Patents

Literature

34 results about "Colossal magnetoresistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

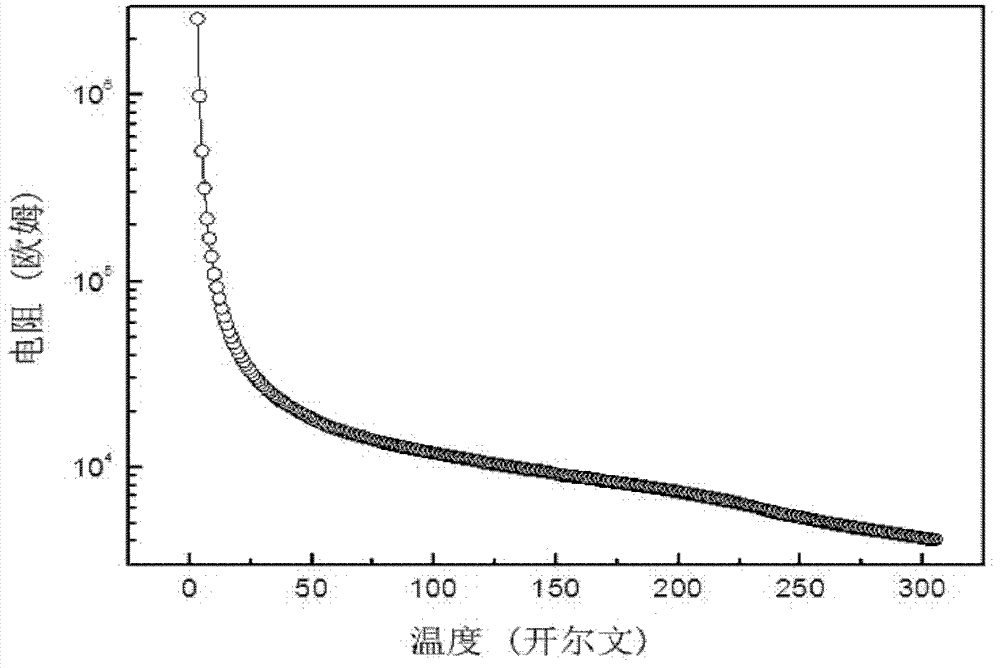

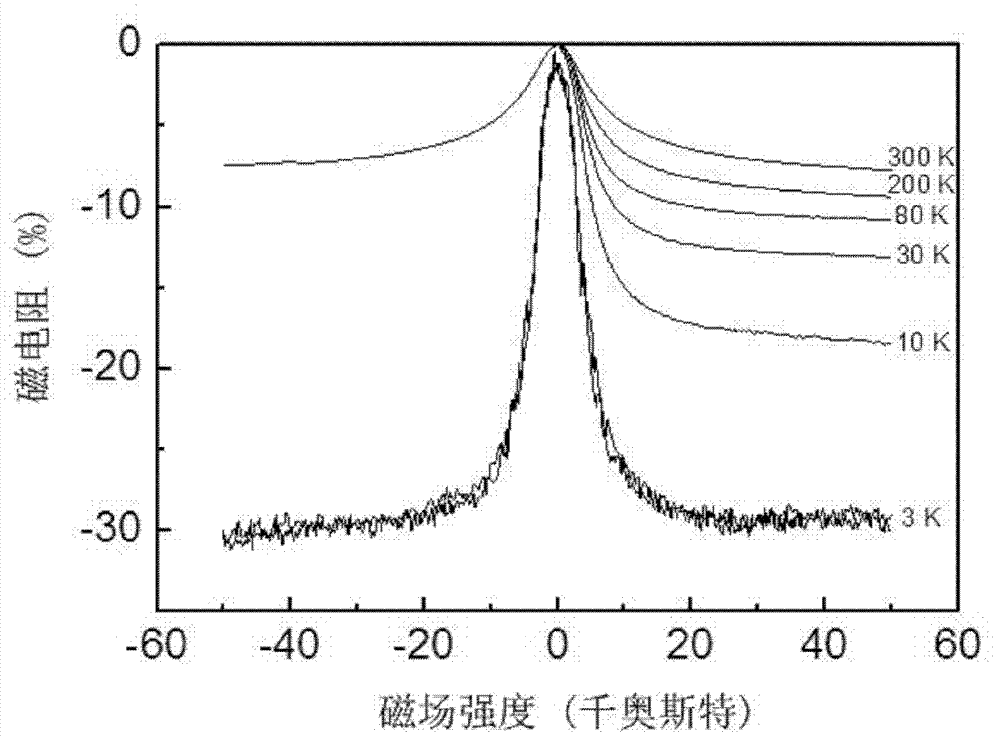

Colossal magnetoresistance (CMR) is a property of some materials, mostly manganese-based perovskite oxides, that enables them to dramatically change their electrical resistance in the presence of a magnetic field. The magnetoresistance of conventional materials enables changes in resistance of up to 5%, but materials featuring CMR may demonstrate resistance changes by orders of magnitude.

Buffered-layer memory cell

InactiveUS7029924B2Reliably programmedSolid-state devicesSemiconductor/solid-state device manufacturingIndiumSemiconductor

