Patents

Literature

47results about How to "Anti-adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refractory far infrared radiation ceramics coating

The invention provides a high temperature resistance infrared radiation pottery dope, which belongs to the thermal engineering field. The dope is a mixture of the following materials in mass share: 200 mesh zirconium dioxide 10, 200 mesh zircon quartz sand 20, 300 mesh feldspar 10, 300 mesh cerium oxide 7, 300 mesh manganese sesquioxide 15, 300 mesh manganic oxide 3, 600 mesh titanium dioxide 2, 200 mesh alumina 10, 400 mesh graphite 10, 400 mesh boron nitride 3 and 200 mesh carborundum 10. The graphite and boron nitride in the dope are of lubricating and anti-bonding functions, the carborundum is of wear resistance function, the manganic oxide, titanium dioxide and alumina are of strong infrared ray emission and the dope mad of zirconium dioxide, zircon quartz, feldspar and cerium oxide has good compact structure and strong fire-proof and the manganese sesquioxide can catalyze C, S and N for conversion. Therefore, the invention is applicable for use in dynamic furnaces such as coal dust furnace, boiling furnace and fluidized bed furnace.

Owner:颐珑达绝热材料技术(北京)有限公司

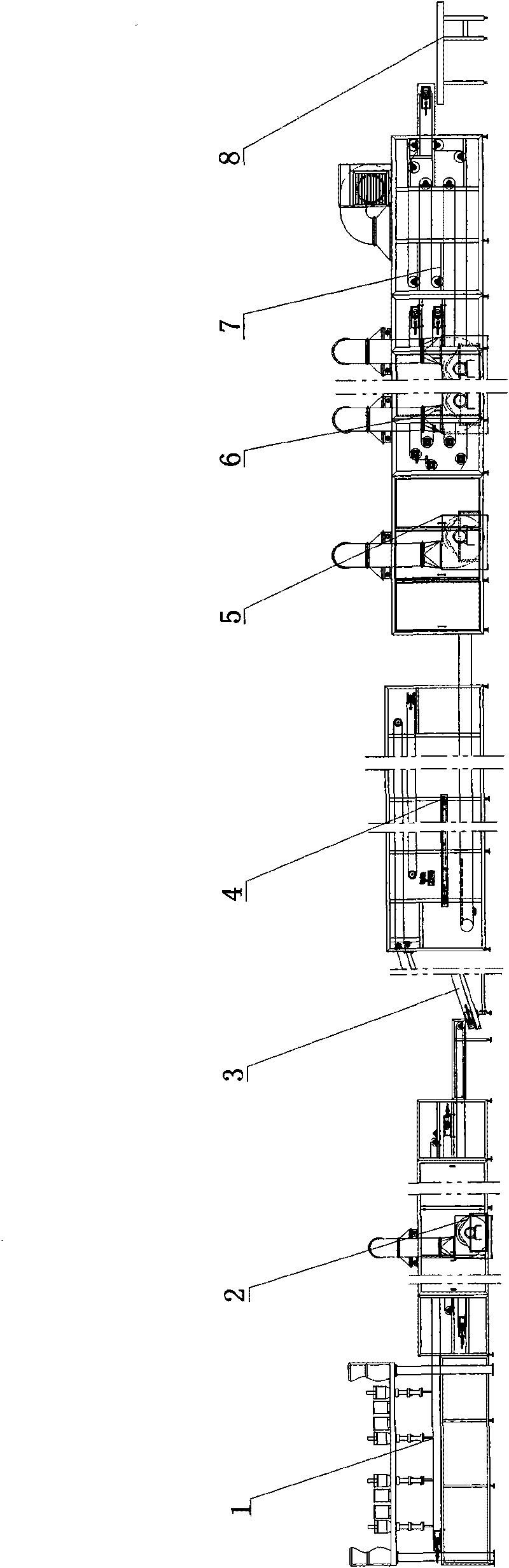

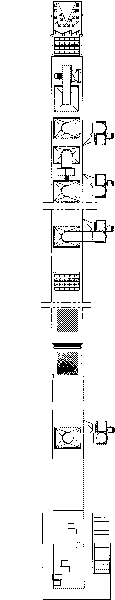

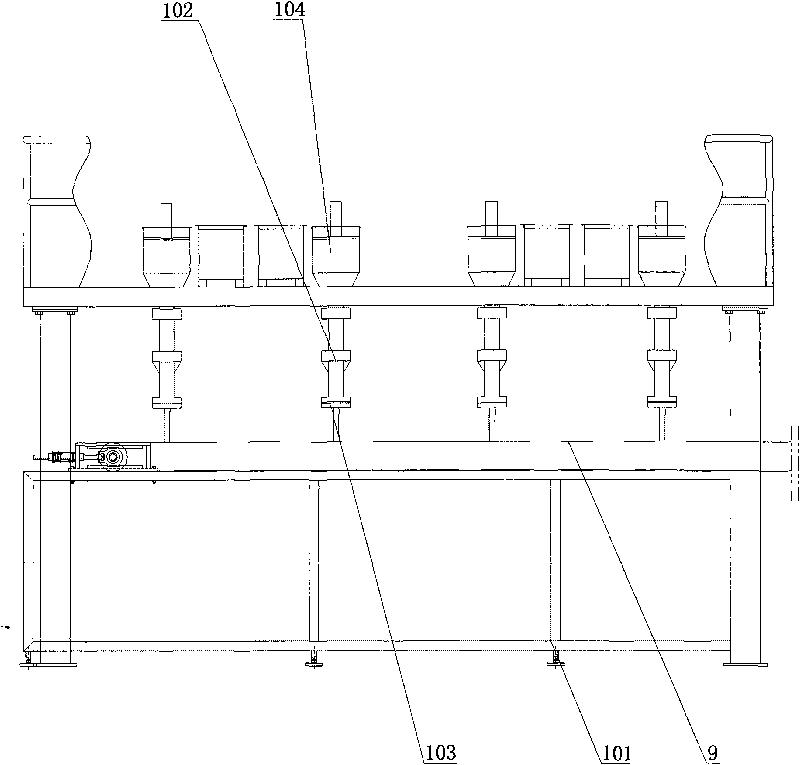

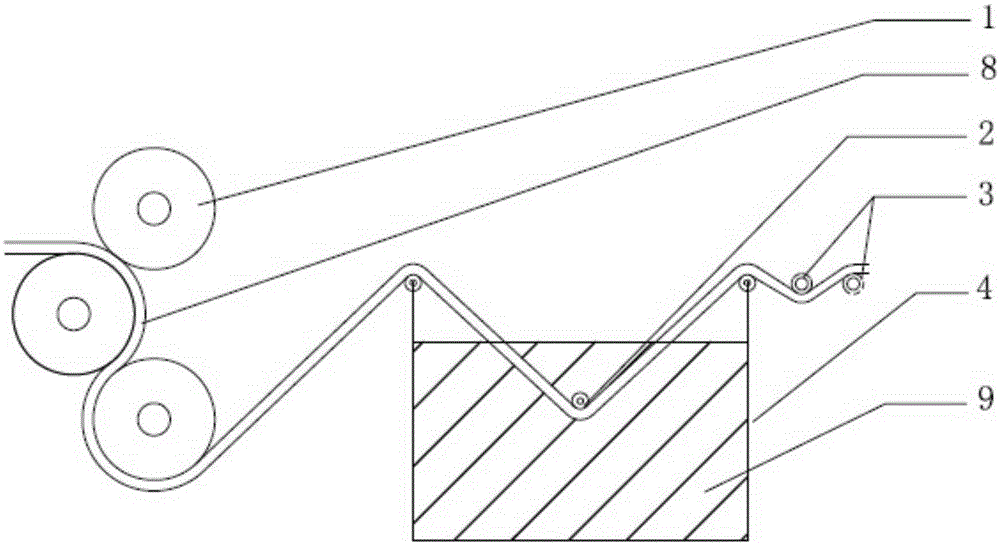

Adhesion-free automatic vermicelli production line and production process thereof

ActiveCN101720974AAnti-adhesiveHigh temperature resistantFood shapingMechanical conveyorsProcess engineeringEnergy consumption

The invention discloses an adhesion-free automatic vermicelli production line, comprising a vermicelli extruder, a pre-dryer, a transition conveyor and a cut-off conveyor which are transmitted according to materials. Both the vermicelli extruder and the pre-dryer are internally provided with conveyer belts which are Teflon conveyer belts. As the conveyer belts are Teflon conveyer belts, the production line lessens the production procedures, reduces the energy consumption, shortens the production time and improves the production efficiency.

Owner:BUHLER WUXI COMML

Biodegradable modified lignin particles and production method thereof

The invention relates to biodegradable modified lignin particles. The biodegradable modified lignin particles comprise the following raw components: 35 to 45 weight parts of lignin, 40 to 55 weight parts of poly(butylene adipate / terephthalate), 4 to 6 weight parts of auxiliary agents and 0.5 to 1 weight part of an organic anti-blocking agent; the auxiliary agents comprise stearic acid and polyethylene wax. A production method for the biodegradable modified lignin particles comprises the following steps: mixing the raw components according to the above parts by weight; heating and obtaining a coarse material after the raw components are mixed uniformly; taking the coarse material and granulating the coarse material to obtain the biodegradable modified lignin particles. The biodegradable modified lignin particles can be completely biodegraded after use, have high mechanical and processing performance, and have important significance to protect ecological environment and reduce white pollution. The biodegradable modified lignin particles are simple in production process and low in cost, and are suitable for batch production.

Owner:高陈堰

Preparation method for colorful polyurethane plastic and construction process for colorful polyurethane plastic track

ActiveCN104710593AHigh hardnessIncrease reaction rateWax coatingsGround pavingsAcrylic resinSports facility

The invention discloses a preparation method and a construction process for a colorful polyurethane plastic track, and belongs to the technical field of sports facilities. The preparation method for colorful polyurethane plastic comprises the following steps: uniformly stirring 10 to 15 parts of polyether polyol, 10 to 30 parts of hydroxylated acrylic resin, 10 to 30 parts of paraffin, 2 to 4 parts of a chain extender and 0.1 to 0.5 part of an age resistor, and raising temperature to 90 to 100 DEG C; adding 30 to 50 parts of a filler, 2 to 9 parts of a pigment and 0.1 to 0.5 parts of an age resistor, and performing uniform stirring; starting a colloid grinder to grind the materials into particle sizes of smaller than 400 meshes; continuing heating, and performing dehydration for 2 to 3 hours under the conditions of temperature of 90 to 100 DEG C and vacuum degree of lower than 0.095Mpa. According to the preparation method and the construction process, with the adoption of the high-functionality polyether polyol, reaction is accelerated, the hardness of a formed film is increased, and construction time is shortened; by the hydroxylated acrylic resin, high glossiness and higher weather resistance and color retention are achieved, and the service life is prolonged.

