Co(x)C(1-x)/Co/Si multilayered structure granule film material having room temperature low field large magnetic resistance effect

A technology of giant magnetoresistance and multilayer structure, which is applied in the field of C1-xCox/Co/Si multilayer structure granular film materials, can solve the problems of relatively harsh preparation process requirements, large-scale preparation limitations, complex structures, etc., and achieve high preparation efficiency , strong controllability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

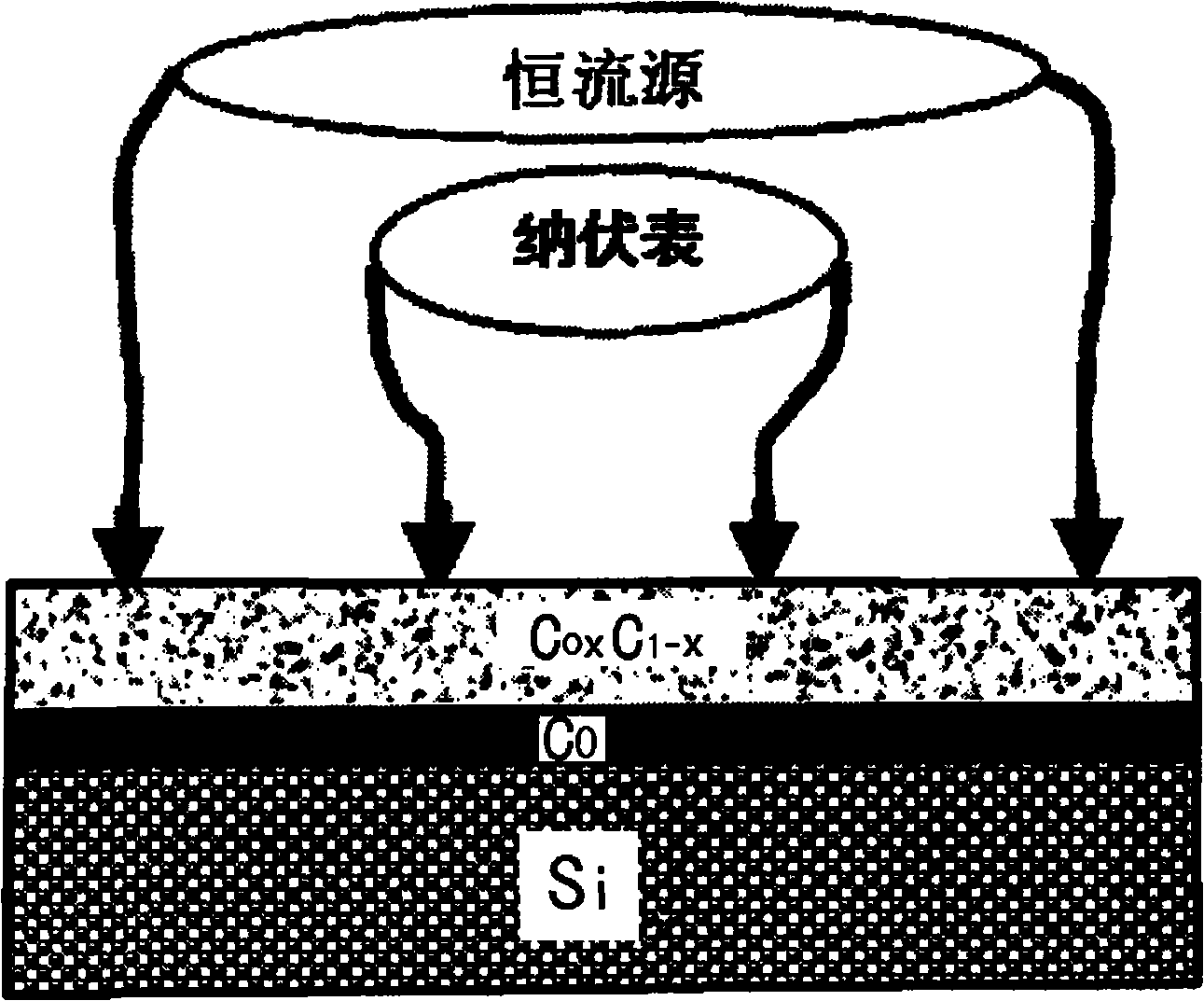

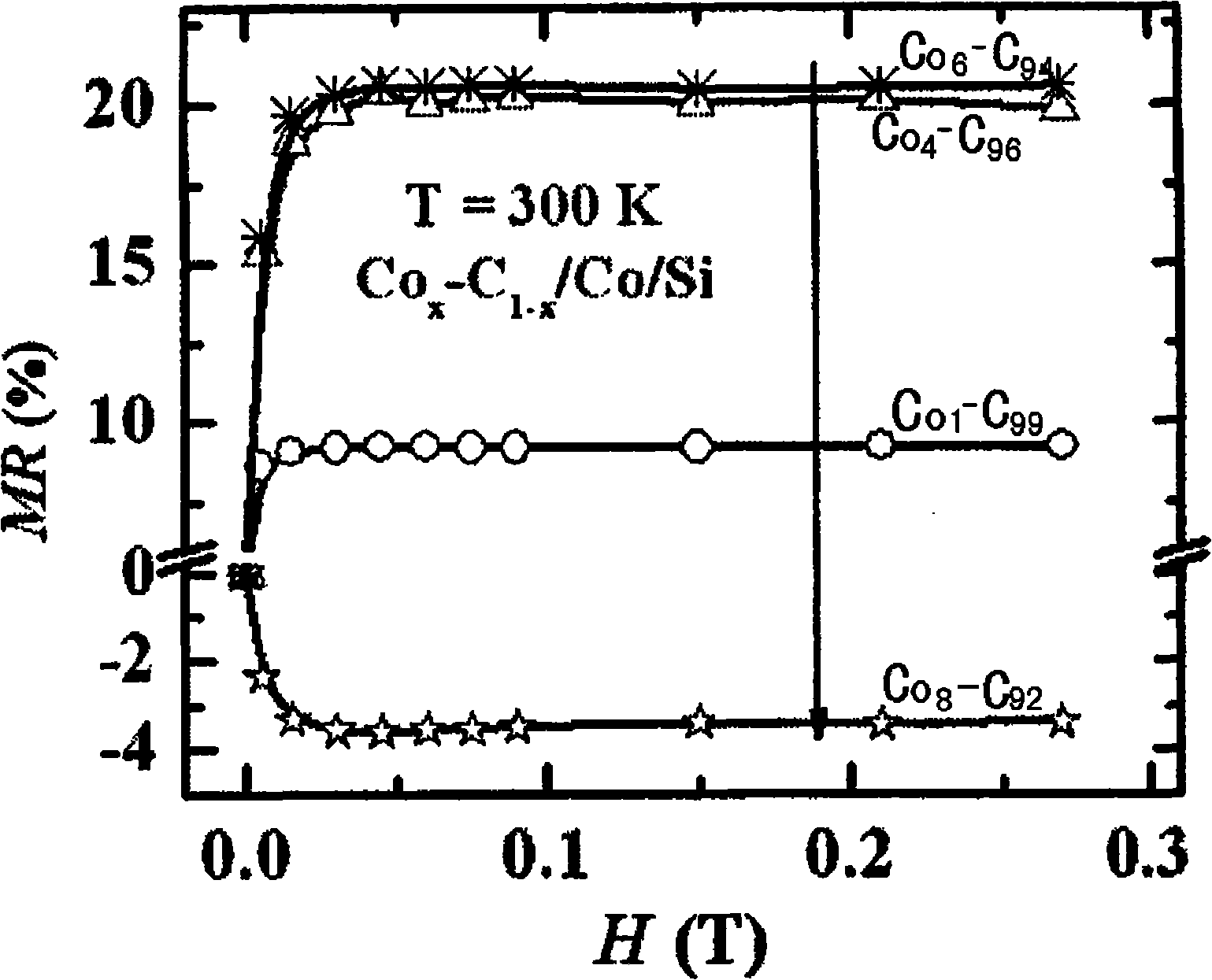

[0013] The invention is a kind of Co with room temperature and low field giant magnetoresistance effect prepared by laser pulse deposition method x C 1-x / Co / Si multilayer structure granular film material. The specific preparation method is as follows: first put the treated Si substrate and target with a lattice orientation of 100 into the vacuum coating chamber of the PLD equipment, and use a mechanical pump and a molecular pump to vacuum the back of the coating chamber to 5×10 -4 After Pa, heat the substrate to T=300K, and then use the KrF laser (LambdaPhysics LPX205, 248nm, 25ns FWHM) to bombard the Co target with a pulse of energy of 250-300mJ, and start the motor to rotate the target and the substrate at the same time, Start to deposit the Co layer film; then change the substrate temperature to T=300K, and deposit Co in the same way x C 1-x layer of granular film. After the deposition, the sample was cooled slowly and then cooled naturally to room temperature. Other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com