Bismuth micron particle and manufacturing method thereof

A technology of micron particles and particles, which is applied in the fields of chemical engineering and functional micro-nano materials, and achieves the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The bismuth microparticles prepared in this example were prepared by the following method: 3 mmol bismuth nitrate and 3 mmol CTAC were added to 60 mL of ethylene glycol, stirred at 500 r / min until dissolved, and then 1 mol / L of KOH was added dropwise therein ethylene glycol solution to a pH greater than 10. After obtaining a clear solution, continue stirring for 1 hour, transfer the solution to a closed polytetrafluoroethylene-lined high-pressure reactor, and place it in a blast oven at 180°C for 12 hours, take it out after natural cooling, and filter the obtained product with suction. Wash with deionized water until neutral, and use ethanol to wash away the template agent. Finally, the filtered product was vacuum-dried at 60° C. for 12 h to obtain the target product.

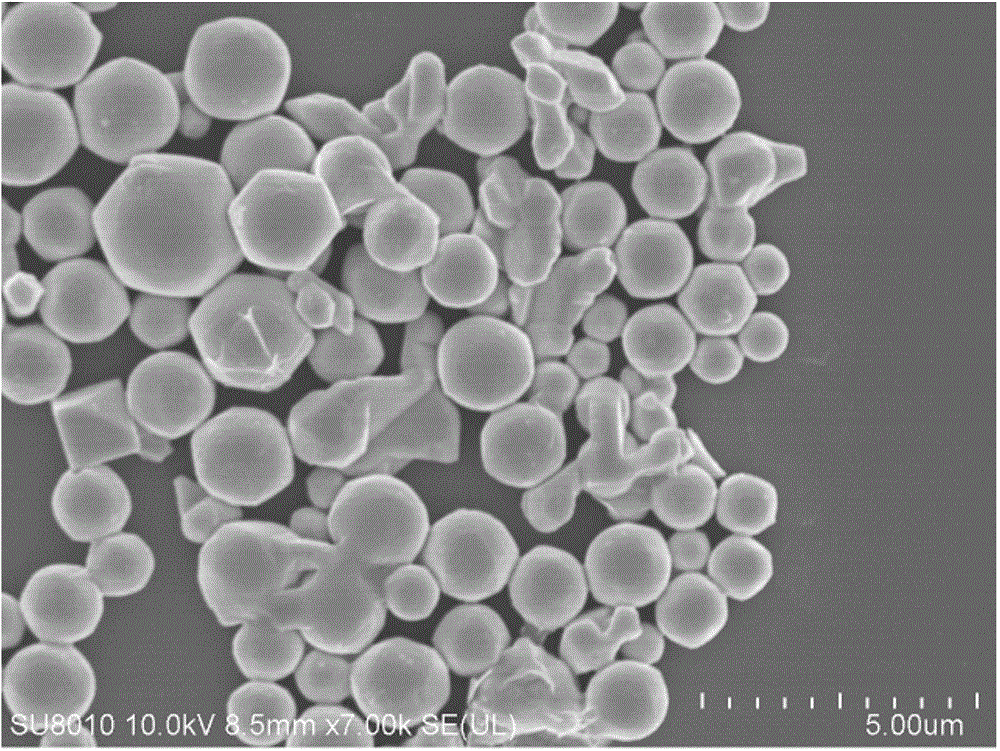

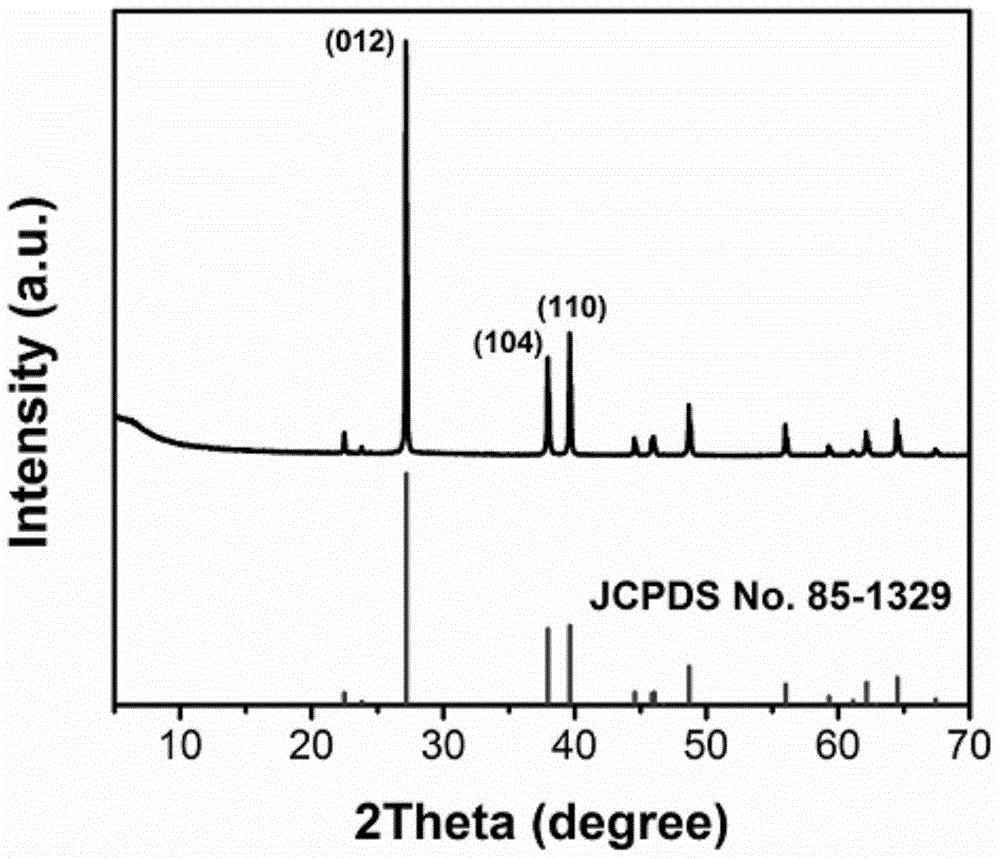

[0016] The field emission scanning electron microscope photograph of the bismuth microparticle provided by the present embodiment is as follows figure 1 shown by figure 1 It can be seen from the figur...

Embodiment 2

