A ferromagnetic LSMO film and a preparation method thereof

A thin film and magnetic technology, applied in the direction of magnetic thin film, magnetic film to substrate application, magnetic objects, etc., can solve the problems of incomplete volatilization of organic solvents, poor film crystal quality, high annealing temperature, etc., to improve film quality and increase The effect of density and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

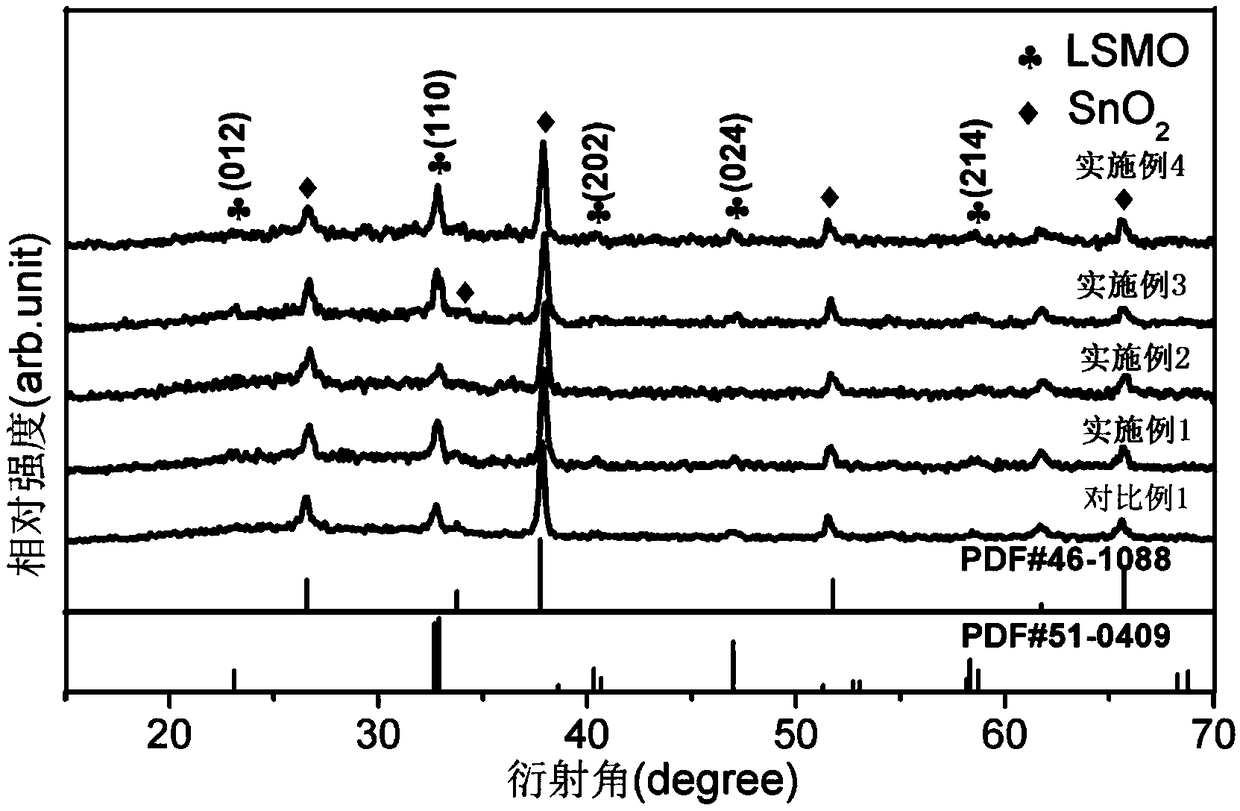

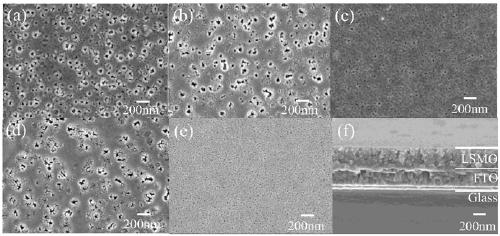

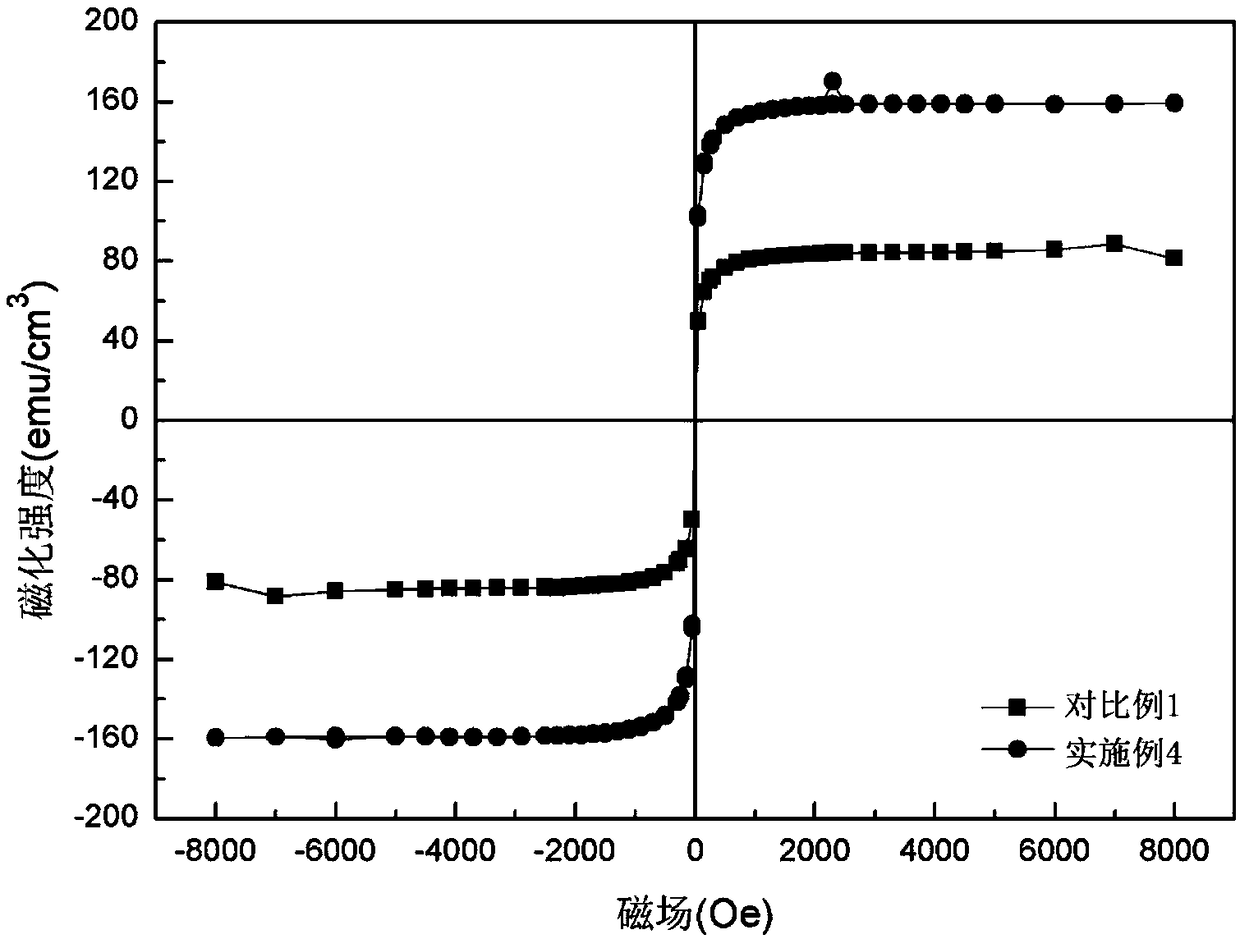

[0043] Step 1: La(NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 and C 4 h 6 MnO 4 4H 2 O is dissolved in ethylene glycol methyl ether at a molar ratio of 0.7:0.3:1 and stirred for 30 minutes, then added deionized water and stirred until completely dissolved, then added acetic anhydride and stirred for 90 minutes, and stood to obtain La 0.7 Sr 0.3 MnO 3 Precursor, La 0.7 Sr 0.3 MnO 3 The concentration of metal ions in the precursor solution is 0.3mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1.1;

[0044] Step 2: Let the precursor solution stand for 12 hours, and spin-coat La on the FTO / Glass substrate by spin coating 0.7 Sr 0.3 MnO 3 Precursor, get La 0.7 Sr 0.3 MnO 3 Wet film, the wet film is uniformly glued and then baked at 160°C for 8 minutes to obtain a dry film. When the temperature is raised to 400°C at a heating rate of 20°C / min, pre-annealing is performed for 20 minutes, and then the temperature is raised at a heating rate of ...

Embodiment 2

