P type doping ZnO based rare magnetic semiconductor material and method of producing the same

A dilute magnetic semiconductor, p-type technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, magnetic objects, etc., can solve the problems of p-type doping difficulties, and achieve high carrier concentration, simple technology, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

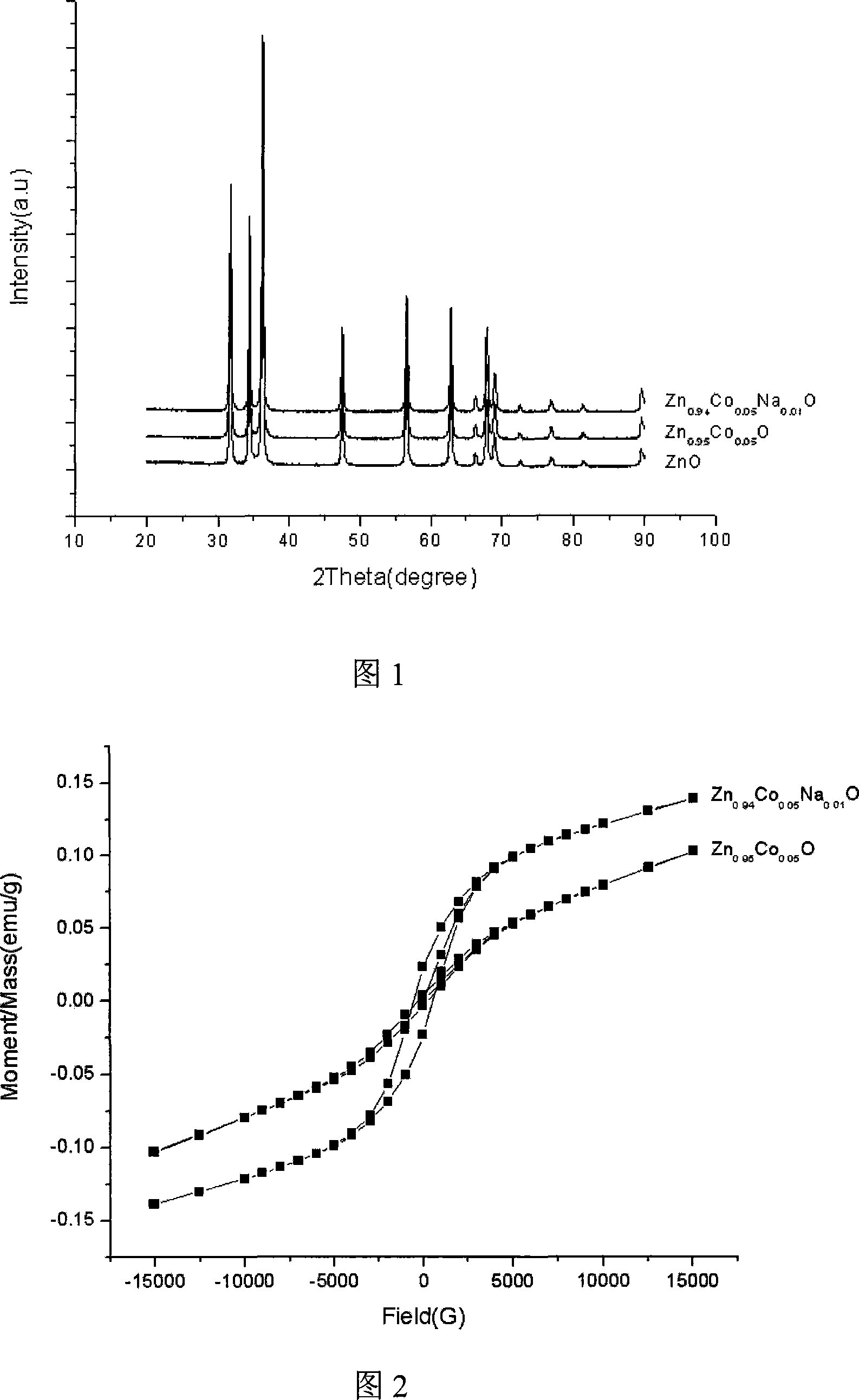

[0027] Embodiment 1: preparation Zn 0.95 co 0.05 O dilute magnetic semiconductor powder

[0028] 1) Add zinc acetate (5.21g) and cobalt acetate (0.31g) with a molar percentage of 95:5 to 50ml of ethylene glycol methyl ether, and then add 0.5ml of ethanolamine to form a solution with a concentration of 0.5mol / L; Stir at room temperature until completely dissolved, continue to stir for 12 hours, and then stand and age for 24 hours to obtain a transparent and uniform sol;

[0029] 2) Put the sol in an oven at 100°C for 24 hours to obtain a gel;

[0030] 3) heat-treat the gel at 300°C for 3 hours, and cool with the furnace to obtain the desired Zn 0.95 co 0.05 O dilute magnetic semiconductor powder.

Embodiment 2

[0031] Embodiment 2: preparation Zn 0.94 co 0.05 Na 0.01 O dilute magnetic semiconductor powder

[0032] 1) Add zinc acetate (5.16g), cobalt acetate (0.31g) and sodium acetate (0.02g) with a molar percentage of 94:5:1 to 50ml of ethylene glycol methyl ether, and then add 0.5ml of ethanolamine to form A solution with a concentration of 0.5mol / L; after stirring at room temperature until completely dissolved, continue to stir for 15 hours, and then stand and age for 36 hours to obtain a transparent and uniform sol;

[0033] 2) Place the sol in an oven at 120°C for 24 hours to obtain a gel;

[0034] 3) The gel was heat-treated at 350°C for 5 hours, and cooled with the furnace to obtain the desired Zn 0.94 co 0.05 Na 0.01 O dilute magnetic semiconductor powder.

Embodiment 3

[0035] Embodiment 3: preparation Zn 0.8 co 0.15 Na 0.5 O dilute magnetic semiconductor film

[0036] 1) Add zinc acetate (4.39g), cobalt acetate (0.93g) and sodium acetate (0.1g) with a molar percentage of 80:15:5 to 50ml of ethylene glycol methyl ether, and then add 0.5ml of ethanolamine to form A solution with a concentration of 0.5mol / L; after stirring at room temperature until completely dissolved, continue to stir for 12 hours, and then stand and age for 24 hours to obtain a transparent and uniform sol;

[0037] 2) Add the colloid solution dropwise on the pre-cleaned quartz glass substrate, coat the colloid evenly by rotating the substrate on a spin coater, and preheat at 100°C for 3 minutes;

[0038] 3) Repeat the coating and preheating process 20 times to complete the pre-coating;

[0039] 4) heat-treat the pre-coated quartz glass substrate at 300°C for 3 hours, and cool with the furnace to obtain the required Zn 0.8 co 0.15 Na 0.5 O dilute magnetic semiconductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com