Owner:山东世纪联合新材料科技有限公司

Environment-friendly separant for rubber film, separant solution and separant coating process

InactiveCN105199596AImprove performanceAnti-adhesiveLiquid surface applicatorsWax coatingsPolymer scienceParaffin oils

The invention discloses an environment-friendly separant for a rubber film, a separant solution and a separant coating process. The environment-friendly separant is composed of, by mass, 40-50 parts of zinc stearate, 35-45 parts of talcum powder and 10-20 parts of paraffin oil. During conventional rubber processing, serious dust pollution is caused by adopting a mode of direct coating of talcum powder, and film performance of rubber is affected due to nonuniform coating. The environment-friendly separant is low in formula cost, uniform in coating and good in film separating effect, and the separant coating process is simple, convenient, feasible and free of dust pollution.

Owner:FAR EAST CABLE +2

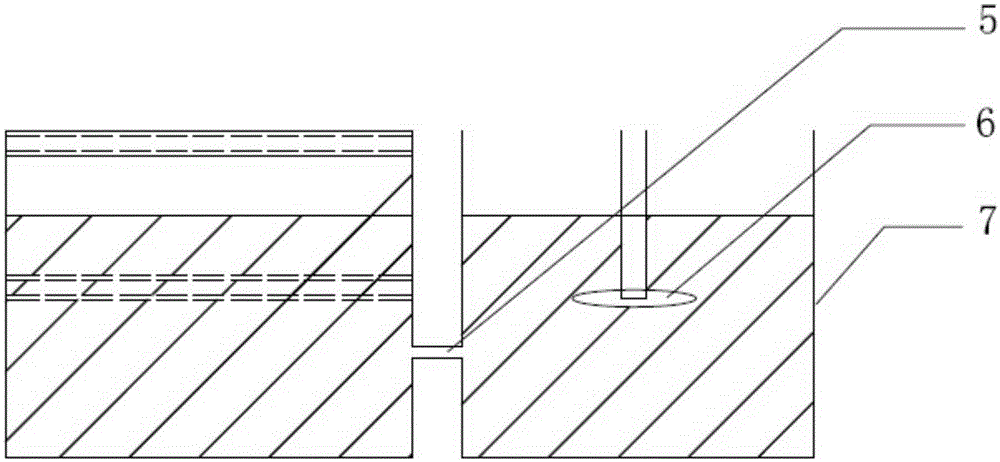

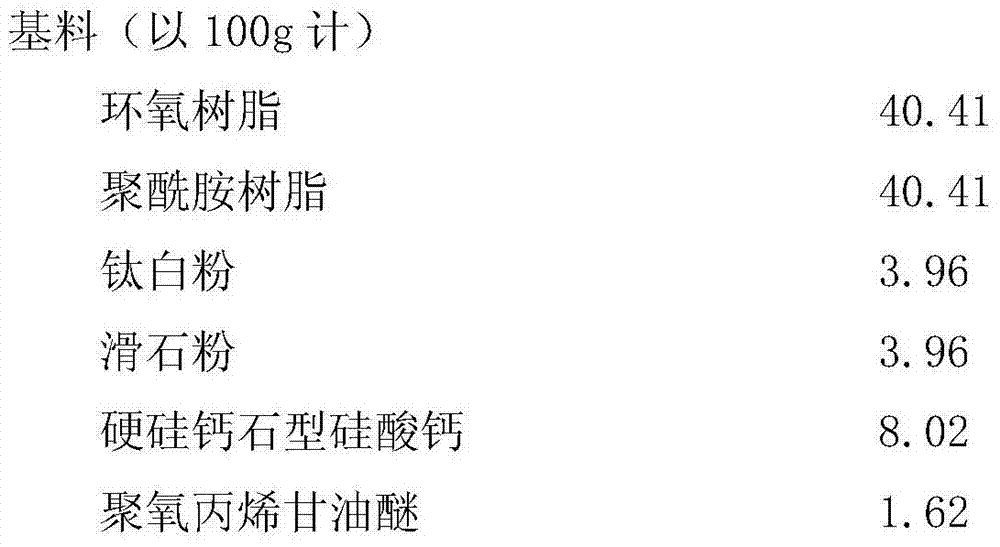

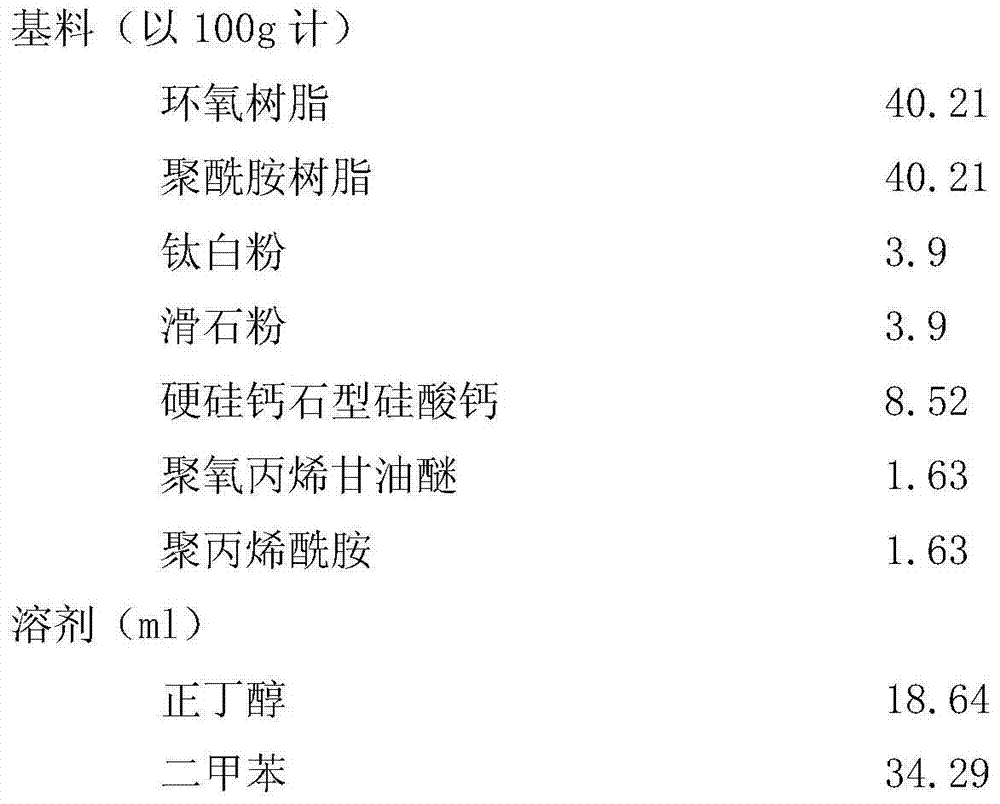

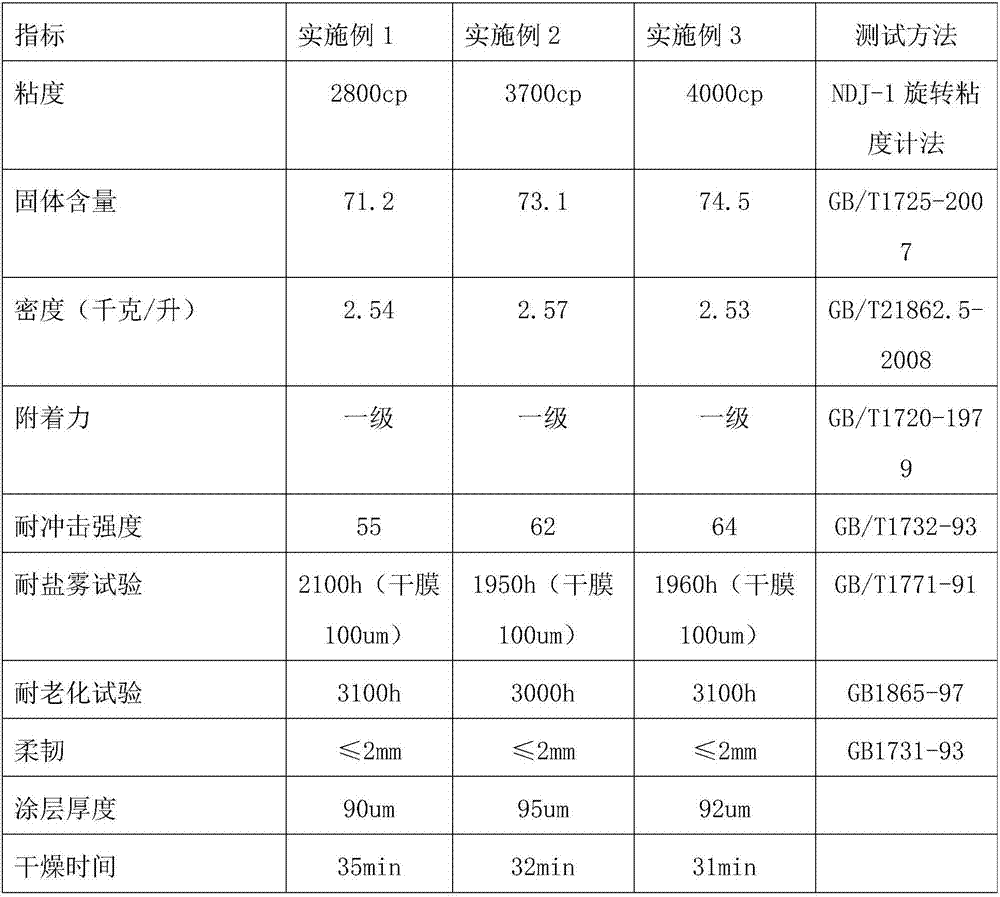

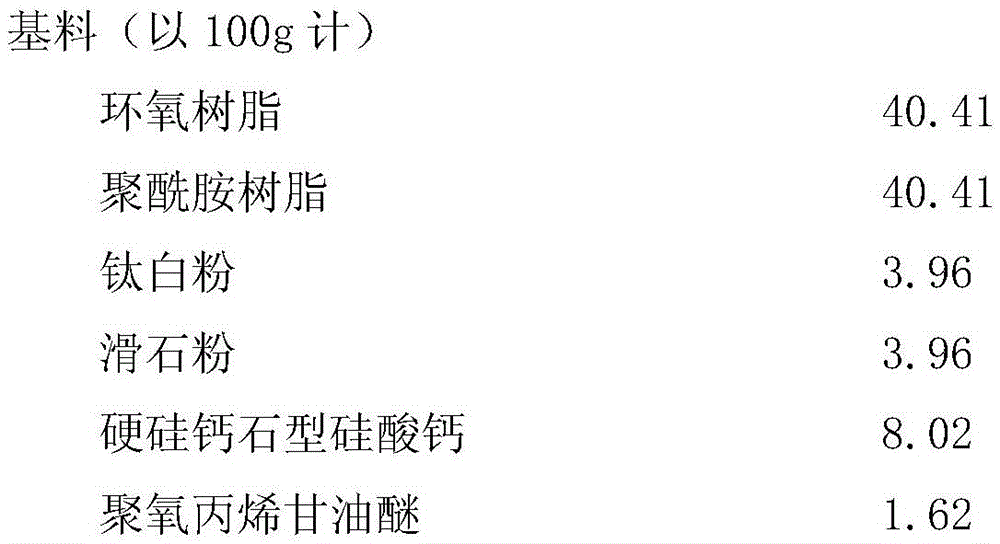

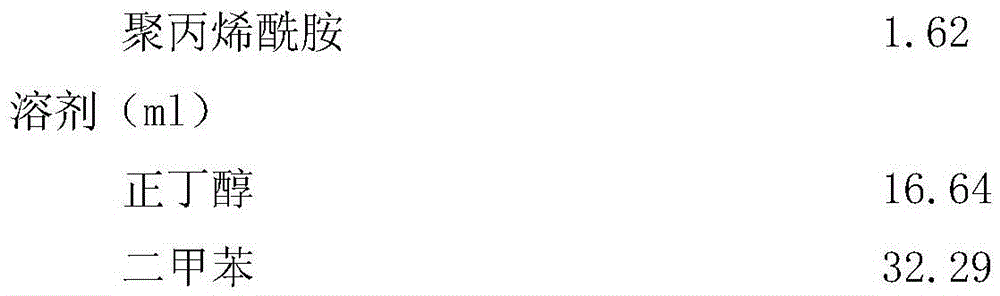

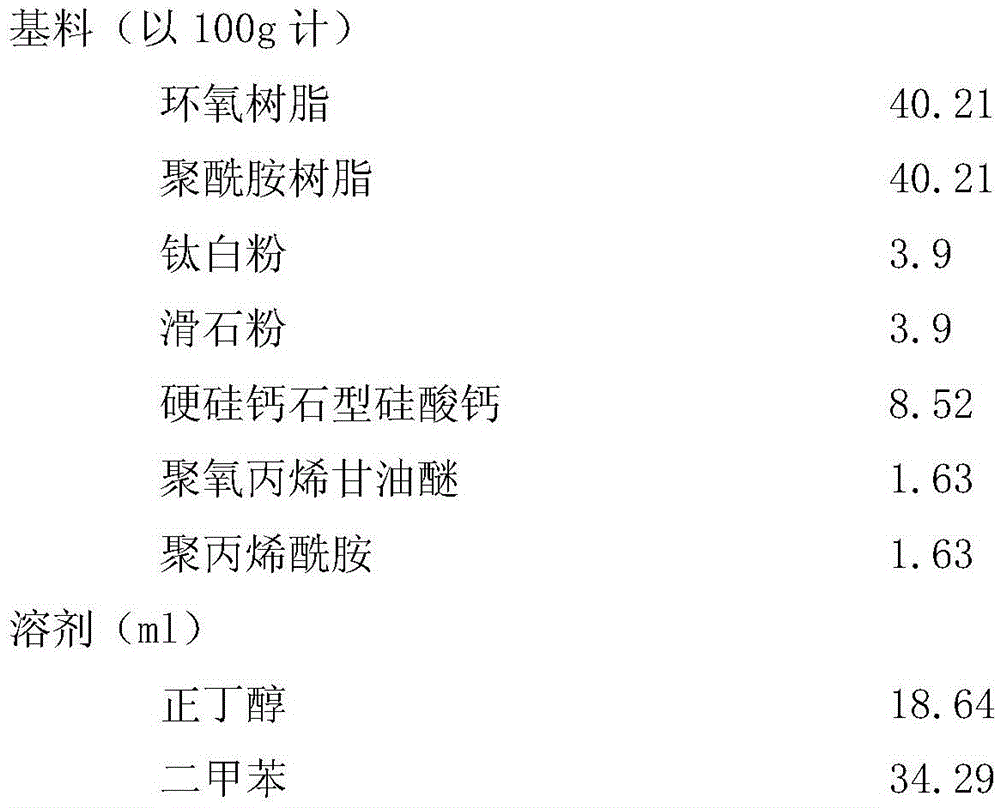

Anticorrosion heat-insulation paint and preparation method thereof

ActiveCN104774528AAddress impact resistanceSolve the strength problemAnti-corrosive paintsPolyamide coatingsCalcium silicateEpoxy

The invention discloses an anticorrosion heat-insulation paint and a preparation method thereof. The paint comprises a base material and a solvent. The base material comprises an expoxy heat-insulation paint, auxiliary pigment and filling materials, a heat-insulation filling material, an antifoaming agent and a dispersant. The expoxy heat-insulation paint is composed of the following components in parts by weight: 40.21 to 40.61 parts of epoxy resin (the membrane), 40.21 to 40.61 parts of polyamide resin (curing agent), 3.76 to 4.16 parts of titanium dioxide, 3.76 to 4.16 parts of talcum powder, 7.52 to 8.52 parts of xonotlite-type calcium silicate (heat-insulation filling material), 1.61 to 1.63 parts of polyoxypropylene glycerol ether (antifoaming agent), 1.61 to 1.63 parts of polyacrylamide (dispersant), 11.86 to 15.1 parts of n-butanol, and 26.05 to 29.49 parts of xylene. After curing, the paint forms an enclosed micro-porous and netted fiber structure on the substrate, has the characteristics of good anticorrosion performance, strong adhesive force, and high compressive strength, and thus solves the problems of bad impact-resistant performance and low adhesive force on wall of conventional barrier heat-insulation paints. Moreover, the paint is convenient for construction, can be painted or brushed, and has strong plasticity.

