Inward passing-type colossal magnetoresistance array probe for nonferromagnetic thin-walled tube defect detection

A defect detection, non-ferromagnetic technology, applied in the direction of measuring devices, material magnetic variables, material analysis through electromagnetic means, etc., can solve the problems of weak anti-interference ability, low detection sensitivity of small defects, high scrap rate, etc., to improve The effect of detecting sensitivity, improving anti-interference ability and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

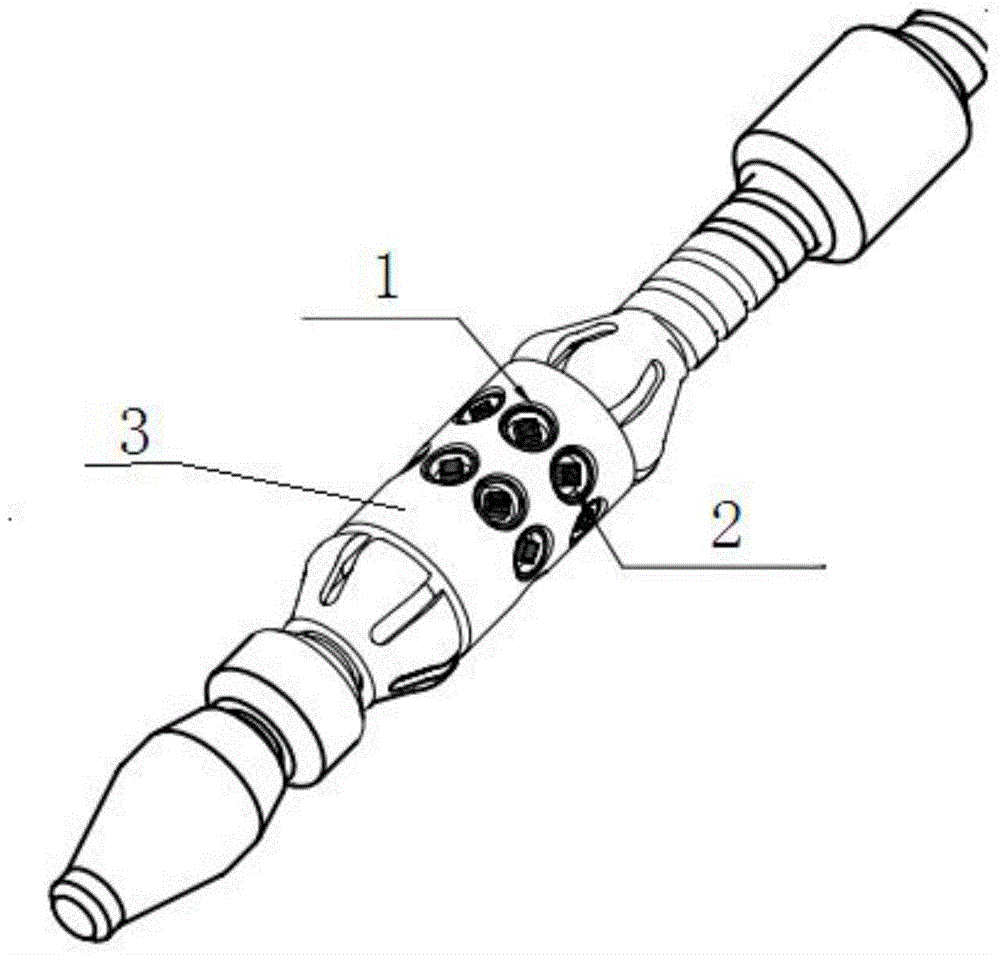

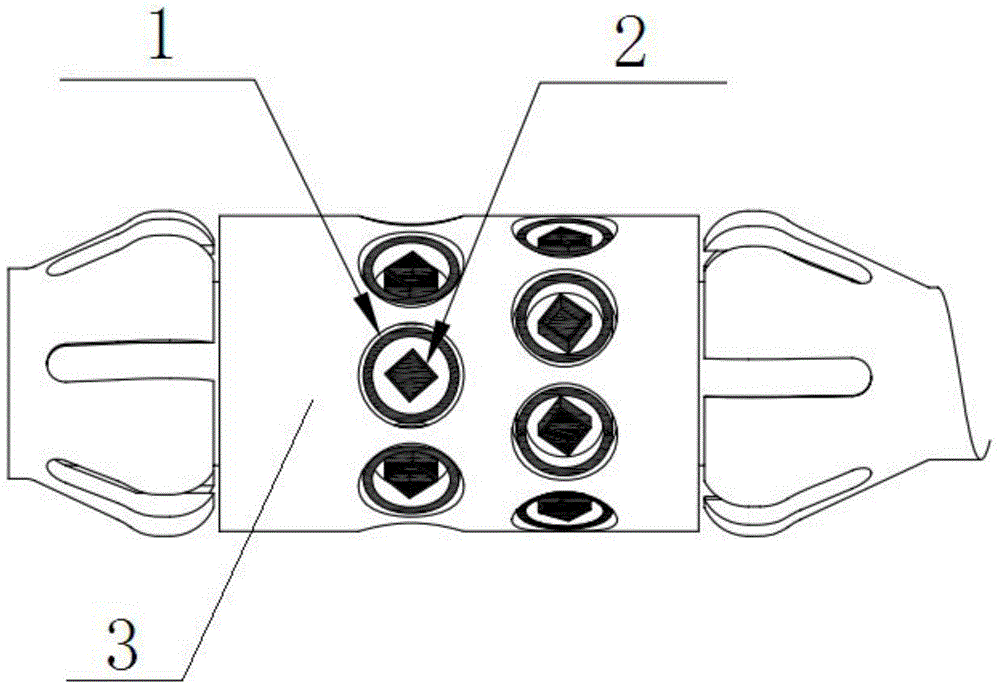

[0015] Such as figure 1 , figure 2 As shown, an internally penetrating giant magnetoresistive array probe for detecting defects in non-ferromagnetic thin-walled tubes includes an excitation coil 1 and a giant magnetoresistive sensor 2 arranged on a probe frame 3, wherein the probe frame 3 is arranged around the circumference A number of excitation coils 1 are installed in each direction, and a giant magnetoresistive sensor 2 is installed in the central area of each excitation coil 1. Among them, the excitation coil 1 adopts a flat flat hollow coil; for example, the probe frame 3 is evenly arranged in the circumferential direction. 4 to N (N≥4) flat hollow coils are arranged, and a giant magnetoresistive sensor is installed at the center of each flat hollow coil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com