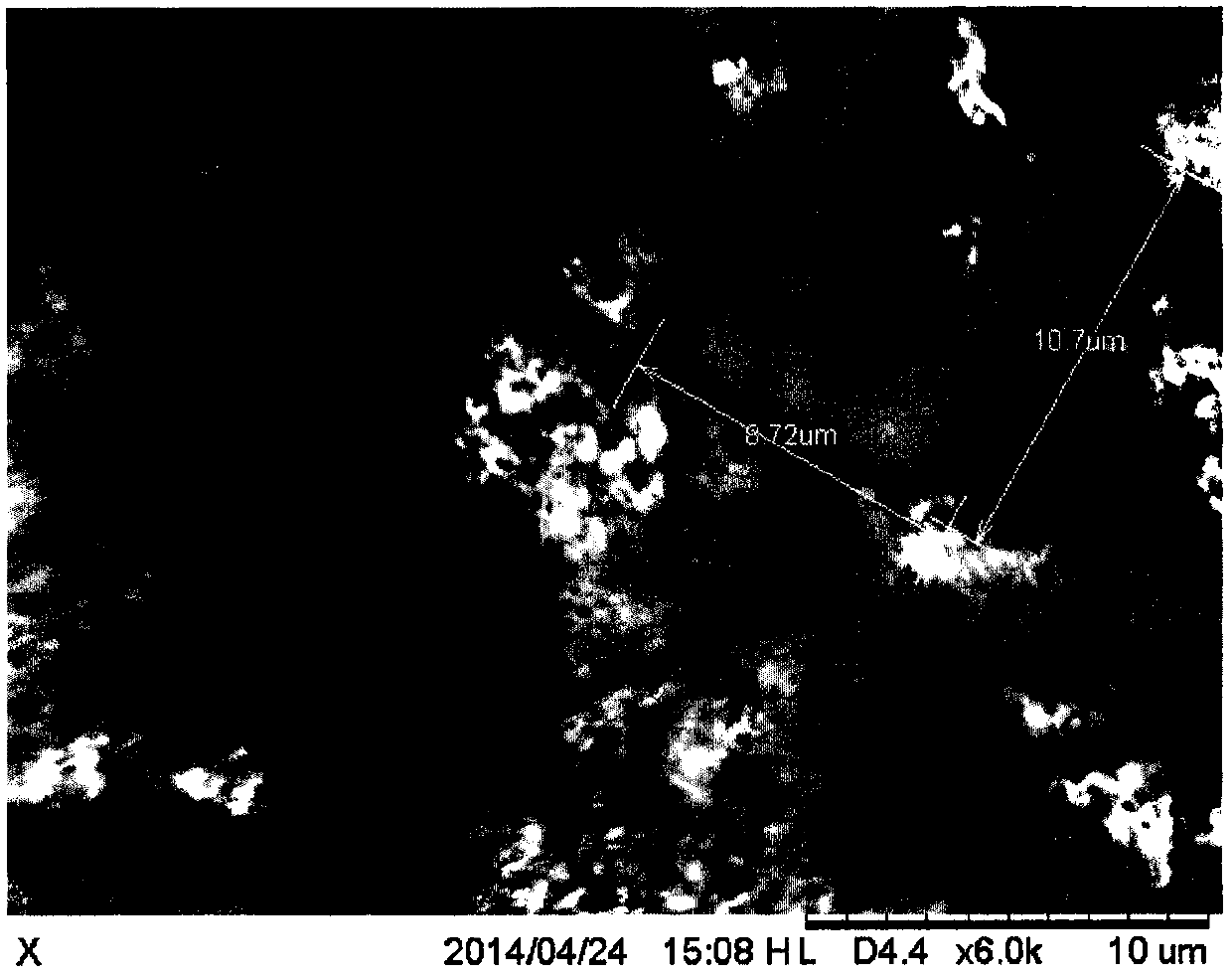

Method for enhancing magnetism of bismuth ferrite nano powder based on size effect

ActiveCN110451575AHigh purityImprove magnetismMaterial nanotechnologyIron compoundsWater bathsCitric Acid Monohydrate

