La2Ti2O7:Mn<4+> multiferroic ceramic and preparation method thereof

A multiferroic ceramics, 24-hour technology, applied in the field of La2Ti2O7:Mn4+ multiferroic ceramics and its preparation, can solve the problems of Curie temperature reduction, impurity phase generation, small electric polarization, etc., and achieve ferroelectricity and ferromagnetism Improvement, simple manufacturing process, and increased feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

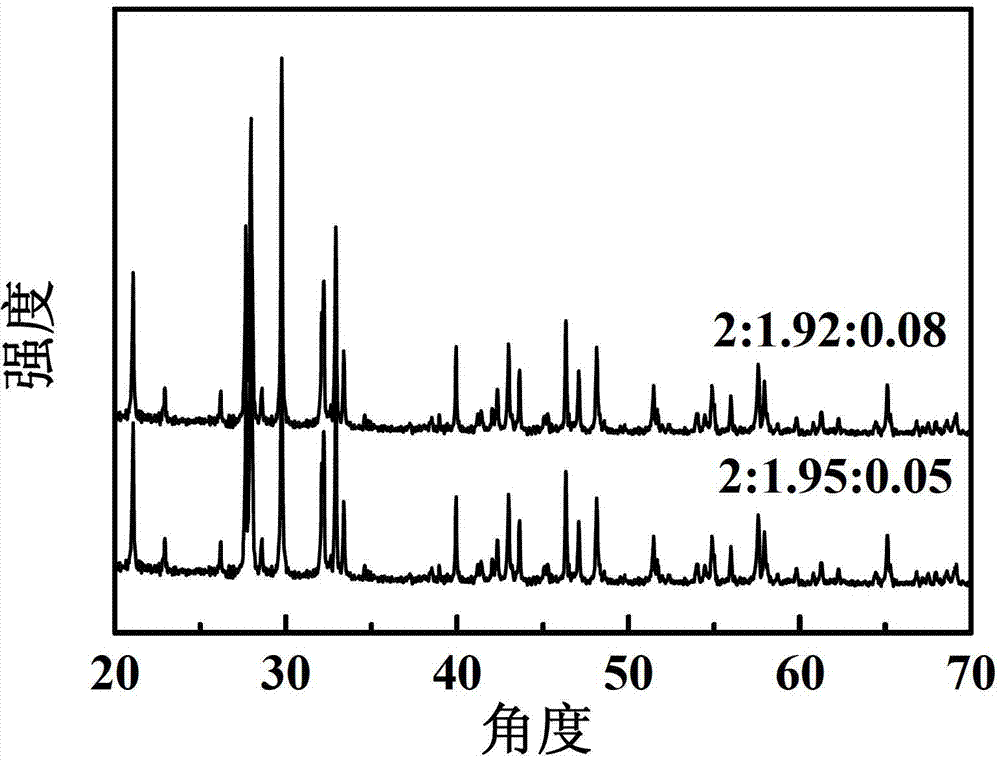

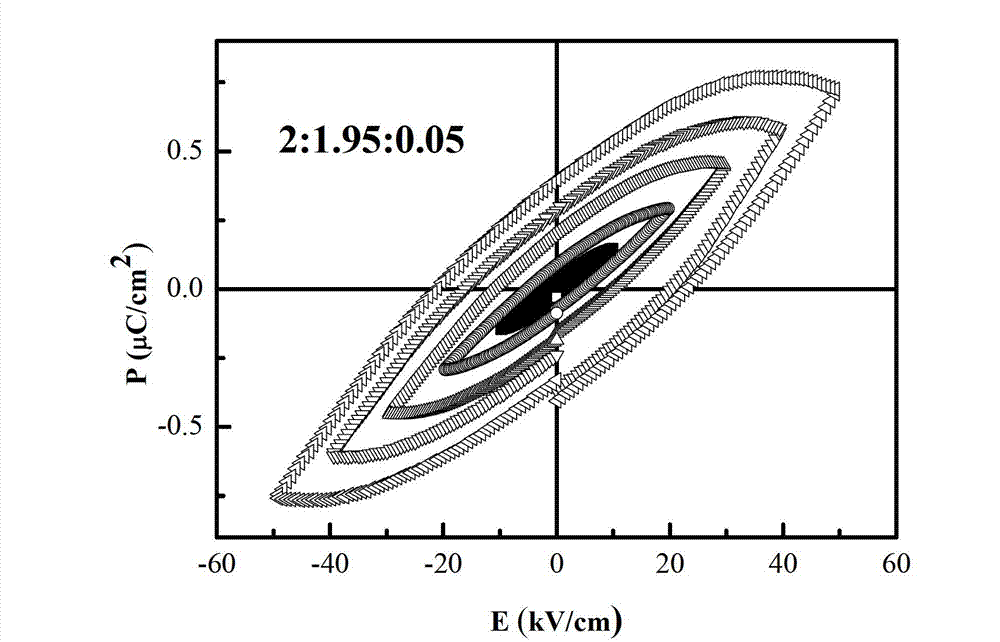

[0028] Preparation of La by solid phase method 2 Ti 2 o 7 :Mn 4+ (The molar ratio of lanthanum, titanium and manganese is 2:1.95:0.05) multiferroic ceramics. First, put 0.03mol of lanthanum oxide, 0.0585mol of titanium oxide and 0.0015mol of manganese oxide in an agate jar, add 25mL of absolute ethanol to mix them evenly, and use a ball mill to perform full ball milling at a speed of 350 rpm. The ball milling time is 24 hours; then, place the ball-milled sample in an oven at 100°C and dry it for 0.5 hours, and place the fully mixed powder in A1 2 o 3 The crucible was pre-fired in an air atmosphere, and the temperature was raised to 1000 °C at a rate of 5 °C / min, and the holding time was 24 hours to remove the moisture in the powder and some organic