Preparing method for (Fe-Co)-BaTiO3 core-tube complex-phase multiferroic materials

A multiferroic material, fe-co technology, applied in the direction of nanotechnology for materials and surface science, metal material coating process, superimposed layer plating, etc., can solve the limitation of material coercive force and saturation magnetization, There is no problem of improving the magnetic properties of nanowires, which is difficult to improve, and achieves the effects of excellent ferroelectric properties, high success rate, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

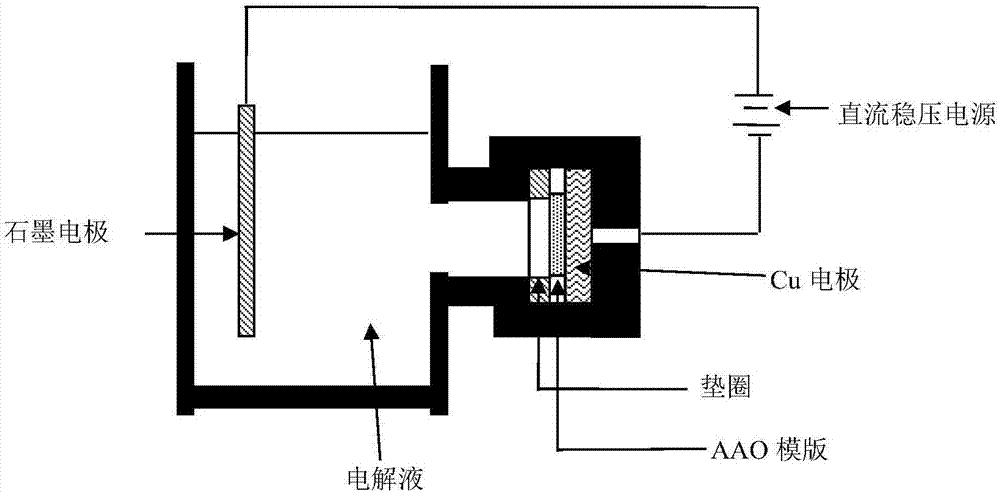

Method used

Image

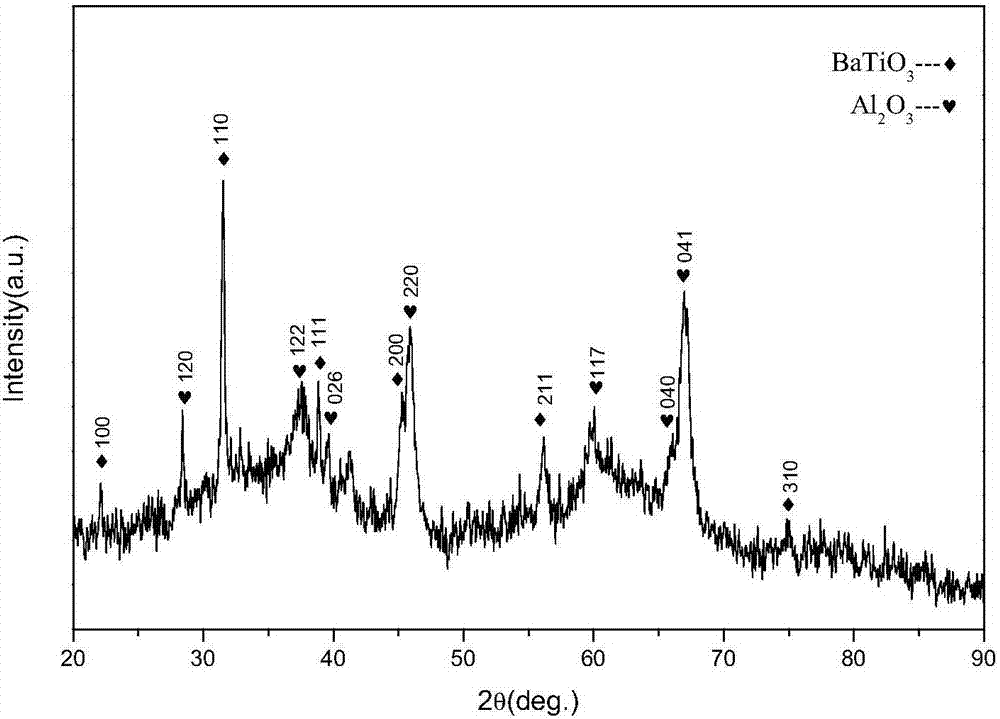

Examples

Embodiment 1

[0040] The first step, preprocessing of AAO template

[0041] Place the AAO template at a distance of 2cm from the UV light source for 1 hour and irradiate for 30 minutes on each side of the template; the power of the UV lamp is 50W;

[0042] The second step, BaTiO 3 Sol preparation

[0043] Ba(OH) 2 ·8H 2 O dissolves in CH 3 In COOH, reflux at 65°C for 2 hours under stirring, then cool to room temperature, then add a mixture of tetrabutyl titanate and absolute ethanol dropwise to it under stirring, and after 50 minutes, barium titanate sol solution is obtained;

[0044] Among them, every 34mL of CH 3 Add 17g of Ba(OH) to COOH 2 ·8H 2 0 and 45mL mixed solution; in the mixed solution, tetrabutyl titanate is 15mL, and absolute ethanol is 30mL;

[0045] The third step, BaTiO 3 Preparation of Nanotube / AAO Template Composite Structure

[0046] will contain BaTiO 3 Put the beaker of the sol on the magnetic stirrer, turn on the magnetic stirrer for single-phase rotation, t...

