Composite moisturizing and curing film with effects of adhering prevention and easy stripping

An anti-adhesion and curing film technology, used in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve problems affecting the appearance and quality of concrete projects, easy to break during tearing, and low strength of non-woven fabrics. and other problems, to achieve the effect of good moisturizing and maintenance effect, good strength and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

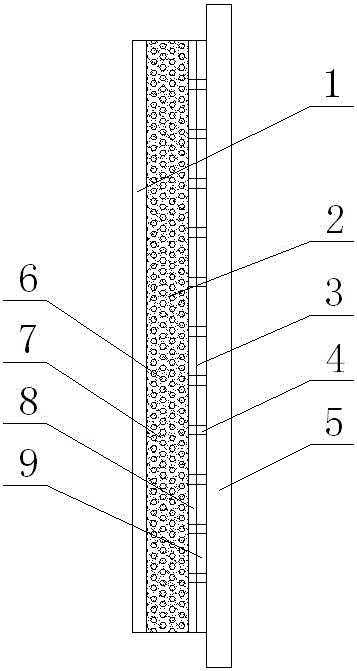

[0018] Such as figure 1 As shown, on the surface of the cement concrete 5, a kind of anti-bonding and easy-release composite moisture-retention curing film is pasted, and the composite moisture-retention curing film for anti-bonding and easy-release is composed of an outer plastic film layer 11, a water-absorbing mixing layer 2, a composite The outer plastic film layer 11 is provided with a water-absorbing mixed layer 2 inside, and the inner side of the water-absorbed mixed layer 2 is provided with a composite material layer 3 .

[0019] The water-absorbing mixed layer 2 is composed of water-absorbing material 6 and viscous glue 7 . The water-absorbing material 6 can be graft copolymerized products of natural polymers such as starch and cellulose, or polymerized products such as sodium acrylate and methyl methacrylate. The polymer water-absorbing material 6 has super-strong water-absorbing and moisturizing properties, can absorb water hundreds to a thousand times its own weig...

Embodiment 2

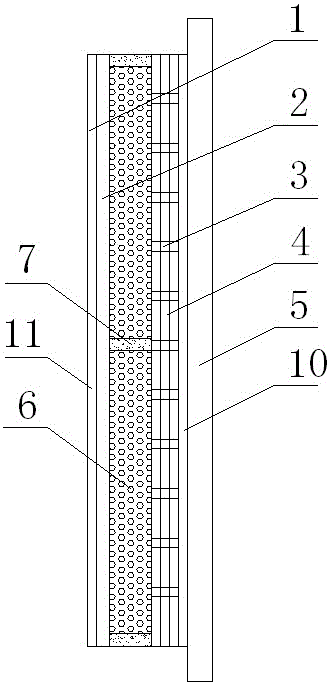

[0022] Such as figure 2 As shown, on the surface of the cement concrete 5, a kind of anti-bonding and easy-release composite moisture-retention curing film is pasted, and the composite moisture-retention curing film for anti-bonding and easy-release is composed of an outer plastic film layer 11, a water-absorbing mixing layer 2, a composite The outer plastic film layer 11 is provided with a water-absorbing mixed layer 2 inside, and the inner side of the water-absorbed mixed layer 2 is provided with a composite material layer 3 .

[0023] The water-absorbing mixing layer 2 consists only of water-absorbing material 6 . The water-absorbing material 6 can be graft copolymerized products of natural polymers such as starch and cellulose, or polymerized products such as sodium acrylate and methyl methacrylate. The composite material layer 3 is composed of a multi-layer film 8 and a multi-layer non-woven fabric 9 by fusing, sewing, hot pressing, or gluing. The outer plastic film la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com