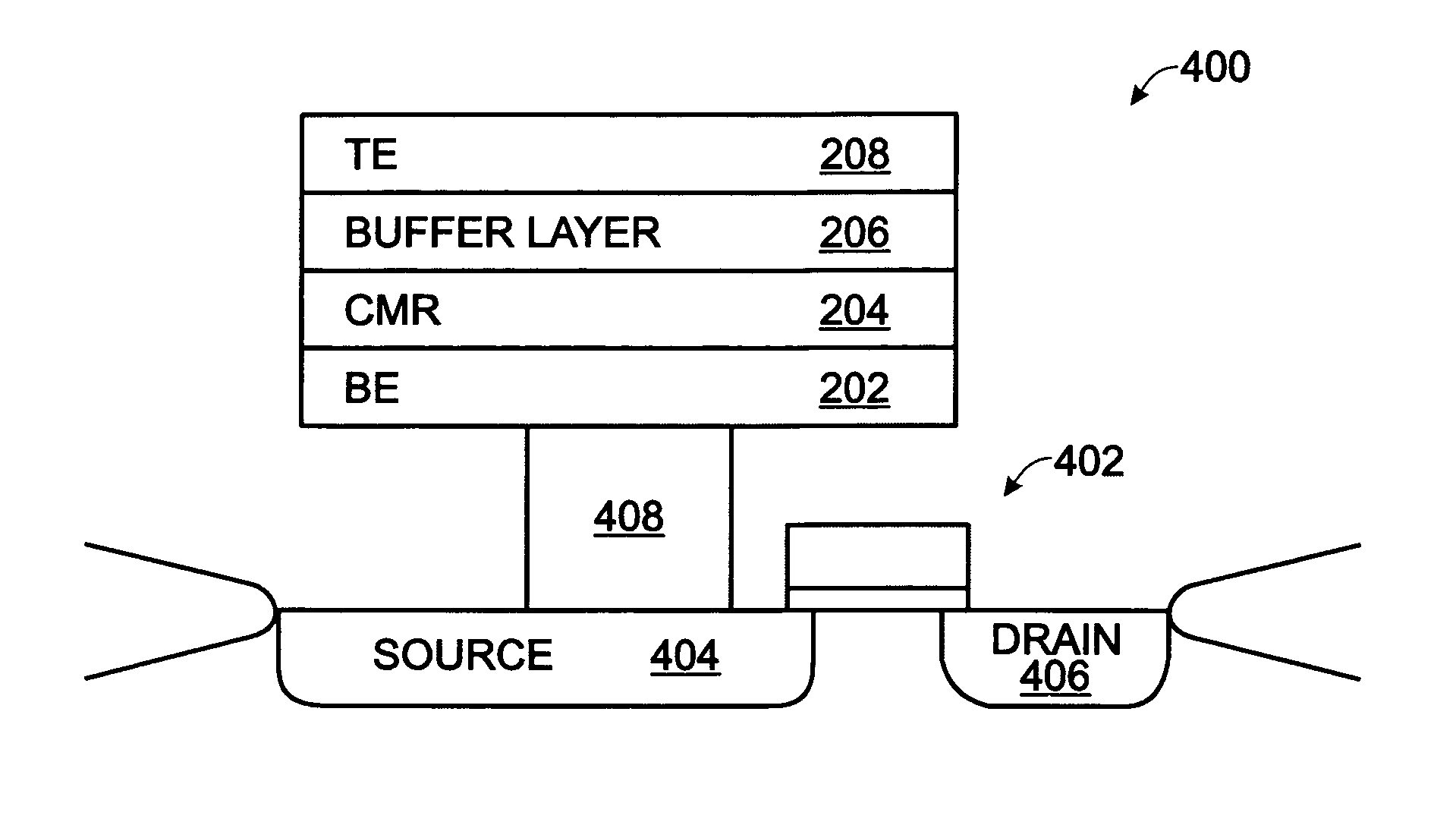

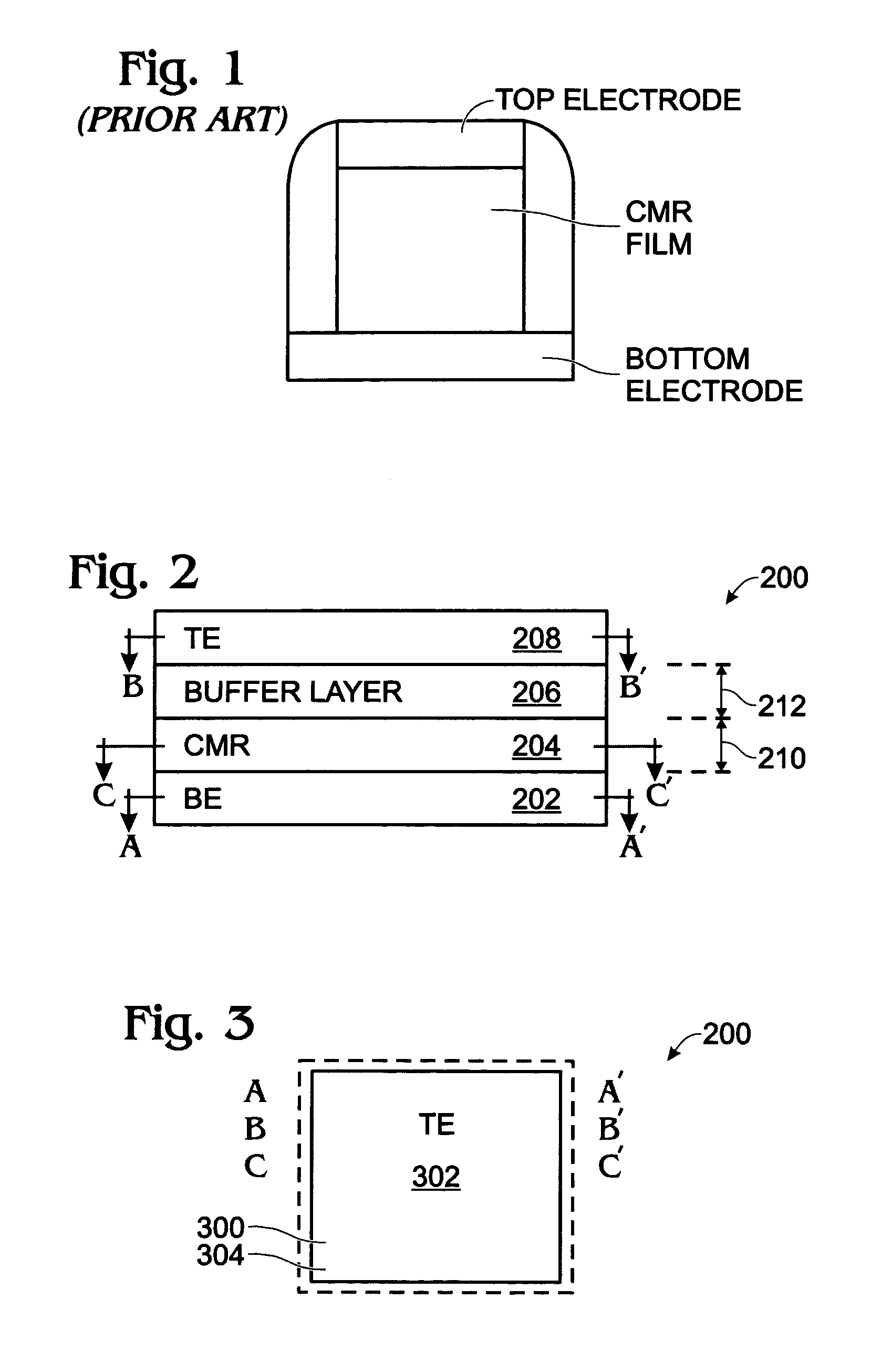

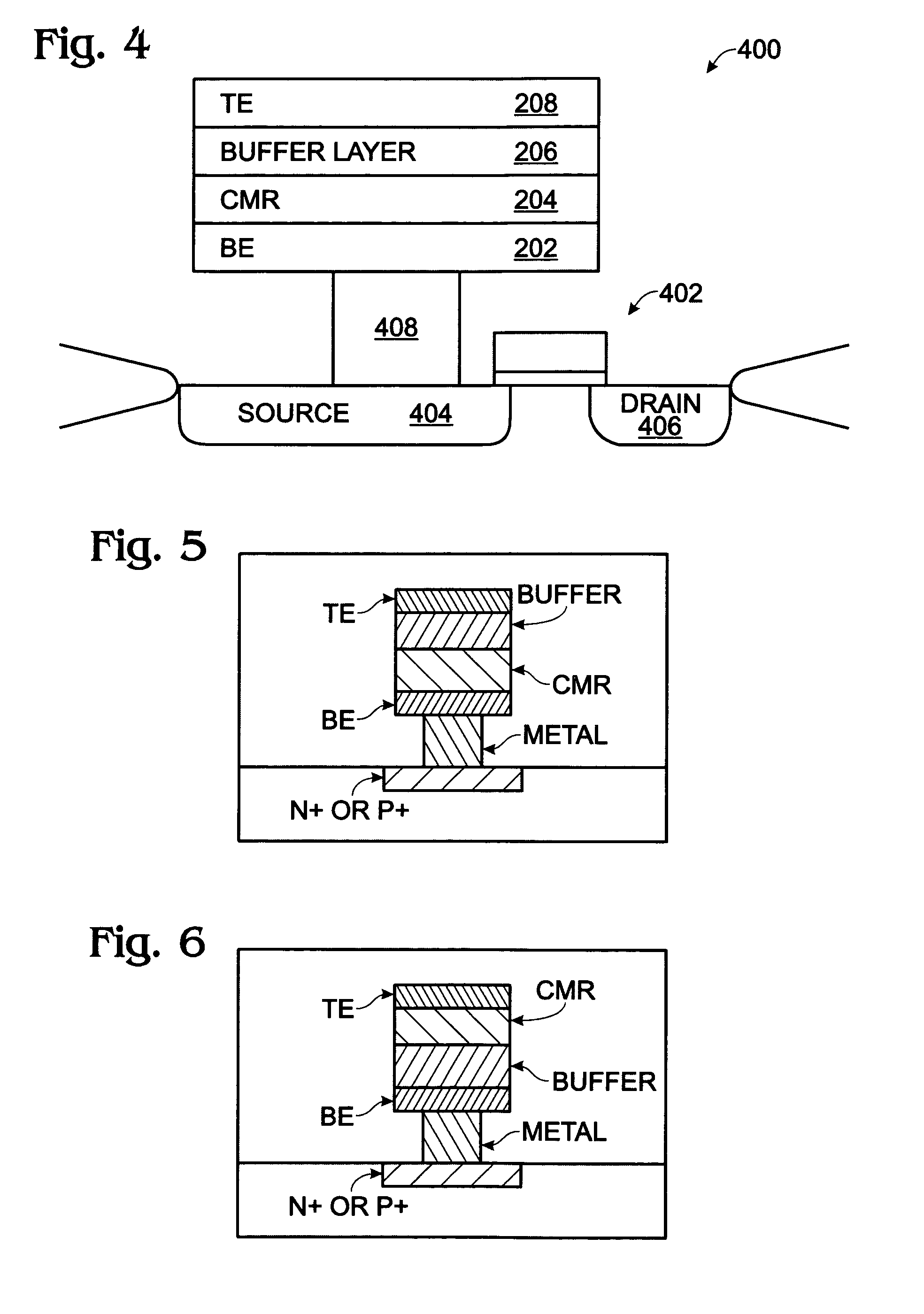

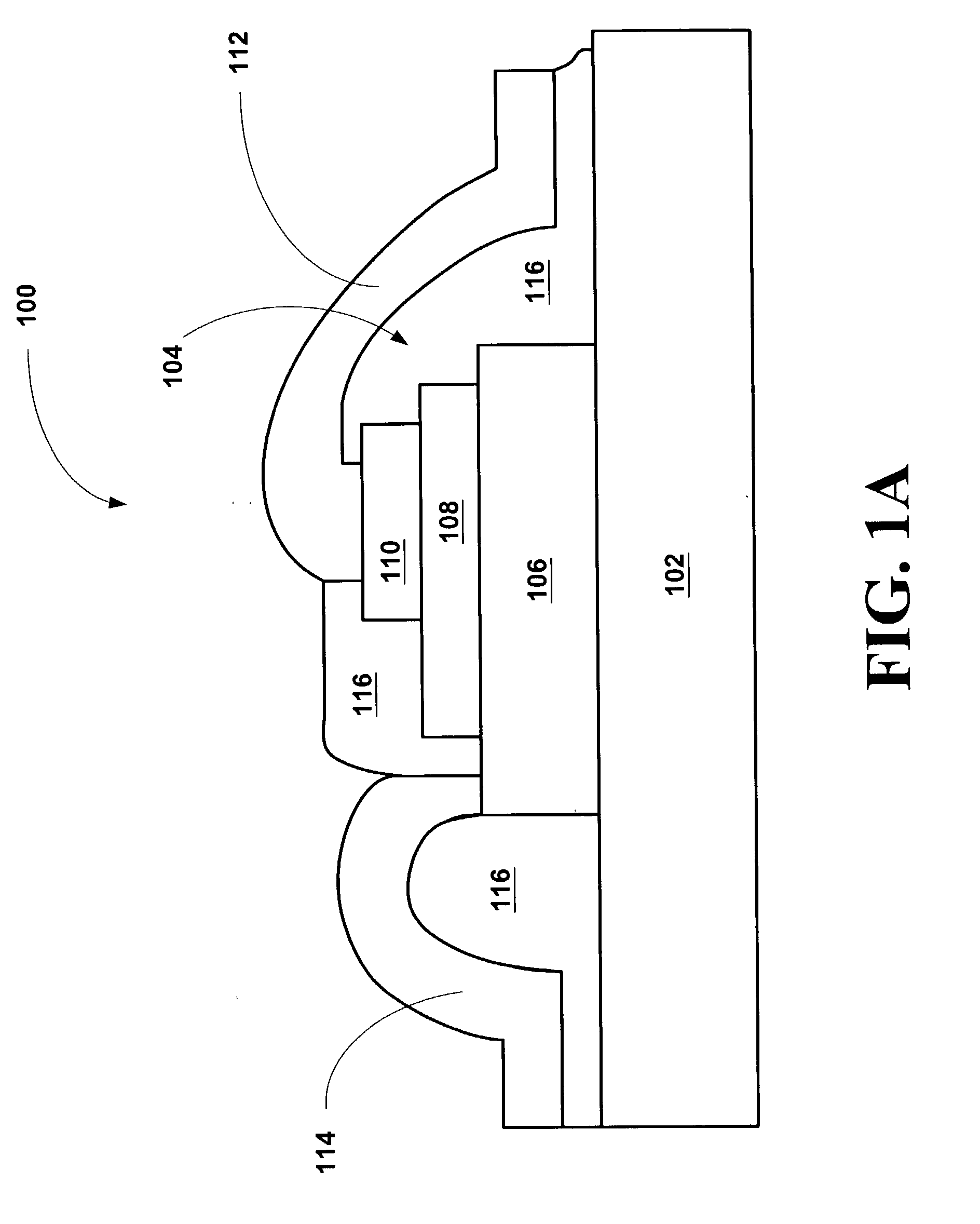

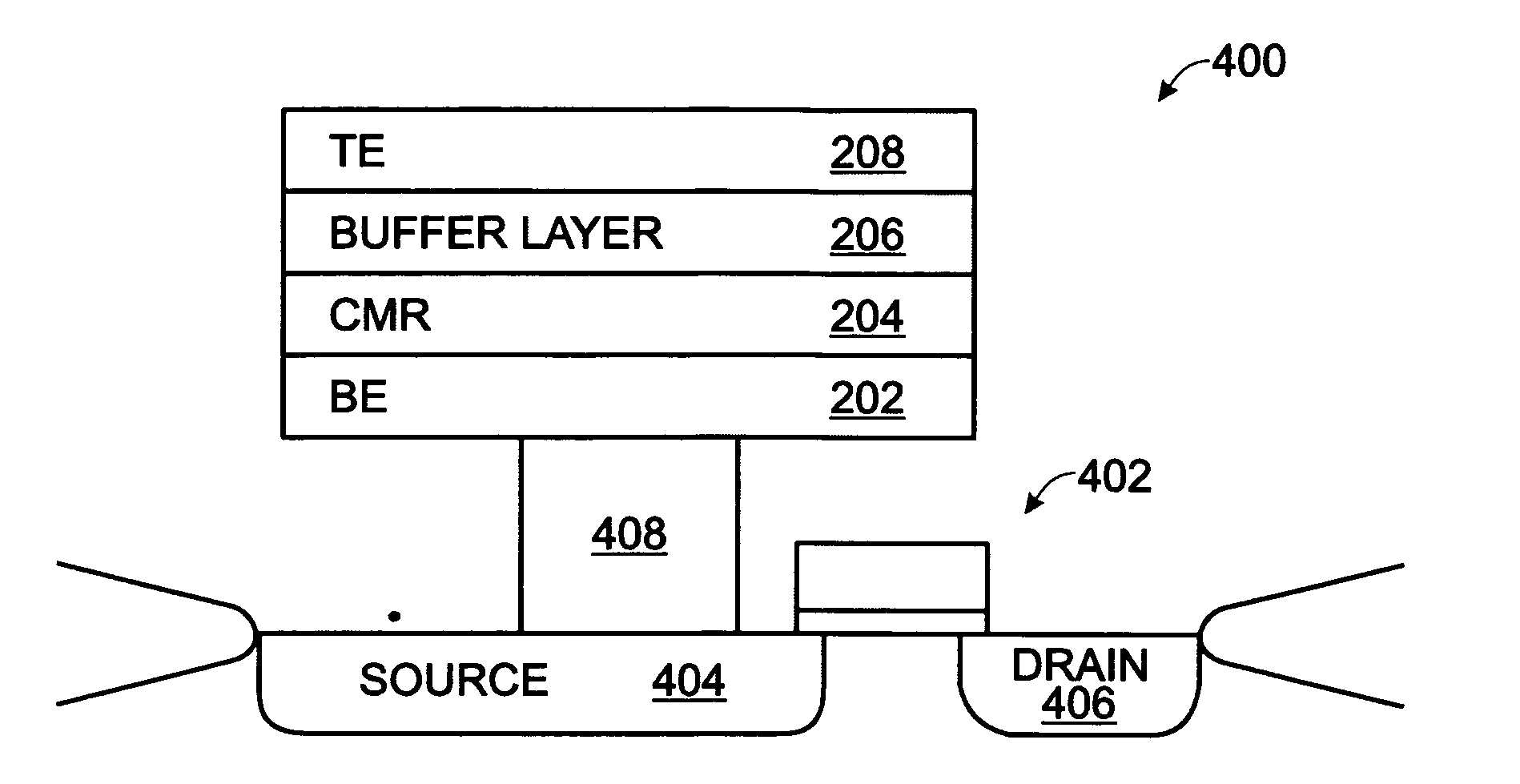

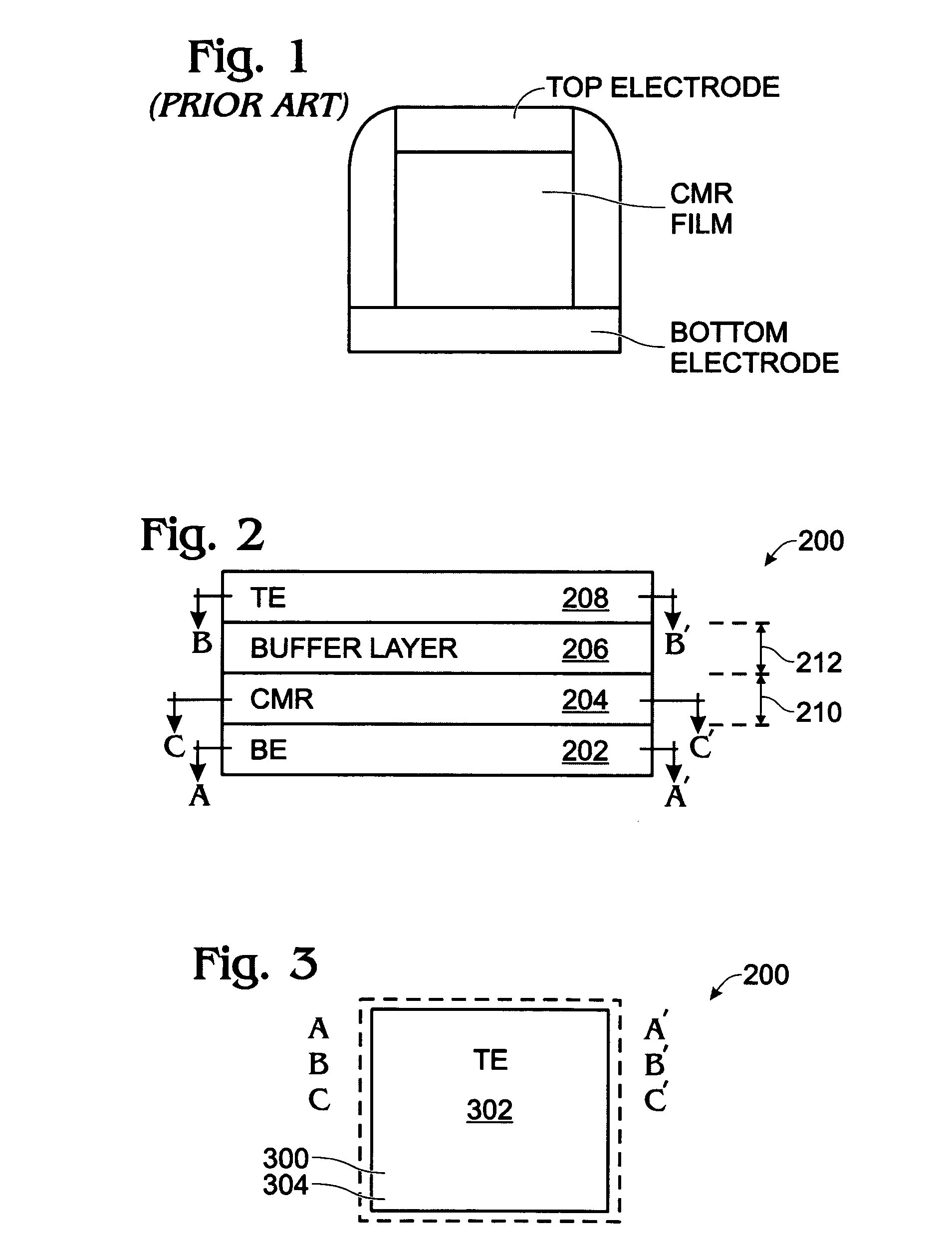

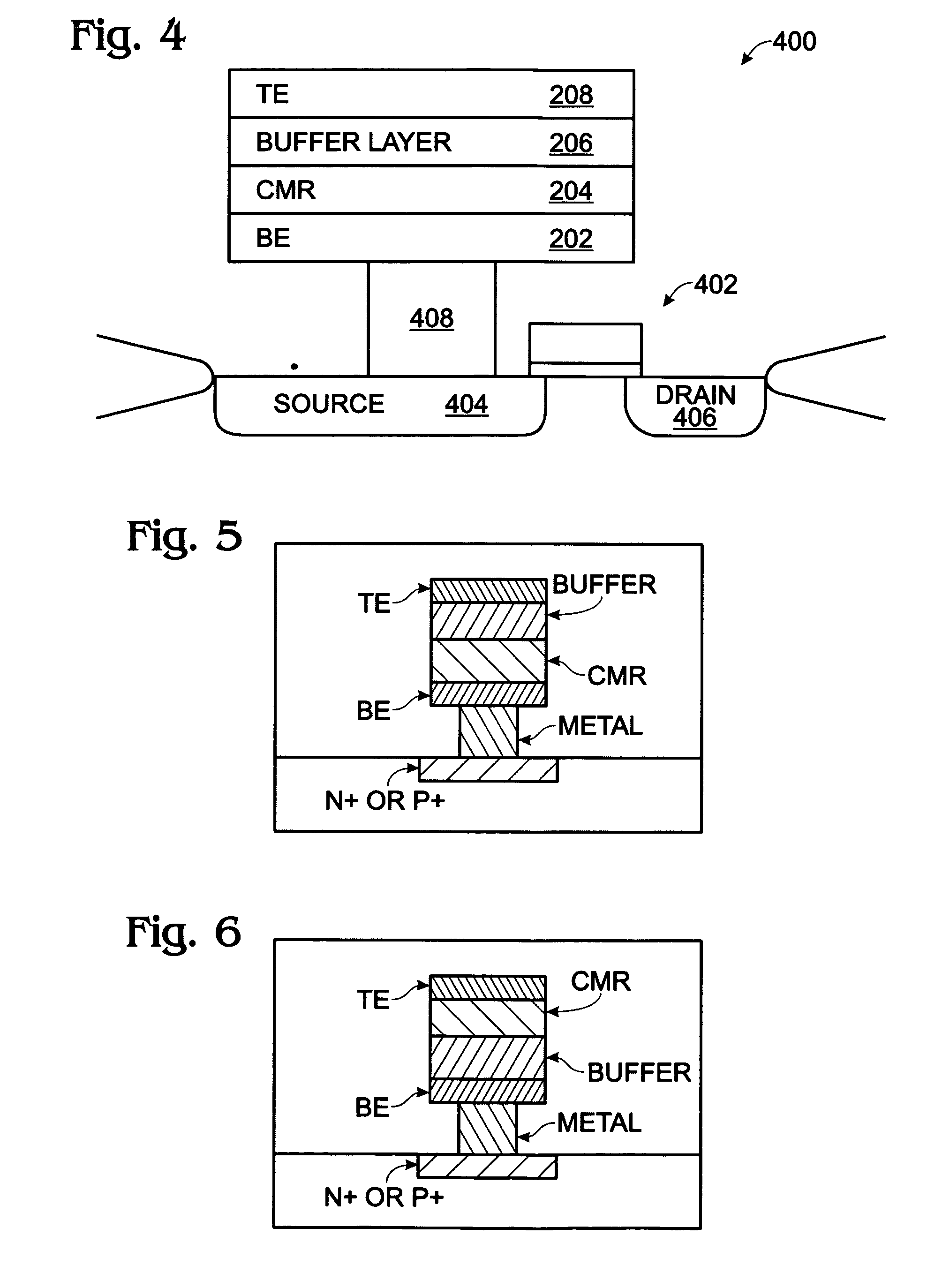

A method is provided for forming a buffered-layer memory cell. The method comprises: forming a bottom electrode; forming a colossal magnetoresistance (CMR) memory film overlying the bottom electrode; forming a memory-stable semiconductor buffer layer, typically a metal oxide, overlying the memory film; and, forming a top electrode overlying the semiconductor buffer layer. In some aspects of the method the semiconductor buffer layer is formed from YBa2Cu3O7-X (YBCO), indium oxide (In2O3), or ruthenium oxide (RuO2), having a thickness in the range of 10 to 200 nanometers (nm). The top and bottom electrodes may be TiN / Ti, Pt / TiN / Ti, In / TiN / Ti, PtRhOx compounds, or PtIrOx compounds. The CMR memory film may be a Pr1-XCaXMnO3 (PCMO) memory film, where x is in the region between 0.1 and 0.6, with a thickness in the range of 10 to 200 nm.

Owner:XENOGENIC DEV LLC

Electrically programmable nonvolatile variable capacitor

A basic form of a variable capacitive apparatus and its actuating method are disclosed. The apparatus is a simple two-terminal structure and may be set by short duration, low voltage electrical pulses. Materials with perovskite structure or perovskite-related structures, especially colossal magnetoresistive materials, are the active constituents of the apparatus. The apparatus overcomes the shortcomings of its predecessors and offers the advantages of non-volatility, two or multi-level storage, non-destructive reading, free-of-power maintenance and potential high radiation hardness.

Owner:UNIV HOUSTON SYST

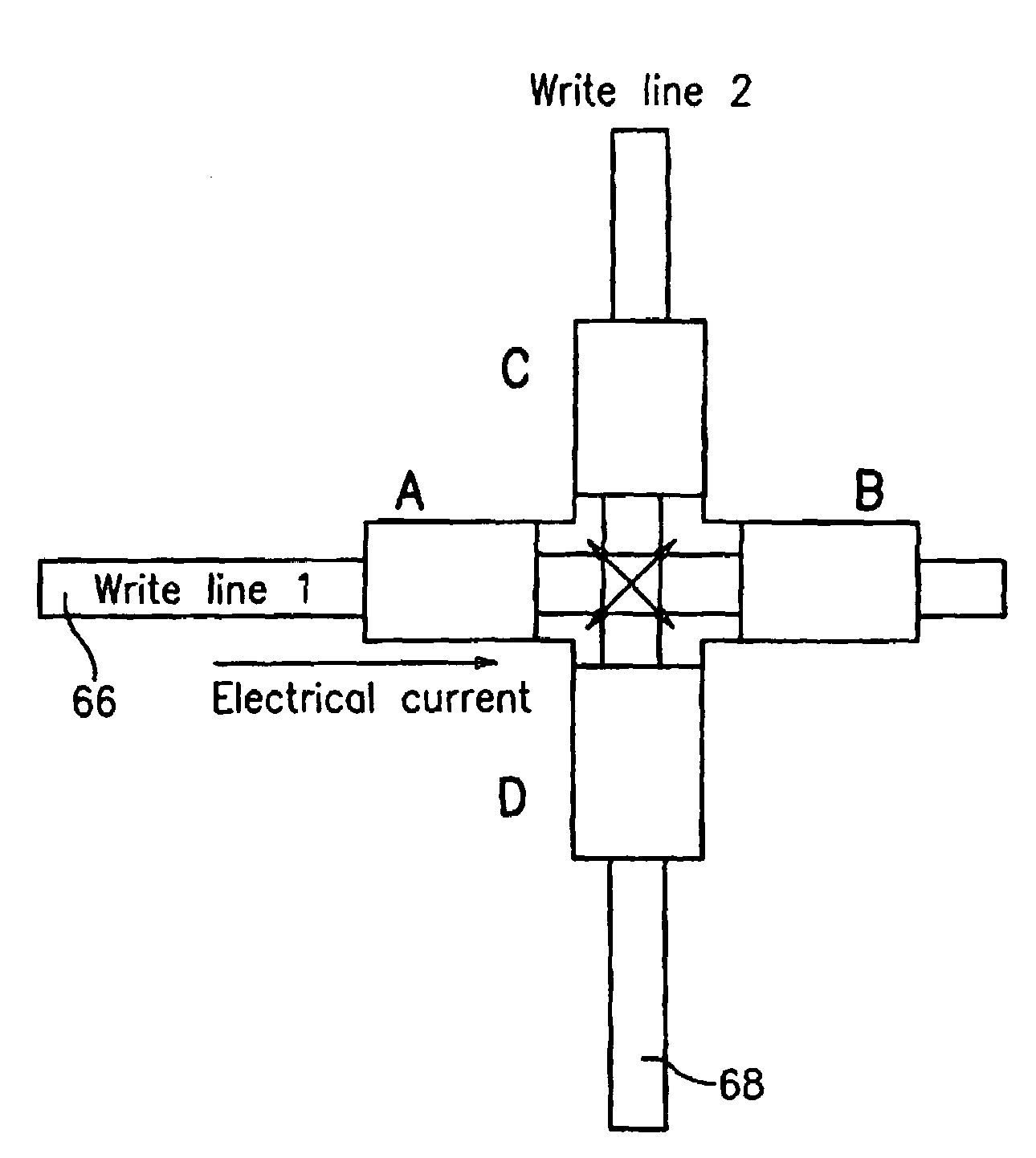

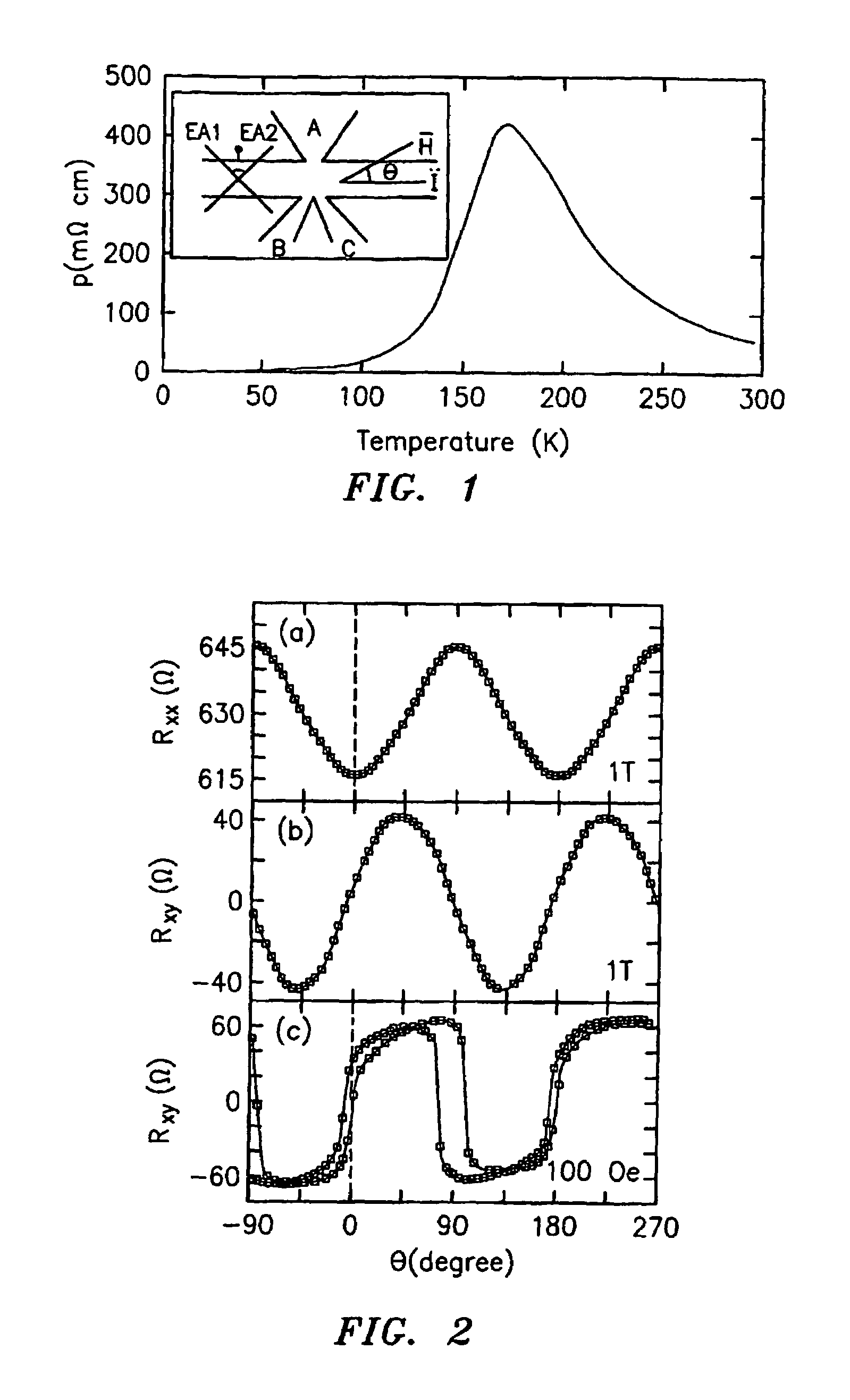

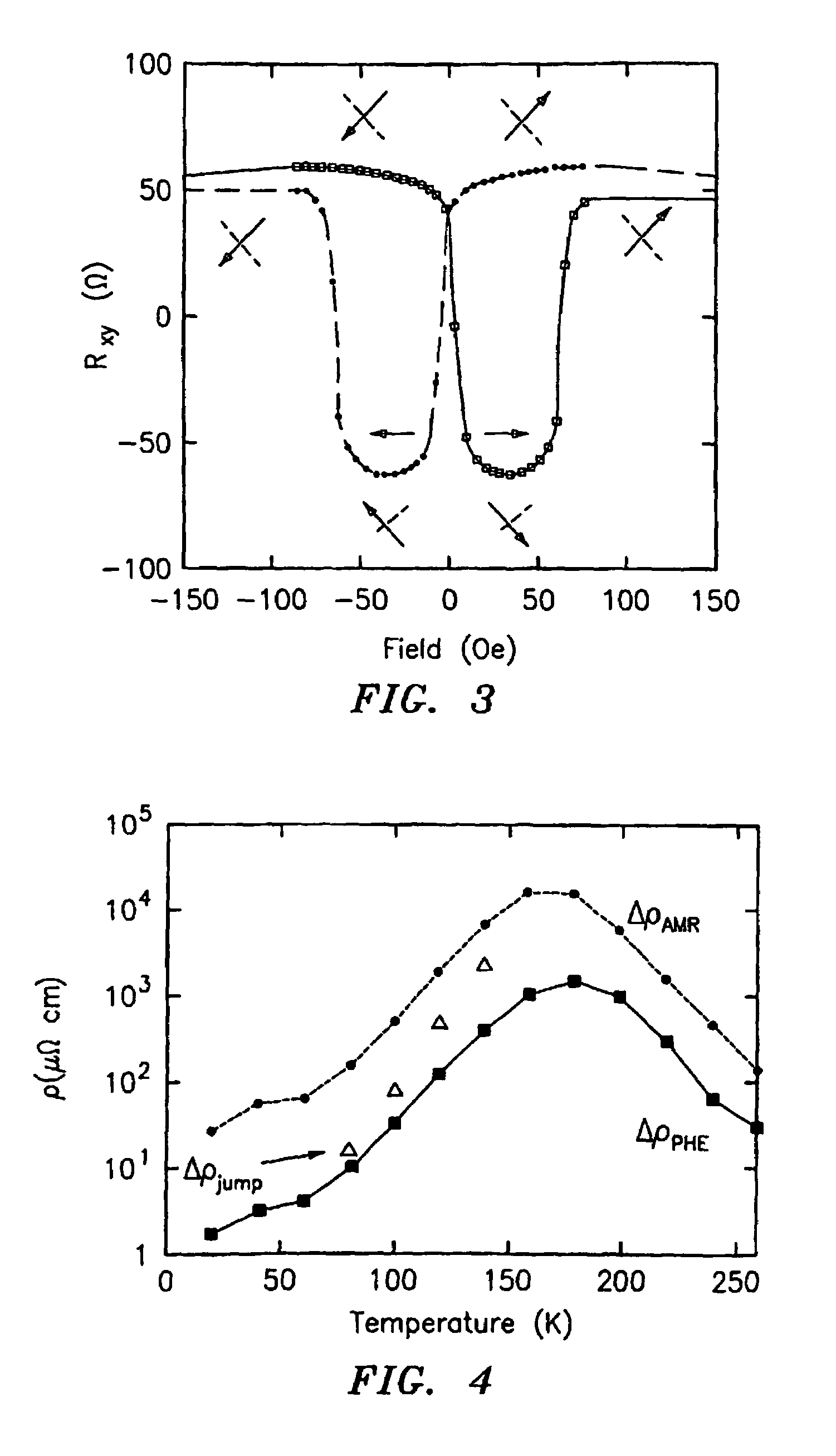

Magnetoelectronic devices based on colossal magnetoresistive thin films

ActiveUS20070096228A1Reduce complexityNanomagnetismMagnetic measurementsPerovskite manganitesAlkaline earth metal

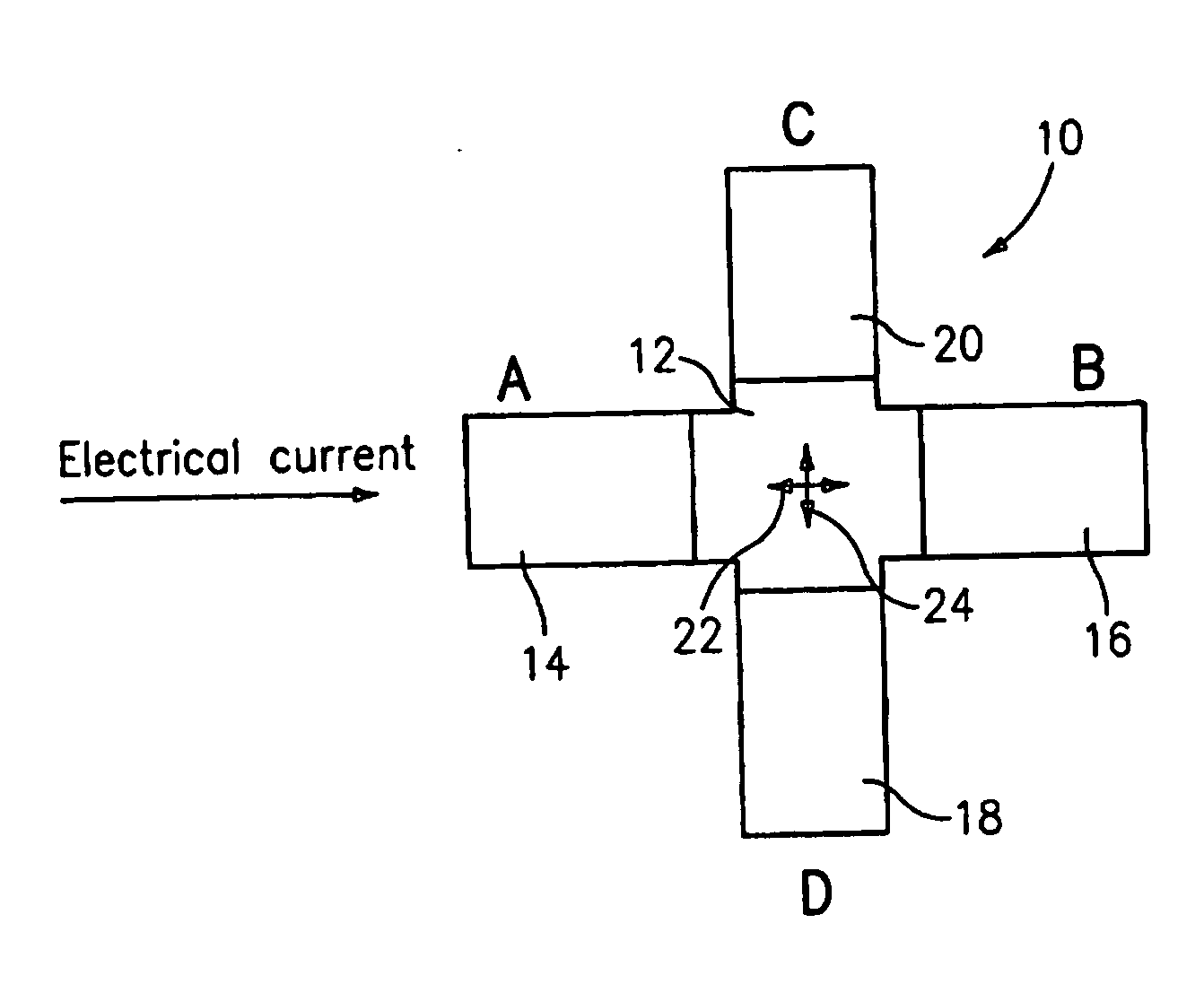

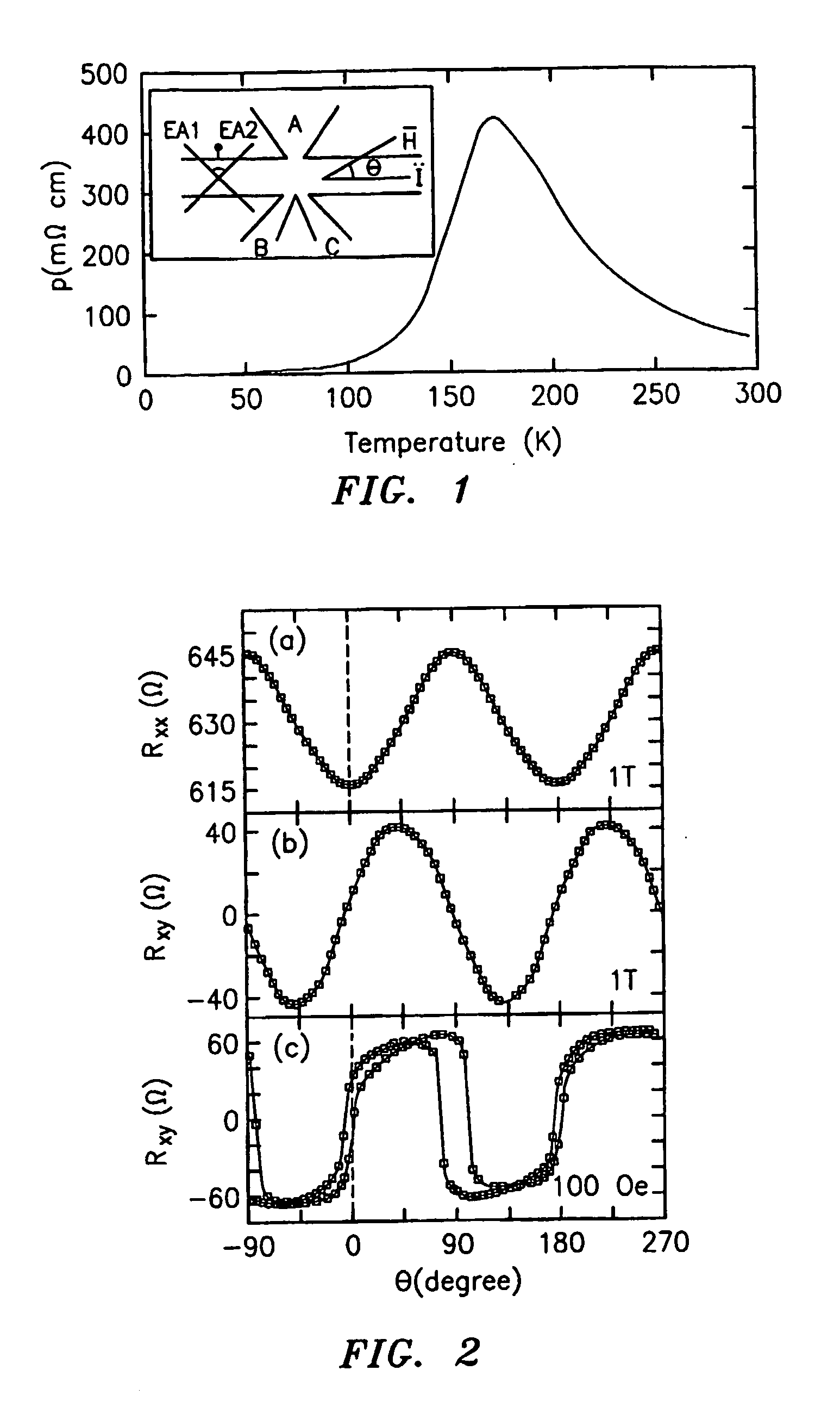

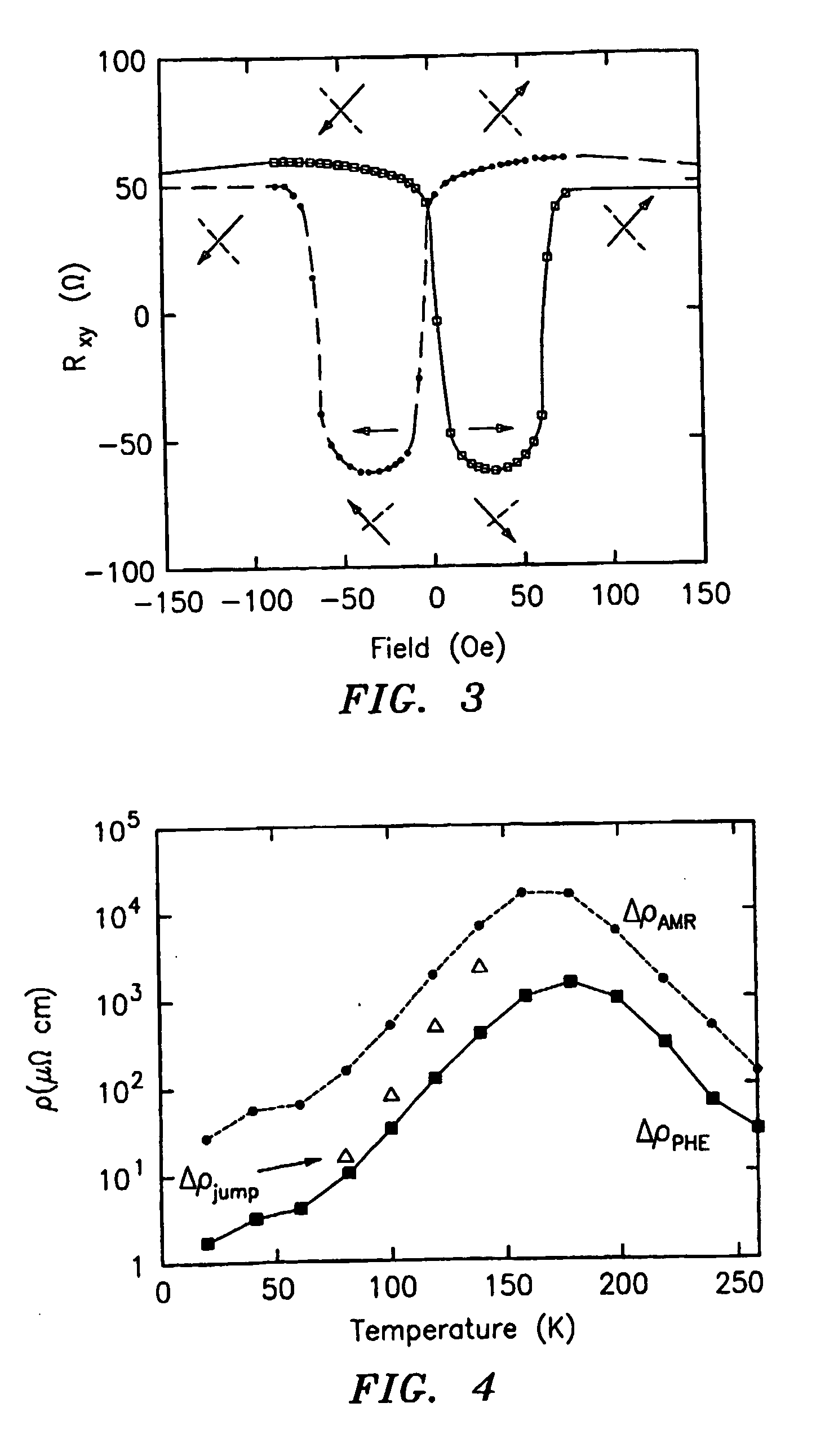

The present invention is directed to the use of perovskite manganite thin films and other magnetic films that exhibit both planar Hall effect and biaxial magnetic anisotropy to form the active area in magnetic sensor devices and in magnetic bit cells used in magnetoresistive random access memory (MRAM) devices. The manganite thin films of the invention are ferromagnetic manganites of the formula R1-xAxMnO3, wherein R is a rare-earth metal, A is an alkaline earth metal, and x is generally between about 0.15 and about 0.5.