Owner:锌盾化工无锡有限公司

Preparation method for anti-carbon deposition layer on the surface of steel material part of engine

InactiveCN102154625AImprove anti-carbon performanceElimination of Physicochemical AdsorptionChemical vapor deposition coatingTemperature resistanceOxidative treatment

The invention discloses a preparation method for anti-carbon deposition layer on the surface of a steel material part of an engine. The preparation method comprises the following steps of: surface leveling, cleaning treatment, chemical polishing, chemical decomposition deposition Si membrane, and oxidation treatment. Technological parameters such as temperature, pressure, flow, heat preservation time and the like are adjusted; a diffusion and penetration process of Si and O elements is controlled; compositions and structures of the surface layer of the material and the bounding force between the surface layer of the material and a substrate are changed so as to obtain a compact, adhesive, structure-controlled FeSi / Si / SiO2 coating; and a FeSi / Si / SiO2 gradient transitional composite membrane is obtained on the surface of the steel material part of the engine. The composite membrane has strong bonding force with the substrate, compact organization, small internal stress and smooth inertness, has characteristics of toughness, high-temperature resistance, corrosion resistance, bonding resistance and the like, endows the material with new surface characteristics, prevents the metal from directly contacting with organic matters, prevents the adhesion and deposition of organic colloidal materials and improves anti-carbon deposition performances.

Owner:ZHEJIANG SCI-TECH UNIV

Low thermal conductivity wall thermal insulation coating and its preparation method

InactiveCN107163831ASolve insulation problemsAddress impact resistanceFireproof paintsAnti-corrosive paintsEpoxyThermal insulation

The invention discloses a low thermal conductivity wall thermal insulation coating and its preparation method and relates to the technical field of building materials. The low thermal conductivity wall thermal insulation coating is prepared from 75 to 85 parts of polyamide resin, 55 to 65 parts of epoxy resin, 45 to 55 parts of modified hollow ceramic beads, 35 to 40 parts of silica airgel, 30 to 33 parts of talc powder, 25 to 27 parts of glass wool, 20 to 23 parts of an inorganic additive, 15 to 20 parts of an infrared reflective pigment, 15 to 18 parts of aids and 85 to 95 parts of deionized water. The low thermal conductivity wall thermal insulation coating can form a low thermal conductivity protection layer on the wall after curing and has good corrosion resistance, cohesiveness and compressive strength.