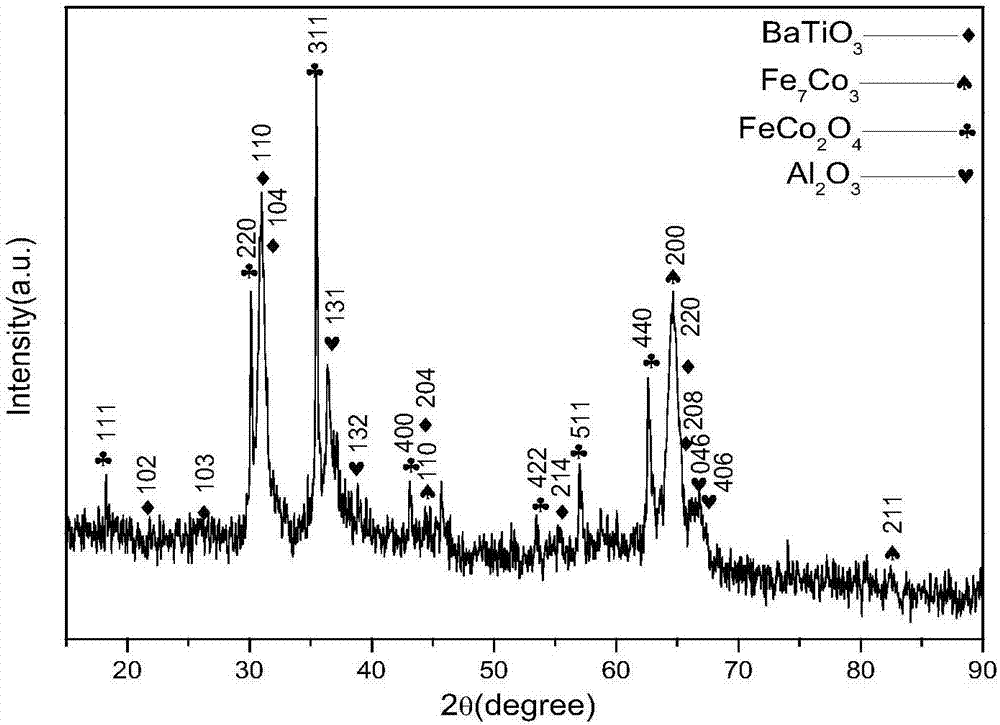

Embodiment 2

[0062] The first step, preprocessing of AAO template

[0063] Place the AAO template at a distance of 4cm from the UV light source for 1 hour and irradiate for 30 minutes on each side of the template, and the power of the UV lamp is 50W;

[0064] The second step, BaTiO 3 Sol preparation

[0065] Ba(OH) 2 ·8H 2 O dissolves in CH 3 In COOH, reflux at 80°C for 2 hours with stirring, then cool to room temperature, then add a mixture of tetrabutyl titanate and absolute ethanol dropwise to it with stirring, and after 45 minutes, barium titanate sol solution is obtained;

[0066] Among them, every 34mL of CH 3 Add 14g of Ba(OH) to COOH 2 ·8H 2 O, and 70mL mixed solution; in the mixed solution, tetrabutyl titanate is 20mL, absolute ethanol is 50mL;

[0067] The third step, BaTiO 3 Preparation of Nanotube / AAO Template Composite Structure

[0068] will contain BaTiO 3 Put the beaker of the sol on the magnetic stirrer, turn on the magnetic stirrer for single-phase rotation, th...

Embodiment 3

[0076] The first step, preprocessing of AAO template

[0077] Put the AAO template at a distance of 3cm from the UV light source and irradiate it for 1.5h, in which each side of the template is irradiated for 0.75h, and the power of the UV lamp is 45W;

[0078] The second step, BaTiO 3 Sol preparation

[0079] Ba(OH) 2 ·8H 2 O dissolves in CH 3 In COOH, reflux at 70°C for 1.6 hours with stirring, then cool to room temperature, then add a mixture of tetrabutyl titanate and absolute ethanol dropwise to it with stirring, and after 39 minutes, a barium titanate sol solution is obtained;

[0080] Among them, every 34mL of CH 3 Add 14g of Ba(OH) to COOH 2 ·8H 2 O, and 60mL mixed solution; in the mixed solution, tetrabutyl titanate is 18mL, absolute ethanol is 42mL;

[0081] The third step, BaTiO 3 Preparation of Nanotube / AAO Template Composite Structure

[0082] will contain BaTiO 3 Put the beaker of the sol on the magnetic stirrer, turn on the magnetic stirrer for single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com