Owner:BAR ILAN UNIV +1

Memory cell with buffered layer

ActiveUS20060099724A1Reliably programmedSolid-state devicesSemiconductor/solid-state device manufacturingIndiumMemory cell

Owner:XENOGENIC DEV LLC

Magnetoelectronic devices based on colossal magnetoresistive thin films

ActiveUS7684147B2Reduce complexityManufacture head surfaceNanomagnetismAlkaline earth metalPerovskite manganites

The present invention is directed to the use of perovskite manganite thin films and other magnetic films that exhibit both planar Hall effect and biaxial magnetic anisotropy to form the active area in magnetic sensor devices and in magnetic bit cells used in magnetoresistive random access memory (MRAM) devices. The manganite thin films of the invention are ferromagnetic manganites of the formula R1-xAxMnO3, wherein R is a rare-earth metal, A is an alkaline earth metal, and x is generally between about 0.15 and about 0.5.

Owner:BAR ILAN UNIV +1

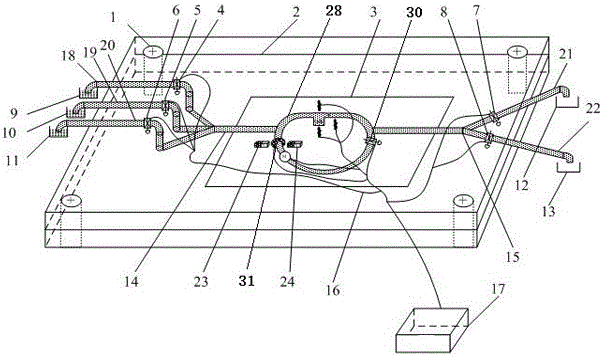

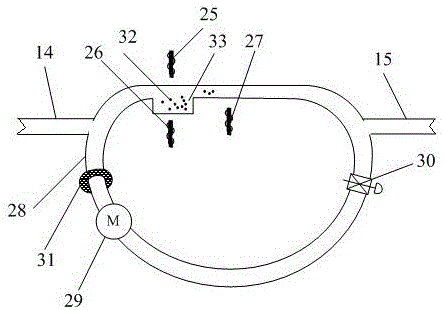

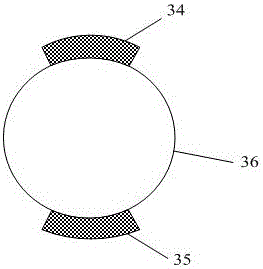

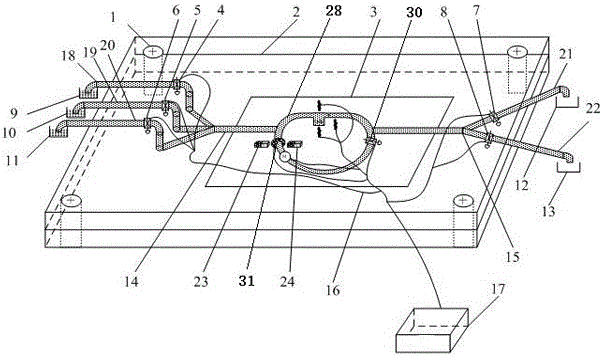

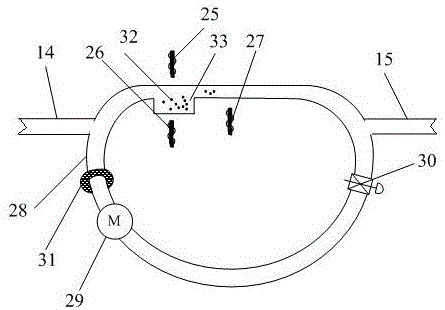

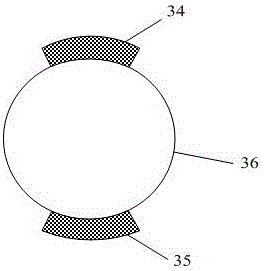

Microfluidic-based magnetic bead separation device and method

The invention discloses a microfluidic-based magnetic bead separation device and method in the field of microfluidic application. An immunomagnetic bead solution inlet pipe, a bacterial mixed solution inlet pipe and a sterile water inlet pipe are integrated into a main inlet pipe, a microfluidic chip is provided with an annular pipe connected to the main inlet pipe and a main outlet pipe, a micro-pump and a sixth solenoid valve are connected to the annular pipe in series, an annular colossal magnetoresistance chip set sleeves the annular pipe, the annular pipe is provided with a groove communicated with the interior of the annular pipe and integrated to the annular pipe, a right ahead side, a right astern side and an outlet side of the groove are provided with electromagnets, an outlet of the main outlet pipe is respectively connected to a mixed solution outlet pipe and a sterile water outlet pipe, through electromagnet and solenoid valve turning-on and off, magnetic beads are gathered, an immunization magnetic bead amount is detected through a magnetoresistance chip, the inner wall of the pipe is cleaned by sterile water and simultaneously, the immunomagnetic beads are collected.

Owner:JIANGSU UNIV

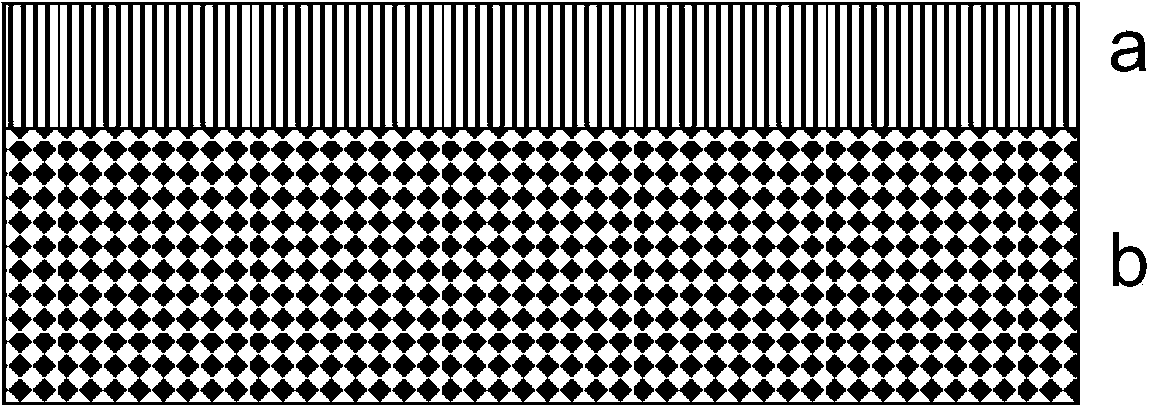

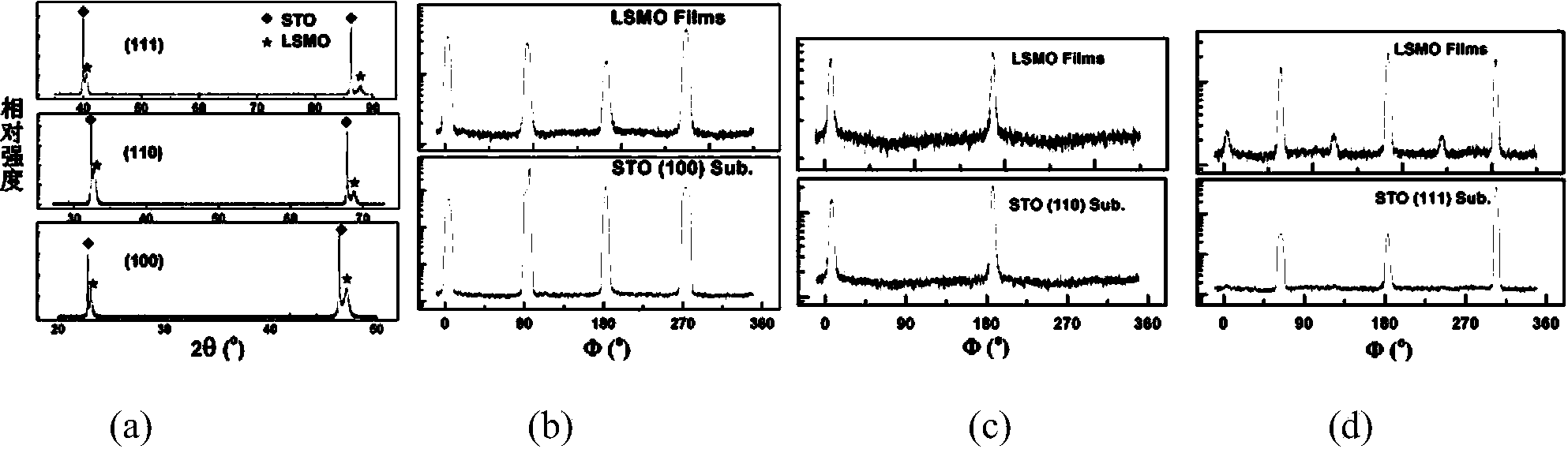

Manganite epitaxial thin film and preparation method thereof

InactiveCN103774227AStrong ferromagnetismGood electrical transportPolycrystalline material growthAfter-treatment detailsChemical solutionManganese

The invention discloses a manganite epitaxial thin film. The manganite epitaxial thin film is of a layered structure and comprises a single crystal basal layer and a manganite epitaxial thin film layer growing on the single crystal basal layer in a stacking manner. The invention aslo discloses a method for preparing the manganite epitaxial thin film by adopting a chemical solution approach. The adjustment of physical properties such as ferromagnetic / paramagnetic curie temperature and electrical transport property of the manganite epitaxial thin film is realized by adjustment of the components. The manganite epitaxial thin film has ferromagnetic property and electrical transport and colossal magnetoresistance effects, is compatible with a semiconductor integrated circuit technology and has wide application prospect in information industries such as magnetoresistance sensors and magnetic memory materials. The preparation method is simple to operate and low in cost; the manganite epitaxial thin film is good in repeatability and suitable for large-scale production.

Owner:EAST CHINA NORMAL UNIVERSITY

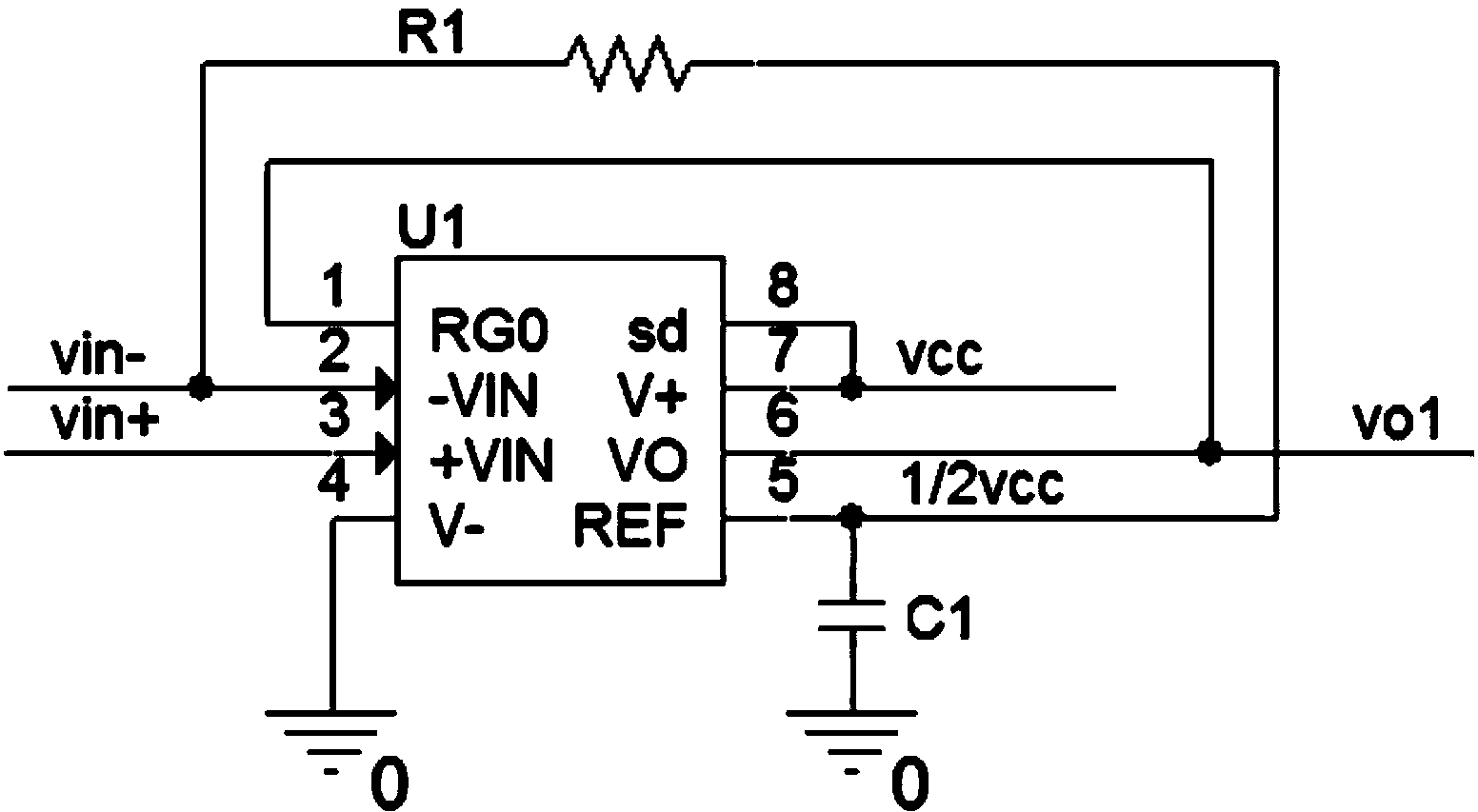

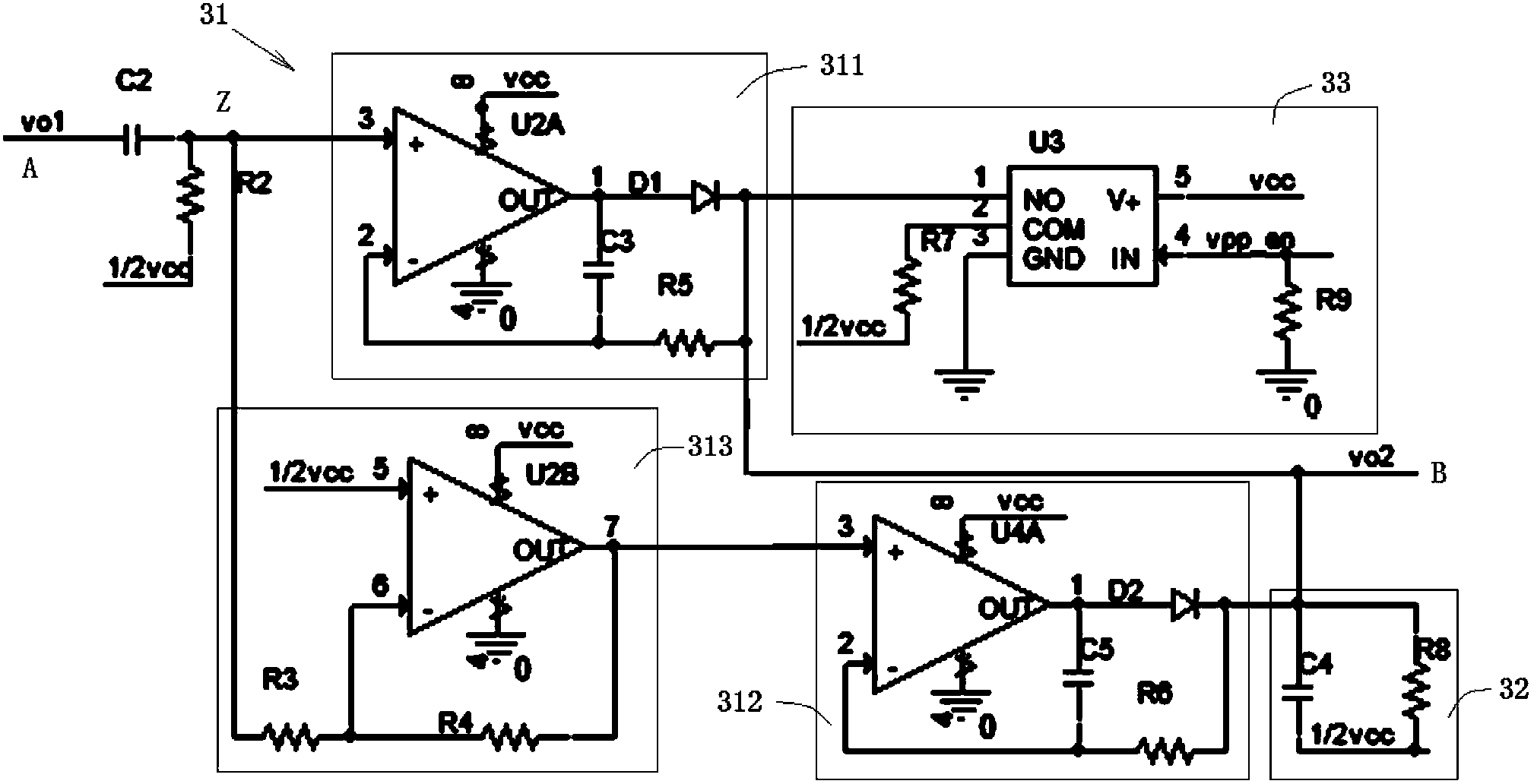

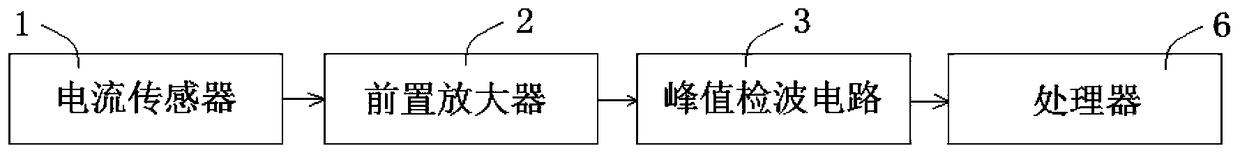

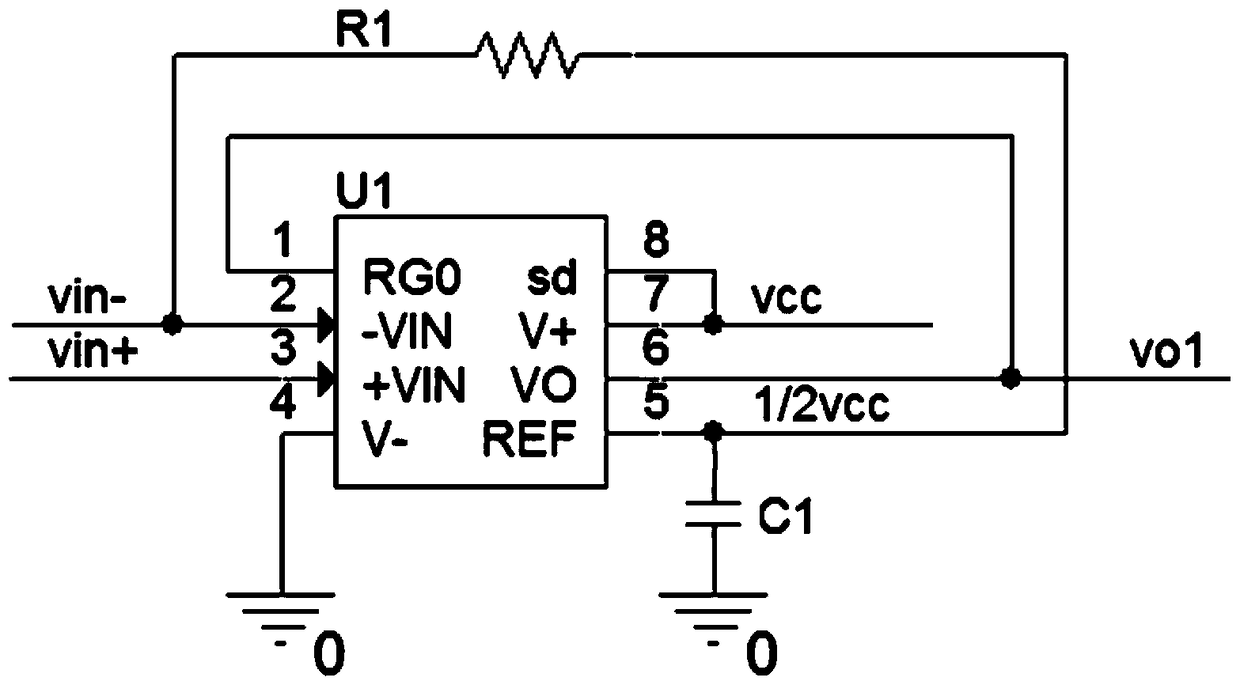

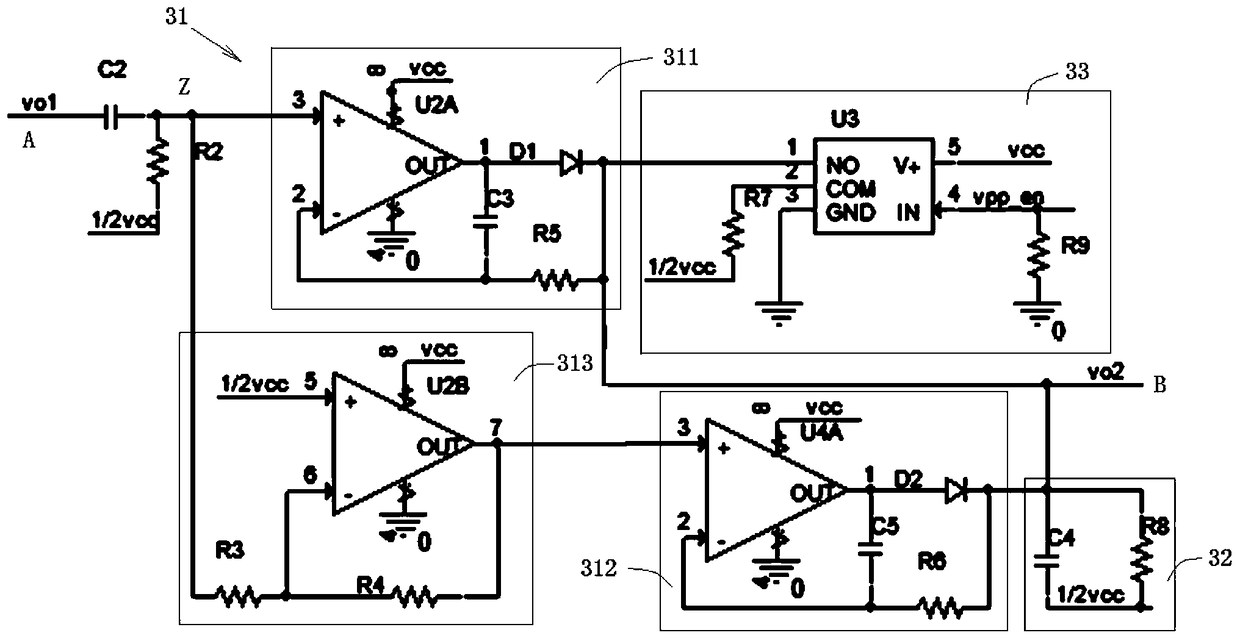

Novel lightning stroke current measuring device

InactiveCN103901256ASimple structureLow costAc/pulses peak value measurementsLightning strokesSmart grid

The invention provides a novel lightning stroke current measuring device. The novel lightning stroke current measuring device comprises a colossal magnetoresistance current sensor for obtaining a voltage signal corresponding to the size of lightning stroke current, a front amplifier for amplifying the voltage signal obtained by the colossal magnetoresistance current sensor, a peak value demodulation circuit for detecting the peak value of the voltage signal so as to obtain a peak value signal, and a processor for obtaining the value of the lightning stroke current according to the peak value signal. The lightning stroke current measuring device has the advantages of simple structure, low cost, high precision and convenient installation, is suitable for low-power occasions, and can be widely applied to occasions in need of lightning stroke current or flashover current measurement, such as high speed railways, intelligent power networks, base stations and the like.