Owner:合肥市淑芹美装饰工程有限公司

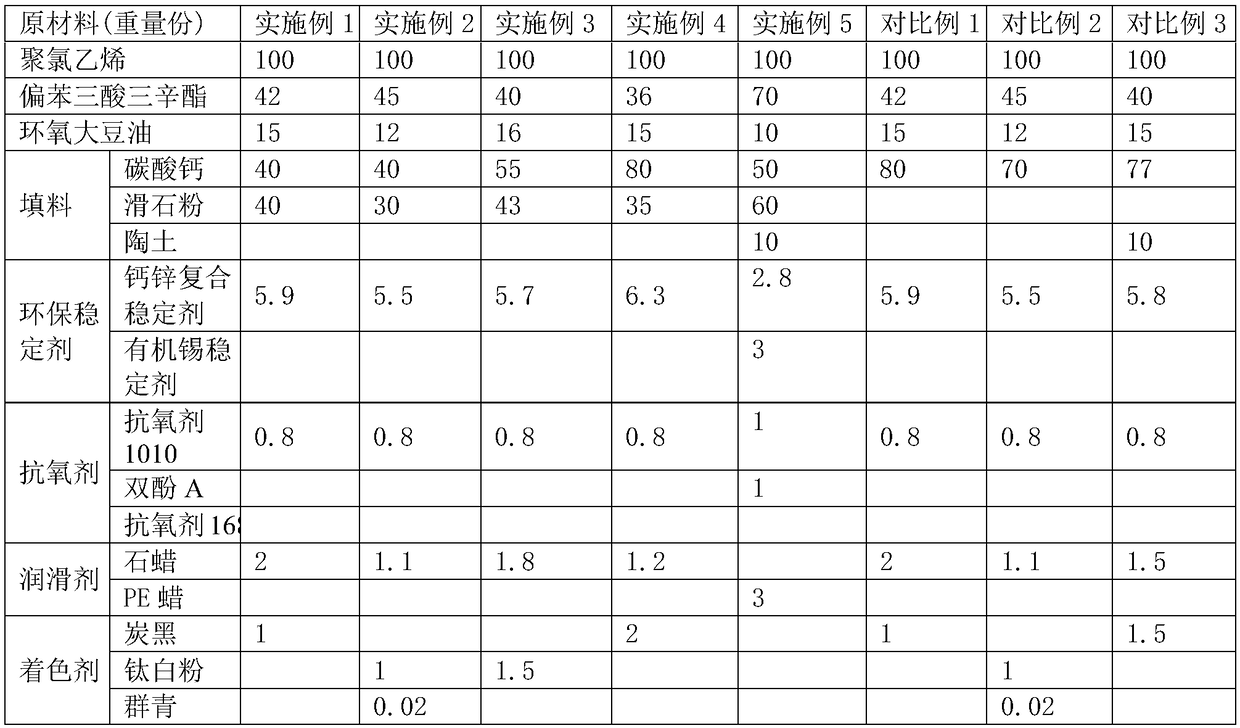

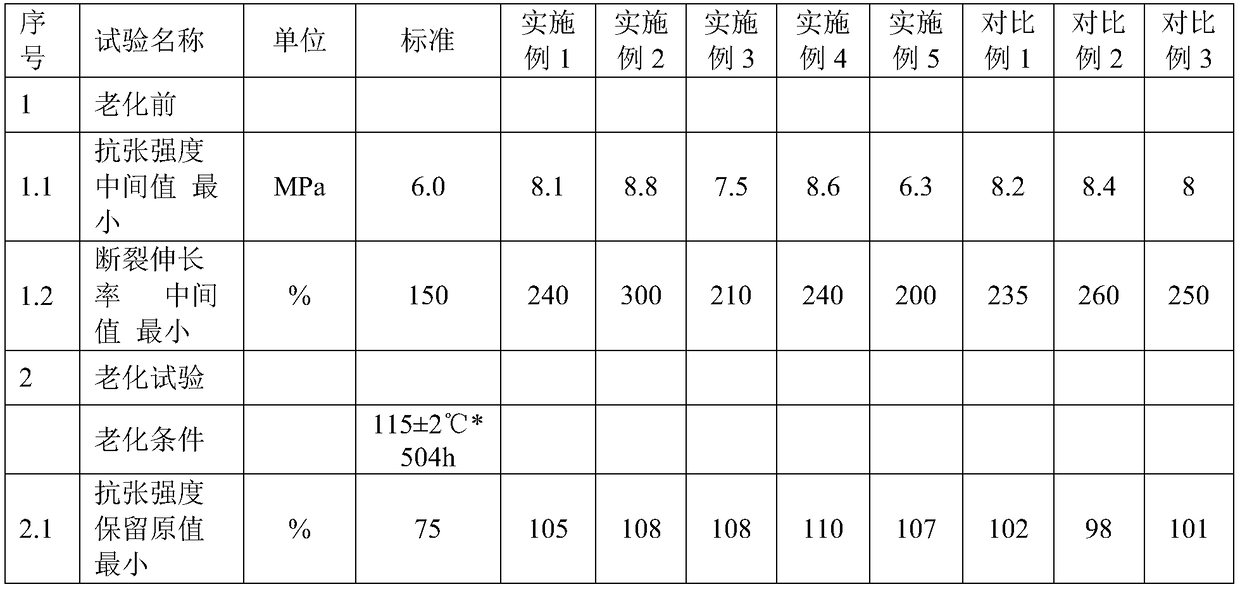

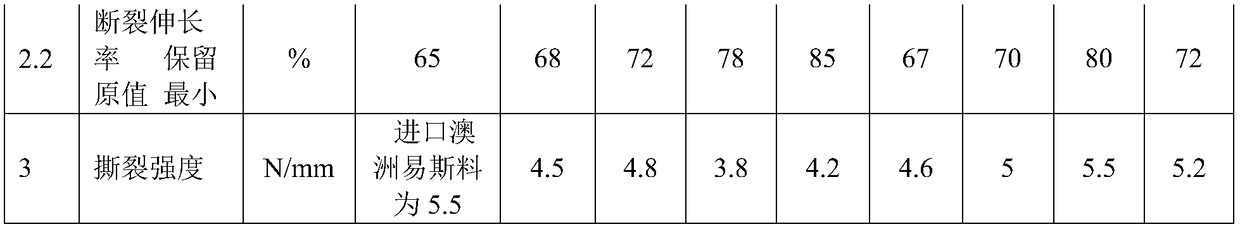

High-temperature-resistant environmentally-friendly easy-to-tear PVC protective jacket cable material and preparation method thereof

InactiveCN108727741AExcellent peelabilityAnti-adhesivePlastic/resin/waxes insulatorsAntioxidantPolyvinyl chloride

The invention discloses a high-temperature-resistant environmentally-friendly easy-to-tear PVC protective jacket cable material and a preparation method thereof. The PVC protective jacket cable material is prepared from the following components in parts by weight: 100 parts of polyvinyl chloride resin, 30 to 70 parts of trioctyl tribenzoate, 10 to 20 parts of epoxidized soybean oil, 70 to 120 parts of filler, 3 to 8 parts of environmentally-friendly stabilizer, 0.5 to 2 parts of antioxidant, 1 to 3 parts of lubricant and 0 to 2 parts of coloring agent, wherein the filler consists of 40 to 80 parts of calcium carbonate, 30 to 60 parts of talcum powder and 0 to 25 parts of argil. The PVC protective jacket cable material meets the requirement of a table 6 in Australian AS / NZS3808:2000 standard, meets various requirements in European Unit ROHS instruction, and is low in cost and high in stripping property.

Owner:GUILIN INT ELECTRIC WIRE & CABLE GROUP

Anti-aging coating for power device and preparation method thereof

InactiveCN107189674AWear-resistantWaterproof and anti-agingFireproof paintsAntifouling/underwater paintsGas phaseMicrosphere

The invention discloses an anti-aging coating for a power device and a preparation method thereof and relates to the technical field of coatings. The anti-aging coating is prepared from 55-65 parts of polyamide resin, 55-60 parts of organic silicone modified epoxy resin, 20-25 parts of thermoplastic expansion hollow microspheres, 18-20 parts of hydrophobic gas-phase silica, 15-17 parts of nano titanium dioxide, 13-15 parts of aluminum nitride, 13-15 parts of talcum powder, 20-25 parts of additive and 55-65 parts of water. The anti-aging coating has abrasion-resisting, waterproof, anti-aging, acid and alkali resistance properties, the preparation method is simple, the power device is effectively protected, and the service life is prolonged.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

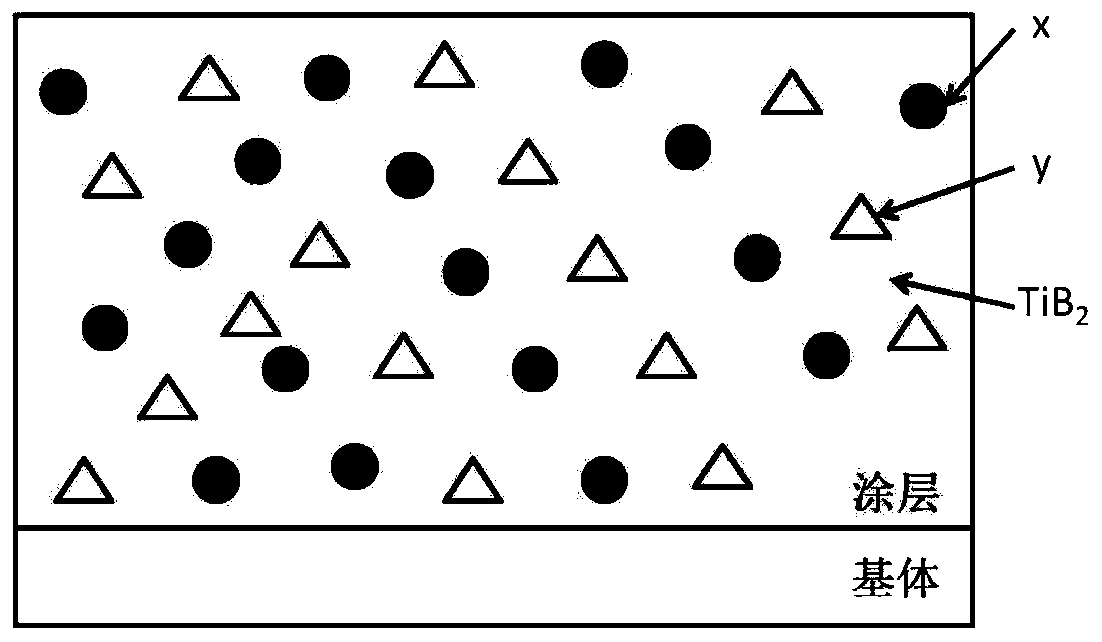

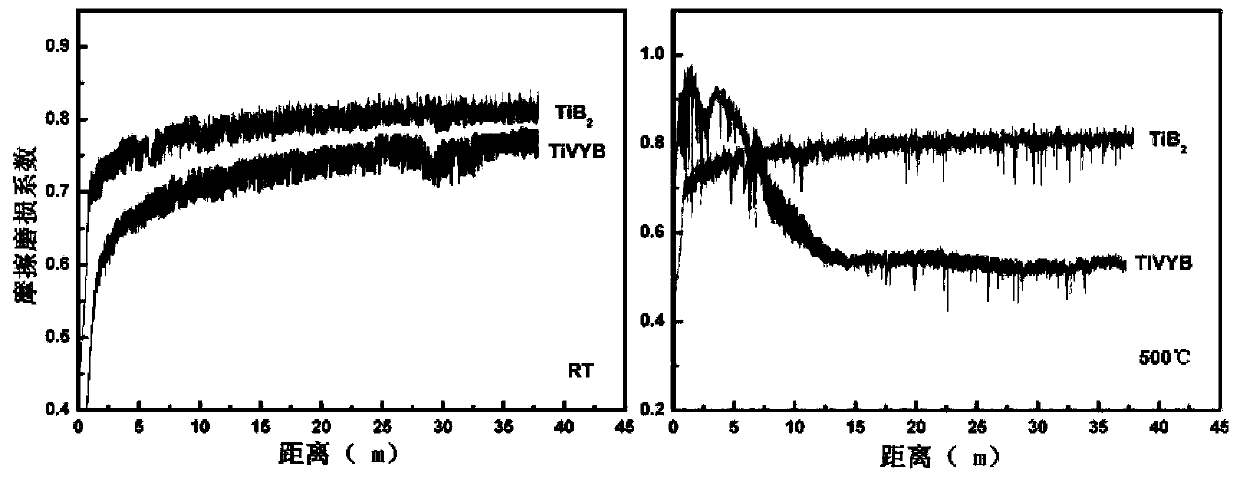

High-temperature wear-resistance self-lubricating TiB2 base coating and preparation method and application thereof