[0047] Step 1: La(NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 and C 4 h 6 MnO 4 4H 2 O is dissolved in ethylene glycol methyl ether at a molar ratio of 0.7:0.3:1 and stirred for 30 minutes, then added deionized water and stirred until completely dissolved, then added acetic anhydride and stirred for 90 minutes, and stood to obtain La 0.7 Sr 0.3 MnO 3 Precursor, La 0.7 Sr 0.3 MnO 3 The concentration of metal ions in the precursor solution is 0.3mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1.1;

[0048] Step 2: Let the precursor solution stand for 12 hours, and spin-coat La on the FTO / Glass substrate by spin coating 0.7 Sr 0.3 MnO 3 Precursor, get La 0.7 Sr 0.3 MnO 3 Wet film, the wet film is uniformly glued and then baked at 160°C for 8 minutes to obtain a dry film. When the temperature is raised to 400°C at a heating rate of 10°C / min, pre-annealing is performed for 20 minutes, and then the temperature is raised at a heating rate of ...

Embodiment 3

[0051] Step 1: La(NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 and C 4 h 6 MnO 4 4H 2 O was dissolved in ethylene glycol methyl ether at a molar ratio of 0.7:0.3:1 and stirred for 30 minutes, then added deionized water and stirred until completely dissolved, then added acetic anhydride and stirred for 90 minutes, and added dropwise polyethylene glycol and stirred evenly, statically La 0.7 Sr 0.3 MnO 3 Precursor, La 0.7 Sr 0.3 MnO 3 The concentration of metal ions in the precursor solution is 0.3mol / L, the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1.1; the volume ratio of polyethylene glycol and acetic anhydride is 0.25:1;

[0052] Step 2: Let the precursor solution stand for 12 hours, and spin-coat La on the FTO / Glass substrate by spin coating 0.7 Sr 0.3 MnO 3 Precursor, get La 0.7 Sr 0.3 MnO 3 Wet film, the wet film is uniformly glued and then baked at 160°C for 8 minutes to obtain a dry film. When the temperature is raised to 400°C at a heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com