Owner:BEIJING JIAYUE TONGLEJI ELECTRONICS

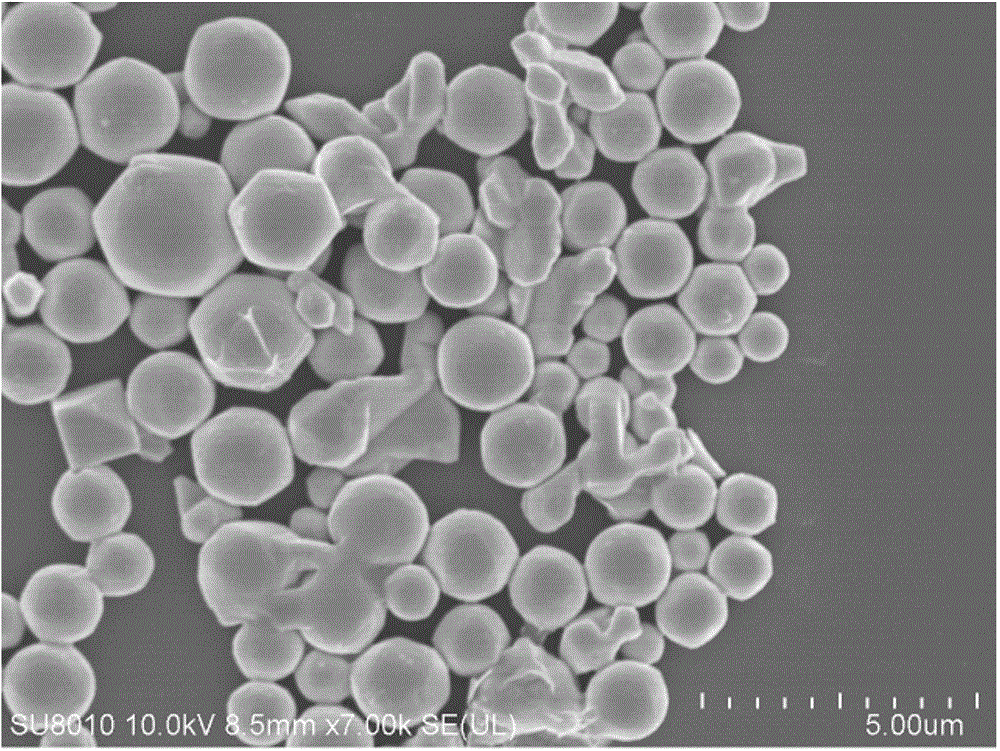

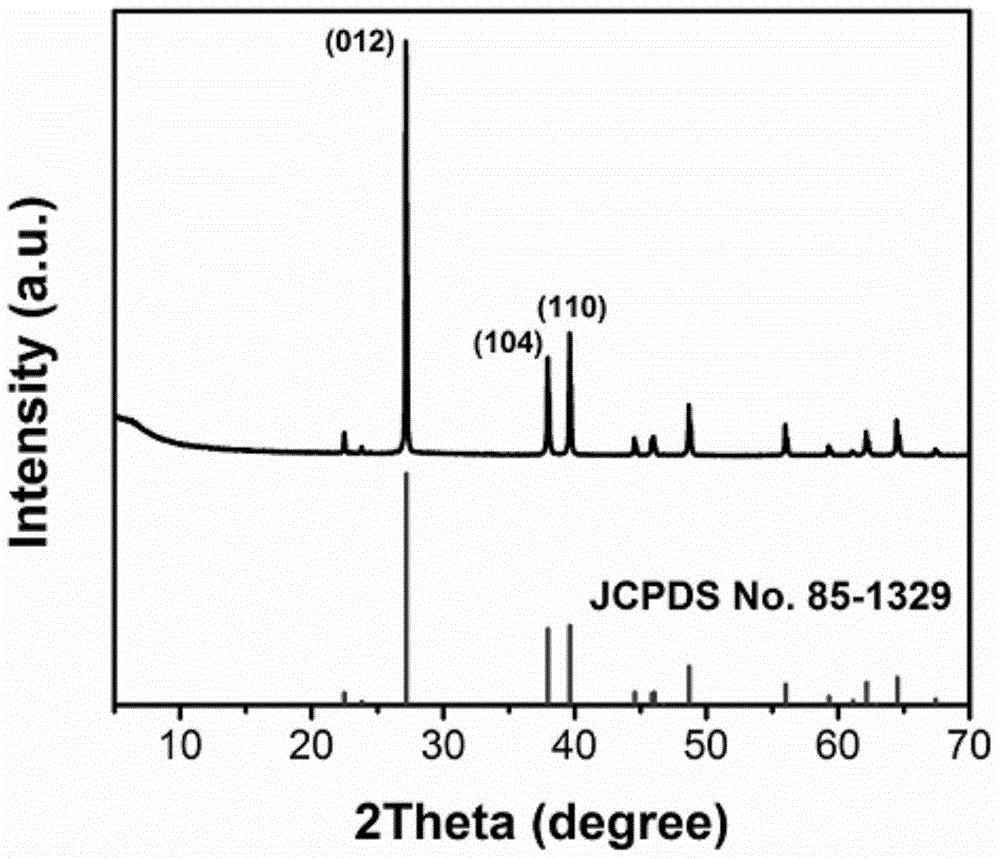

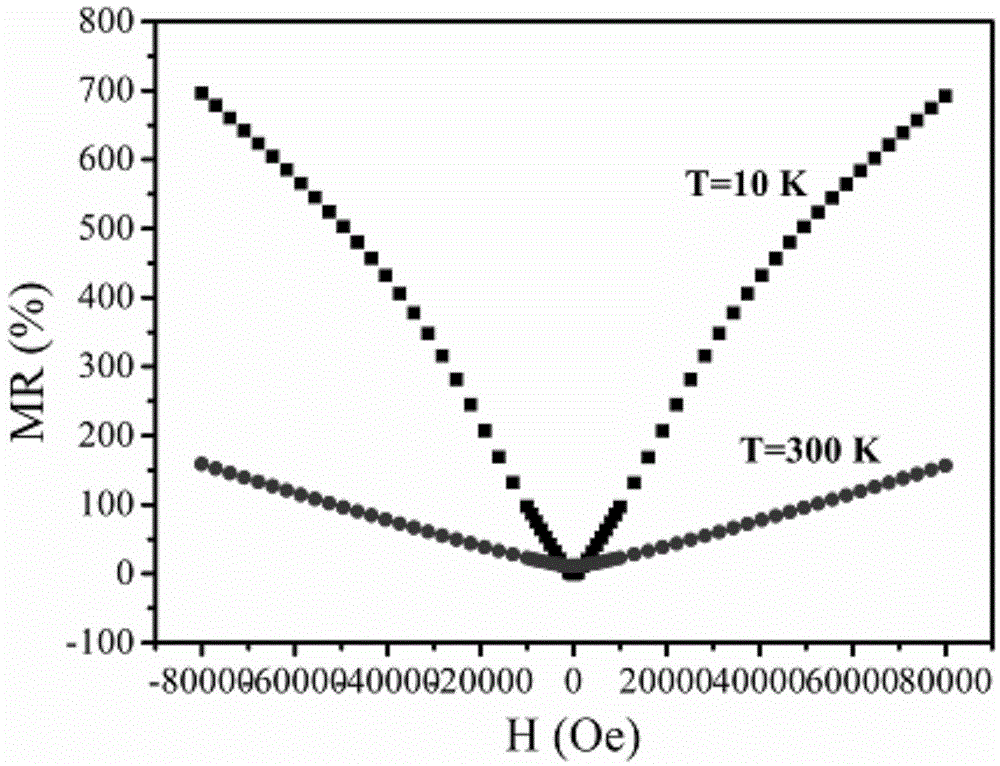

Bismuth micron particle and manufacturing method thereof

The invention provides a bismuth micron particle. The particle is a bismuth elementary substance, the particle size of the particle is 1 micron to 3 microns, and the particle is spherical or polyhedral. The method for manufacturing the particle comprises the following steps that a bismuth source and template agents are added to glycol and stirred to be completely dissolved, then the pH value of a solution is adjusted to be larger than 10 while stirring is carried out, after solute is completely dissolved, the solution is transferred into a closed polytetrafluoroethylene lining high-pressure reaction still, a reaction is carried out for more than 10 h under the condition of 160 DEG C to 200 DEG C, a product is centrifuged or filtered after the reaction is finished, residual solute is removed through washing, and the bismuth micron particle can be obtained through drying and cooling. The positive colossal magnetoresistance of the bismuth micron particle is more than 700 percent at low temperature, the positive colossal magnetoresistance of the bismuth micron particle is more than 180 percent at indoor temperature, and the manufacturing method of the bismuth micron particle is simple.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

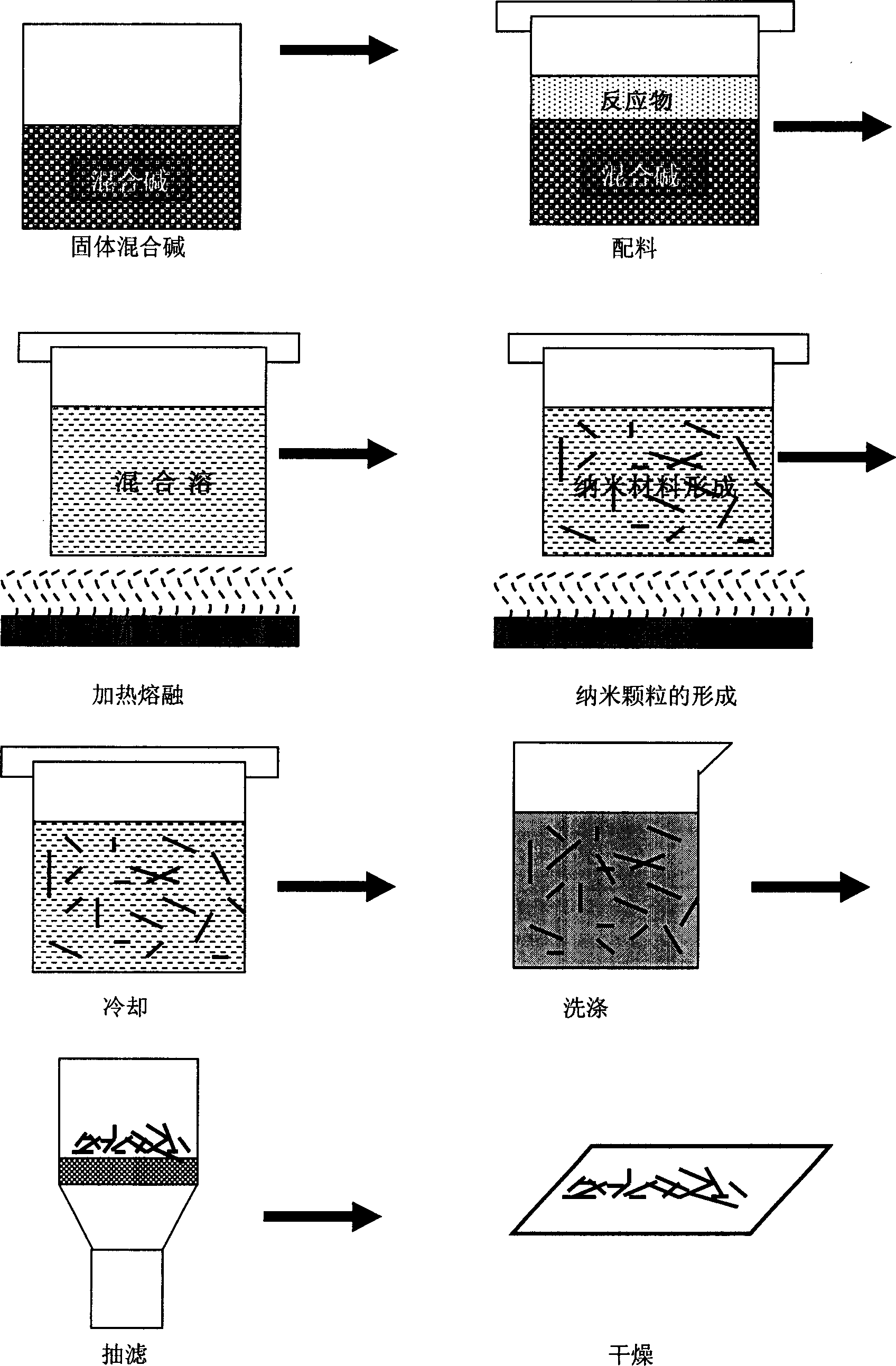

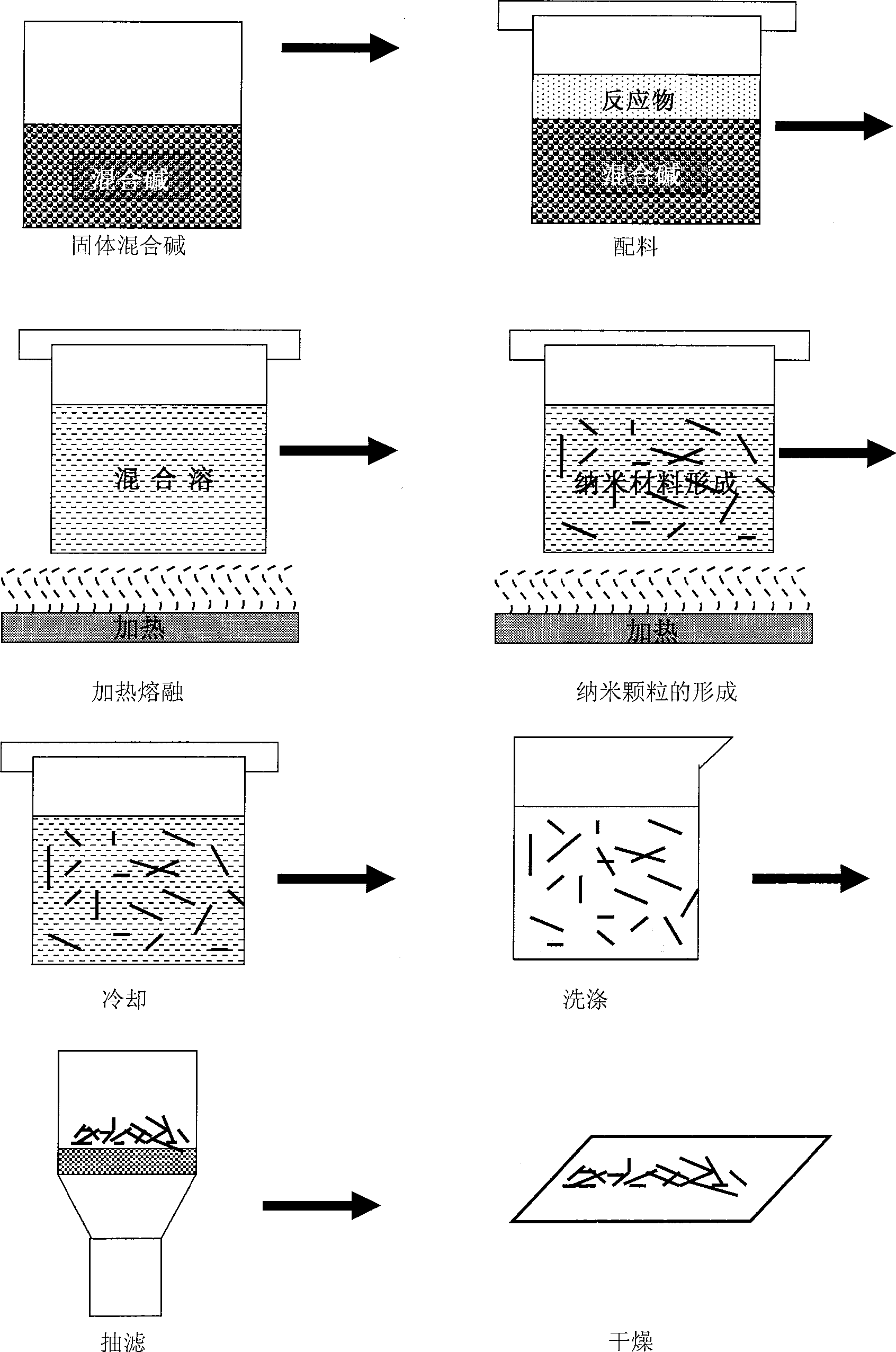

Low-temperature alkaline-solution synthesis of oxygen metal inorganic compound monocrystal nano-material

InactiveCN1896341AUniversal synthesis methodSuitable for synthesisPolycrystalline material growthSingle crystal growth detailsSemiconductor materialsInorganic compound

The present invention discloses a hypothermal alkali liquation synthesis process of monocrystalline nanometer materials of oxygenous metal inorganic compounds. The compound oxide monocrystalline nanometer materials are synthesized with the inorganic salt of a metal and the oxide of another metal as main materials, melted mixed alkali as solvent, at atmospheric pressure and relatively low temperature of about 200DEG C. The present invention uses melted alkali as solvent for the first time and can synthesize oxide nanometer materials of different structures, compositions and functions, or monocrystalline nanometer materials of simple oxide and hydroxide. This process utilizes conventional materials and only controls the time and temperature during synthesis in favor of the industrial application. The produced monocrystalline nanometer materials includes ferroelectric and piezoelectric materials, ferromagnetic materials, semiconductive materials, ionic conductive materials, colossal magnetoresistance materials, high dielectric materials superconductors and etc. that can be applied to microelectronics, photoelectronics and communication.