InactiveCN109930108AGood flexibilityImprove adhesionVacuum evaporation coatingSputtering coatingCoated surfaceLanthanum

The invention belongs to the field of surface treatment protecting, and discloses a high-temperature wear-resistance self-lubricating TiB2 base coating and a preparation method and application thereof. The TiB2 base coating is characterize in that an x element and a y element are dissolve in TiB2 crystals, wherein the x element is yttrium or lanthanum, and the y element is vanadium, molybdenum ortungsten. The x metal element and y metal element are introduced into the TiB2 base coating, functions of bonding resisting, high-temperature self lubricating and the like are achieved by the surfaceof the coating, the friction wearing and metal adhesion on the TiB2 coating when titanium alloy is cut in high speed by using a cutter, the coating is more suitable for severer application environments, and therefore better surface protecting effect is achieved.

Owner:GUANGDONG UNIV OF TECH

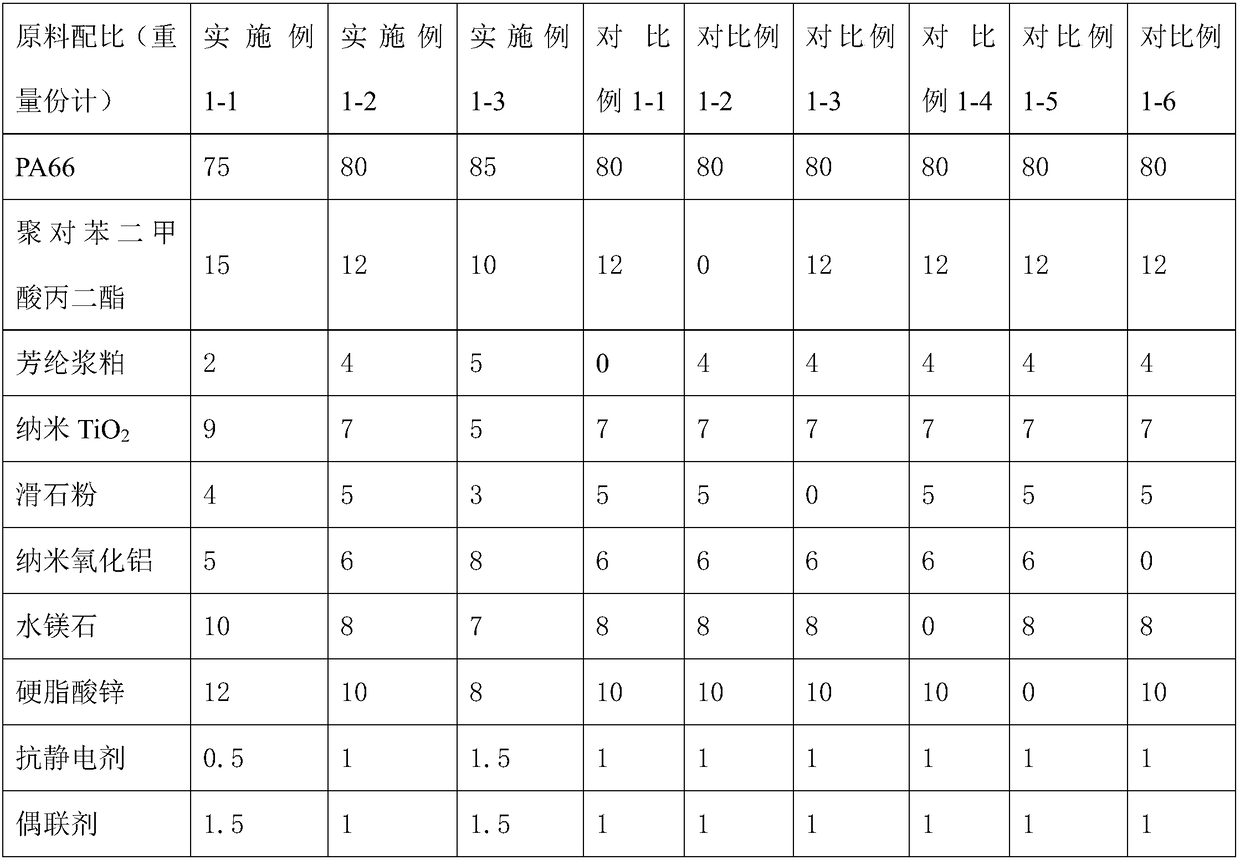

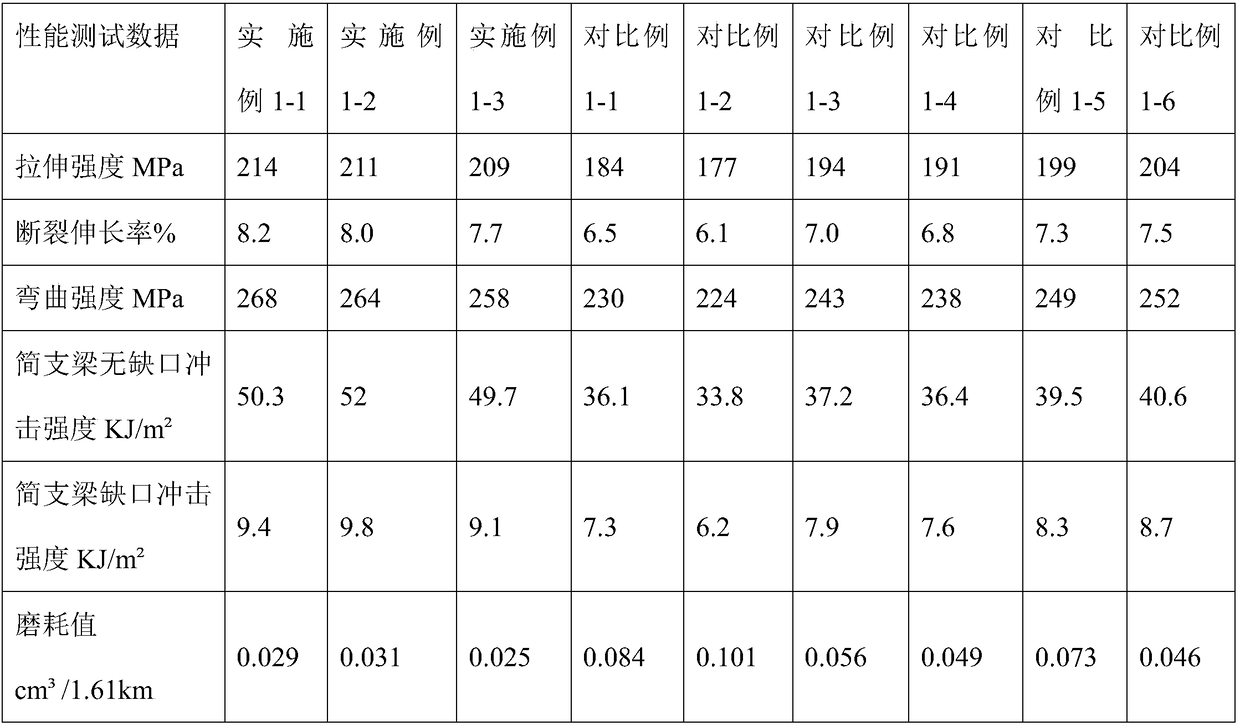

Modified PA66 composite material and preparation method thereof

The invention belongs to the technical field of high molecular material preparation, and particularly relates to a modified PA66 composite material and a preparation method thereof. The modified PA66composite material is prepared from PA66, polytrimethylene terephthalate, aramid fiber pulp, nanometer TiO2, talcum powder, nanometer aluminum oxide, brucite, zinc stearate, anti-static agents and coupling agents. The prepared composite material has the advantages of excellent mechanical property, good friction-resistant performance, high temperature resistance and aging resistance; the preparation method is simple, can be easily controlled, and can be widely applied to automobile industry, instruction casings and other products with anti-impact, high-intensity and high-wear-resistant requirements.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

