Method for strengthening Cr-doped ZnO thin film ferromagnetism through Ar particle irradiation

A ferromagnetic and irradiation technology, applied in the application of conductive/insulating/magnetic materials on magnetic films, magnetic objects, magnetic materials, etc., can solve the problems of low spin electron injection efficiency and low saturation magnetization, and achieve The method is stable and effective, and the effect of ferromagnetic enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the Cr-doped ZnO thin film comprises: clean and dry substrate, Zn 1-x Cr x The O target is placed in the chamber. Vacuum the chamber background to ≤5.0×10 -4 Pa, feed high-purity Ar at a flow rate of 20-30 sccm, adjust the pressure of the cavity at 1.0-1.5 Pa, and then heat the substrate to 300-350°C. Finally, turn on the radio frequency power supply, and sputter for 1.5-2 hours at a power of 100-150W. In one example, the deposition step may include: (1) Si substrate and Zn 1-x Cr x O (0 -4 Pa, and then heat the Si substrate to 300 °C, and then vacuum the chamber background to ≤5.0×10 -4 Pa. (3) By introducing high-purity Ar gas at a flow rate of 20 sccm, adjust the pressure of the cavity to 1.0 Pa, turn on the radio frequency power supply, and deposit at a power of 150 W for 2 hours. (4) After the preparation is completed, the temperature is naturally lowered to room temperature, and the prepared film sample is taken out.

[0039] Zn w...