Owner:SHANDONG UNIV +2

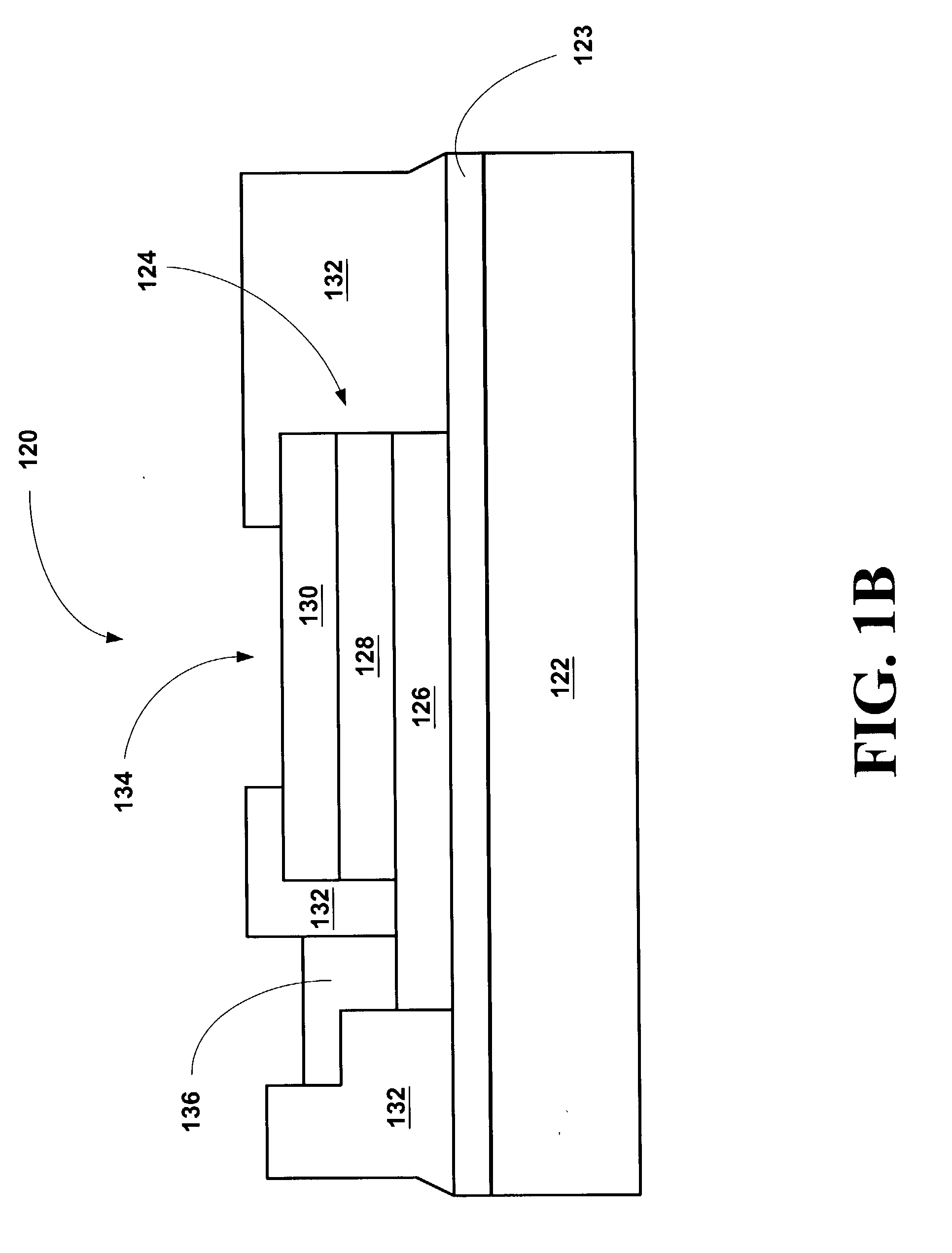

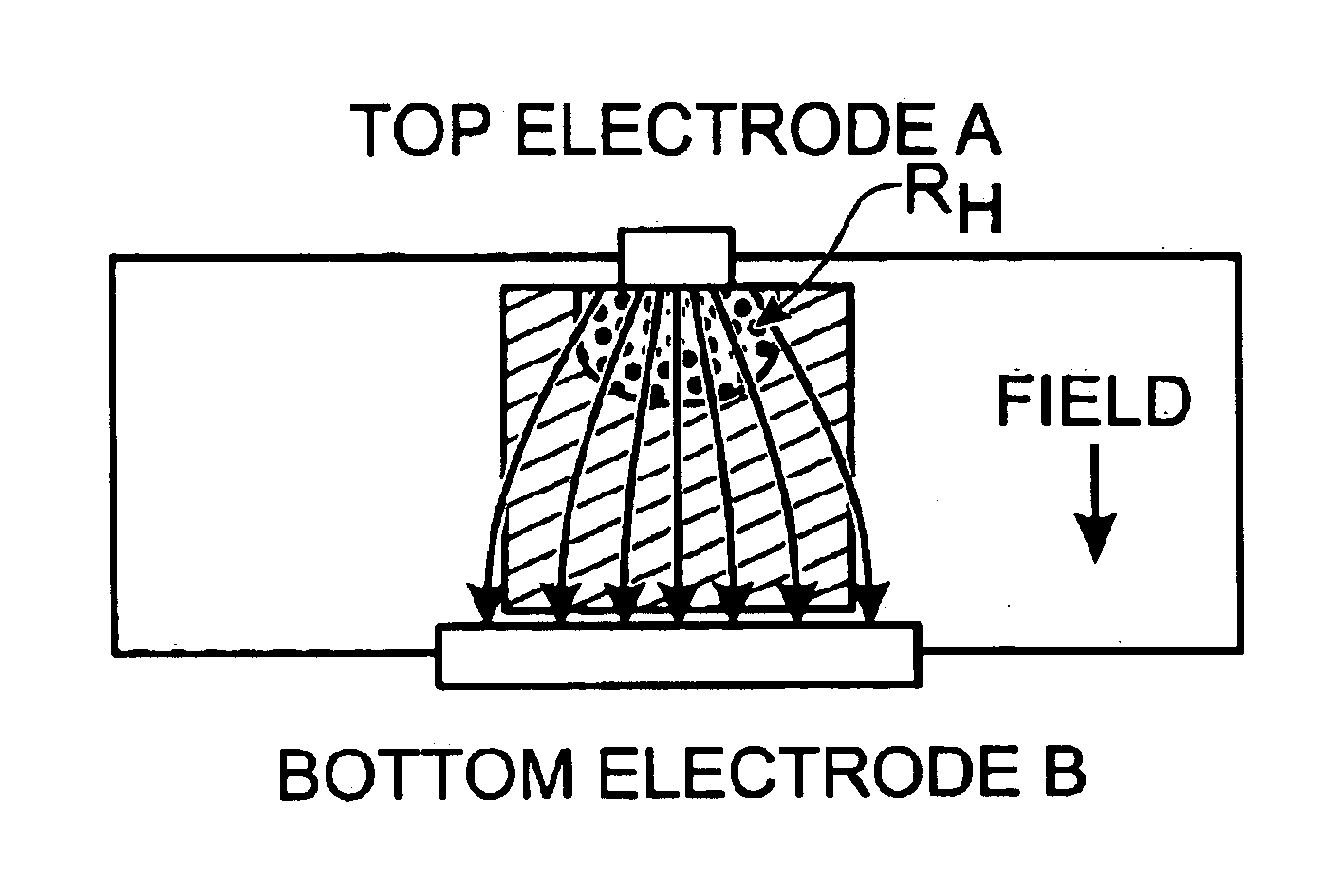

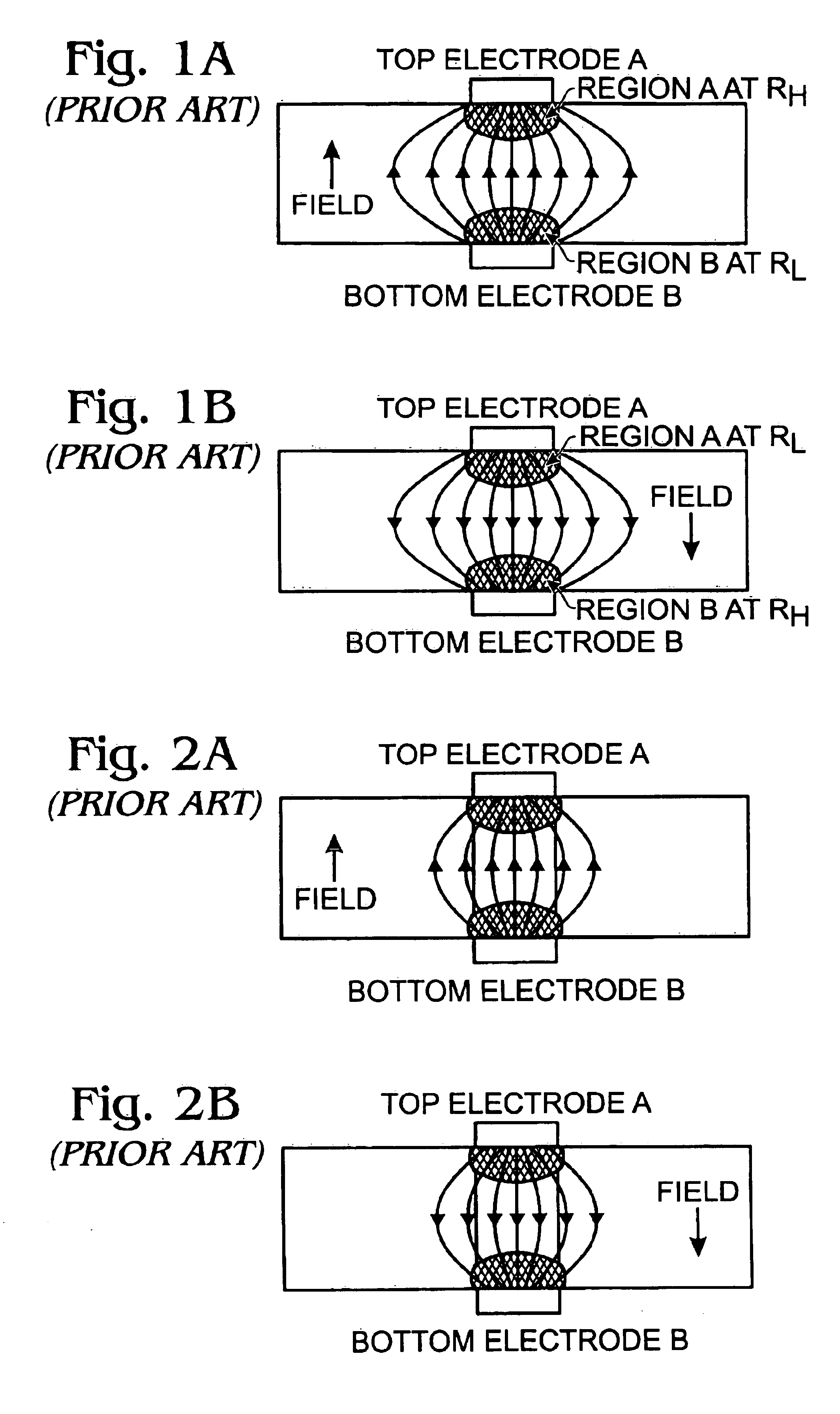

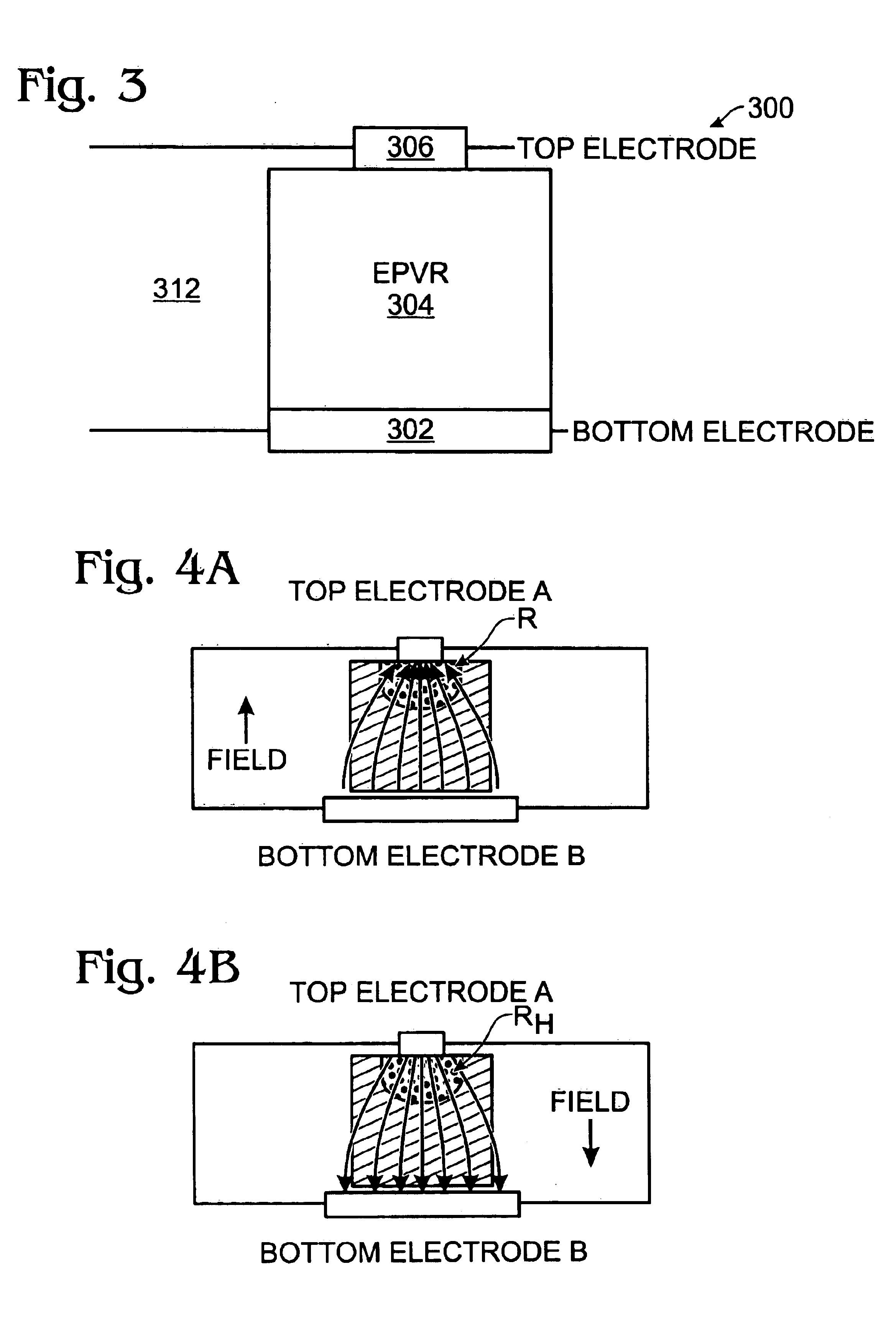

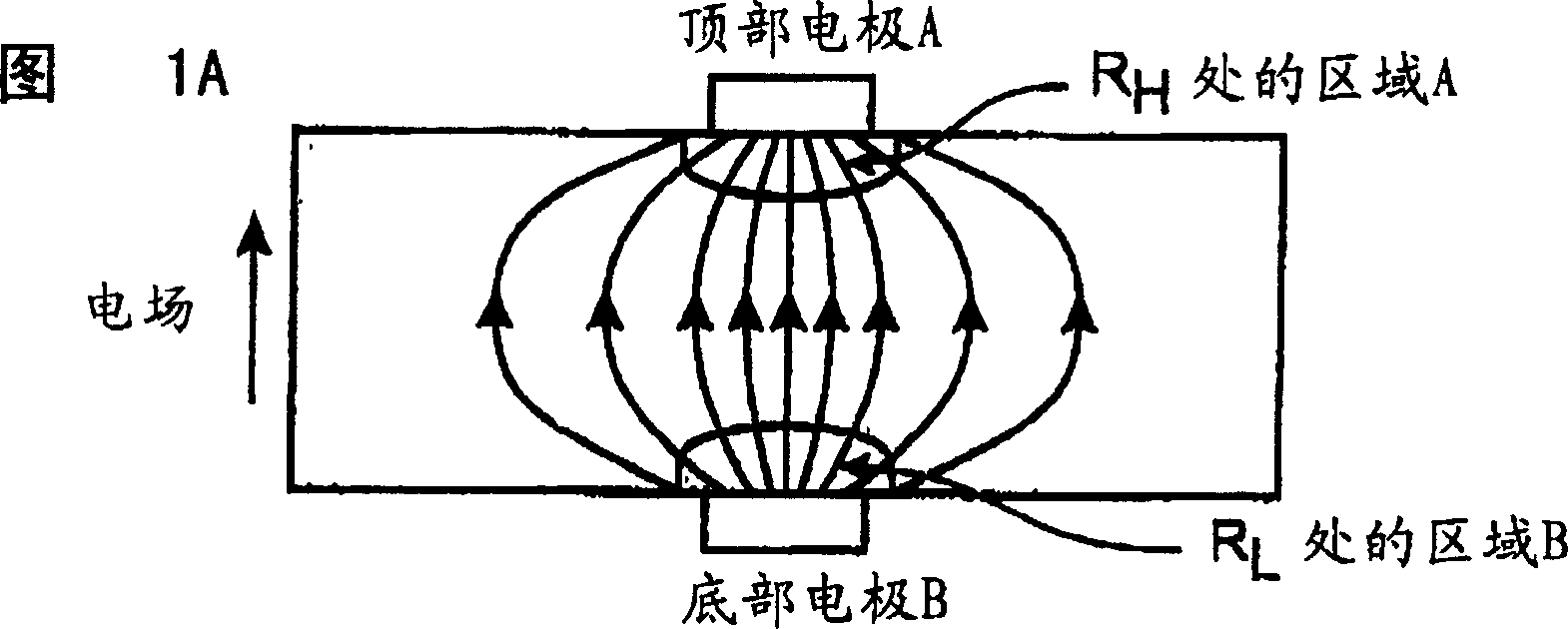

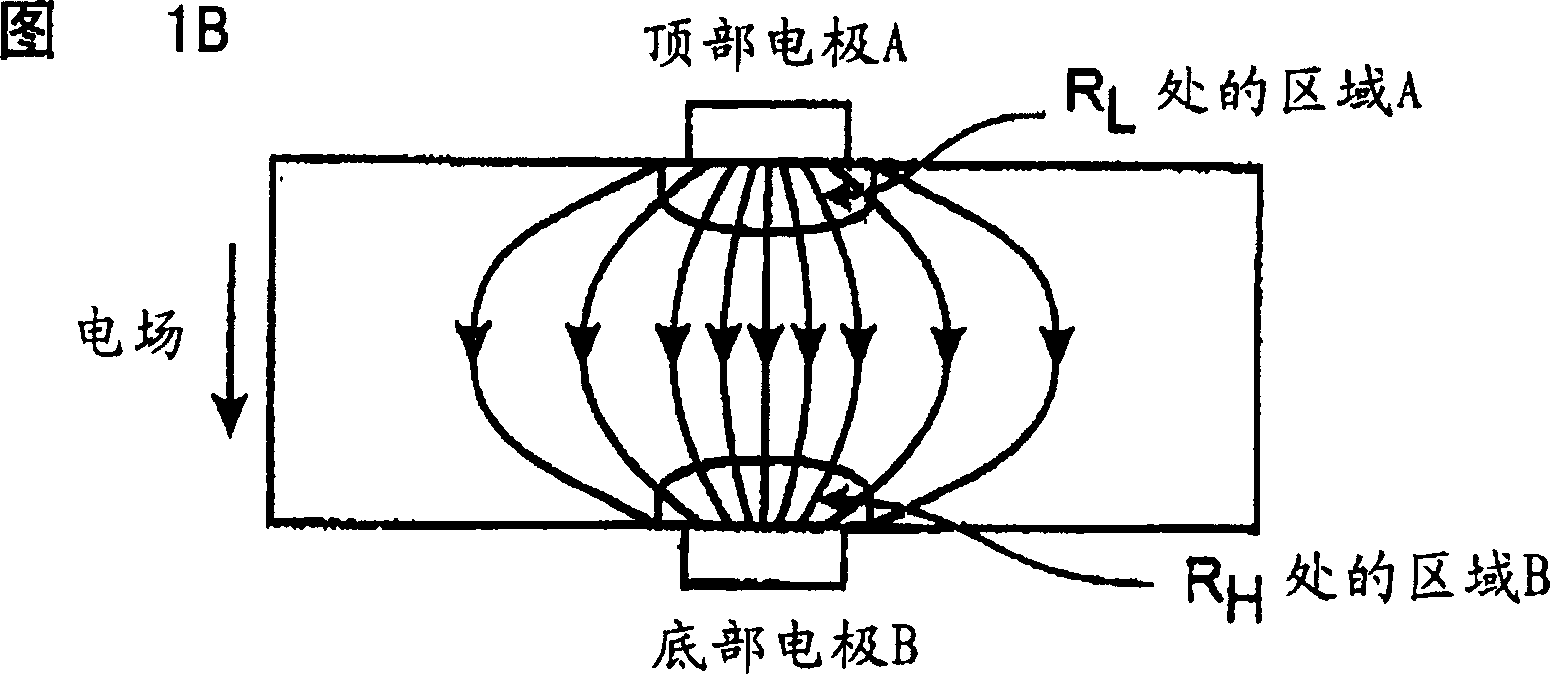

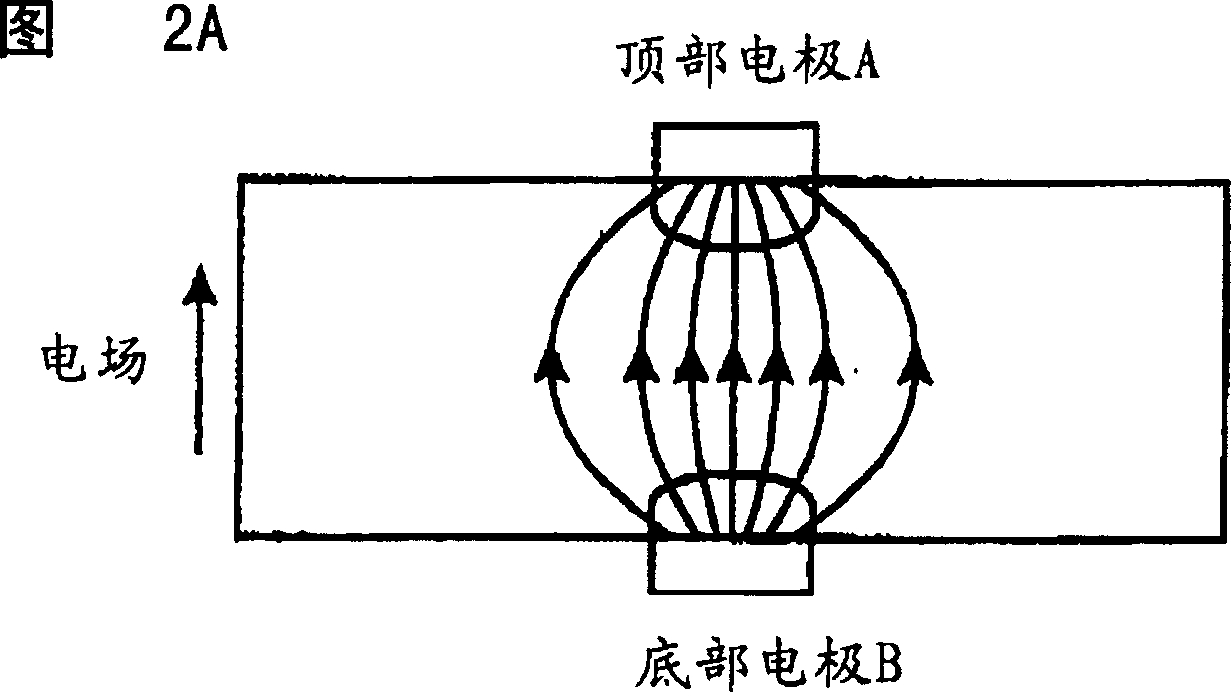

Asymmetric memory cell

ActiveUS6927074B2NanoinformaticsMagnetic-field-controlled resistorsElectrical resistance and conductanceNon symmetric

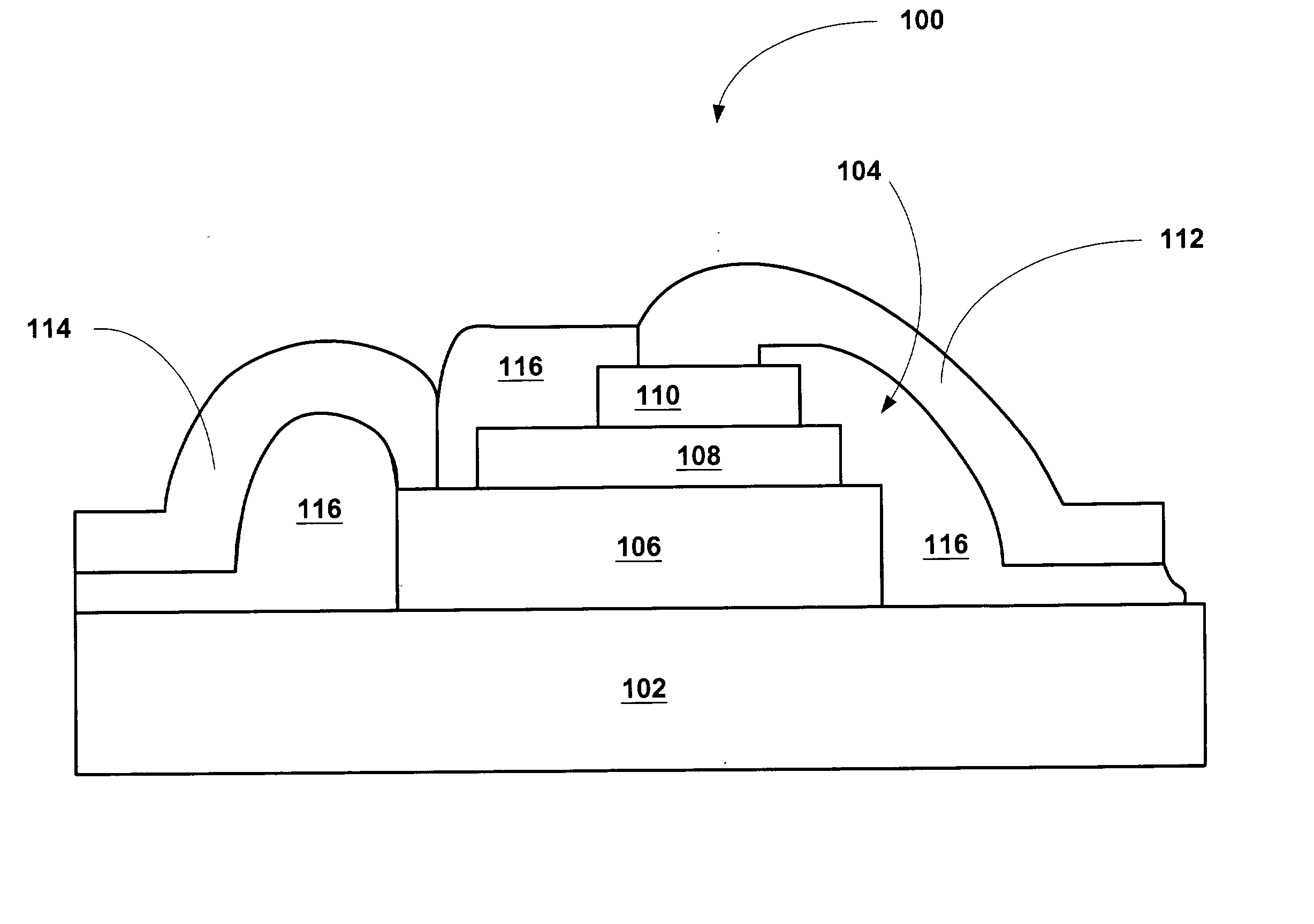

An asymmetric memory cell and method for forming an asymmetric memory cell are provided. The method comprises: forming a bottom electrode having a first area; forming an electrical pulse various resistance (EPVR) material overlying the bottom electrode; forming a top electrode overlying the EPVR layer having a second area, less than the first area. In some aspects the second area is at least 20% smaller than the first area. The EPVR is a material such as colossal magnetoresistance (CMR), high temperature super conducting (HTSC), or perovskite metal oxide materials. The method further comprises: inducing an electric field between the electrodes; inducing current flow through the EPVR adjacent the top electrode; and, in response to inducing current flow through the EPVR adjacent the top electrode, modifying the resistance of the EPVR. Typically, the resistance is modified within the range of 100 ohms to 10 mega-ohms.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation method of colossal magnetoresistance effect Fe-Ti-O amorphous film

InactiveCN102345104ASimple preparation conditionsLarge room temperature magnetoresistance effectVacuum evaporation coatingSputtering coatingSputteringPower flow

A preparation method of a colossal magnetoresistance effect Fe-Ti-O amorphous film adopts an ultra-high vacuum three-target codeposition magnetron sputtering coating machine for the preparation, and comprises the following steps: 1) mounting a Ti target and a Fe target on a target head of the coating machine respectively; 2) mounting a glass substrate on a substrate support; 3) turning on the magnetron sputtering device to vacuumize a sputtering chamber; 4) introducing mixed gas of O2 and Ar into the vacuum chamber to obtain a vacuum degree of 1 Pa of the vacuum chamber; 5) turning on a sputtering direct-current power supply, applying a current and a voltage to the Ti target and the Fe target; 6) opening a baffle plate of the substrate, rotating the substrate support, growing a film on the substrate; 7) after the sputtering is completed, injecting nitrogen into the vacuum chamber to obtain the prepared target product. The advantages of the invention are that: the process method is simple and easy to carry out, and the prepared film has high room-temperature magnetoresistance effect; the production cost is low, and the method is applicable to large-scale popularization and application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

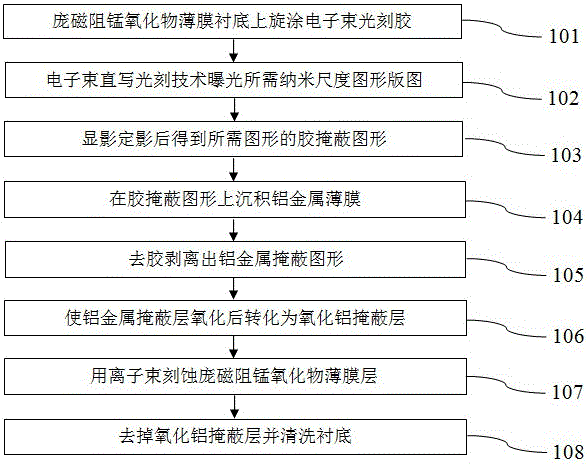

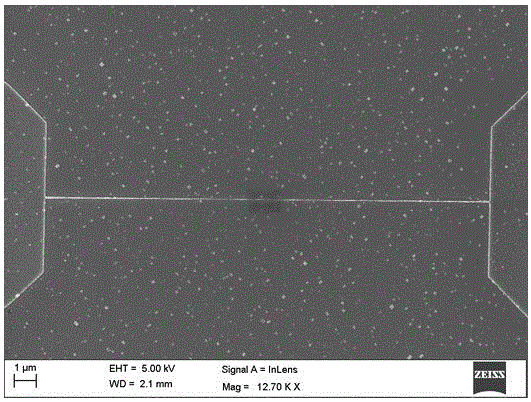

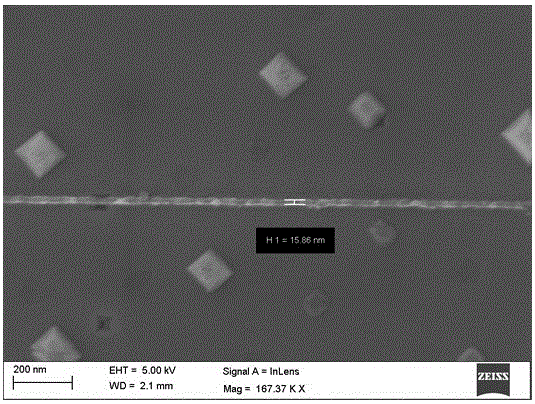

Method for patterning colossal magnetoresistance manganese oxide thin film on nanoscale

ActiveCN106252204ASolve the problem of poor etch rate ratioGood removal effectSemiconductor/solid-state device manufacturingResistMicro nano

The invention belongs to the technical field of micro-nano machining, and particularly provides a method for patterning a colossal magnetoresistance manganese oxide thin film on a nanoscale. The method comprises the steps of firstly carrying out spin-coating of electron beam photoresist on a strontium titanate substrate on which the colossal magnetoresistance manganese oxide thin film grows, carrying out baking and then exposing a required nanoscale graphic layout by use of an electron beam direct writing lithography; carrying out developing and fixing, obtaining a resist mask graphic of a required nanoscale graphic, depositing an aluminum metal thin film and then removing the resist to strip out an aluminum metal mask graphic; oxidizing an aluminum metal mask layer, transforming the aluminum metal mask layer into an aluminum oxide mask layer, and then etching the colossal magnetoresistance manganese oxide thin film by use of ion beams to form a colossal magnetoresistance manganese oxide graphic; and finally removing the aluminum oxide mask layer and cleaning the substrate. By the method, the problem that the etching rate ratio of electron beam resist to the colossal magnetoresistance manganese oxide layer during ion-beam etching is poor is solved; the thickness requirement of the electron beam resist is reduced; the resolution ratio of the electron beam direct-writing lithography is improved; and the problem that some electron beam resist cannot be easily removed after etching is also solved.

Owner:FUDAN UNIV

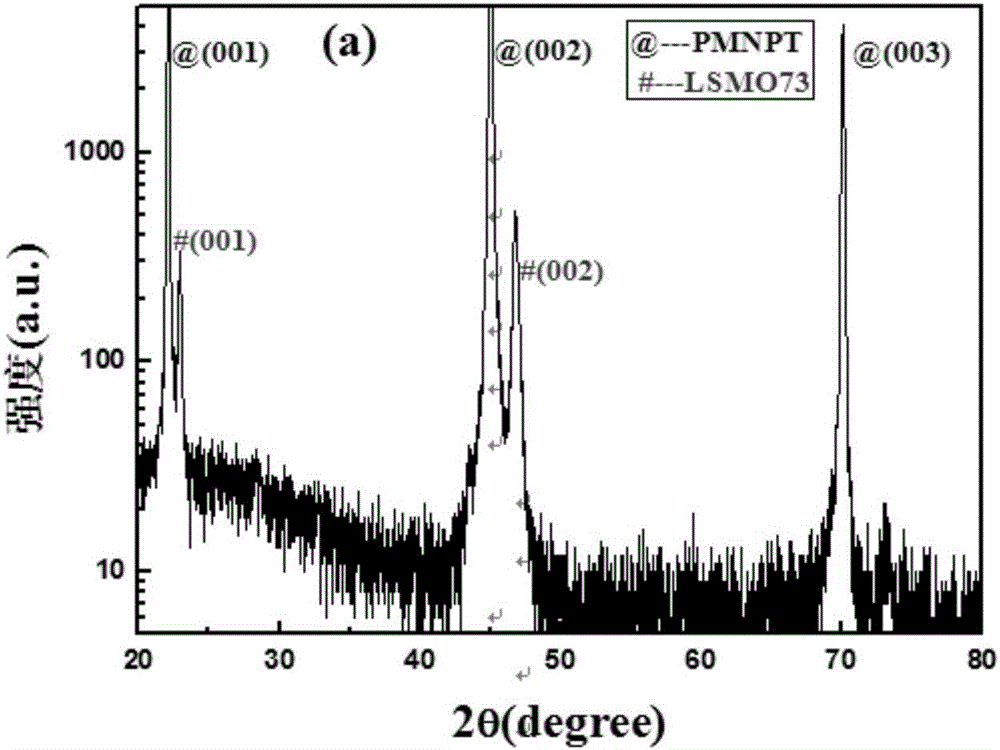

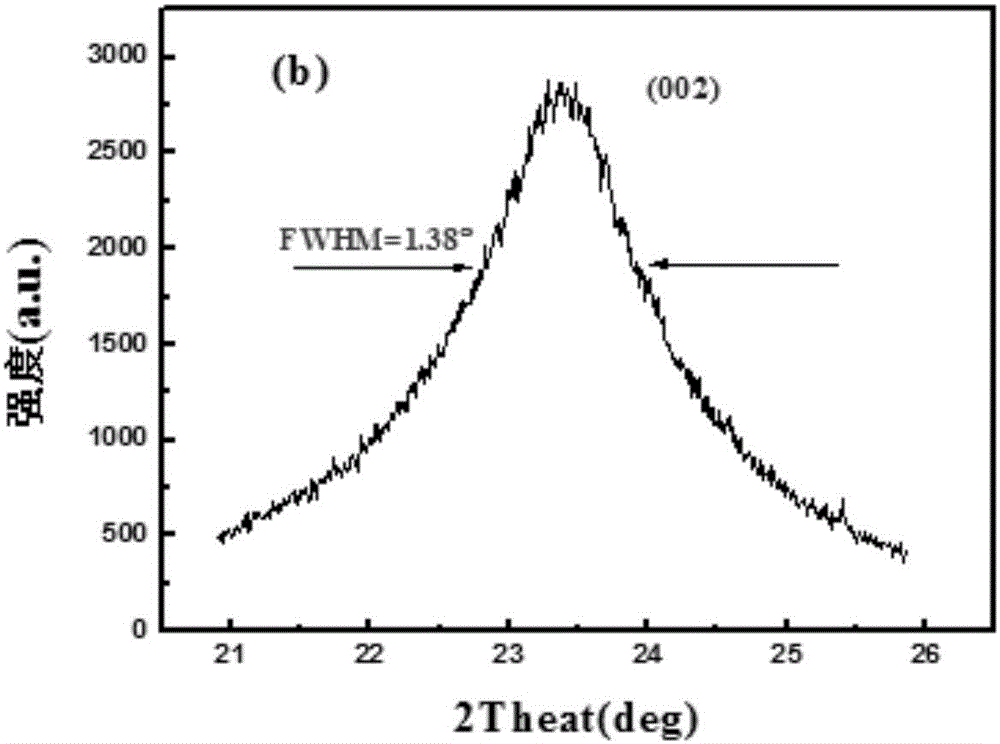

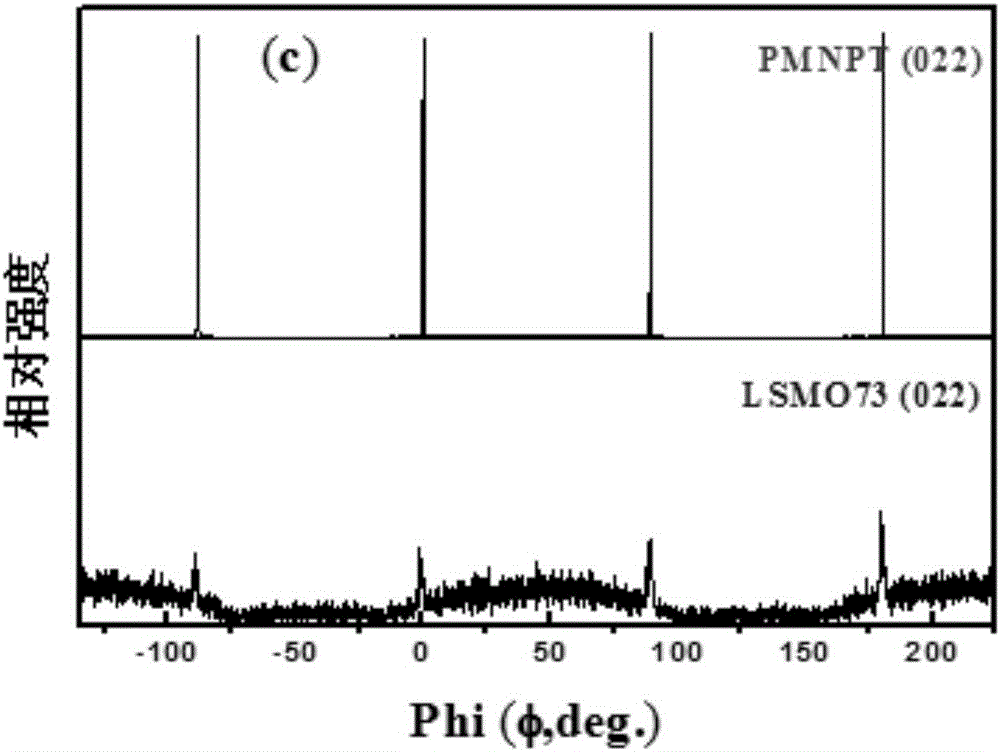

Multiferroic composite magnetoelectric film and preparation method thereof

InactiveCN106591807AIncrease the areaImprove performanceLiquid/solution decomposition chemical coatingComposite filmMagnetic memory

The invention discloses a multiferroic composite magnetoelectric film and a preparation method thereof. The magnetoelectric composite film comprises a (001)PMN-PT substrate and a manganese-lanthanum oxide film (La1-xRexMnO3, Re=Sr, Ca, Ba and the like) deposited on the substrate. The invention belongs to the technical field of films. The method is preparing a manganese-lanthanum oxide epitaxial film on the (001)PMN-PT substrate through a wet chemical method (sol-gel method), and comprises the following steps: preparing a precursor solution, carrying out pre-treatment on the PMN-PT substrate and carrying out deposition and heat treatment on the film on the substrate, and finally obtaining the needed composite magnetoelectric film. The manganese-lanthanum oxide / (001)PMN-PT composite magnetoelectric film disclosed by the invention has ferromagnetic performance, electrical transport performance and colossal magnetoresistance effect, and has a wide application prospect in the information industry and the devices of magneto-resistance sensors, ferromagnetic film devices, spin electronic devices, magnetic memory materials and the like.

