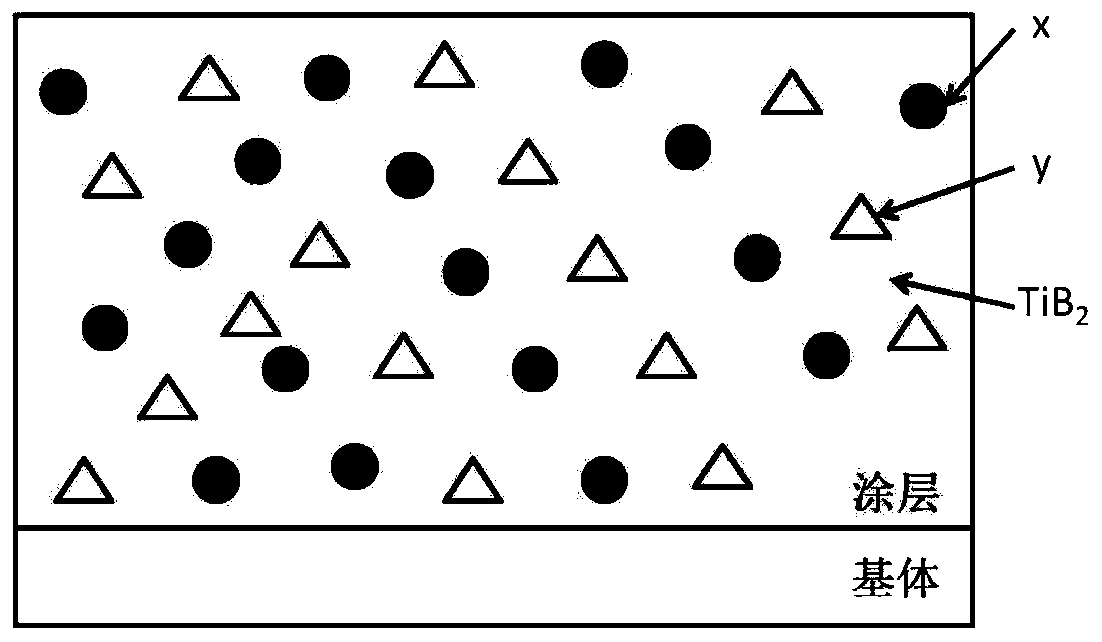

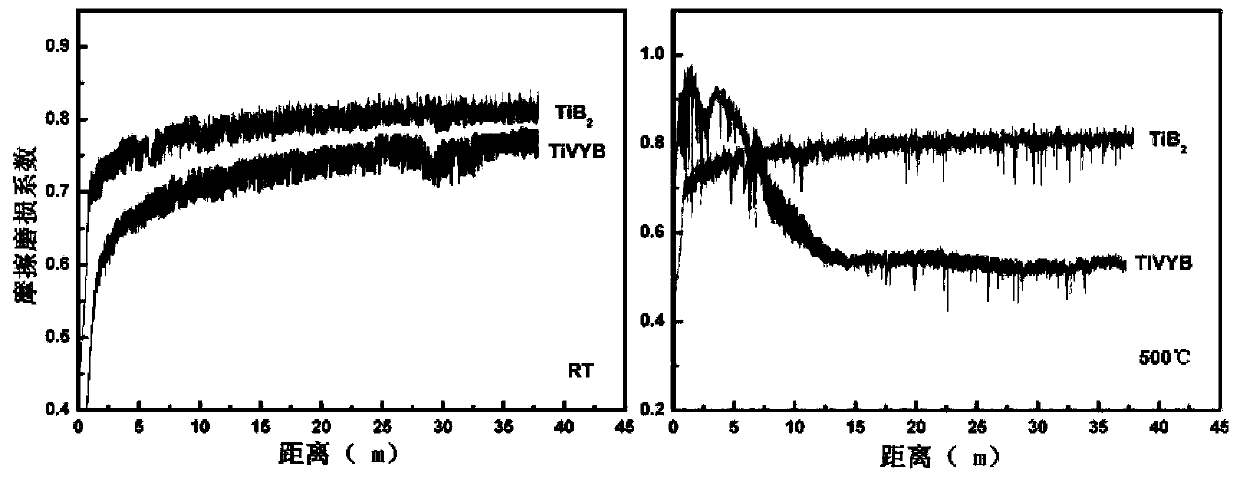

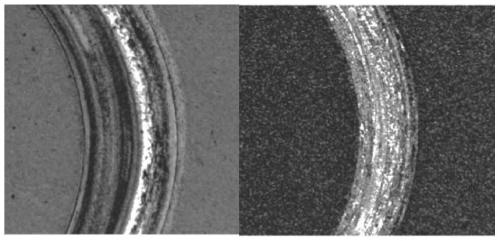

High-temperature wear-resistance self-lubricating TiB2 base coating and preparation method and application thereof

A high-temperature wear-resistant and self-lubricating technology, which is applied in coatings, metal material coating processes, ion implantation plating, etc., can solve the problems of poor high-temperature friction and wear properties of coatings, limited applications, and low melting point, so as to reduce friction Abrasion, enhanced flexibility and adhesion, reduced metal adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of composite coating machine: This implementation chooses to use a composite magnetron sputtering coating machine, including a vacuum chamber, three magnetron sputtering sources, an ion source and a workpiece support that can rotate at the same time. The workpiece support is installed inside the vacuum chamber ; Two magnetron sputtering sources are loaded with 99.8% pure yttrium target and 99.8% pure vanadium target, and the other magnetron sputtering source is loaded with 99.8% pure TiB 2 target;

[0026] 2. Sample pre-cleaning treatment: ultrasonically clean the sample to be coated with alcohol, then rinse with deionized water, and blow dry with dry compressed nitrogen;

[0027] 3. Place the substrate on the workpiece holder of the vacuum chamber, and vacuum the vacuum chamber to a vacuum degree of 5.0×10 –3 Below Pa, turn on the ion source, pass 120sccm argon gas into the ion source, set the ion source power to 2kW, set the workpiece holder bias voltage to 1...

Embodiment 2