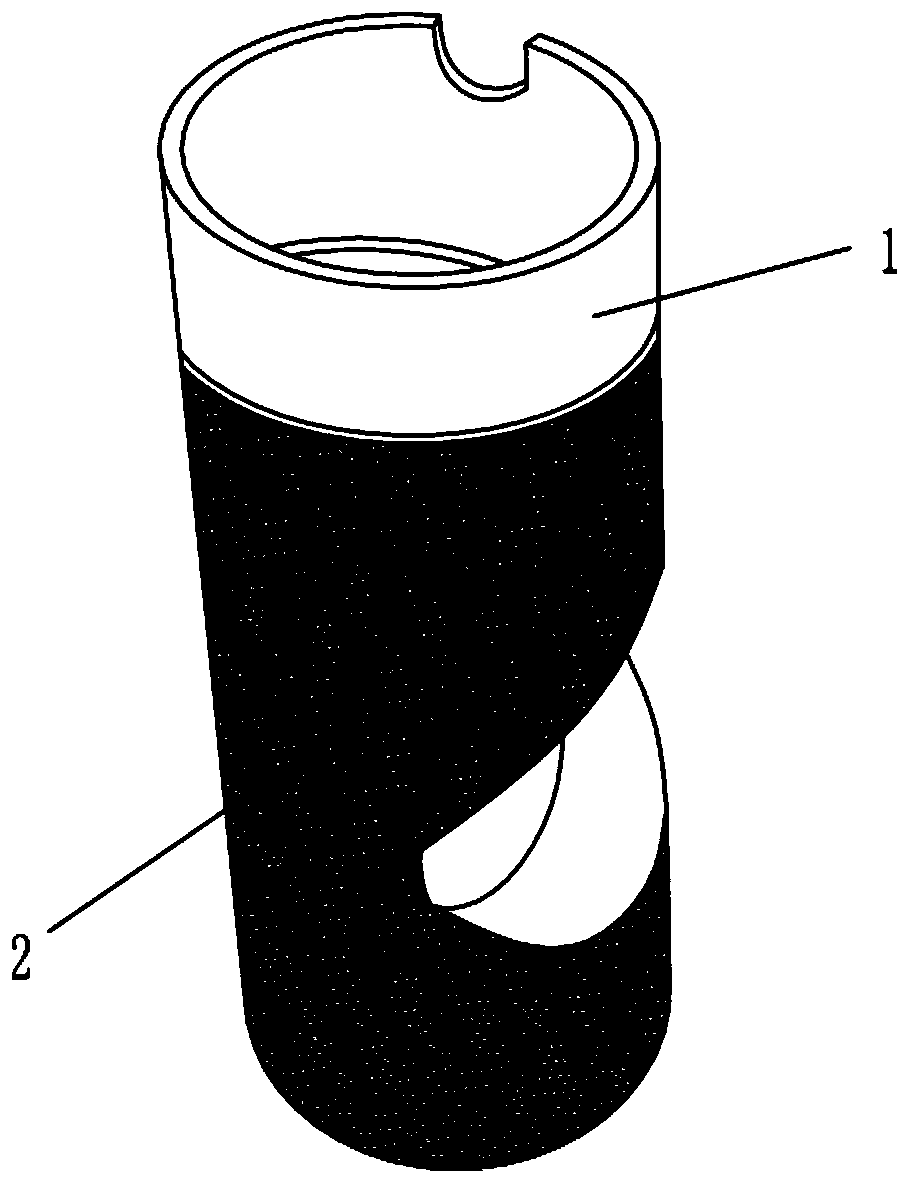

Compound moisturizing maintenance film

InactiveCN108238813AAnti-adhesiveFacilitated releaseSynthetic resin layered productsPlastic filmBuilding construction

The invention relates to a compound moisturizing maintenance film which is composed of an outer plastic thin film layer, a water absorbing and mixing layer and a composite material layer, wherein thewater absorbing and mixing layer is arranged on the inner side of the outer plastic thin film layer and is composed of a water absorbing material and sticky glue, the composite material layer is arranged on the inner side of the water absorbing material, and the composite material layer is formed by hot pressing the film and a non-woven fabric. The compound moisturizing maintenance film has the advantages of being stick-preventative, easy to release, good in moisturizing and maintaining effect, high in strength and high in construction speed.

Owner:长沙水能量新材料有限公司

Inorganic fire-prevention rust-prevention coating for steel structures and preparation method thereof

InactiveCN103205143AImprove high temperature resistanceHigh temperature resistance solutionFireproof paintsAlkali metal silicate coatingsMetasilicateGranularity

The invention discloses an inorganic fire-prevention rust-prevention coating for steel structures and a preparation method thereof. The coating is a mixture of powder and colloid. The weight ratio of power to colloid is 1:(0.8-1.2). The colloid is potassium metasilicate. The powder is prepared from the following components in percentage by weight: 5-40% of magnesium mountain powder, 5-40% of talcum powder, 4-35% of silica powder and 4-25% of silicon aluminium powder. The granularity of the magnesium mountain powder is 2500-6500 meshes, the granularity of the talcum powder is 2000-6000 meshes, the granularity of the silica powder is 3000-8000 meshes, and the granularity of the silicon aluminium powder is 600-2000 meshes. According to the preparation method of the inorganic fire-prevention rust-prevention coating for steel structures, provided by the invention, the powder and the colloid are mixed uniformly. The inorganic fire-prevention rust-prevention coating for steel structures has good high-temperature-resistant performance and good rust-prevention effect.

Owner:王建文

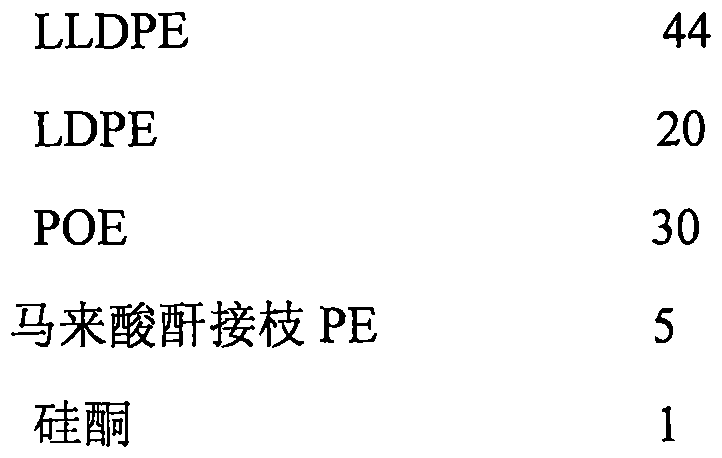

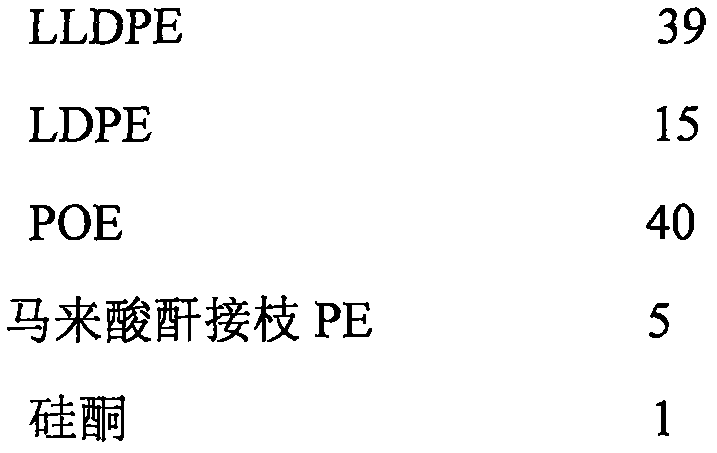

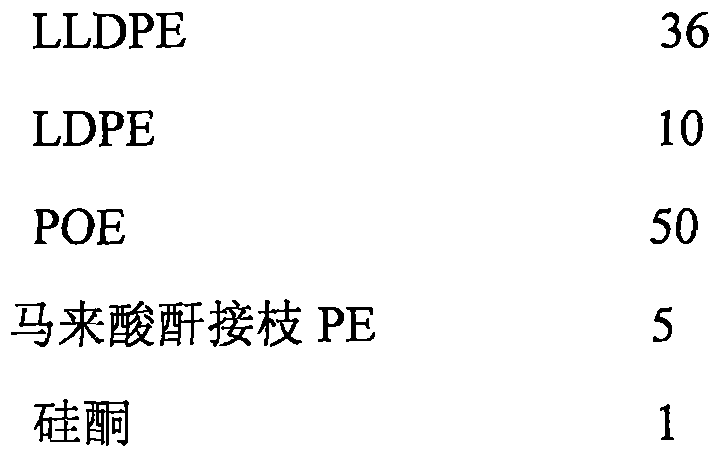

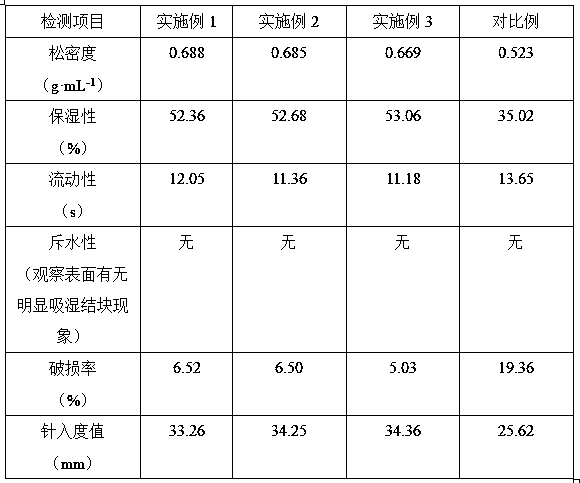

High-elasticity composite material for gloves

InactiveCN106633334ASolving Elasticity ProblemsAddress resilienceGlovesProtective garmentMetallurgyPolyresin

A high-elasticity composite material for gloves comprises, by weight, 30-60% of resin, 30-60% of POE, 3-10% of compatilizer and 1-3% of lubricant. Disposable gloves made of the material have the advantages of convenience for taking on and off, high comfort and high resilience.

Owner:惠州市纳米金塑胶科技有限公司

Preparation method of gel dry water fire extinguishing agent

The invention relates to a preparation method of a gel dry water fire extinguishing agent, which belongs to the technical field of fire extinguishing materials. The hydrophobic nano silicon nitride powder is used as a raw material; ammonium dihydrogen phosphate, ammonium sulfate, magnesium hydroxide and talcum powder are added; and the gel dry water fire extinguishing agent is prepared; the ammonium dihydrogen phosphate and ammonium sulfate can be decomposed at high temperature; chemical inhibition and side catalysis are carried out on free radicals or active groups generated by fuel in the combustion process, a chain reaction of combustion is interrupted to extinguish fire; the talcum powder is added, so that the stability and the dispersity of the dry water extinguishing agent can be effectively improved; the magnesium hydroxide is decomposed when being heated and absorbs heat on the surface of a comburent; the silicon nitride belongs to an inert substance, is attached to the outsideof the surface of the comburent, prevents the contact between a reactant and a combustion improver, isolates the comburent from oxygen, suffocates and extinguishes the comburent, and the gel dry water fire extinguishing agent has the advantages of favorable dry water flowability, favorable dispersity, no toxicity, no harm, no electricity and no secondary pollution.