Owner:XI AN JIAOTONG UNIV

Method for improving exchange bias field heat stability of ferromagnetic/antiferromagnetic dual-layer membrane by laser annealing

InactiveCN102832336ASimple processEasy to operateGalvano-magnetic device manufacture/treatmentHeat stabilityExchange bias

The invention discloses a method for improving exchange bias field heat stability of a ferromagnetic / antiferromagnetic dual-layer membrane by laser annealing. The method comprises the following steps of: 1, depositing a ferromagnetic layer and an antiferromagnetic layer on a substrate by using a PVD (Physical Vapor Deposition) method to obtain a ferromagnetic / antiferromagnetic dual-layer membrane; and 2, carrying out laser rapid annealing on the dual-layer membrane by using a continuous wave laser or pulse laser as a light source, wherein the output power is 2-10W and the scanning speed is 5-20cm / s. The method can be applied to a colossal magnetoresistance resistor sensor, a magnetic random access storage, a magnetic recording device and the like based on the ferromagnetic / antiferromagnetic dual-layer membrane, and has the advantages of simple operation and high efficiency.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

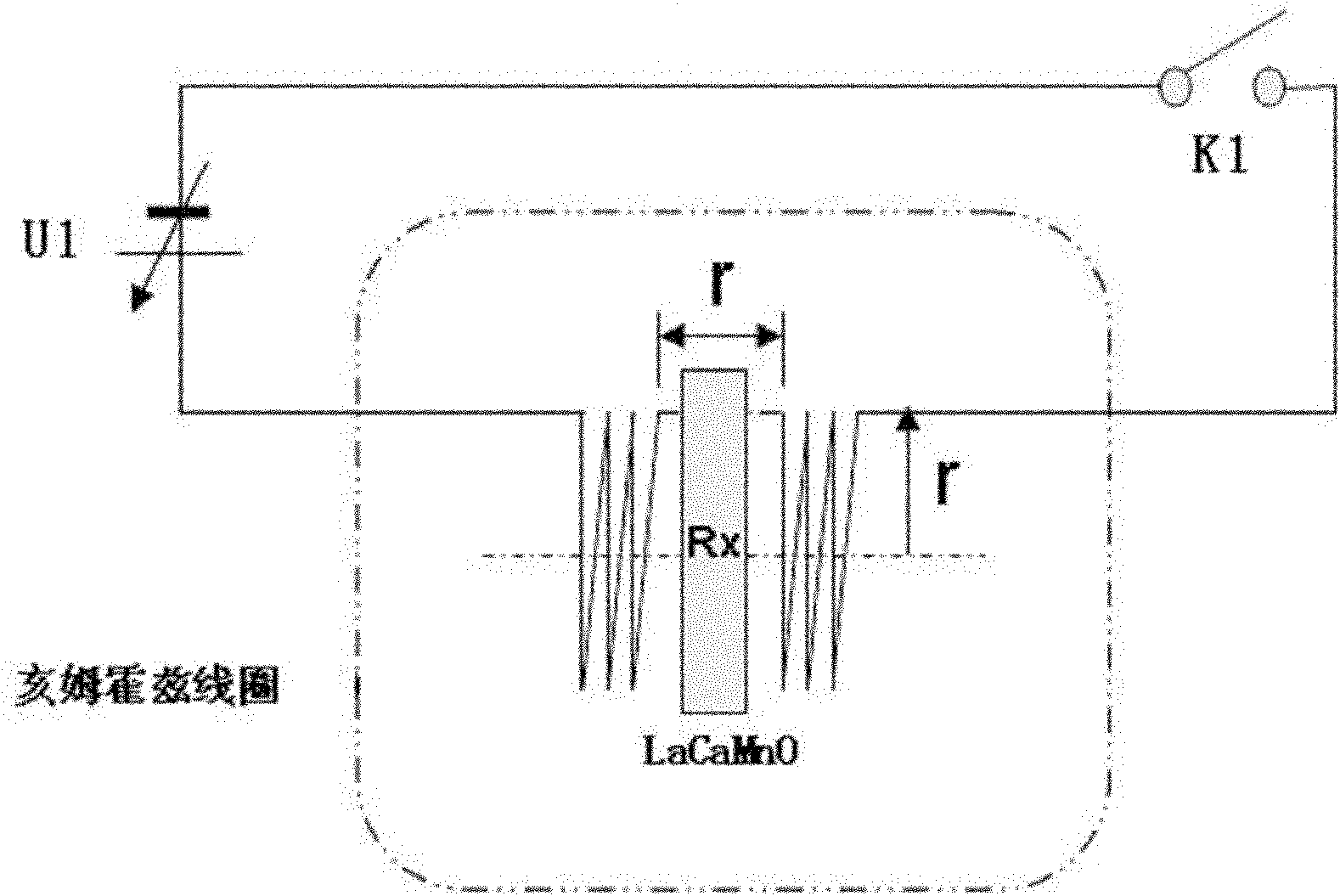

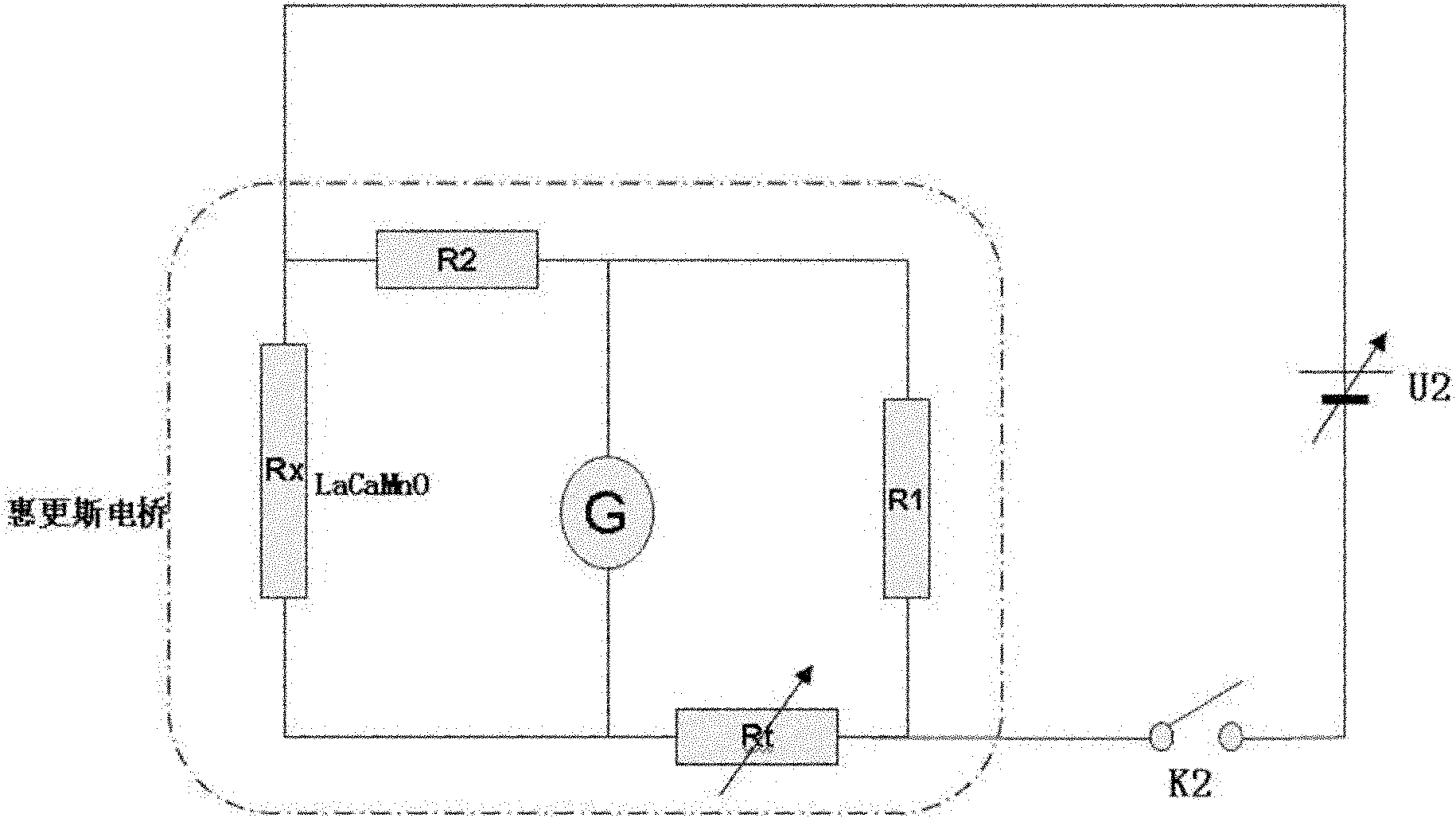

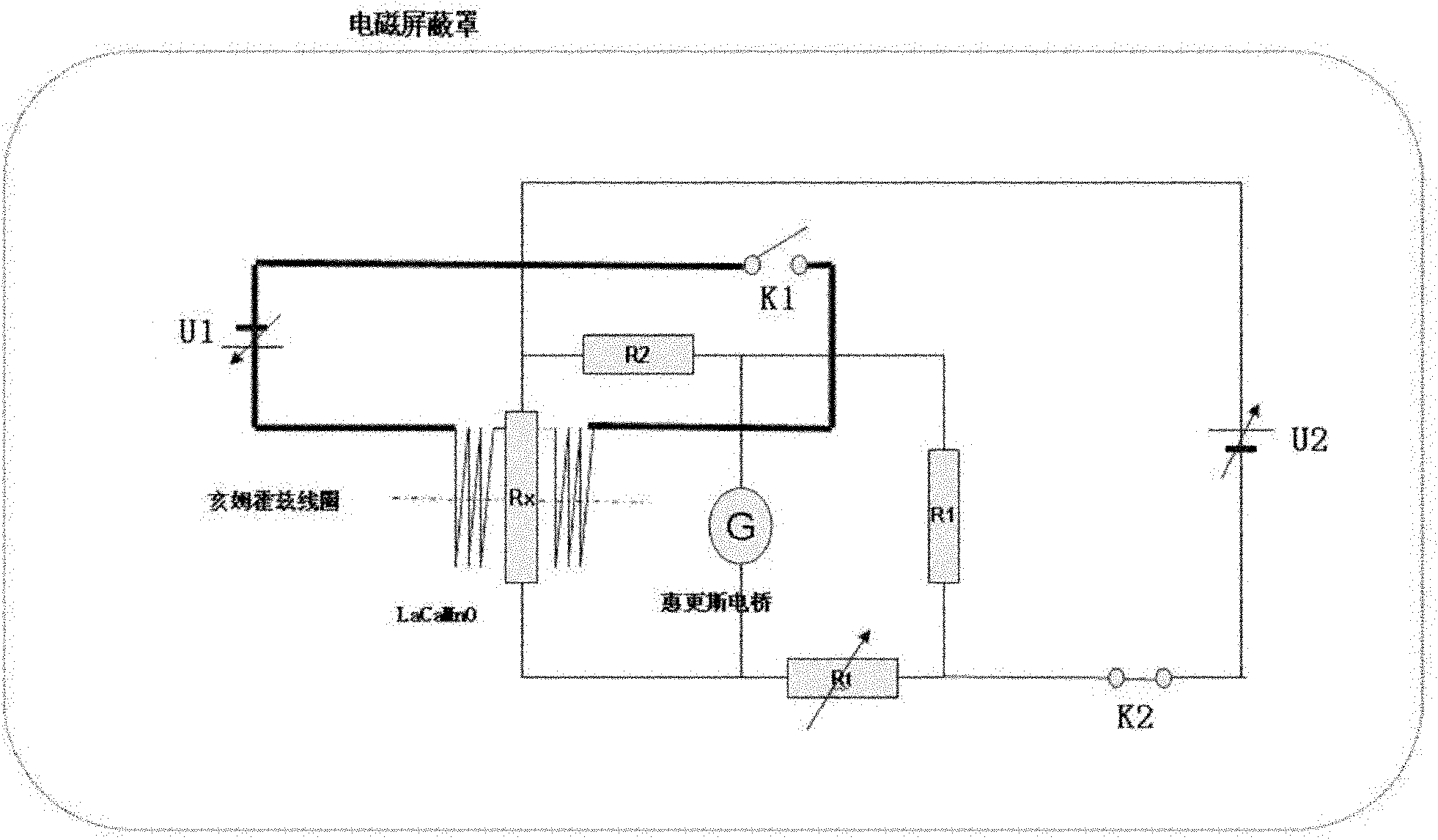

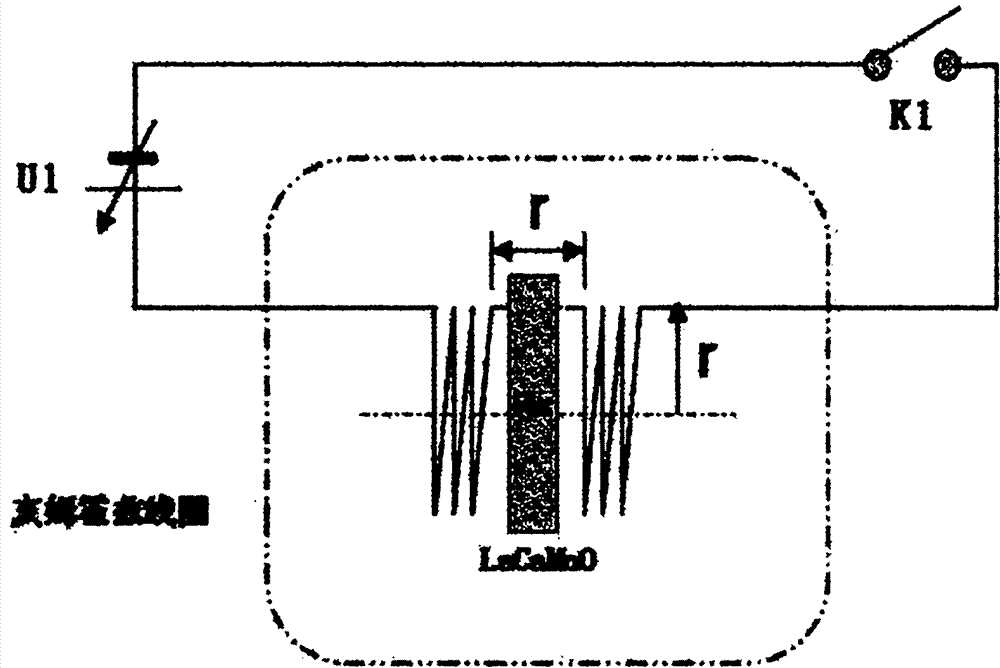

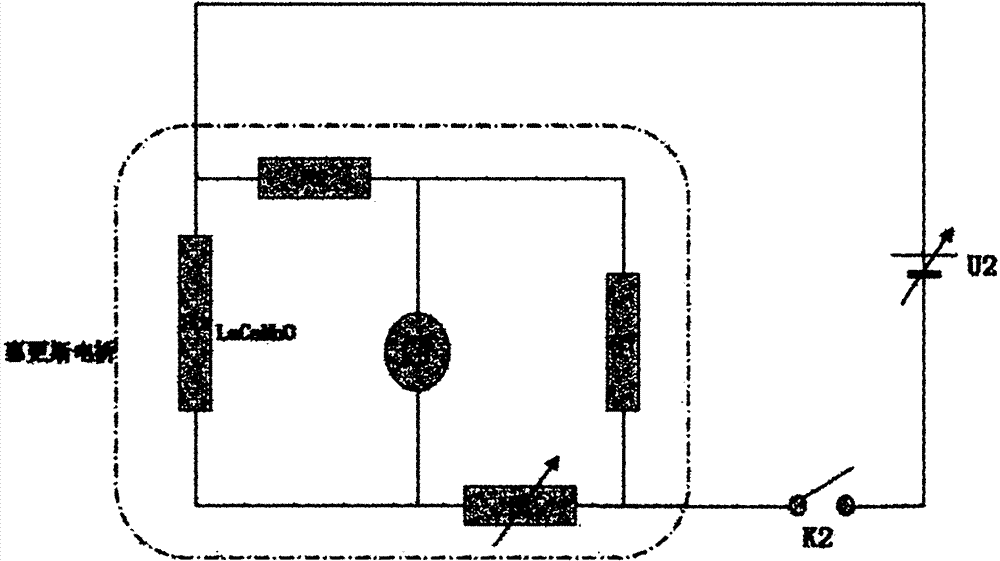

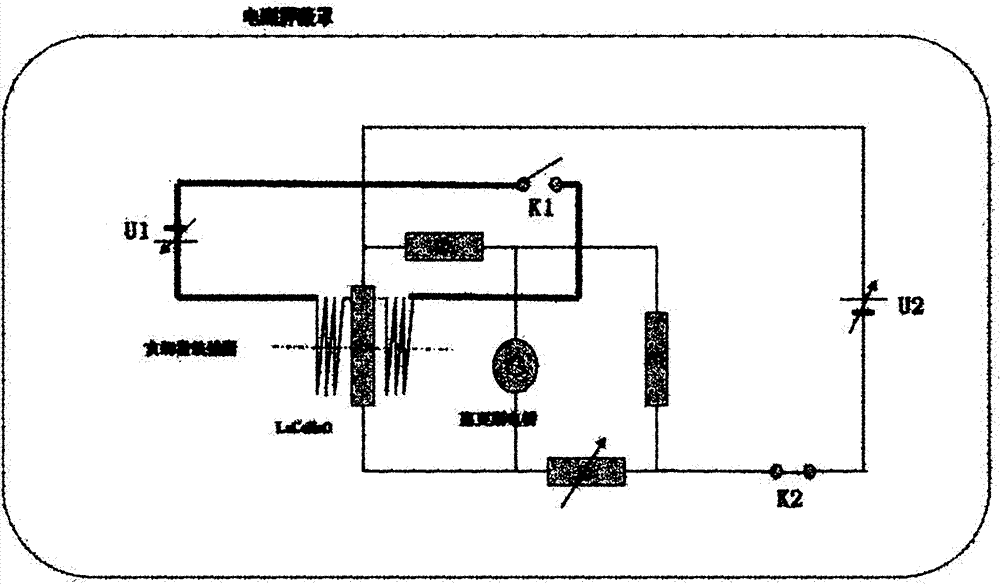

Device and method for measuring magnetic induction intensity based on colossal magnetoresistance effect

ActiveCN102103193AHigh sensitivityImprove accuracyMagnetic measurementsElectrical resistance and conductanceHelmholtz coil

The invention relates to a device and a method for measuring magnetic induction intensity, in particular relates to a device and a method for measuring the magnetic induction intensity based on colossal magnetoresistance effect. The measuring device comprises an electromagnetic shielding device, a first loop and a second loop, wherein, the first loop comprises a colossal magnetoresistance device,a Helmholtz coil and a first power supply device; and the second loop comprises a Huygens electrical bridge and a second power source device. In the invention, the distinct effect of the colossal magnetoresistance effect is utilized, and the Helmholtz coil is adopted to provide the reversed magnetic field for balancing the magnetic field to be detected, when the Huygens electrical bridge is in balance, the numerical value of the magnetic field to be detected is equal to that of the Helmholtz coil, but the direction is reverse; and the resistance of a colossal magnetoresistance device needs not to be calculated, thus the accuracy and the precision of calculation is improved; the electromagnetic shielding device is adopted to shield the environmental magnetic field, thus the measuring environment with zero magnetic field intensity is provided, and non-interference basic parameters are provided for the follow-up measurement, thereby being beneficial for improving the accuracy of measurement.

