Patents

Literature

50results about How to "Achieve anchoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

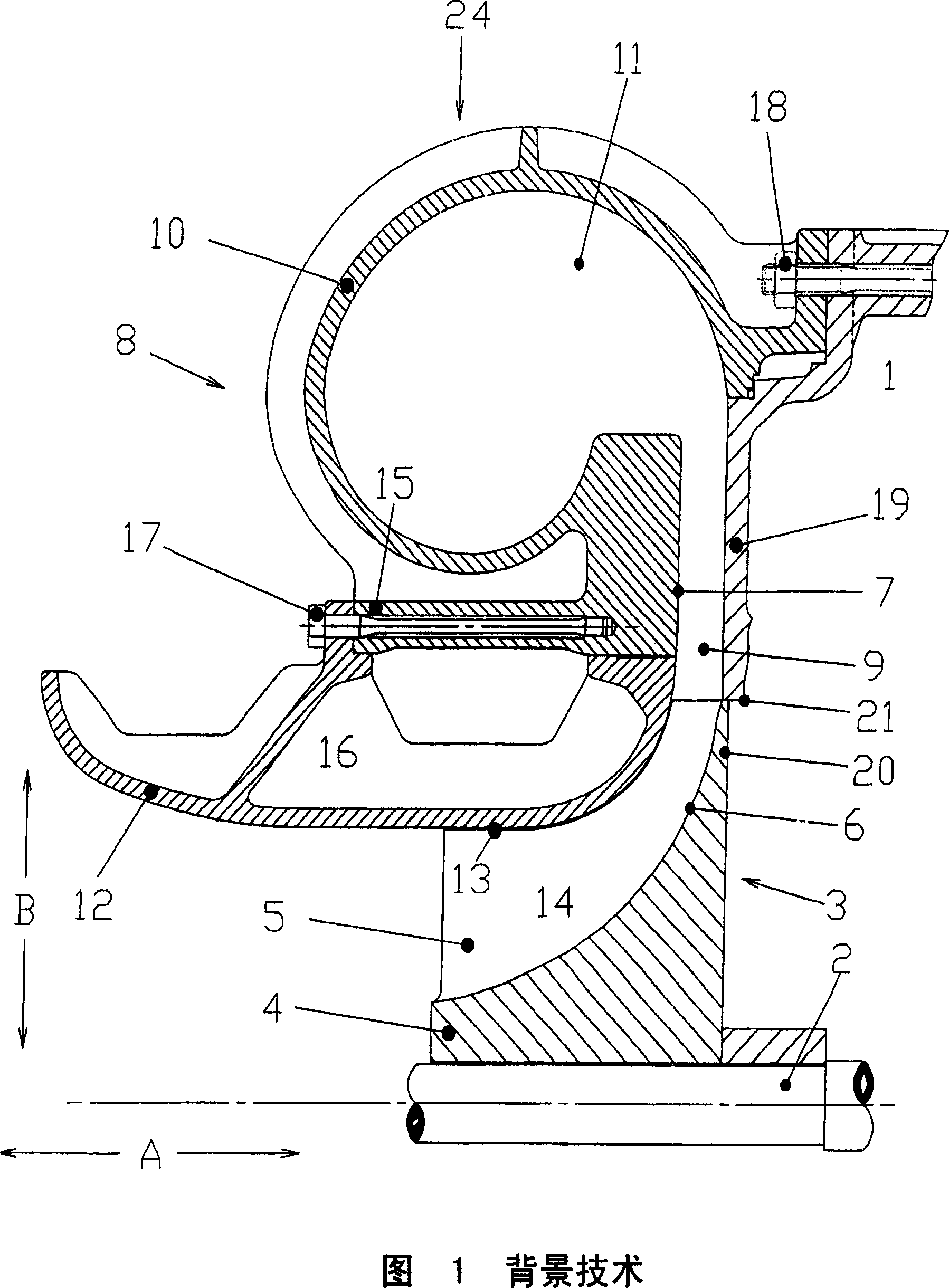

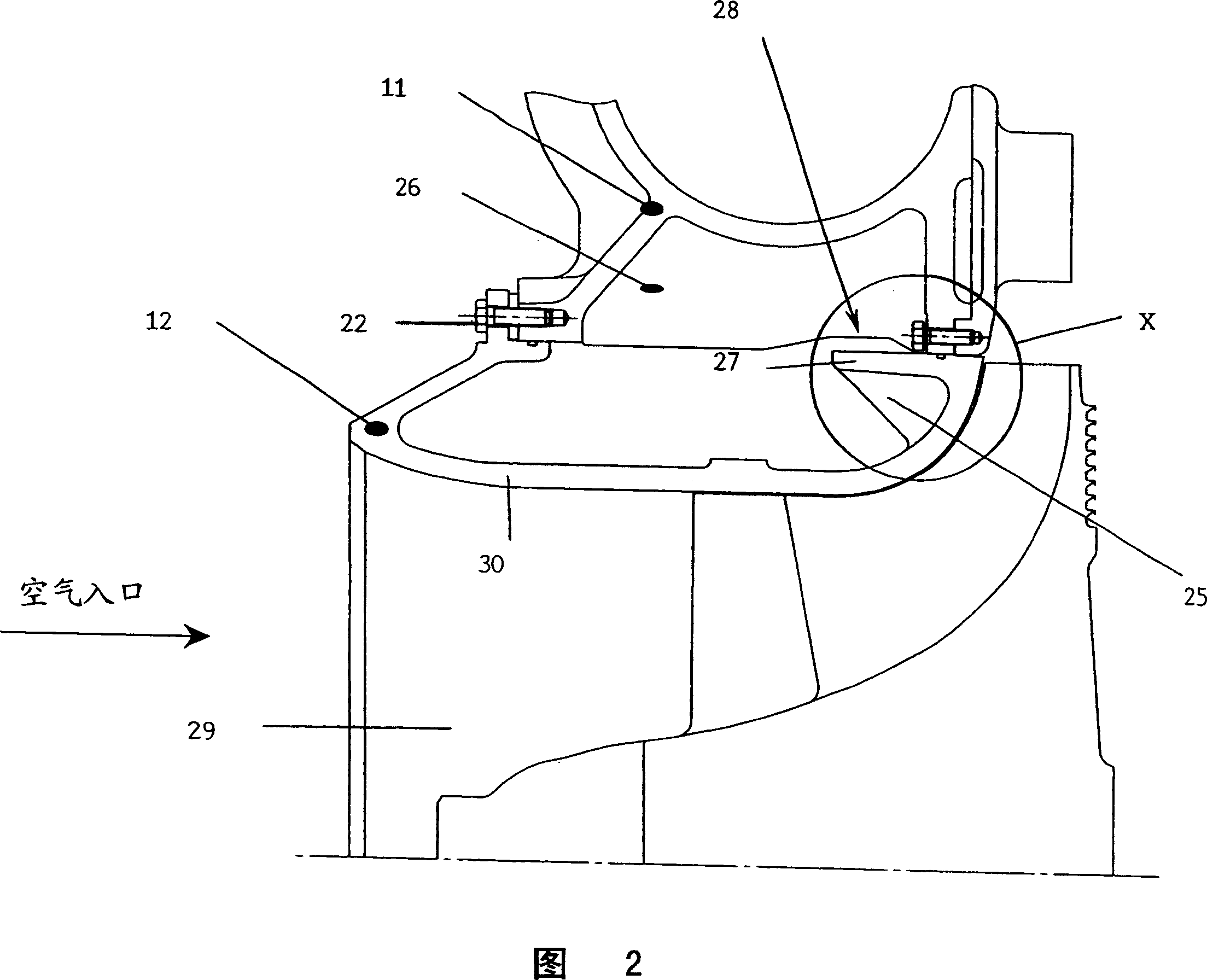

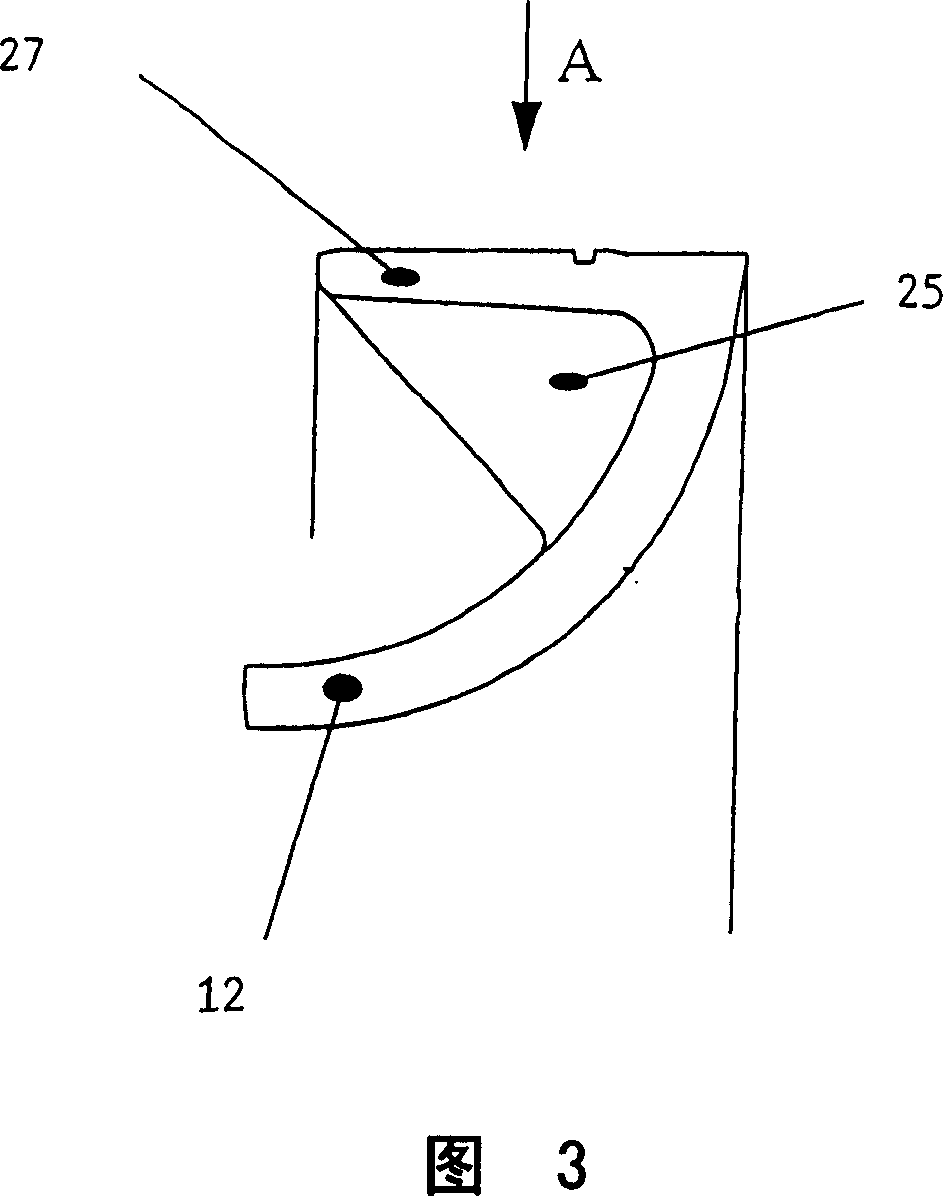

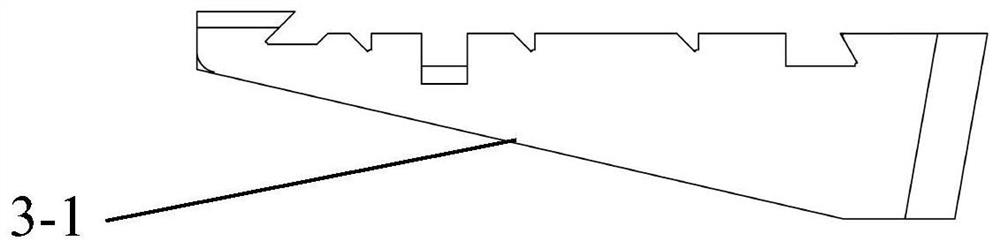

External housing safety device for turbocharger with axial flow fluid compressor

InactiveCN1920312AAchieve anchoringEasy maintenancePump componentsEfficient propulsion technologiesTurbochargerEngineering

The invention relates to a turbomachine with a compressor wheel (3) through which fluid flows radially. The compressor housing (8) consists of an outer spiral housing (10) and an inner housing insert (12). The compressor wheel (3) may break due to aging. Ideally the breakout should be caught by the casing insert (12) in order to secure the casing of the turbine. Taking into account the force of the shock release due to the breaking part of the compressor wheel (3), the invention proposes a special construction, in particular of the housing inner insert (12) as a spare part, so that the breaking part can be Reliable and cost-effective retention in the turbine, that is to say keeping the casing of the turbine secure.