Owner:李宏伟

High-temperature-resistant easily degradable shell for capacitor and preparing method of high-temperature-resistant degradable shell

The invention discloses a high-temperature-resistant degradable shell for a capacitor and a preparing method of the high-temperature-resistant degradable shell. The high-temperature-resistant degradable shell is prepared from, by weight, 26-30 parts of polyacrylic resin, 22-24 parts of starch, 20-22 parts of straw powder, 16-18 parts of linear polyethylene, 14-16 parts of cellulose acetate fiber,12-14 parts of mica powder, 10-14 parts of ferric oxide powder, 8-10 parts of talcum powder, 6-8 parts of photosensitizer, 3-6 parts of plasticizer, 2-5 parts of coupling reagent, 2-4 parts of dispersant, 1-3 parts of antioxidant, 1-3 parts of heat stabilizer and 1-2 parts of hydrolase. The high-temperature-resistant degradable shell has high high-temperature resistance and shock resistance, besides, the material cost is low, the materials are easy to obtain, the using value is high, and the application prospect is good.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

Burst-proof non-toxic protective layer for valve core of water faucet

InactiveCN110746171AExtend your lifeAchieve explosion-proofValve arrangementsEnvironmental engineeringMechanical engineering

The invention belongs to the technical field of equipment and materials of kitchens and bathrooms and particularly relates to a burst-proof non-toxic protective layer for a valve core of a water faucet. The burst-proof non-toxic protective layer for the valve core of the water faucet, provided by the invention, has the advantages that the valve core of the water faucet can be prevented from bursting and the surface of the valve core is prevented from corrosion. The burst-proof non-toxic protective layer for the valve core of the water faucet comprises a water faucet valve core and a protectivelayer, wherein the water faucet valve core is smeared with the protective layer; and the protective layer is prepared from the following raw materials in percentage by mass (100%): 10% of gypsum powder, 10% of talcum powder, 5% of blockage preventer, 25% of glass glue, 0.5% of strengthening agent and 49.5% of iron sand. The burst-proof non-toxic protective layer achieves the effects of preventingbursting, preventing corrosion and prolonging the service life of the valve core.

Owner:苏连吉

Composite moisturizing and curing film with effects of adhering prevention and easy stripping

InactiveCN106747646ADoes not affect appearanceDoes not affect qualitySynthetic resin layered productsAdhesivePlastic film

The invention relates to a composite moisturizing and curing film with effects of adhering prevention and easy stripping. The composite moisturizing and curing film consists of an outer plastic thin film layer, a water absorbing mixing layer and a composite material layer, wherein the water absorbing mixing layer is arranged at the inner side of the outer plastic thin film layer, and is made of water absorbing material and an adhesive; the composite material layer is arranged at the inner side of the water absorbing mixing layer, and is formed by hotly pressing a thin film and a nonwoven cloth. The composite moisturizing and care film has the advantages that the adhesion is prevented, the stripping is easy, the moisturizing and curing effects are good, the strength is high, and the construction speed is high.

Owner:长沙水能量新材料有限公司

High-temperature-resistant intelligent vehicular charger

InactiveCN107955474AHigh strengthImprove toughnessFireproof paintsBatteries circuit arrangementsRare-earth elementFoaming agent

The invention discloses a high-temperature-resistant intelligent vehicular charger. The high-temperature-resistant intelligent vehicular charger comprises a shell and a main circuit board arranged inside the shell and is characterized in that each of the inner surface and the outer surface of the shell is provided with a protecting layer, and each protecting layer comprises acrylic resin, poly(phthalazinone ether sulfone ketone) modified resin, polyvinyl methyl ether, fluorinated graphene, talcum powder, chlorinated paraffin, a stabilizer, an ADC foaming agent, silicone oil, a composite flameretardant, a chain extender, a neutralizing agent, a catalyst and rare-earth elements. The charger is good in high-temperature resistance, long in service life and capable of lowering cost.

Owner:苏州威斯道智能科技有限公司

Sound-insulation ceramic tiles

The invention discloses sound-insulation ceramic tiles and belongs to building decoration materials. The ceramic tiles are prepared from, by weight, 28-41 parts of clay, 12-24 parts of feldspar, 8-20.5 parts of powdery quartz, 3.3-4.8 parts of chalk powder, 3-4.35 parts of magnesite, 2.85-4.15 parts of talcum powder, 2.4-3.9 parts of nepheline syenite, 2.28-3.76 parts of pyrophyllite, 2.1-3.53 parts of spodumene, 1.85-4 parts of fibrous brucite and 0.01-0.025 part of beryl. The problem that existing ceramic tiles are poor in sound-insulation effect can be solved.

Owner:柳州市国正机电物资有限责任公司

Anticorrosive paint used in waste gas treatment equipment and preparation method thereof

InactiveCN107987577AHigh mechanical strengthImprove oxidation stabilityAnti-corrosive paintsSodium BentoniteAntioxidant

The invention provides an anticorrosive paint used in waste gas treatment equipment and a preparation method thereof, and relates to the technical field of anticorrosive materials. The anticorrosive paint comprises the following raw materials in parts by weight: acrylic acid, n-butyl acetate, N-methyl pyrrolidone, VAE emulsion, laurinol polyoxyethylene ether, acetone, palygorskite, lithium-based bentonite, nanometer silica, nanometer titania, ethylene glycol monomethyl ether, polyurethane, graphite, talcum powder, acetylacetone, a thickener, a flatting agent, a phenol antioxidant and a compatilizer; the preparation method comprises the following steps: (1) weighing the raw materials; (2) preparing a base material; (3) preparing a mixed nanometer material; (4) preparing the modifier; (5) mixing, stirring, cooling and packaging. The anticorrosive paint overcomes the disadvantages that the anticorrosive base treatment requirement is high, the coating is too thick and is easy to crack, thepaint film is greatly influenced by temperature and humidity during curing, the curing time is long and the paint is low in weather resistance and not high in adhesive property existing in the anticorrosive paint used in the waste gas treatment equipment in the prior art.

Owner:中科协创环境科技江苏有限公司

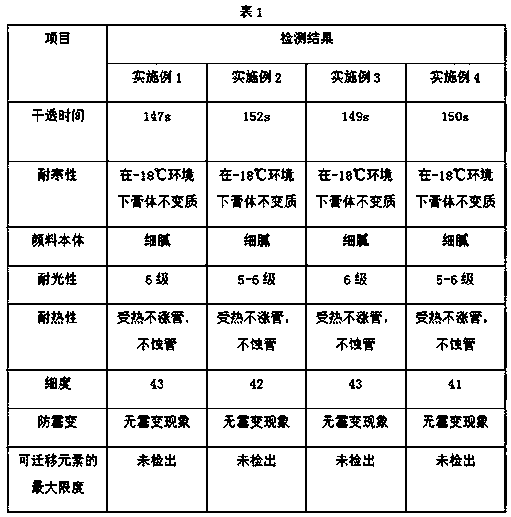

Red pigment for wall surface painting and preparation method of red pigment

InactiveCN109486265AThe coloring ingredients are safe, non-toxic and environmentally friendlyHigh yieldAntifouling/underwater paintsArtist's paintsWater basedDefoamer

The invention relates to the technical field of pigment production processes, in particular to a red pigment for wall surface painting and a preparation method of the red pigment. The red pigment forwall surface painting comprises the following raw materials in parts by weight: 40-50 parts of an anemone red pigment extract, 55-65 parts of polyacrylic acid emulsion, 10-15 parts of arabian jasmineflower powder, 3-5 parts of oxidized hydroxypropyl starch, 30-40 parts of talcum powder, 1-3 parts of a water-based defoamer BEK-750, 3-5 parts of D-mannitol, 3-5 parts of sodium benzoate, 1-3 parts of fungicide, 2-4 parts of propylene glycol, 6-8 parts of sodium alginate and 55-60 parts of water. The prepared pigment is safe and environmentally friendly, is stable in quality, high in coloring power, bright in color and abundant and saturated in color, and the pigment has high color retention and flexibility; and the red pigment for wall surface painting has the characteristic of rapid drying,is bright in color, high in coloring power and long in storage time, cannot fade out due to solarization when used in an outdoor environment, is environmentally friendly and nontoxic when used in anindoor environment, is easy to store for a long time, and is quite suitable for wall surface painting of a school.

Owner:陈琼燕

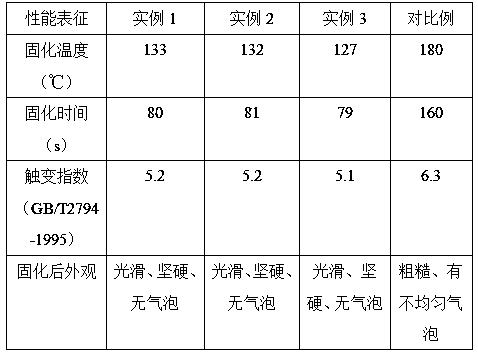

Preparation method of SMT (surface-mounted technology) adhesive

InactiveCN110003833AImprove thermal conductivityImprove insulation performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyChemical reaction

The invention relates to a preparation method of an SMT (surface-mounted technology) adhesive, and belongs to the technical field of binding materials. According to the preparation method of the SMT adhesive, micro silicon powder is taken as packing for preparation of the SMT adhesive, does not easily react with other substances and does not chemically react with most acid and alkali, particles ofthe micro silicon powder uniformly cover the surface of an object and have higher corrosion resistance, tensile strength and compressive strength of a cured product can be enhanced, and wear resistance can be improved; besides, the micro silicon powder is high in purity, low in impurity content and stable in performance and can reduce exothermic peak temperature of an epoxy resin curing reaction,reduce linear expansion coefficient and shrink rage of the cured product and increase flame retardant property, so that the high-temperature resistance of the SMT adhesive is improved. By means of addition of talcum powder for preparation of the SMT adhesive, the talcum powder can be subjected to a chemical reaction with an organosilicon functional group in a silane coupling agent, silicon oxygenbonds with certain adhesive strength and protection force are formed, a coating can continuously bear certain heat load, high-temperature adhesive force is increased, and the high-temperature resistance of the SMT adhesive is improved accordingly.

Owner:常州市贝特织造有限公司

Wear-resistant ship mooring rope

PendingCN114369966ALarge bearing safety factorHigh modulusTextile cablesChemistryCorrosion resistant

The invention belongs to the technical field of marine cables, and particularly relates to a wear-resistant ship mooring rope which comprises a rope core, a wear-resistant outer coating layer is alternately woven on the outer surface of the rope core, and the wear-resistant outer coating layer is formed by interweaving S-twist-direction strands and Z-twist-direction strands. Each of the S-twist-direction strands and the Z-twist-direction strands comprises a composite reinforced high-molecular polyethylene strand and a protective coating coated on the surface of the composite reinforced high-molecular polyethylene strand. The steel wire rope is adopted as the rope core, so that the product has a large bearing safety coefficient, and long-distance loading can be achieved; the wear-resistant outer coating layer formed by interweaving the composite reinforced high-molecular polyethylene strands in the S twisting direction and the Z twisting direction is adopted, the product has the excellent characteristics of high-molecular polyethylene, and after modification, the product has a series of excellent characteristics of high modulus, high strength, high toughness, high wear resistance, high and low temperature resistance, corrosion resistance, weather resistance, adhesion resistance, self-lubrication and the like.