Owner:STATE GRID CORP OF CHINA +2

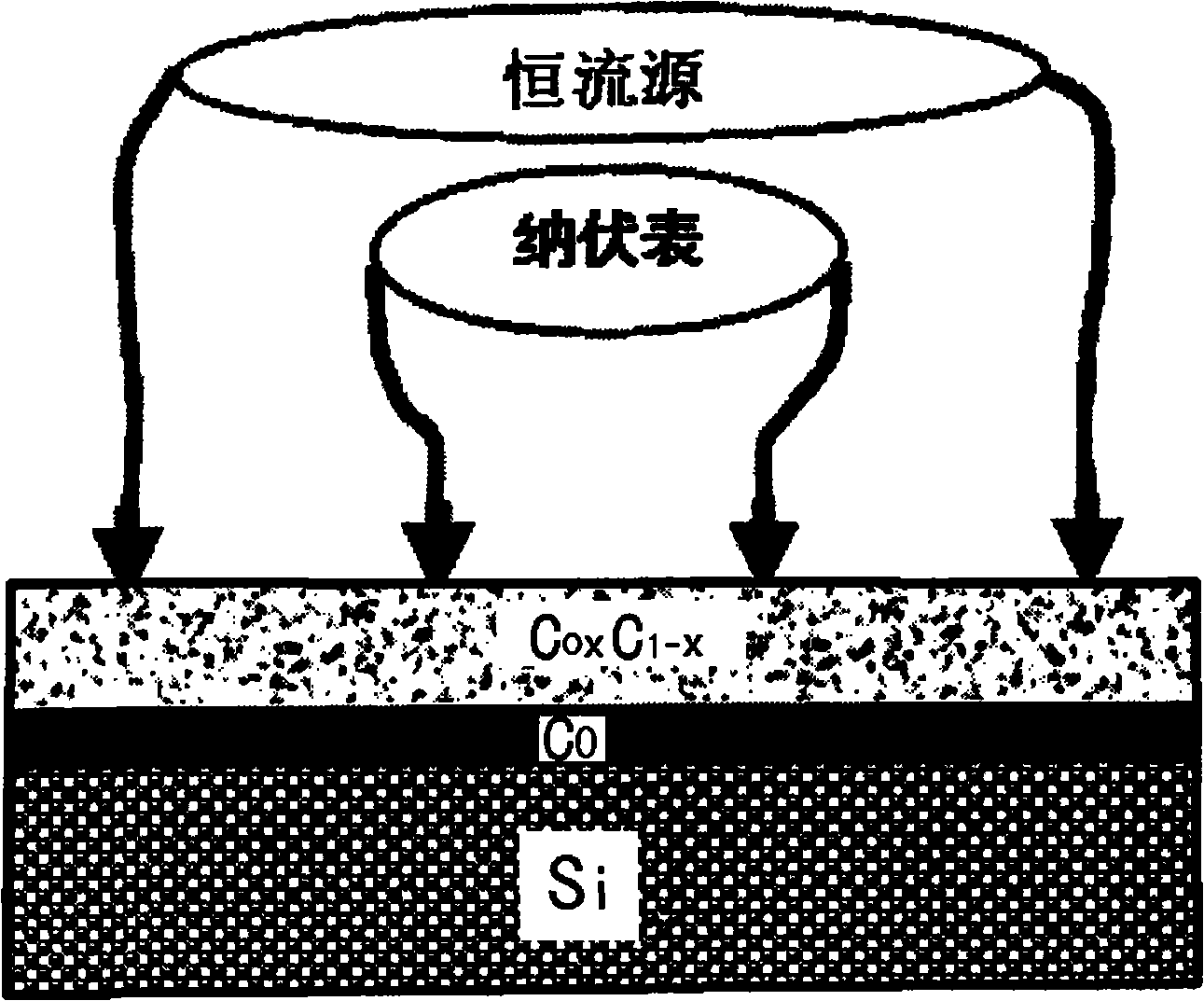

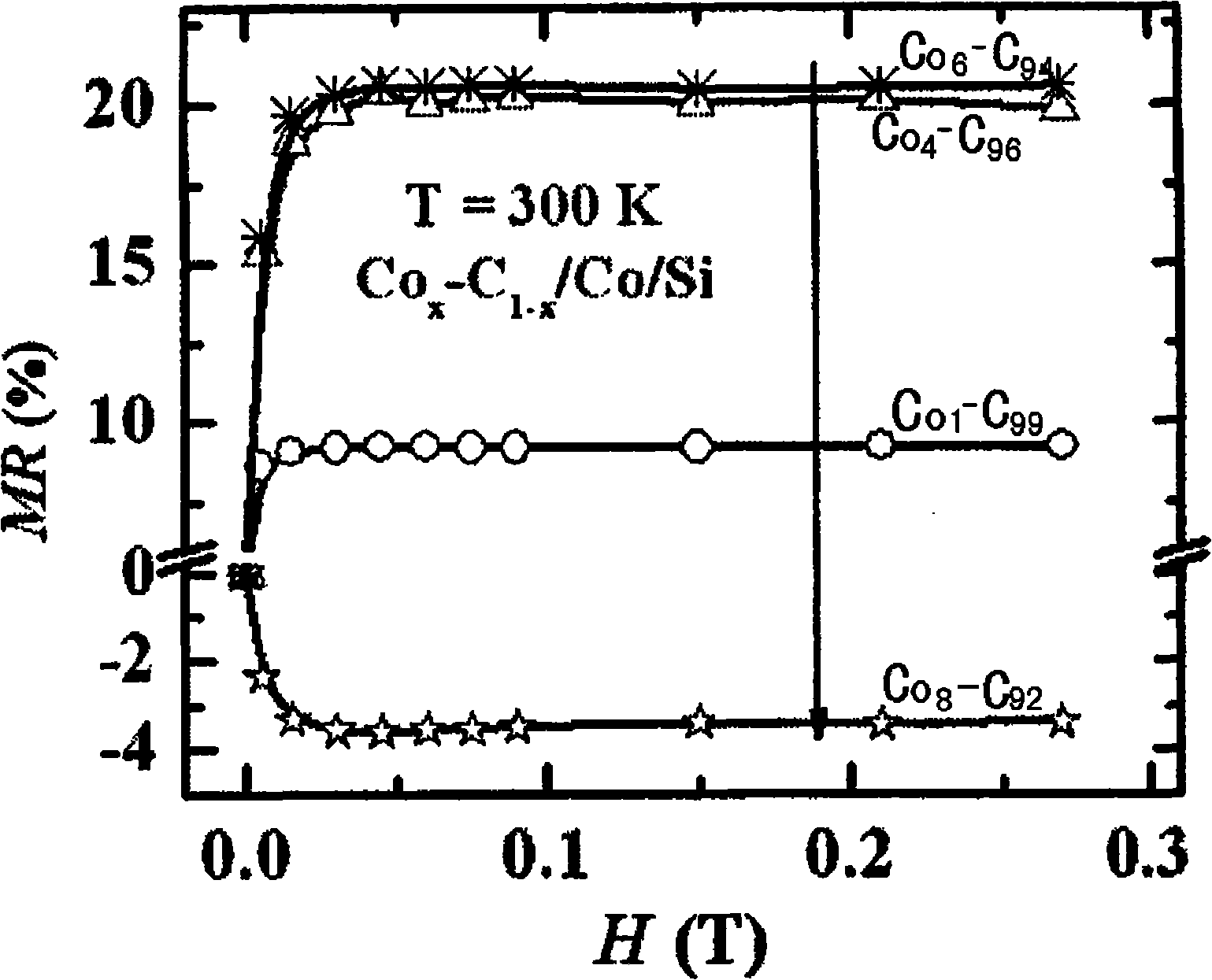

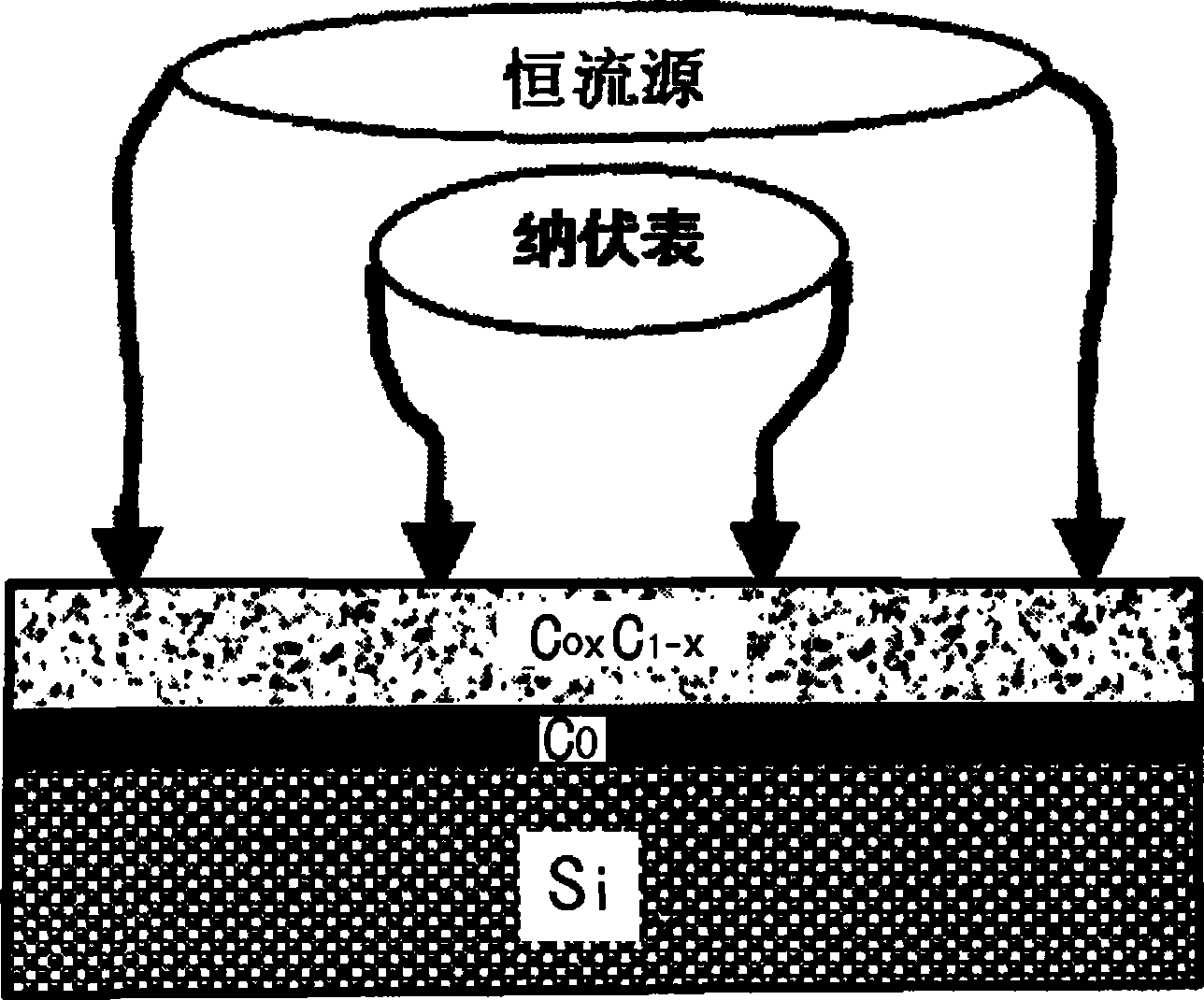

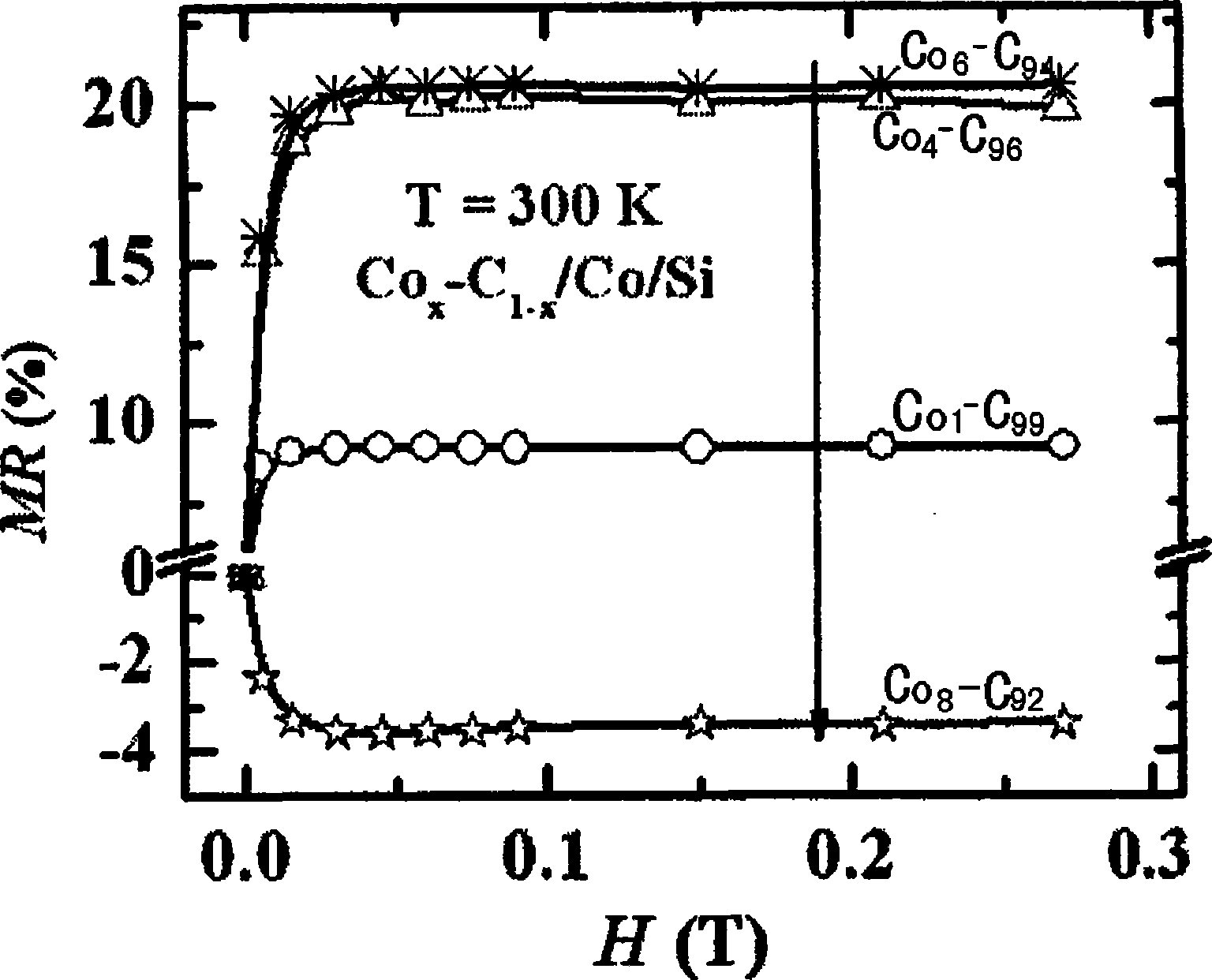

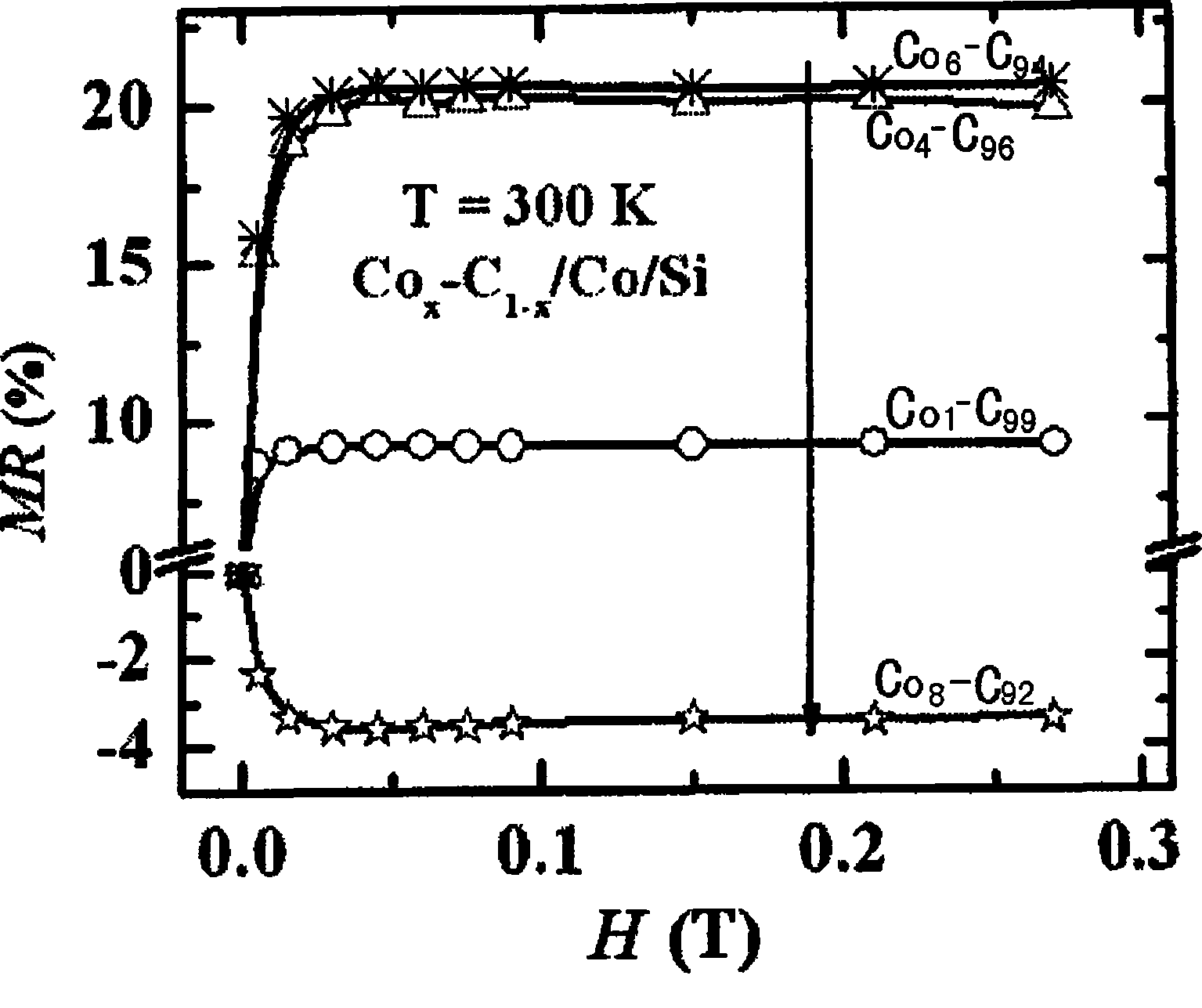

Co(x)C(1-x)/Co/Si multilayered structure granule film material having room temperature low field large magnetic resistance effect

InactiveCN101359716ALow costGood giant magnetoresistance effectMagnetic measurementsMagnetic-field-controlled resistorsElectrical resistance and conductanceRoom temperature

The invention discloses a CoxC1-x / Co / Si multilayer granule membrane material with giant magneto resistance effect in a magnetic field under room temperature, belonging to magnetic quantity sensor material. A Co layer and a CoxC1-x layer are sequentially deposited on an n-Si substrate at lattice orientation 100 through laser pulse. The positive colossal magnetoresistance effect of the material under room temperature with external magnetic filed of 0.01T can reach +20.6%. With the advantages of low price and excellent performance, the material is good material for a magnetic sensor.

Owner:TSINGHUA UNIV

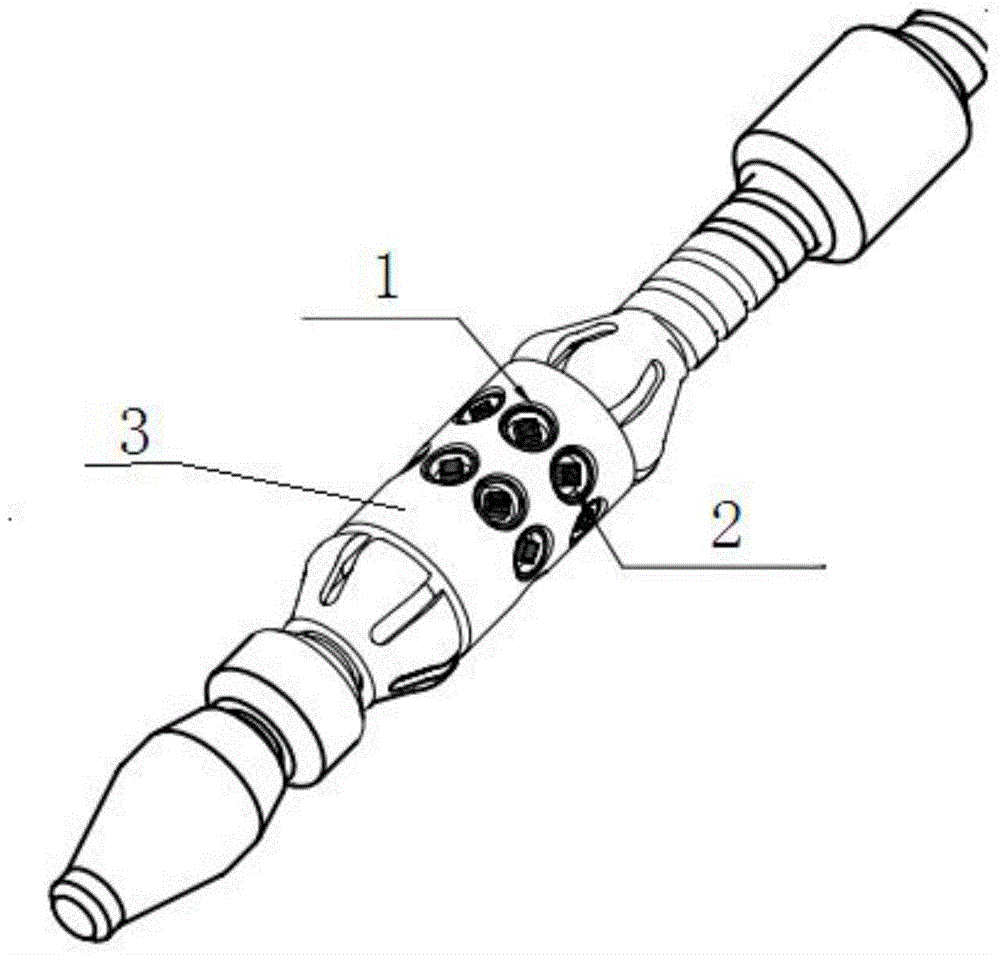

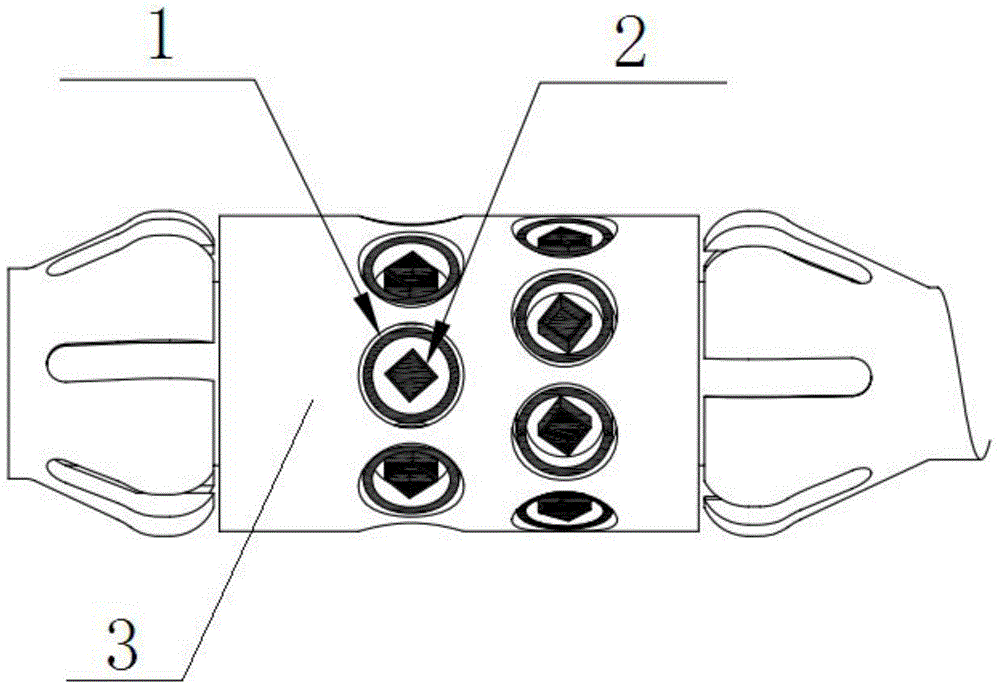

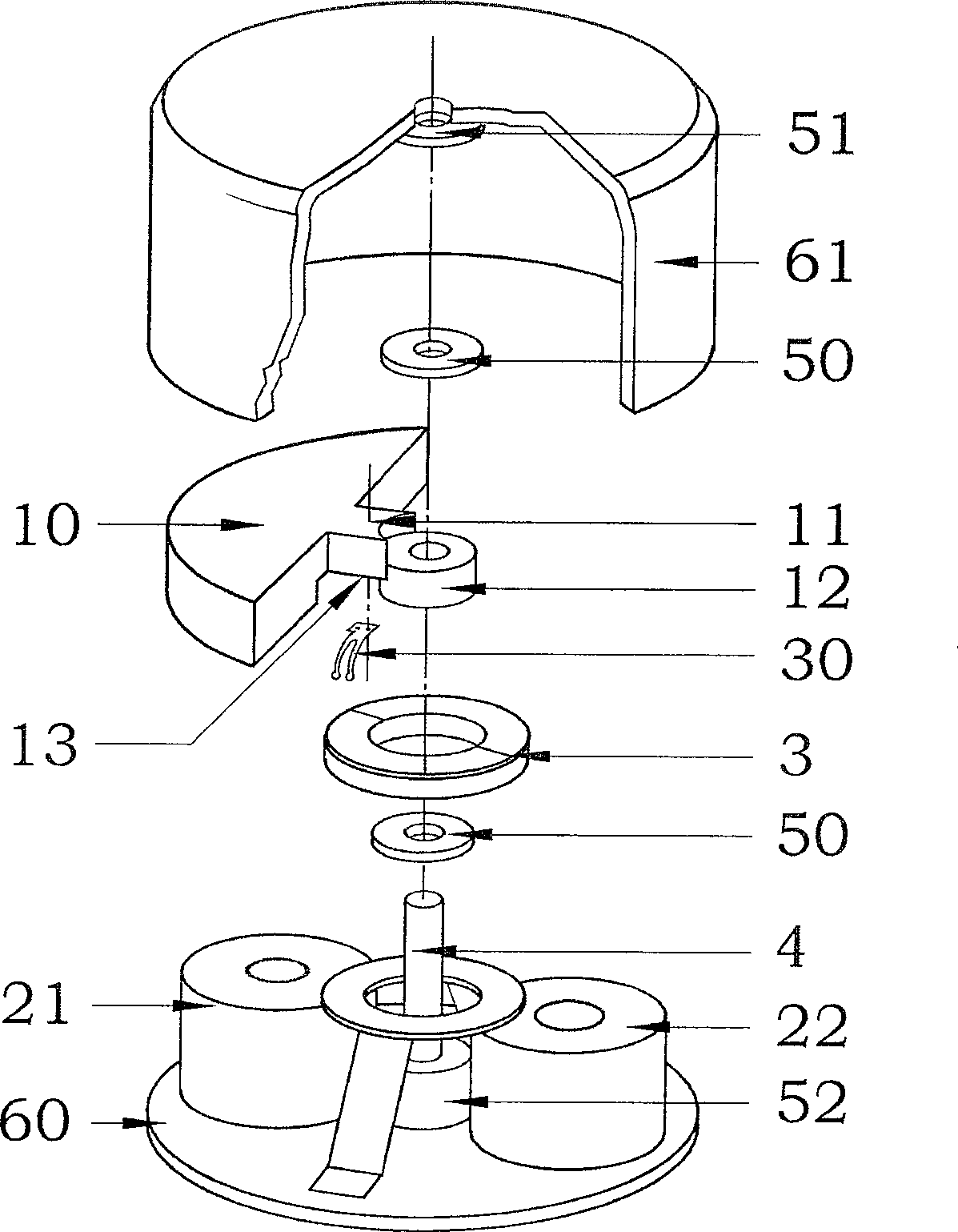

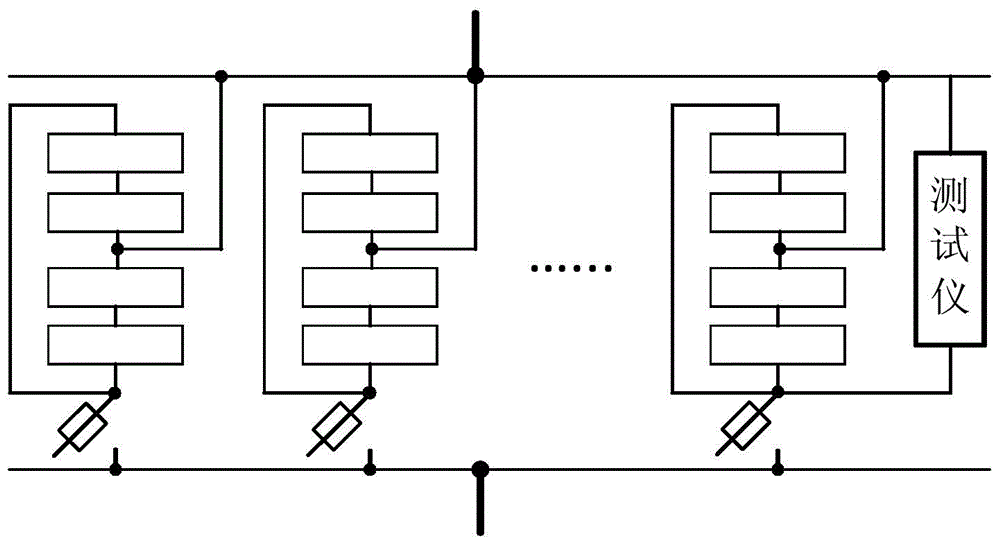

Inward passing-type colossal magnetoresistance array probe for nonferromagnetic thin-walled tube defect detection

InactiveCN105806933AHigh detection sensitivityImprove anti-interference abilityMaterial magnetic variablesThermodynamicsDefect size

The invention relates to the technical field of inward passing-type eddy current nondestructive tests and discloses an inward passing-type colossal magnetoresistance array probe for nonferromagnetic thin-walled tube defect detection. The probe comprises an exciting coil and a colossal magnetoresistance sensor, the exciting coil and the colossal magnetoresistance sensor are arranged in a probe framework and the colossal magnetoresistance sensor is located in the center of the exciting coil. The probe is used for thin-walled tube eddy current detection, improves nonferromagnetic small-caliber pipe defect detection sensitivity of the array probe, widens a defect size detection range of the probe, improves an anti-interference capability of the array probe and prolongs a probe use period.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

