Preparation method of gel dry water fire extinguishing agent

A technology of fire extinguishing agent and dry water, which is applied in the direction of fire prevention equipment, etc., can solve the problems of suffocation hazards for operators, environmental pollution, and bulky equipment, etc., and achieve the effects of good fluidity and dispersibility, high melting point, and preventing molten droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

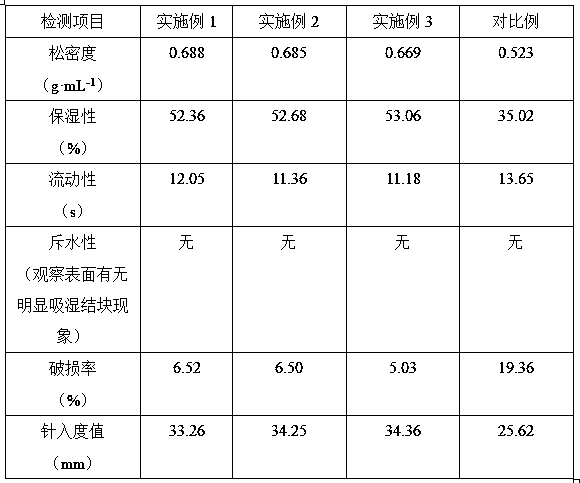

Embodiment 1

[0042] In terms of parts by weight, weigh 30 parts of nano-silica powder and 12 parts of carbon powder respectively, add the carbon powder to the nano-silica powder, place it in a high-speed mixer, and stir and mix at 800r / min for 12 minutes at room temperature. To obtain mixed powder, put the mixed powder in a tubular atmosphere furnace, feed nitrogen gas at a rate of 120mL / min, raise the temperature to 1600°C at a rate of 20°C / min at room temperature, keep the temperature for calcination for 1~2h, and cool down with the furnace to At room temperature, calcined powder is obtained. Put the calcined powder in a muffle furnace, raise the temperature to 400°C at a rate of 5°C / min at room temperature, keep the temperature for calcination for 30 minutes, and cool down to room temperature with the furnace to obtain nano-silicon nitride powder; then press In terms of parts by weight, weigh 40 parts of nano-silicon nitride powder, 12 parts of hexamethyldisilazane, 8 to 10 parts of stea...

Embodiment 2

[0044] In terms of parts by weight, weigh 35 parts of nano-silica powder and 14 parts of carbon powder respectively, add the carbon powder into the nano-silica powder, place it in a high-speed mixer, stir and mix at 900r / min for 14min at normal temperature, To obtain the mixed powder, place the mixed powder in a tubular atmosphere furnace, feed nitrogen gas at a rate of 140mL / min, raise the temperature to 1700°C at a rate of 20°C / min at room temperature, keep the temperature for calcination for 1.5h, and cool to room temperature with the furnace , to obtain calcined powder, put the calcined powder in a muffle furnace, raise the temperature to 500°C at a heating rate of 5°C / min at room temperature, heat-preserve and calcinate for 35min, and cool to room temperature with the furnace to obtain nano-silicon nitride powder; In terms of parts, weigh 45 parts of nano-silicon nitride powder, 13 parts of hexamethyldisilazane, 9 parts of stearic acid, 4.5 parts of glycerin, 180 parts of ...

Embodiment 3

[0046] In terms of parts by weight, weigh 40 parts of nano-silica powder and 16 parts of carbon powder respectively, add the carbon powder into the nano-silica powder, place in a high-speed mixer, stir and mix at 1000r / min for 16 minutes at normal temperature, To obtain the mixed powder, place the mixed powder in a tubular atmosphere furnace, feed nitrogen gas at a rate of 160mL / min, raise the temperature to 1800°C at a rate of 20°C / min at room temperature, keep the temperature for calcination for 2 hours, and cool to room temperature with the furnace. To obtain calcined powder, place the calcined powder in a muffle furnace, raise the temperature to 600°C at a heating rate of 5°C / min at room temperature, keep the heat for calcination for 40min, and cool to room temperature with the furnace to obtain nano-silicon nitride powder; Counting, weighing 50 parts of nano-silicon nitride powder, 15 parts of hexamethyldisilazane, 10 parts of stearic acid, 5 parts of glycerin, 200 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com