[0033] 1. Preparation of the coating machine: The ion beam composite magnetron sputtering coating machine selected in this implementation includes a vacuum chamber, three magnetron sputtering sources, an ion source and a workpiece support that can rotate at the same time. The workpiece support is installed in a vacuum Inside the chamber; two magnetron sputtering sources are loaded with 99.5% purity lanthanum targets and 99.5% purity molybdenum targets, and the other magnetron sputtering source is loaded with 99.5% purity TiB 2 target;

[0034] 2. Sample (substrate) pre-cleaning treatment: ultrasonically clean the sample (substrate) to be coated with alcohol, then rinse with deionized water and blow dry with dry compressed nitrogen;

[0035] 3. Place the substrate on the workpiece holder of the vacuum chamber, and vacuum the vacuum chamber to a vacuum degree of 5.0×10 –3 Below Pa, turn on the ion source, pass 120sccm argon gas into the ion source, set the ion source power to 1.5kW, s...

Embodiment 3

[0040] 1. Preparation of composite coating machine: The ion beam composite magnetron sputtering coating machine selected in this implementation includes a vacuum chamber, two magnetron sputtering sources, an ion source and a workpiece support that can rotate at the same time. The workpiece support is installed in Inside the vacuum chamber; two magnetron sputtering sources are loaded with 99.6% pure yttrium target and 99.6% pure tungsten target, and the other magnetron sputtering source is loaded with 99.6% pure TiB 2 target;

[0041] 2. Sample (substrate) pre-cleaning treatment: ultrasonically clean the sample (substrate) to be coated with alcohol, then rinse with deionized water and blow dry with dry compressed nitrogen;

[0042] 3. Place the substrate on the workpiece holder of the vacuum chamber, and vacuum the vacuum chamber to a vacuum degree of 5.0×10 –3 Below Pa, turn on the ion source, pass 120sccm argon gas into the ion source, set the ion source power to 1kW, set the workp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com