Embodiment 1

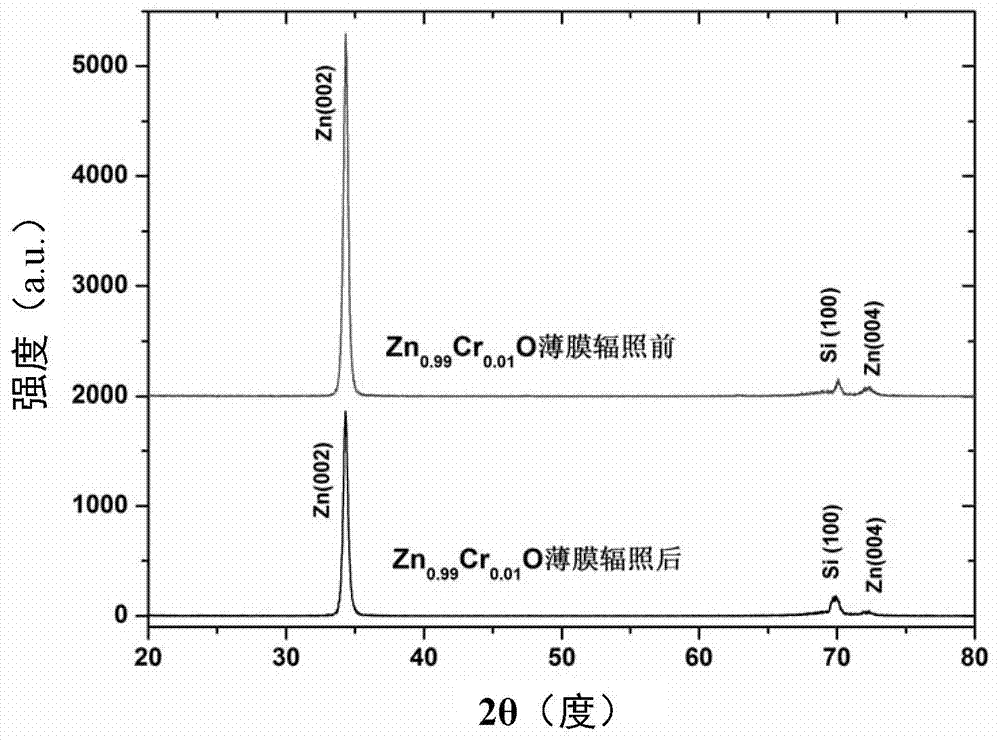

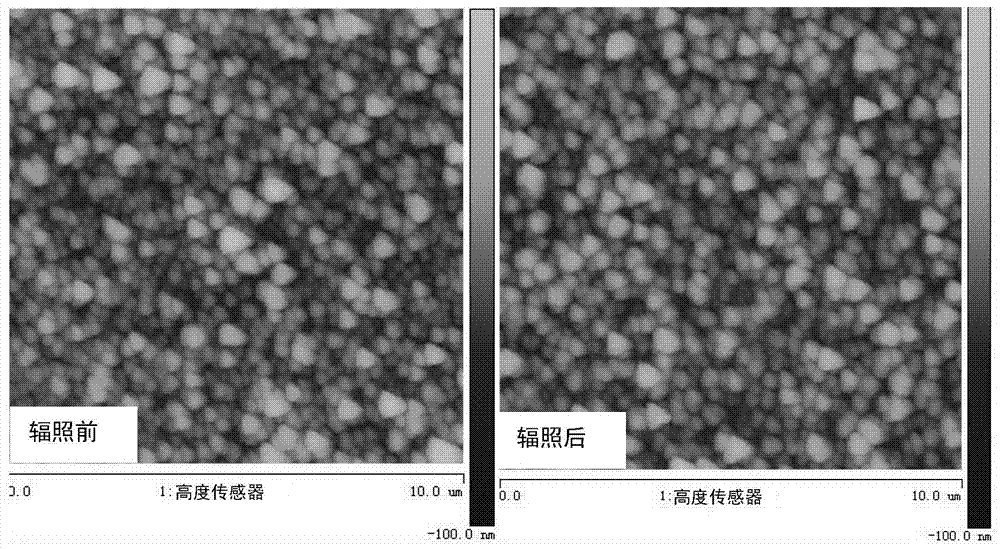

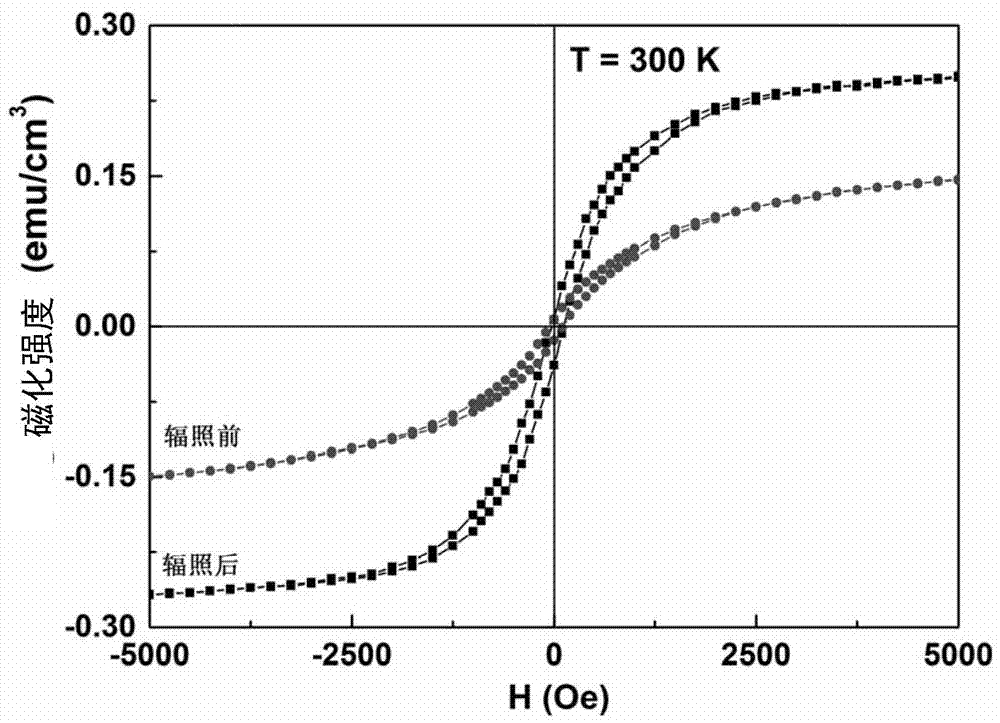

[0050] (1) Put the Si substrate in acetone for ultrasonic cleaning for 15 minutes, and then rinse it with deionized water for 10 minutes; 2) put the Si substrate in alcohol for ultrasonic cleaning for 15 minutes, and then rinse it with deionized water for 10 minutes; (3) High purity N for substrate 2 Dry; (4) Si substrate, Zn 0.99 Cr 0.01 O The target is placed in the chamber; (5) The background vacuum of the chamber is evacuated to ≤5.0×10 -4 Pa, feed high-purity Ar at a flow rate of 20sccm, and maintain the chamber pressure at 1.0Pa, then heat the sapphire substrate to 300°C; (6) finally turn on the radio frequency power supply, and sputter for 2.0h at a power of 150W , get Zn 0.99 Cr 0.01 O film with a thickness of 450nm; (7) at room temperature, with an energy of 2.8MeV and a dose of 7×10 14 cm -2 The Ar particle flow is used to modify the film by irradiation; (8) The magnetic test results show that the room temperature saturation magnetization of the film after irra...

Embodiment 2

[0052] (1) Put the Si substrate in acetone for ultrasonic cleaning for 15 minutes, and then rinse it with deionized water for 10 minutes; 2) put the Si substrate in alcohol for ultrasonic cleaning for 15 minutes, and then rinse it with deionized water for 10 minutes; (3) High purity N for substrate 2 Dry; (4) Si substrate, Zn 0.95 Cr 0.05 O The target is placed in the chamber; (5) The background vacuum of the chamber is evacuated to ≤5.0×10-4 Pa, feed high-purity Ar at a flow rate of 20sccm, and maintain the chamber pressure at 1.0Pa, then heat the sapphire substrate to 300°C; (6) finally turn on the radio frequency power supply, and sputter for 2.0h at a power of 150W , get Zn 0.95 Cr 0.05 O thin film with a thickness of 450nm; (7) at room temperature with an energy of 2.8MeV and a dose of 5×10 16 cm -2 The Ar particle flow is used to modify the film by irradiation; (8) The magnetic test results show that the room temperature saturation magnetization of the film after ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com