Wear-resistant ship mooring rope

A ship cable, wear-resistant technology, applied in textile cables, textiles and papermaking, etc., can solve the problems of short service life, strength, toughness, high and low temperature resistance, corrosion resistance, weather resistance and other poor comprehensive performance, and achieve the goal of using Effects of long life, high modulus, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

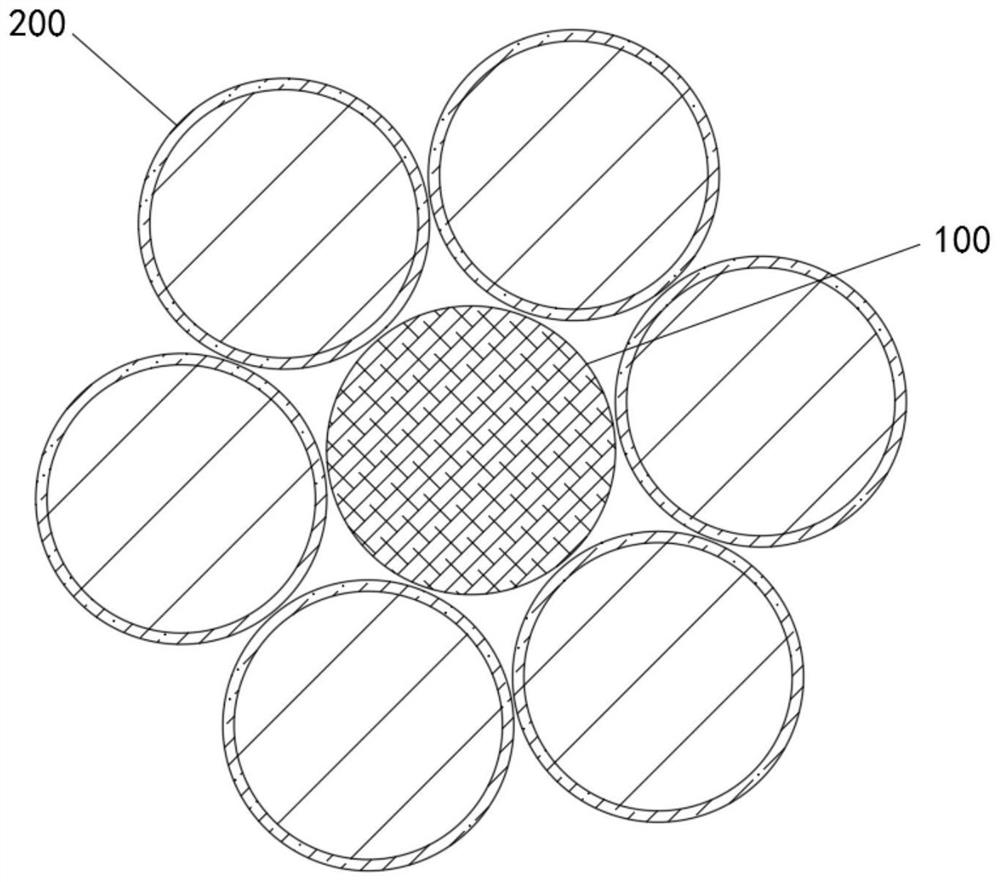

[0024] Such as figure 1 As shown, a wear-resistant ship cable proposed by an embodiment of the present invention includes a rope core 100, and the rope core 100 is a steel wire rope to ensure that the ship cable has a large bearing safety factor and can carry loads from a long distance; the outer surface of the rope core 100 The surface is alternately woven with wear-resistant outer covering layers 200. The wear-resistant outer covering layers 200 are interwoven with S twisted strands and Z twisted strands. Both S twisted strands and Z twisted strands include composite reinforced polymer polymer Ethylene strands and the protective coating coated on the surface of the composite reinforced polymer polyethylene strands, the wear-resistant outer cladding layer 200 formed by interweaving the composite reinforced polymer polyethylene strands in the S twist direction and the Z twist direction, The product itself has the excellent characteristics of high molecular polyethylene. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com