Owner:JIANGSU XIANGCHUANG ROPE TECH

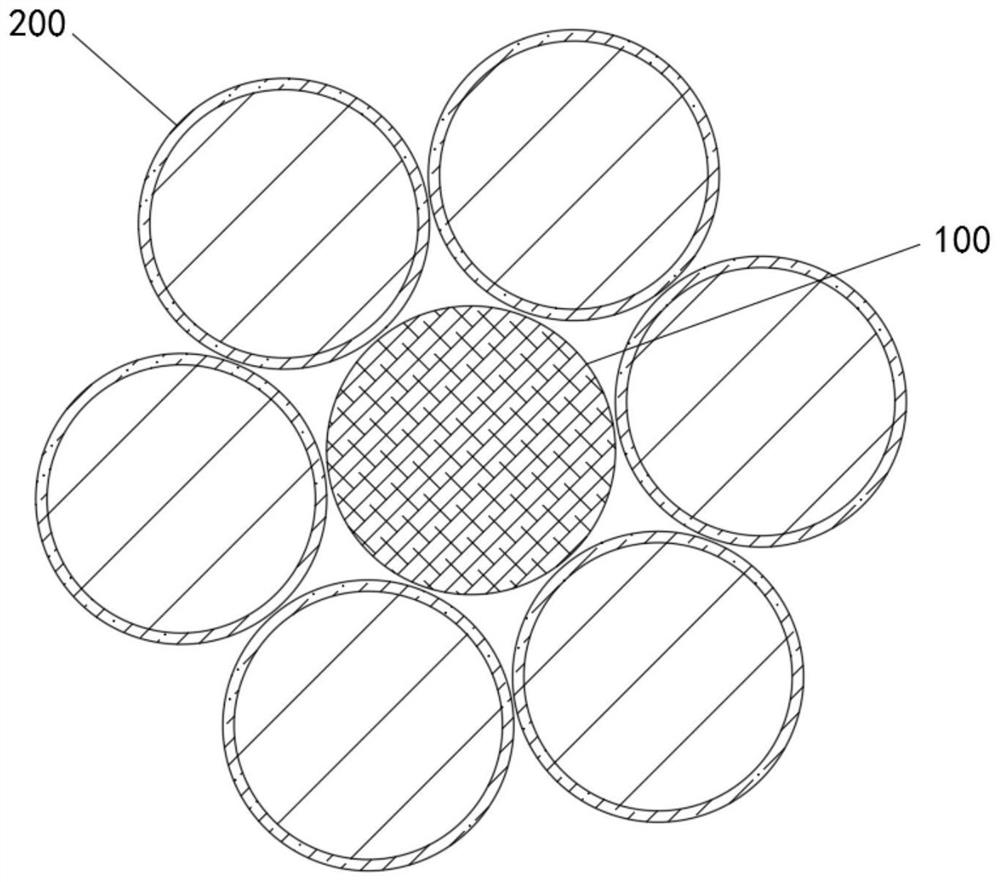

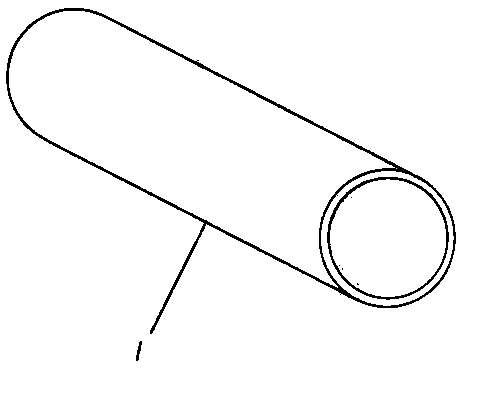

Thermoplastic large-pipe-diameter polytetrafluoroethylene thin-wall pipe

InactiveCN103375674AHeat resistantAnti-adhesiveElongated constructional elementsRigid pipesEngineeringPolytetrafluoroethylene

Disclosed is a thermoplastic large-pipe-diameter polytetrafluoroethylene thin-wall pipe which comprises a thin-wall pipe body. The thermoplastic large-pipe-diameter polytetrafluoroethylene thin-wall pipe is characterized in that the inner diameter of the thin-wall pipe body is 50-1000mm, and the wall thickness is 0.5-3mm. The thermoplastic large-pipe-diameter polytetrafluoroethylene thin-wall pipe has the advantages that requirements in use of large-pipe-diameter pipes with the inner diameters of 50-1000mm, thermal composite rollers or rollers for printing and the like can be met, performance of the large-pipe-diameter pipes, the thermal composite rollers or the rollers for printing can be improved, using cost of the thermoplastic large-pipe-diameter polytetrafluoroethylene thin-wall pipe can be effectively lowered, and the service life of the thermoplastic large-pipe-diameter polytetrafluoroethylene thin-wall pipe can be prolonged. The thermoplastic large-pipe-diameter polytetrafluoroethylene thin-wall pipe can be applied to industries like chemical engineering and machinery.

Owner:LINGQI ENVIRONMENTAL PROTECTION EQUIP FACTORY SHANGHAI

Method for induction heating on threaded surface of oil casing collar

InactiveCN104388637AIncrease usageReduce mining costsFurnace typesIncreasing energy efficiencyWear resistantInductor

The invention discloses a method for induction heating on a threaded surface of an oil casing collar. The method comprises the following steps: turning threads on a collar, conveying the collar to a platform and clamping the collar, closing end ports, putting the collar into a sealed oven, putting the oven into an inductor, heating internal threads and external threads in the ends of the collar by the inductor first and then sending the collar into a cooling water system with a filtering function for quenching, tempering once, exiting from the cooling water system, greasing the threads of the collar with a co-cementation layer, marking the collar, testing pressure, performing anticorrosive treatment and packaging. The treated collar is corrosion-resistant, wear-resistant and free of brittleness and has an anti-sticking function; due to the adoption of the method, an aim of increasing the using times of the oil casing is achieved and the cost of oilfield exploitation is saved; therefore, the induction heating method has a very high popularization value.

Owner:WUXI IMPRINT NANO TECH

Talcum powder-nylon thermal conductive composite for LED lamps and preparation method thereof

The invention relates to a talcum powder-nylon thermal conductive composite for LED lamps. The talcum powder-nylon thermal conductive composite is prepared from, by weight, 200 parts of nylon 6, 20-30 parts of talcum powder, 20-30 parts of carbon fibers, 50-60 parts of acetone, 80-100 parts of 60-70% nitric acid, 3-4 parts of polyvinylpyrrolidone, 2-3 parts of lauryl sodium sulfate, 1-2 parts of texanol, 3-5 parts of glyceryl stearate, 15-20 parts of phenylene diisocyanate, 20-25 parts of hydroxyethyl methacrylate, 0.4-1 part of catalyst, 0.4-2 parts of polymerization inhibitor, 150-170 parts of tetrahydrofuran, 80-100 parts of methylbenzene and appropriate deionized water. By the aid of the talcum powder which has lubricity, sticking resistance, flow aiding, fire resistance, acid resistance, insulativity, high melting point and inactive chemical property and with the aid of synergistic action of the talcum powder and the carbon fibers, heat-conducting property of the nylon thermal conductive composite is improved.

Owner:TONGLING RIXING ELECTRONICS

Anti-corrosion heat insulation coating and preparation method thereof

ActiveCN104774528BHigh bonding strengthExcellent dielectric propertiesAnti-corrosive paintsPolyamide coatingsEpoxyThermal insulation

The invention discloses an anticorrosion heat-insulation paint and a preparation method thereof. The paint comprises a base material and a solvent. The base material comprises an expoxy heat-insulation paint, auxiliary pigment and filling materials, a heat-insulation filling material, an antifoaming agent and a dispersant. The expoxy heat-insulation paint is composed of the following components in parts by weight: 40.21 to 40.61 parts of epoxy resin (the membrane), 40.21 to 40.61 parts of polyamide resin (curing agent), 3.76 to 4.16 parts of titanium dioxide, 3.76 to 4.16 parts of talcum powder, 7.52 to 8.52 parts of xonotlite-type calcium silicate (heat-insulation filling material), 1.61 to 1.63 parts of polyoxypropylene glycerol ether (antifoaming agent), 1.61 to 1.63 parts of polyacrylamide (dispersant), 11.86 to 15.1 parts of n-butanol, and 26.05 to 29.49 parts of xylene. After curing, the paint forms an enclosed micro-porous and netted fiber structure on the substrate, has the characteristics of good anticorrosion performance, strong adhesive force, and high compressive strength, and thus solves the problems of bad impact-resistant performance and low adhesive force on wall of conventional barrier heat-insulation paints. Moreover, the paint is convenient for construction, can be painted or brushed, and has strong plasticity.

Owner:锌盾化工无锡有限公司

Refractory far infrared radiation ceramics coating

The invention provides a high temperature resistance infrared radiation pottery dope, which belongs to the thermal engineering field. The dope is a mixture of the following materials in mass share: 200 mesh zirconium dioxide 10, 200 mesh zircon quartz sand 20, 300 mesh feldspar 10, 300 mesh cerium oxide 7, 300 mesh manganese sesquioxide 15, 300 mesh manganic oxide 3, 600 mesh titanium dioxide 2, 200 mesh alumina 10, 400 mesh graphite 10, 400 mesh boron nitride 3 and 200 mesh carborundum 10. The graphite and boron nitride in the dope are of lubricating and anti-bonding functions, the carborundum is of wear resistance function, the manganic oxide, titanium dioxide and alumina are of strong infrared ray emission and the dope mad of zirconium dioxide, zircon quartz, feldspar and cerium oxide has good compact structure and strong fire-proof and the manganese sesquioxide can catalyze C, S and N for conversion. Therefore, the invention is applicable for use in dynamic furnaces such as coal dust furnace, boiling furnace and fluidized bed furnace.

Owner:颐珑达绝热材料技术(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com