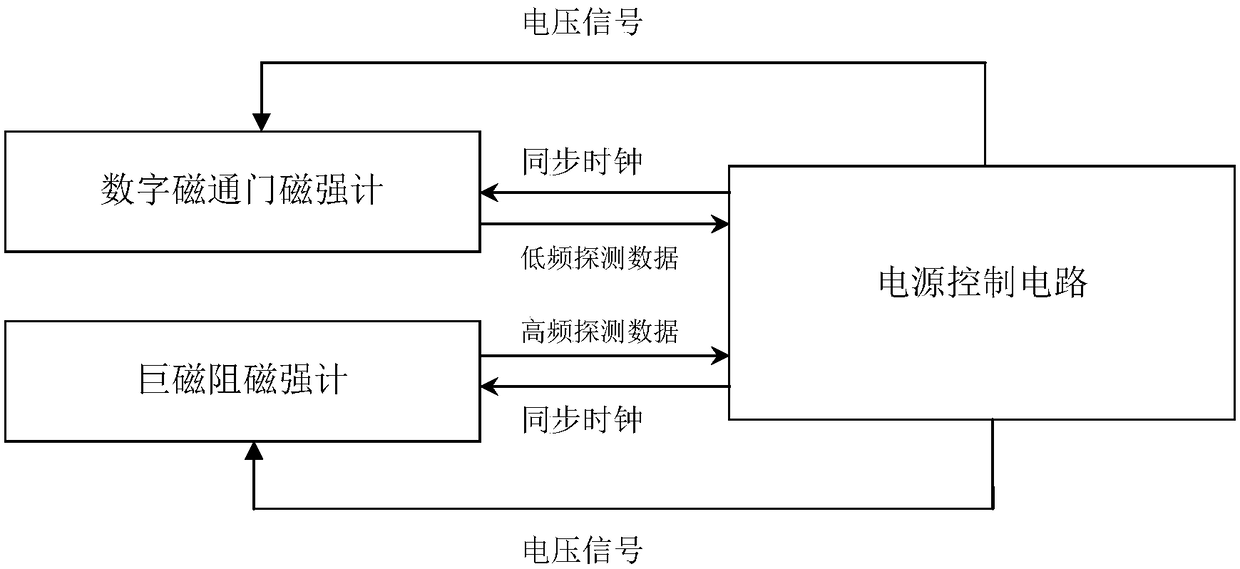

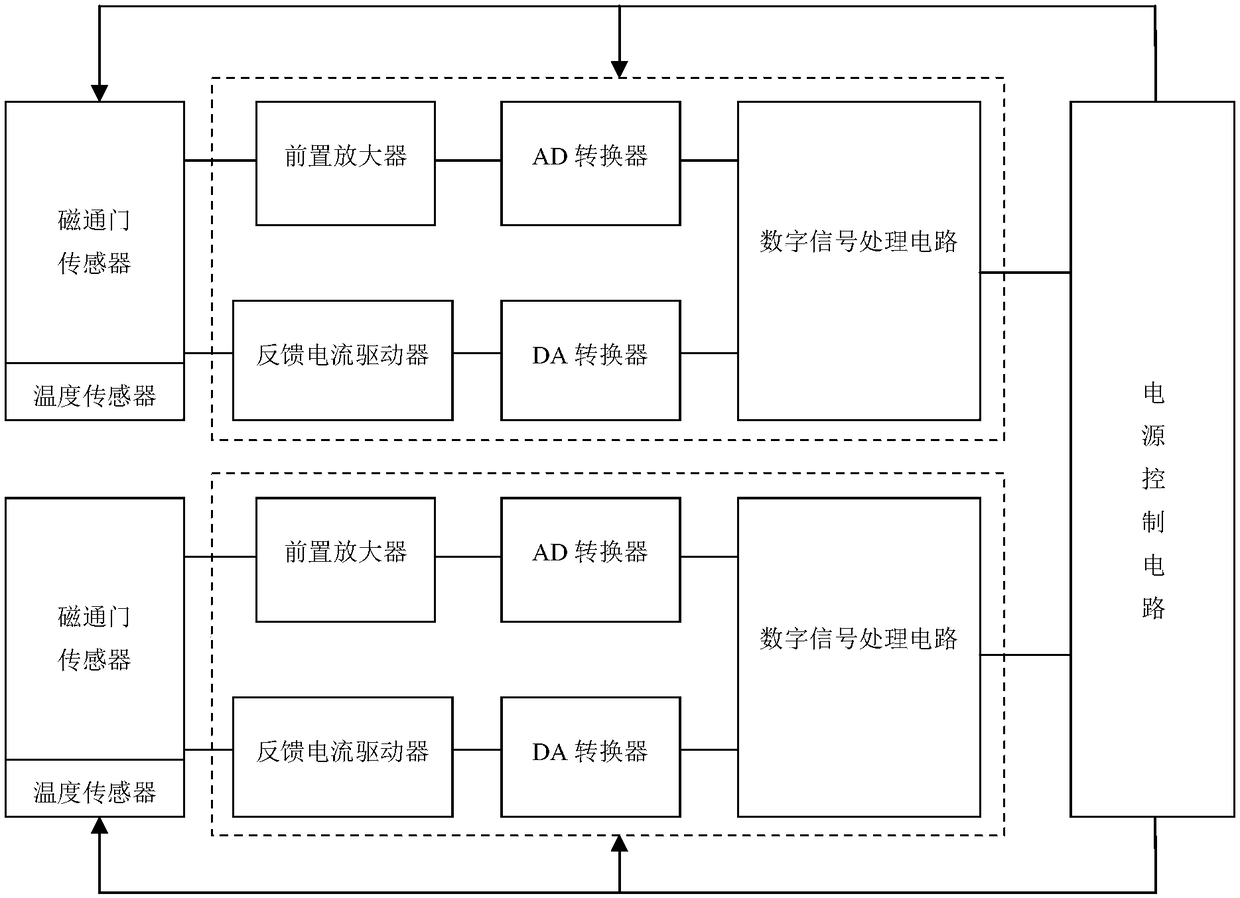

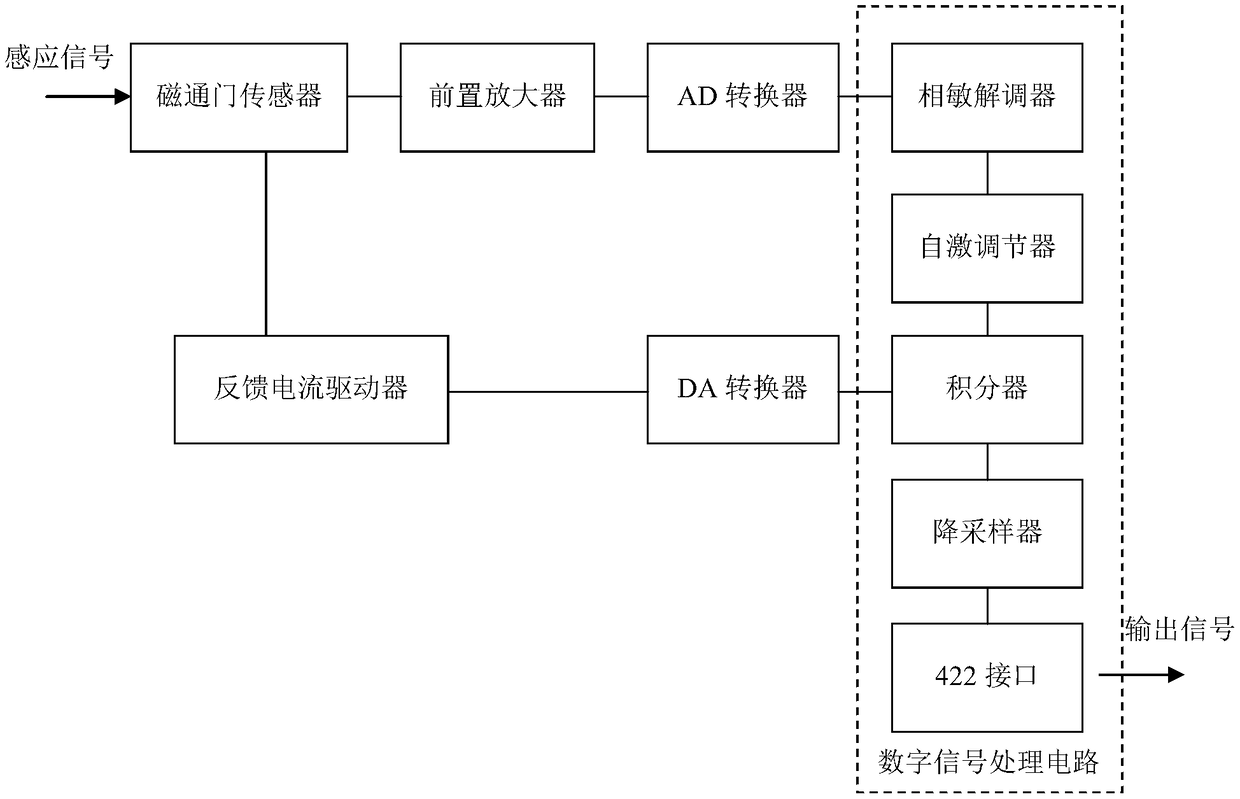

A detection device used for a satellite space magnetic field

ActiveCN108572336AImprove detection accuracyRealize synchronous detectionMagnetic field measurement using flux-gate principleCommunication interfaceControl circuit

The invention provides a detection device used for a satellite space magnetic field. The device includes a digital flux gate magnetometer, a colossal magnetoresistance magnetometer and a power supplycontrol electric circuit. The digital flux gate magnetometer is connected with a communication interface of the colossal magnetoresistance magnetometer and the power supply control electric circuit, the input voltage of the digital flux gate magnetometer and the colossal magnetoresistance magnetometer is controlled by the power supply control electric circuit through the satellite signal, the synchronized clock signal of running of the magnetometer is provided simultaneously, and the magnetic field detection data outputted by the magnetometer is packed and arranged and then inputted to the satellite. The low frequency signal and high frequency signal of the satellite space magnetic field can be detected and obtained simultaneously by the detection device, and the relative independent signal processing can be performed.

Owner:NAT SPACE SCI CENT CAS

Magnetic bead separation device and method based on microfluidics

The invention discloses a microfluidic-based magnetic bead separation device and method in the field of microfluidic application. An immunomagnetic bead solution inlet pipe, a bacterial mixed solution inlet pipe and a sterile water inlet pipe are integrated into a main inlet pipe, a microfluidic chip is provided with an annular pipe connected to the main inlet pipe and a main outlet pipe, a micro-pump and a sixth solenoid valve are connected to the annular pipe in series, an annular colossal magnetoresistance chip set sleeves the annular pipe, the annular pipe is provided with a groove communicated with the interior of the annular pipe and integrated to the annular pipe, a right ahead side, a right astern side and an outlet side of the groove are provided with electromagnets, an outlet of the main outlet pipe is respectively connected to a mixed solution outlet pipe and a sterile water outlet pipe, through electromagnet and solenoid valve turning-on and off, magnetic beads are gathered, an immunization magnetic bead amount is detected through a magnetoresistance chip, the inner wall of the pipe is cleaned by sterile water and simultaneously, the immunomagnetic beads are collected.

Owner:JIANGSU UNIV

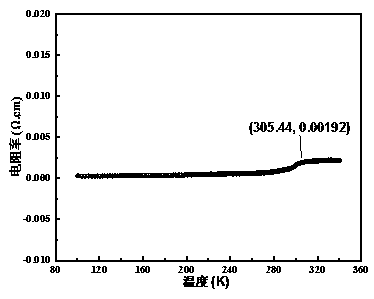

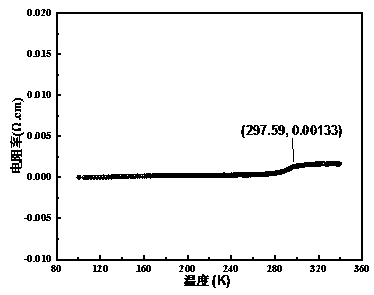

Method for improving electrical transport property of polycrystalline ceramic

The invention discloses a method for improving the electrical transport property of La(1-x)CaxSryMnO3-based polycrystalline ceramic, which can improve the electrical transport property of perovskite polycrystalline ceramic through excellent electrical conductivity of graphene. The method comprises the steps as follows: synthesis of La(1-x)CaxSryMnO3 matrix powder, preparation of a synthetic phasematerial and preparation of the polycrystalline ceramic. The resistance of the prepared polycrystalline ceramic is reduced, so that the TCR (temperature coefficient of resistance) is increased, the metal-insulator transformation temperature (Tp) is closer to the room temperature, and the polycrystalline ceramic can be more widely applied to near-room-temperature electronic devices, CMR (colossal magnetoresistance) bolometers, infrared detectors and other devices.

Owner:KUNMING UNIV OF SCI & TECH

Asymmetric memory cell

InactiveCN1574295ANanoinformaticsMagnetic-field-controlled resistorsElectrical resistance and conductanceStorage cell

Owner:SHARP KK

Co(x)C(1-x)/Co/Si multilayered structure granule film material having room temperature low field large magnetic resistance effect

InactiveCN101359716BLow costGood giant magnetoresistance effectMagnetic measurementsMagnetic-field-controlled resistorsElectrical resistance and conductanceRoom temperature

Owner:TSINGHUA UNIV

Low-temperature alkaline-solution synthesis of oxygen metal inorganic compound monocrystal nano-material

InactiveCN100497757CUniversal synthesis methodSuitable for synthesisPolycrystalline material growthSingle crystal growth detailsSemiconductor materialsInorganic compound

The present invention discloses a hypothermal alkali liquation synthesis process of monocrystalline nanometer materials of oxygenous metal inorganic compounds. The compound oxide monocrystalline nanometer materials are synthesized with the inorganic salt of a metal and the oxide of another metal as main materials, melted mixed alkali as solvent, at atmospheric pressure and relatively low temperature of about 200DEG C. The present invention uses melted alkali as solvent for the first time and can synthesize oxide nanometer materials of different structures, compositions and functions, or monocrystalline nanometer materials of simple oxide and hydroxide. This process utilizes conventional materials and only controls the time and temperature during synthesis in favor of the industrial application. The produced monocrystalline nanometer materials includes ferroelectric and piezoelectric materials, ferromagnetic materials, semiconductive materials, ionic conductive materials, colossal magnetoresistance materials, high dielectric materials superconductors and etc. that can be applied to microelectronics, photoelectronics and communication.

Owner:SHANDONG UNIV +2

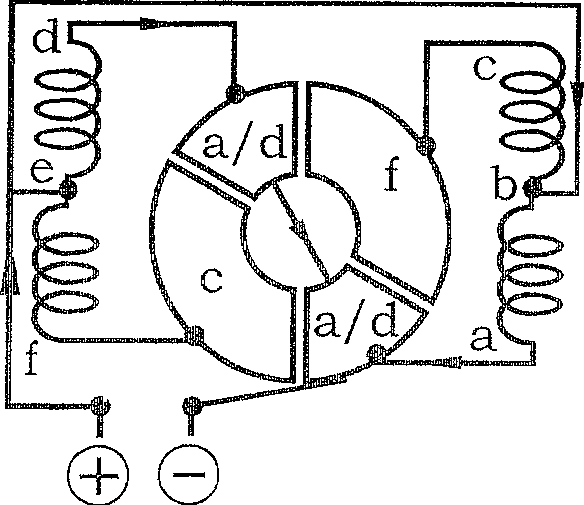

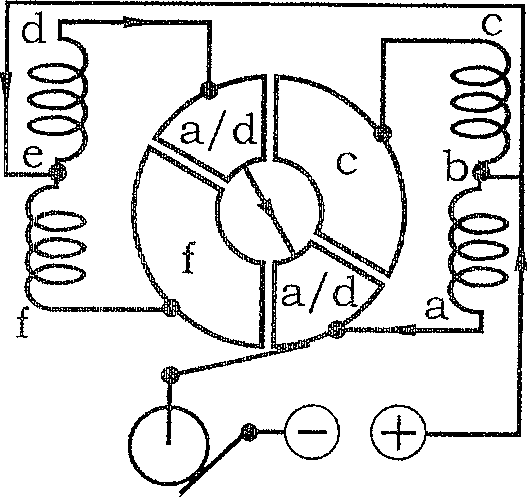

Single-brush two-phase 2/2 pole magnetoresistance vibrating electric machine

InactiveCN100514799CNo short circuitSmall starting currentRotary current collectorDC commutatorPermanent magnet rotorStator coil

A structure of a two-phase 2 / 2-pole permanent magnet rotor DC vibration motor. One end of the coil in the stator is connected to the commutator piece, the other end is connected to one pole of the power supply, and the brush is connected to the other pole of the power supply; the rotor is composed of an eccentric permanent magnet and a shaft sleeve, and the stator is composed of coils arranged in line on both sides of the fixed shaft Composition, the rotor rotates on the fixed shaft with the help of the rotor sleeve; the fixed shaft neither coincides with the center of mass of the rotor, nor is it on the line of the rotor magnetic poles, thus forming an eccentric vibrator; the single brush commutator provides the starting torque and Stable running torque. After balancing the center of gravity of the rotor, the same motor structure can also be used for ordinary power motors; the same single-brush commutator can also be used for permanent magnet DC motors with armature rotors, and rotor position sensors that replace ordinary permanent magnet rotor DC motors , directly drive the high-power commutation circuit. The motor structure can also be applied to the multi-pole permanent magnet rotor DC motor.

Owner:冯鲁民

Device and method for measuring magnetic induction intensity based on colossal magnetoresistance effect

ActiveCN102103193BAdjust current sizeHigh sensitivityMagnetic measurementsElectrical resistance and conductanceHelmholtz coil

The invention refers to a device and method for measuring magnetic induction intensity, especially to a device and method for measuring magnetic induction intensity based on the colossal magnetoresistive effect. The device includes an electromagnetic shielding device, a first loop and a second loop; the first loop includes a colossal magnetoresistive element, a Helmholtz coil and a first power supply device; the second loop includes a Huygens bridge and a second power supply device. The Helmholtz coil is utilized to supply a counter magnetic field by the use of significant action of the colossal magnetoresistive effect, so as to balance a magnetic field to be measured. When the Huygens bridge is balanced, the magnetic field to be measured is numerically equal to the magnetic field of the Helmholtz coil, but their directions are opposite, therefore, the device is not required to calculate the resistance of the colossal magnetoresistive element, thereby improving calculation accuracy and precision. The electromagnetic shielding device is utilized to effectively shield the environmental magnetic field, provide a measuring environment with zero magnetic field intensity, provide basic parameters without interference for the subsequent measuring, and improve the measuring accuracy.

Owner:STATE GRID CORP OF CHINA +2

A New Type of Lightning Strike Current Measuring Equipment

InactiveCN103901256BSimple structureLow costAc/pulses peak value measurementsLightning strokesCurrent sensor

The invention provides a novel lightning stroke current measuring device. The novel lightning stroke current measuring device comprises a colossal magnetoresistance current sensor for obtaining a voltage signal corresponding to the size of lightning stroke current, a front amplifier for amplifying the voltage signal obtained by the colossal magnetoresistance current sensor, a peak value demodulation circuit for detecting the peak value of the voltage signal so as to obtain a peak value signal, and a processor for obtaining the value of the lightning stroke current according to the peak value signal. The lightning stroke current measuring device has the advantages of simple structure, low cost, high precision and convenient installation, is suitable for low-power occasions, and can be widely applied to occasions in need of lightning stroke current or flashover current measurement, such as high speed railways, intelligent power networks, base stations and the like.

Owner:BEIJING JIAYUE TONGLEJI ELECTRONICS

Preparation method of colossal magnetoresistance effect Fe-Ti-O amorphous film

InactiveCN102345104BLarge room temperature magnetoresistance effectSimple process conditionsVacuum evaporation coatingSputtering coatingSputteringPower flow

A preparation method of a colossal magnetoresistance effect Fe-Ti-O amorphous film adopts an ultra-high vacuum three-target codeposition magnetron sputtering coating machine for the preparation, and comprises the following steps: 1) mounting a Ti target and a Fe target on a target head of the coating machine respectively; 2) mounting a glass substrate on a substrate support; 3) turning on the magnetron sputtering device to vacuumize a sputtering chamber; 4) introducing mixed gas of O2 and Ar into the vacuum chamber to obtain a vacuum degree of 1 Pa of the vacuum chamber; 5) turning on a sputtering direct-current power supply, applying a current and a voltage to the Ti target and the Fe target; 6) opening a baffle plate of the substrate, rotating the substrate support, growing a film on the substrate; 7) after the sputtering is completed, injecting nitrogen into the vacuum chamber to obtain the prepared target product. The advantages of the invention are that: the process method is simple and easy to carry out, and the prepared film has high room-temperature magnetoresistance effect; the production cost is low, and the method is applicable to large-scale popularization and application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

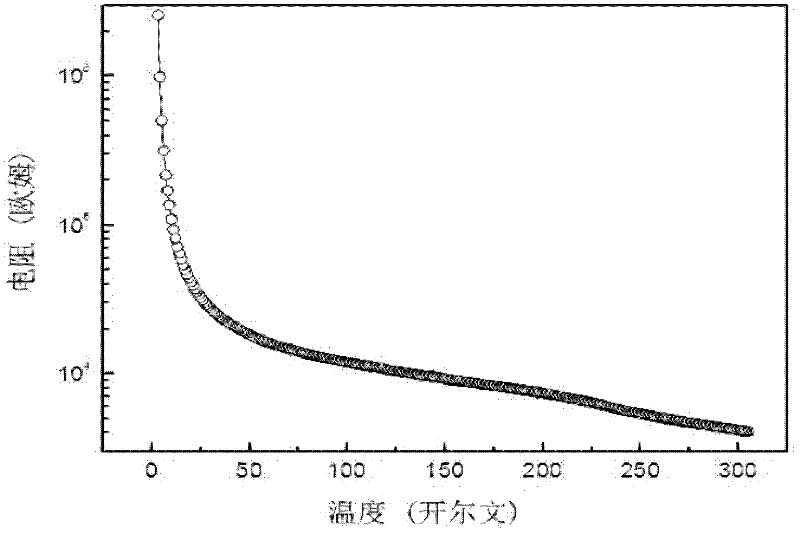

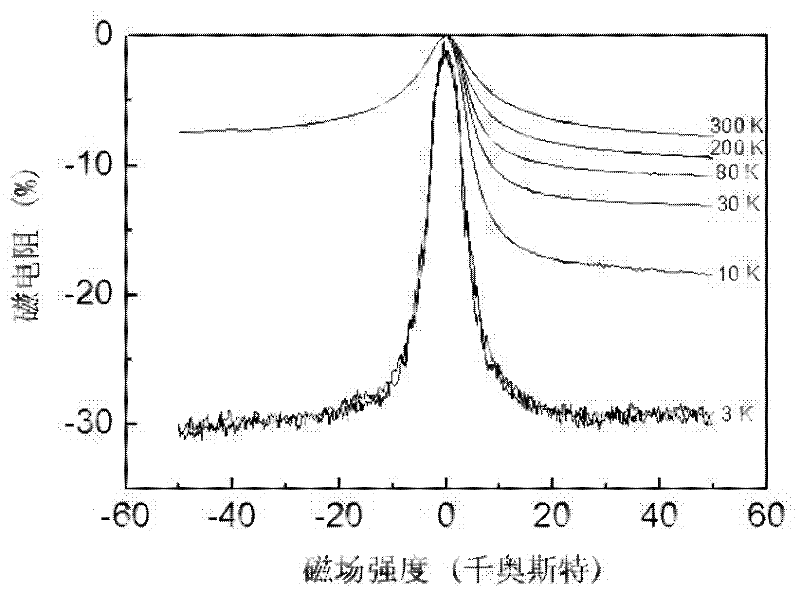

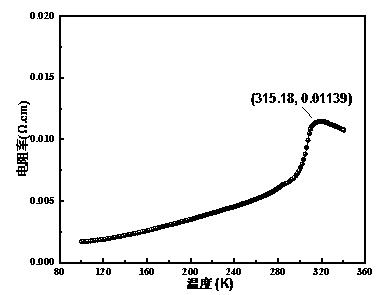

Perovskite-structure manganese oxide-based colossal magnetoresistance material and preparation method thereof

ActiveCN106431402AImprove magnetoelectric propertiesSignificant change in resistanceCrystal structureMetal insulator

The invention discloses a perovskite-structure manganese oxide-based colossal magnetoresistance material. The general chemical formula of the colossal magnetoresistance material is (PrCLaDSrECaF)MnO3, wherein Mn is manganese metal, O is oxygen, C+D=0.7, E+F=0.3, and the colossal magnetoresistance material is of a ABO3 type perovskite crystal structure. The invention further discloses a preparation method of the perovskite-structure manganese oxide-based colossal magnetoresistance material. The control method of the perovskite-structure manganese oxide-based colossal magnetoresistance material is simple in technology and easy to achieve. The prepared magnetic material is significant in resistance variation under an additional magnetic field, magnetoresistance is high, metal-insulator transformation temperature and maximum magnetoresistance can be continuously adjusted along with the composition change within the temperature range of 200 K to 300 K, and the colossal magnetoresistance material has a good electromagnetic property.

Owner:长沙赢睿知识产权运营有限公司

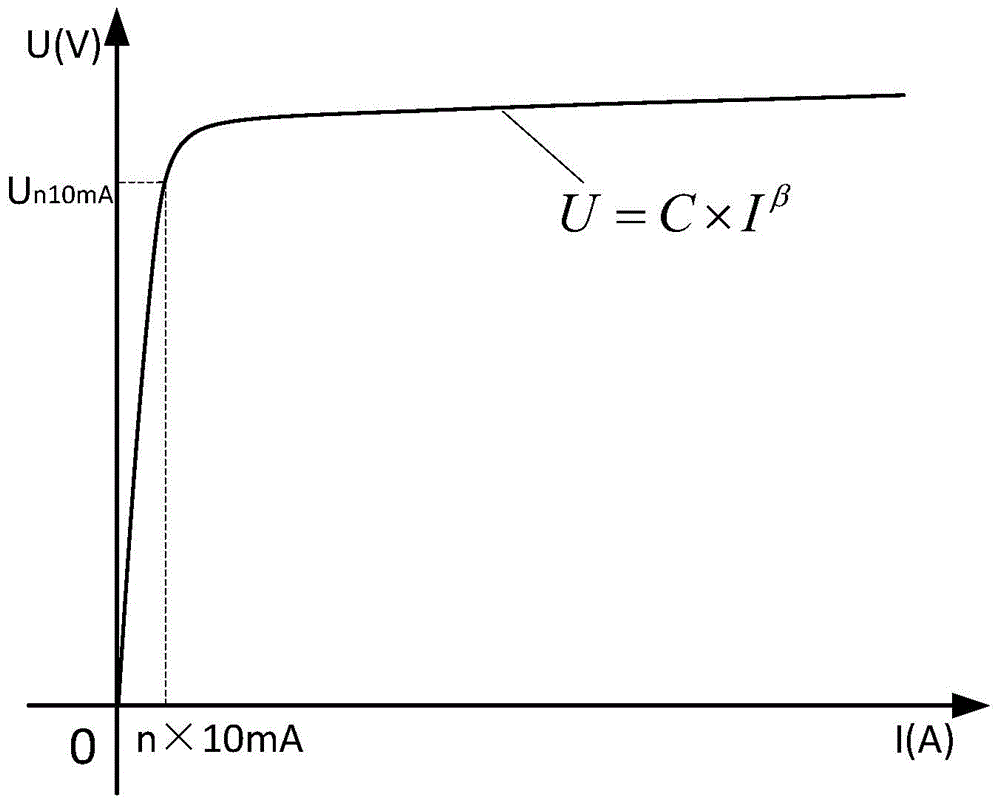

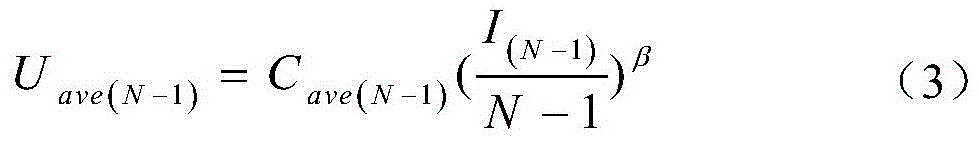

A safety assessment method for zinc oxide demagnetization resistor components

ActiveCN104237689BWith precisionTargetedElectrical testingElectrical resistance and conductanceCritical index

The invention discloses a zinc oxide field suppression resistance assembly safety assessment method. As an accurate and unified assessment and calculation method based on zinc oxide field suppression resistance site testing data does not exist at present, after the data are measured, the characteristic change degrees and the variation trends of assemblies can only be roughly seen. According to the zinc oxide field suppression resistance assembly safety assessment method, a newly-defined zinc oxide field suppression resistance breakdown voltage safety critical index K is deduced for serving as a judgment basis, the safety critical index is converted into a corresponding safety critical value Kact through the adoption of the maximum assembly field suppression energy and the maximum assembly allowing energy, after the breakdown voltage of the assemblies is obtained through site measurement, only the ratio of the minimum actual measurement assembly breakdown voltage to the average other-assembly breakdown voltage needs to the calculated, and then the ratio is compared with the safety critical value to be capable of obtaining an assembly safety assessment conclusion. By means of the zinc oxide field suppression resistance assembly safety assessment method, the aims of assembly safety calculation and assembly safety assessment after zinc oxide field suppression resistance site measurement are achieved, and the accuracy of the safety calculation and assessment conclusion is improved.

Owner:STATE GRID CORP OF CHINA +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com