Method for improving electrical transport property of polycrystalline ceramic

An electrical transport and ceramic technology, applied in the field of improving the electrical transport performance of polycrystalline ceramics and La1-xCaxSryMnO3-based polycrystalline ceramics, can solve the problem of general regulation effect, reduced ceramic life, low regulation temperature range, etc. problems, to achieve the effect of being beneficial to popularization and commercial use, improving the service life of ceramics, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

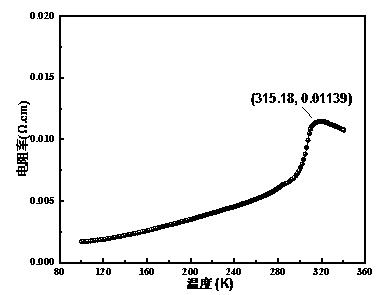

Embodiment 1

[0044] A way to improve La 1-x Ca x Sr y MnO 3 The method of base polycrystalline ceramic electric transport performance includes the following steps:

[0045] 1. La 0.95 Ca 0.05 Sr 0.01 MnO 3 Base powder synthesis:

[0046] 1.1 Weigh out 0.95mol La(NO 3 ) 3 , 0.05mol Ca(NO 3 ) 2 , 0.01mol Sr(NO 3 ) 2 , 1mol Mn(NO 3 ) 2 And 3mol citric acid, sequentially poured into deionized water and coordinated with synchronous stirring to obtain Process I;

[0047] 1.2 Add 6 mL of ethylene glycol (the volume ratio of ethylene glycol to process I is 3%) to process product I obtained in step 1.1 to obtain process product II;

[0048] 1.3 The process product II obtained in step 1.2 is subjected to high-temperature evaporation treatment to obtain process product III in a non-flowing gel state;

[0049] 1.4 Carry out high-temperature drying treatment on the process product III obtained in step 1.3 to obtain the process product IV in a dry gel state, the drying treatment temperature is 120 ℃, and the dryi...

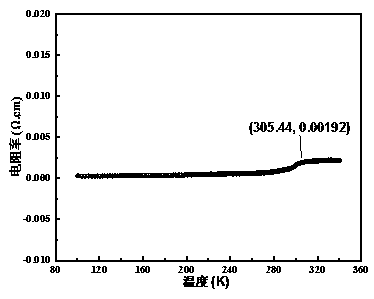

Embodiment 2

[0065] A way to improve La 1-x Ca x Sr y MnO 3 The method of base polycrystalline ceramic electric transport performance includes the following steps:

[0066] 1. La 0.85 Ca 0.15 Sr 0.03 MnO 3 Base powder synthesis:

[0067] 1.1 Weigh 0.85mol La(NO 3 ) 3 , 0.15mol Ca(NO 3 ) 2 , 0.03mol Sr(NO 3 ) 2 , 1mol Mn(NO 3 ) 2 And 4mol citric acid, sequentially poured into deionized water and coordinated with synchronous stirring to obtain Process I;

[0068] 1.2 Add 8 mL of ethylene glycol (the volume ratio of ethylene glycol to process I is 4%) to process product I obtained in step 1.1 to obtain process product II;

[0069] 1.3 The process product II obtained in step 1.2 is subjected to high-temperature evaporation treatment to obtain process product III in a non-flowing gel state, and the flow state of process product III is used as the reaction stop criterion;

[0070] 1.4 The process product III obtained in step 1.3 is subjected to high-temperature drying treatment to obtain the process produ...

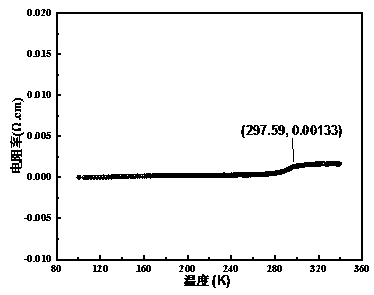

Embodiment 3

[0086] A way to improve La 1-x Ca x Sr y MnO 3 The method of base polycrystalline ceramic electric transport performance includes the following steps:

[0087] 1. La 0.685 Ca 0.315 Sr 0.06 MnO 3 Base powder synthesis:

[0088] 1.1 Weigh 0.685mol La(NO 3 ) 3 , 0.315mol Ca(NO 3 ) 2 , 0.06mol Sr(NO 3 ) 2 , 1mol Mn(NO 3 ) 2 And 5mol citric acid, sequentially poured into deionized water and coordinated with synchronous stirring to obtain Process I;

[0089] 1.2 Drop 10 mL of ethylene glycol (the volume ratio of ethylene glycol to process product I is 5%) to process product I obtained in step 1.1 to obtain process product II;

[0090] 1.3 The process product II obtained in step 1.2 is subjected to high-temperature evaporation treatment to obtain process product III in a non-flowing gel state, and the flow state of process product III is used as the reaction stop criterion;

[0091] 1.4 The process product III obtained in step 1.3 is subjected to high-temperature drying treatment to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com