[0018] The bismuth microparticles prepared in this example were prepared by the following method: 3 mmol of bismuth acetate and 2.5 mmol of CTAC were added to 60 mL of ethylene glycol, stirred at 500 r / min until dissolved, and then 1 mol / L of KOH in ethylene glycol to a pH greater than 10. After obtaining a clear solution, continue stirring for 1 hour, transfer the solution to a closed polytetrafluoroethylene-lined high-pressure reactor, and place it in a blast oven at 160°C to react for 12 hours, take it out after natural cooling, and filter the obtained product with suction. Wash with deionized water until neutral, and use ethanol to wash away the template agent. Finally, the filtered product was vacuum-dried at 60° C. for 12 h to obtain the target product.

Embodiment 3

[0020] The bismuth microparticles prepared in this example were prepared by the following method: 3 mmol of bismuth nitrate and 1 mmol of CTAC were added to 60 mL of ethylene glycol, stirred at 500 r / min until dissolved, and then 1 mol / L of KOH was added dropwise therein ethylene glycol solution to a pH greater than 10. After obtaining a clear solution, continue stirring for 1 hour, transfer the solution to a closed polytetrafluoroethylene-lined high-pressure reactor, and place it in a blast oven at 160°C to react for 12 hours, take it out after natural cooling, and filter the obtained product with suction. Wash with deionized water until neutral, and use ethanol to wash away the template agent. Finally, the filtered product was vacuum-dried at 60° C. for 12 h to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com