Preparation method of SMT (surface-mounted technology) adhesive

A patch adhesive and preparation step technology, which is applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems of high part drop rate and poor high temperature resistance, and achieve high hardness and high temperature resistance Good performance and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

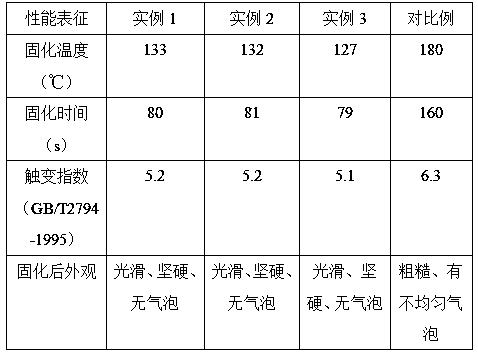

Examples

Embodiment Construction

[0031]Put quartz sand with an average particle size of 45~55μm in a closed ball mill tank, ball mill at room temperature at a speed of 150~200r / min for 8~10h, and then dry it at 110~120°C to obtain an average particle size of 0.1~ 0.3μm silica powder, weigh 25~30 parts of sodium silicate, 0.1~0.3 parts of cetyltrimethylammonium bromide, 10~15 parts of absolute ethanol, 40~50 parts of Deionized water, add sodium silicate to deionized water, stir at 150~200r / min at room temperature for 10~15min to obtain sodium silicate solution, add cetyltrimethylammonium bromide to sodium silicate solution , ultrasonically dispersed for 30-40 min, then placed in a water bath at 85-95°C and stirred at a speed of 150-200r / min for 20-30 min to obtain a sodium silicate mixture, adding absolute ethanol to the sodium silicate mixture, Stir rapidly at a speed of 500~600r / min for 40~60min in a water bath at ~95°C, adjust the pH to 6~7 with phosphoric acid with a mass concentration of 1% to obtain sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com