A hand-push cargo truck

A technology for transporting vehicles and goods, which is applied to trolleys, multi-axis trolleys, motor vehicles, etc. It can solve the problems of difficult control of precision, difficult assembly, high cost, etc., and achieves a large load safety factor, easy to carry and transport, and safe and reliable to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

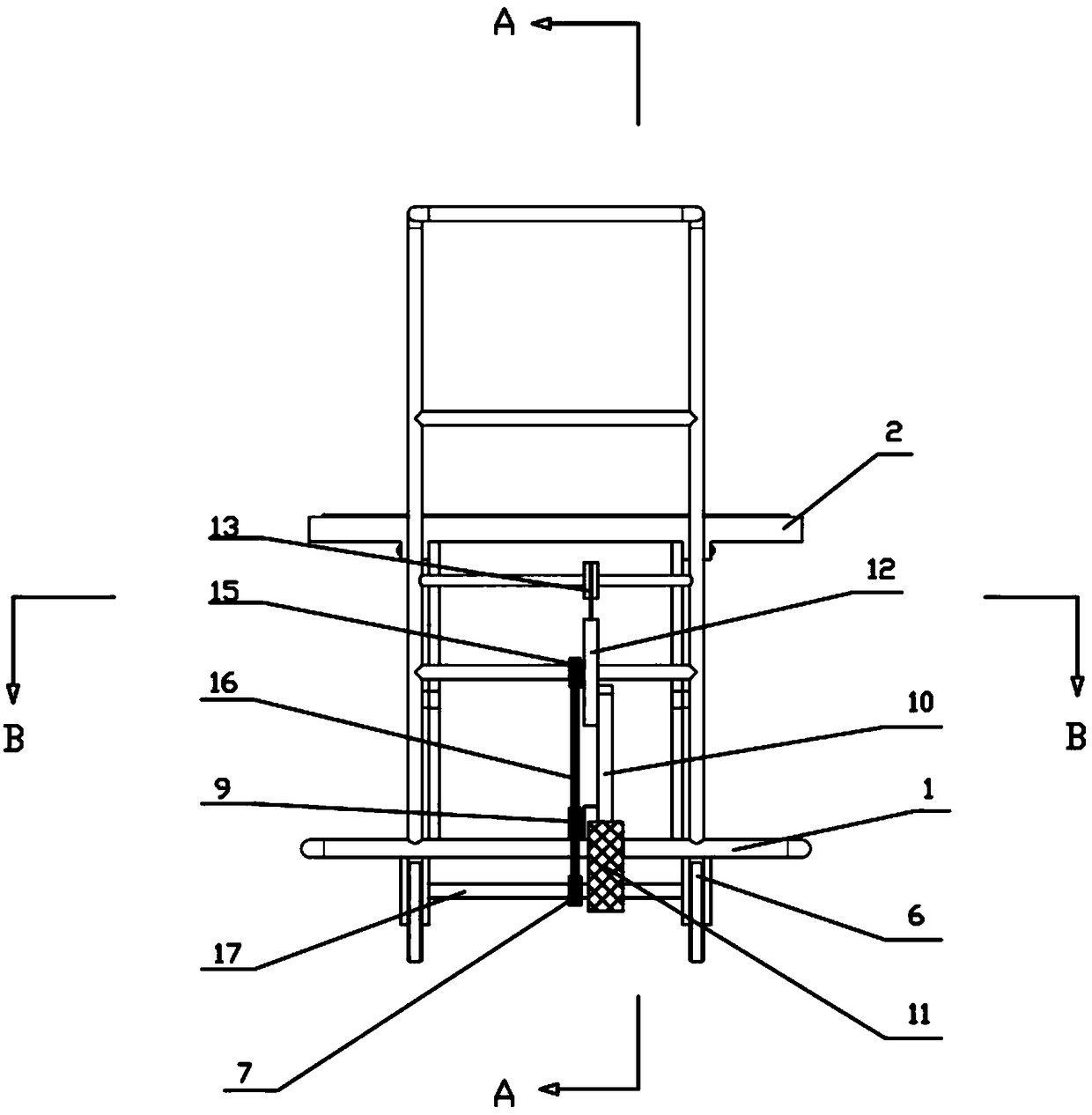

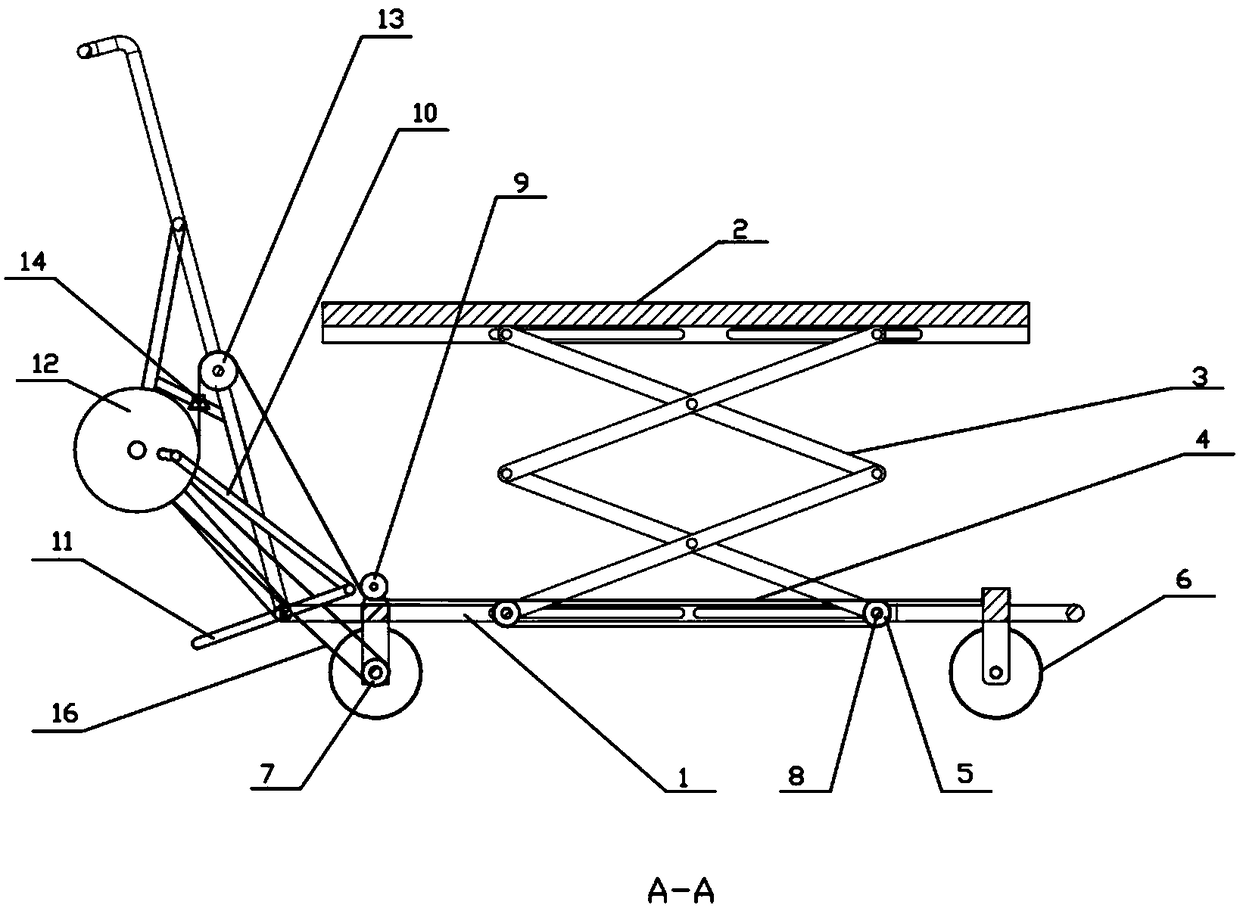

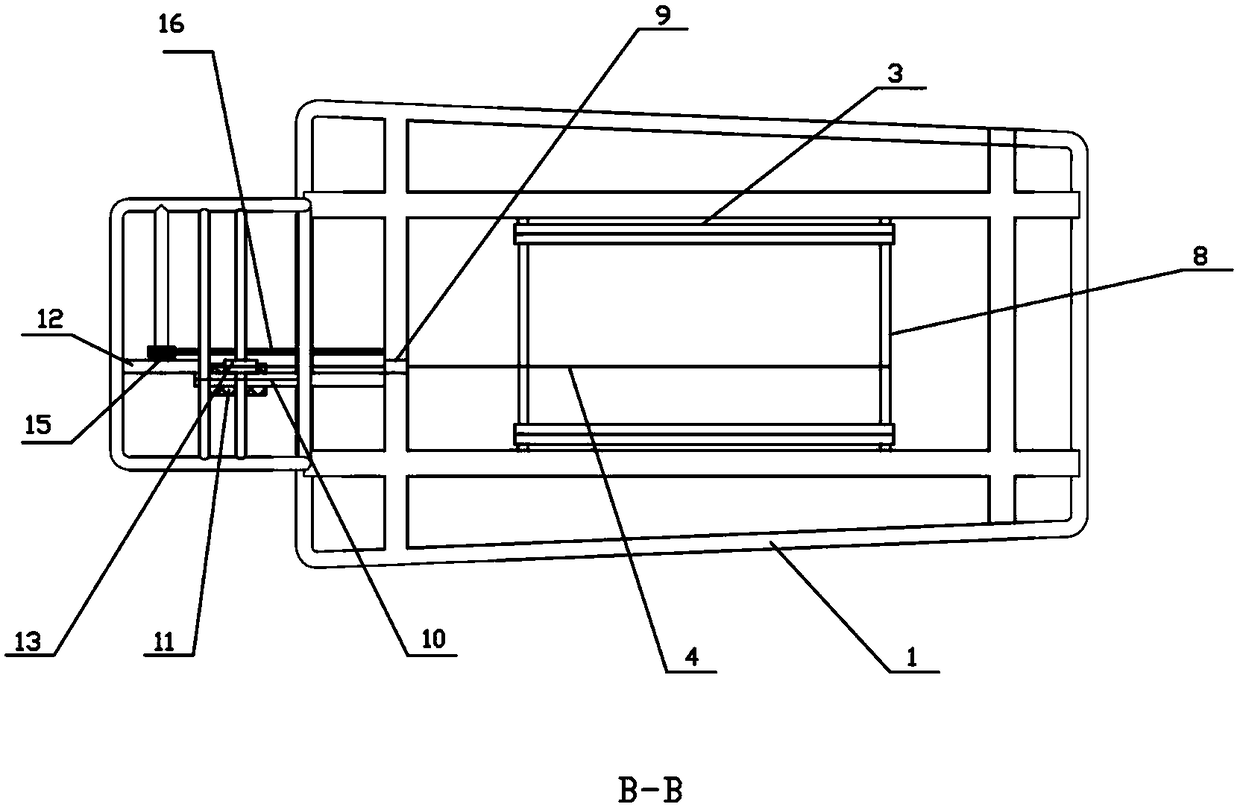

[0020] A specific embodiment of the present invention is a hand-push cargo truck, including a trolley frame 1 and wheels 6, and scissor linkage mechanisms 3 are arranged symmetrically on the left and right sides of the bottom plate of the trolley frame 1, and the scissor linkage mechanisms 3 on each side The rod mechanism 3 has two sets of connecting rods with hinges, and there are chutes on the lower sides of the lifting plate 2. The upper end of the two sets of connecting rods of the scissor linkage mechanism 3 is provided with chutes on both sides of the lifting plate 2. Cooperating cylindrical pins; the lower end of the two sets of connecting rods of the scissor linkage mechanism 3 is provided with a through hole, and the scissor linkage mechanism 3 on both sides is respectively sleeved on the two ends of the front and rear synchronous shafts 8 through the through holes, and the front and rear synchronous shafts 8 are respectively sleeved. The rear synchronous shaft 8 runs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com