Owner:MAN ENERGY SOLUTIONS SA

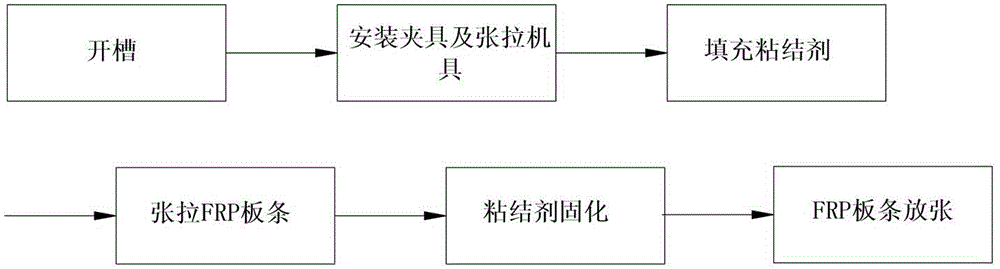

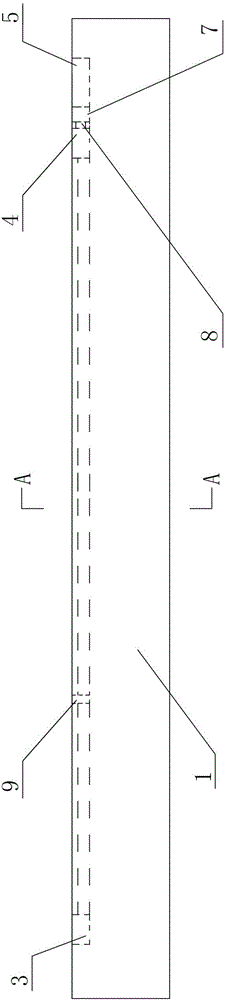

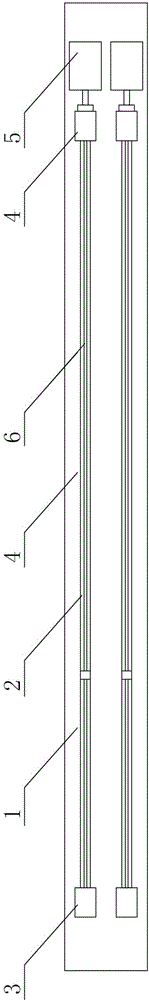

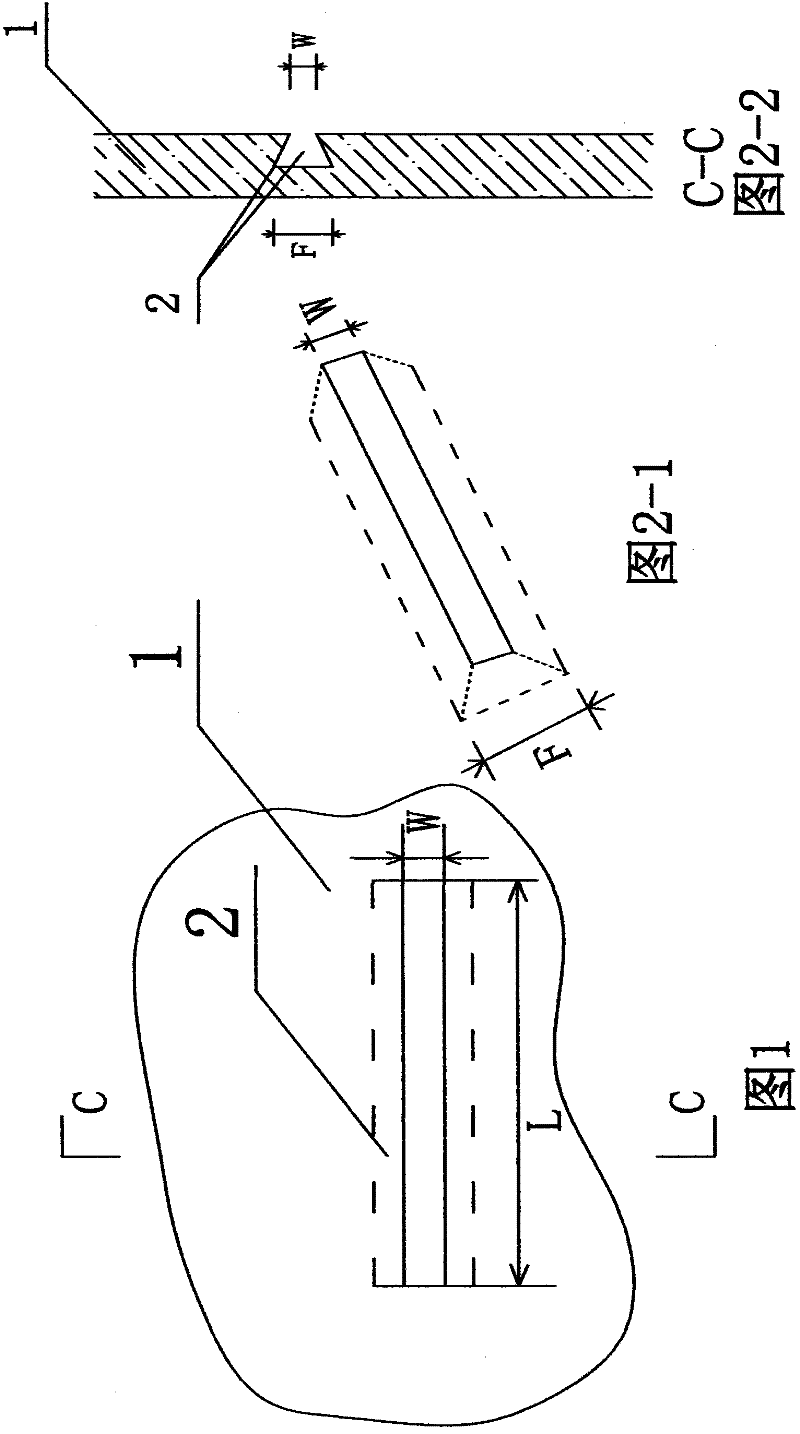

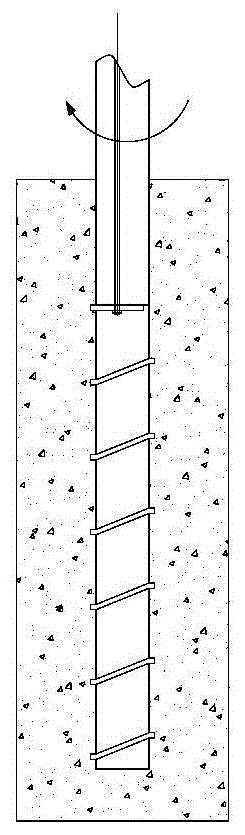

Concrete structure reinforcing method based on near surface mounted prestressed FRP (Fiber Reinforced Polymer)

ActiveCN102425311BAchieve anchoringGive full play to high-strength performanceBuilding repairsFiberSurface mounting

The invention discloses a concrete structure reinforcing method based on near surface mounted prestressed FRP (Fiber Reinforced Polymer), which comprises the steps of: 1, slotting, arranging more than one preformed groove on a concrete structure to be reinforced; 2, installing a tensioning tool of an FRP strip and an FRP strip clamp; 3, tensioning internal FRP strips in the tensioning tool and the FRP strip tool so that the internal FRP strips are tensioned, placing the internal FRP strips in the preformed groove, filling an adhesive, keeping a clamping and anchoring state for a period of time and then curing; and 4, relaxing: when adhesive resin is cured completely to reach the strength, dismantling the FRP strip clamp. The concrete structure has the advantages of low cost, convenience for construction, long service life, good reliability and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