matter mixed in the ball milling process; finally, the pre-fired Dissolve the powder with nitric acid solution to remove unreacted oxides, dry the sample, and after ball milling for 0.5 hours, press it into a small circle with ...

Embodiment 2

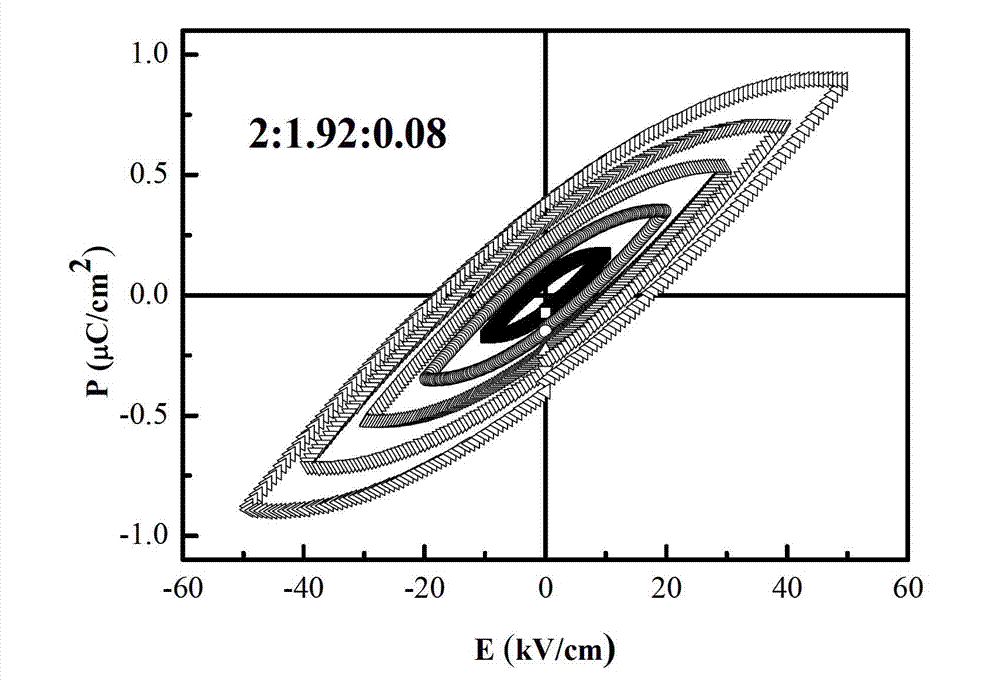

[0031] Preparation of La by solid phase method 2 Ti 2 o 7 :Mn 4+ (The molar ratio of lanthanum, titanium and manganese is 2:1.92:0.08) multiferroic ceramics. First, put 0.03mol of lanthanum oxide, 0.0576mol of titanium oxide and 0.0024mol of manganese oxide in an agate jar, add 25mL of absolute ethanol to mix them evenly, and use a ball mill to perform full ball milling at a rate of 350 rpm. The ball milling time is 24 hours; then, place the ball-milled sample in an oven at 100°C and dry it for 0.5 hours, and place the fully mixed powder in A1 2o 3 The crucible was pre-fired in an air atmosphere, and the temperature was raised to 1000 °C at a rate of 5 °C / min, and the holding time was 24 hours to remove the moisture in the powder and some organic matter mixed in the ball milling process; finally, the pre-fired Dissolve the powder with nitric acid solution to remove unreacted oxides, dry the sample, ball mill for 0.5 hours, and press it into a small circle with a diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com