The invention discloses a method for enhancing magnetism of bismuth ferrite nano powder based on the size effect, and belongs to the technical field of multiferroic materials / magneto-electric couplingmaterials. The method aims to solve the two technical problems that an existing single-phase multiferroic material bismuth ferrite easily generates an impurity phase and the ferromagnetism is low. The method includes the following steps that 1, bismuth nitrate pentahydrate and ferric sulfate nonahydrate are sequentially added into ethylene glycol monomethyl ether under the stirring condition, andafter addition, dilute nitric acid is dropwise added until the pH value is 3-4; 2, stirring continues, citric acid monohydrate is added, and after uniform stirring, ethylene glycol is added and evenly stirred; 3, the mixture is put into a water bath for magnetic stirring and then dried; 4, two-stage heat preservation is conducted; 5, the mixture is grinded, dilute nitric acid is added, the mixture is cleaned with deionized water after magnetic stirring, the mixture is dried, and BiFeO3 pure-phase nano powder is obtained. According to the method, the ferromagnetic property of bismuth ferrite can be remarkably enhanced.

Owner:HARBIN INST OF TECH

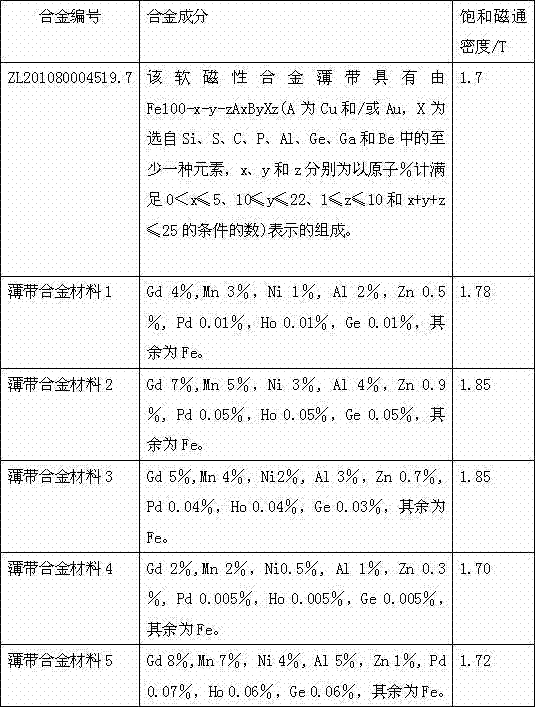

Iron-based sub-microcrystal alloy material for soft magnetic thin strip and preparation method of iron-based sub-microcrystal alloy material

InactiveCN102832007AEnhanced Amorphous Formation AbilityHigh curie temperatureMagnetic materialsManganeseMetallic materials

The invention provides an iron-based sub-microcrystal alloy material for a soft magnetic thin strip, and a preparation method of the iron-based sub-microcrystal alloy material, belonging to the technical field of metal materials. The alloy material comprises the following components by weight percentage: 4%-7% Gd (Gadolinium), 3%-5% Mn (Manganese), 1%-3% Ni (Nickel), 12%-4% Al (Aluminum), 0.5%-0.9% Zn (Zinc), 0.01%-0.05% Pd (Palladium), 0.01%-0.05% Ho (Holmium), 0.01%-0.05% Ge (Germanium), and the balance of Fe (Ferrum); the preparation method comprises the following steps of: dosing; putting raw materials into a vacuum induction furnace; smelting the raw materials at a temperature between 1530 DEG C and 1550 DEG C, so as to obtain a master alloy; then re-melting the master alloy at a temperature between 1510 DEG C and 1530 DEG C; preparing an alloy thin strip; then heating the alloy thin strip in a nitrogen furnace to a temperature between 180 DEG C and 200 DEG C; preserving heat for 2-3 hours; and preserving heat for 1-1.5 hours at a temperature between 350 DEG C and 380 DEG C, thus obtaining the iron-based sub-microcrystal alloy material for the soft magnetic thin strip. The iron-based sub-microcrystal alloy material for the soft magnetic thin strip prepared by the invention has high saturation flux density.

Owner:SHANXI SANYIQIANG MAGNETIC IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000011.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000012.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000021.PNG)

![Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d995d881-416d-434e-a495-429efc7a0c24/HDA0000631249920000011.PNG)

![Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d995d881-416d-434e-a495-429efc7a0c24/HDA0000631249920000012.PNG)

![Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d995d881-416d-434e-a495-429efc7a0c24/HDA0000631249920000021.PNG)