Single-brush two-phase 2/2 pole magnetoresistance vibrating electric machine

A brush and electrode technology, applied in circuits, current collectors, electrical components, etc., can solve the problems of high speed, lack of practical application value, uncertain direction of starting torque, etc., and achieve improved life, simple and reliable structure, and starting current. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

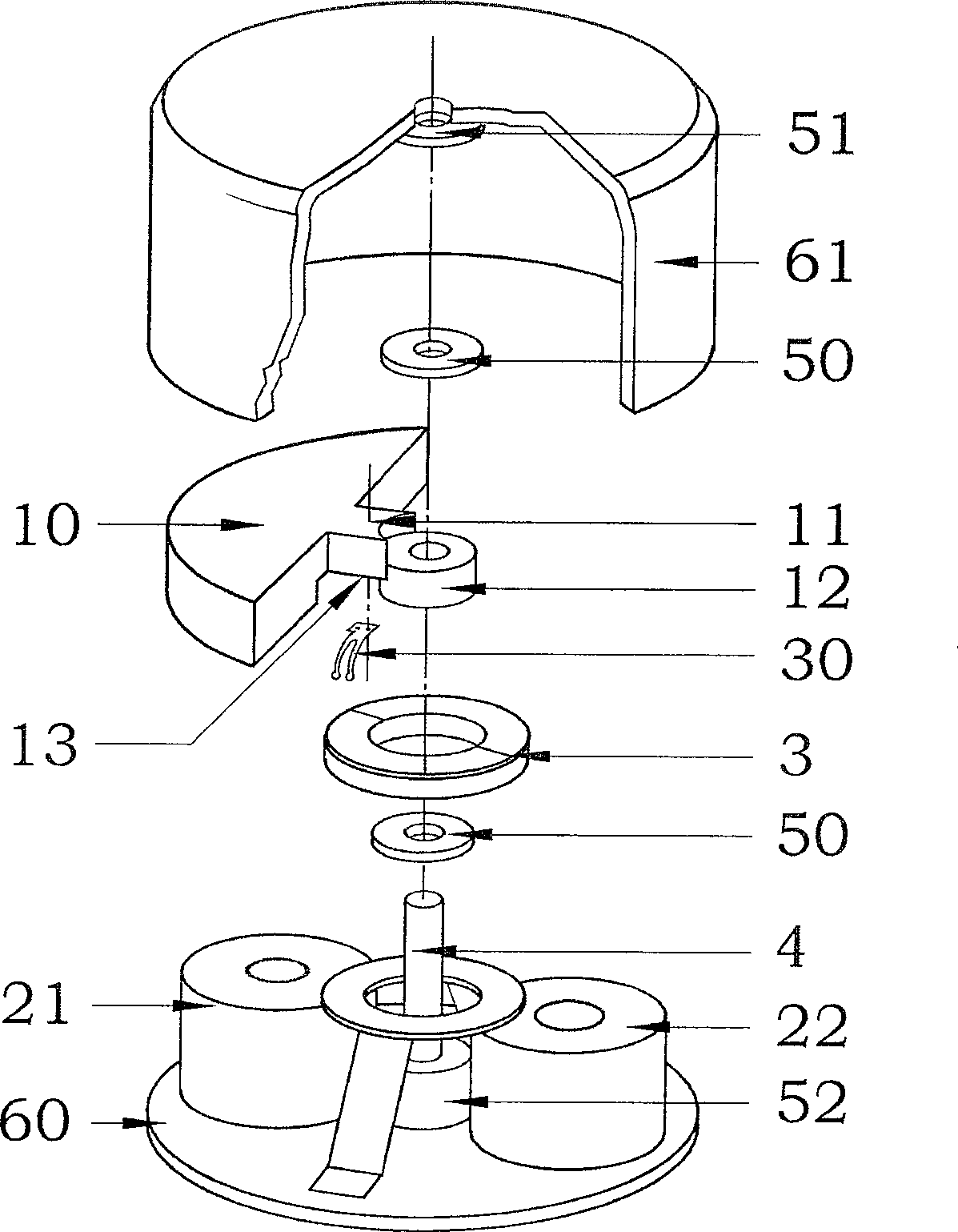

[0025] figure 1 Shown is a structural diagram of a DC miniature vibration motor according to the first preferred embodiment of the present invention. The motor adopts the stator coreless two-phase coils in series, and the rotor is in the form of two-pole eccentric permanent magnets.

[0026] The permanent magnet eccentric rotor (1) is located on the axial side of the stator coils 1 (21) and 2 (22), and is supported by the lower shaft seat (52) so that the rotor (1) and the stator coil (2) are in the axial direction. To maintain a very small magnetic air gap. The stator coils 1 (21) and 2 (22) are hollow, the axes of the two coils (21) and (22) are parallel to the fixed axis, and the line between the axes of the two stator coils is perpendicular to the axis of the fixed axis (4) . The stator coil 1 (21) and the stator coil 2 (22) are bonded and fixed on the motor bottom plate (60). One end of the fixed shaft (4) is fixed on the lower axle seat (52) of the motor base plate (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com