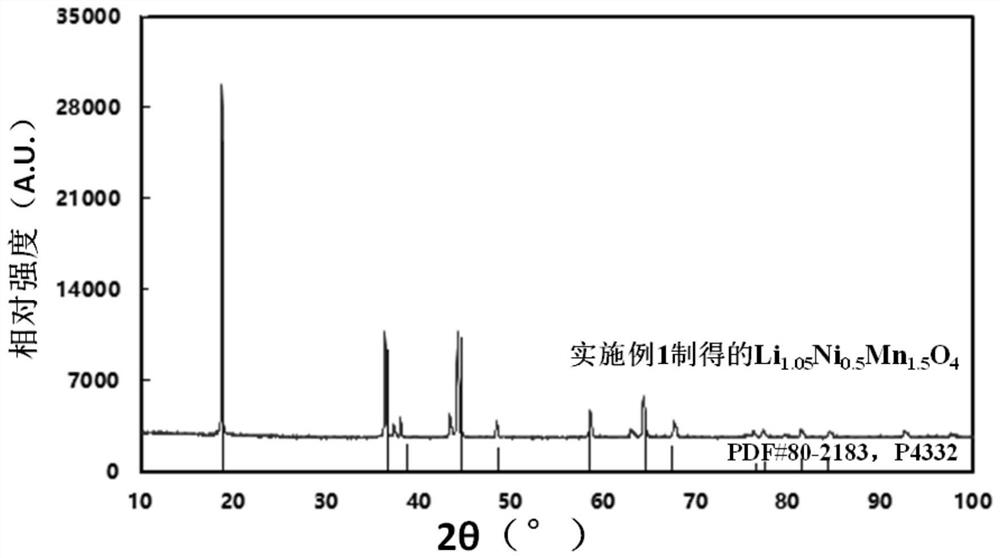

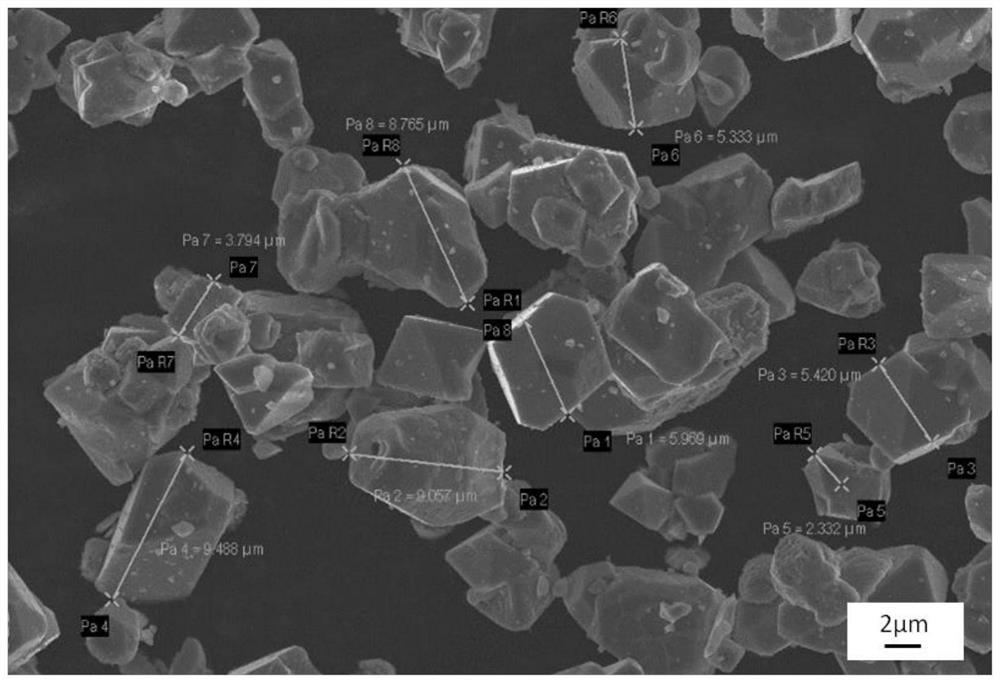

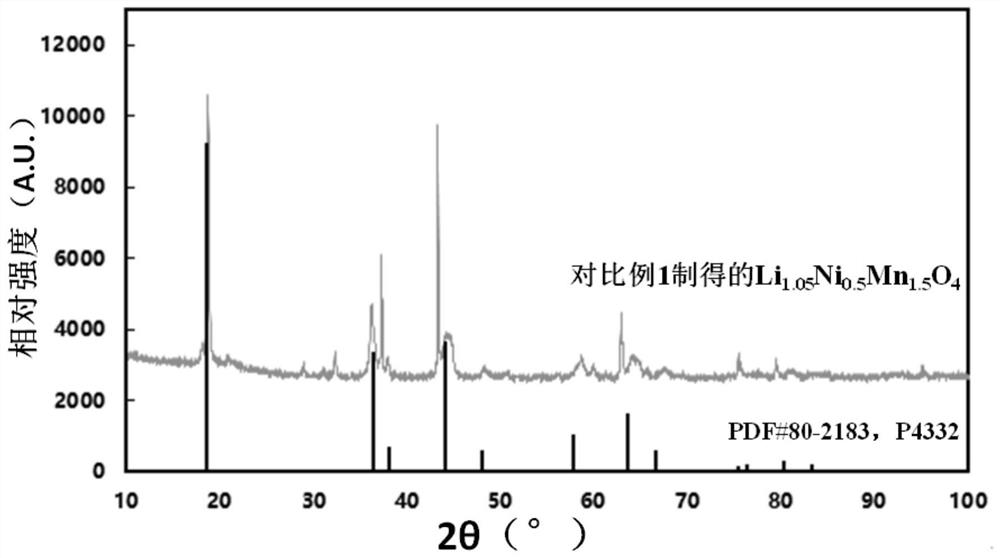

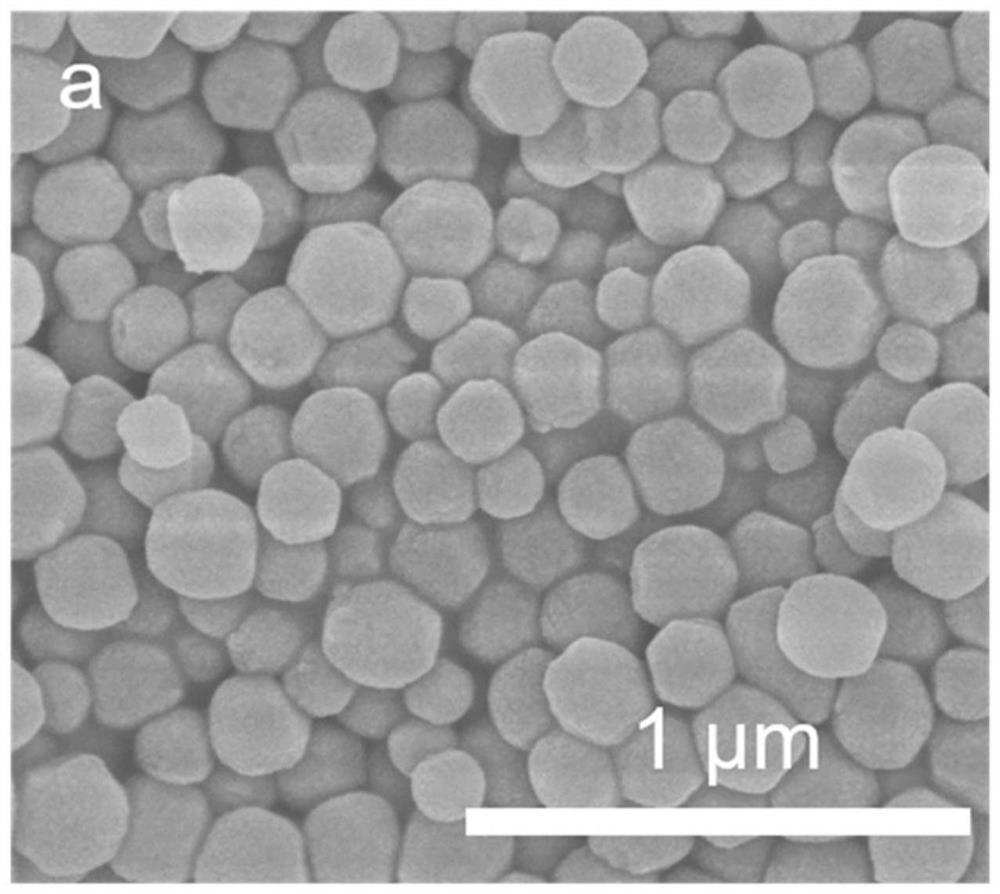

Lithium nickel manganese oxide positive electrode material, preparation method thereof and lithium ion battery

PendingCN113845152AAchieve anchoringReduce the chance of mix-upsCell electrodesFinal product manufactureDischarge efficiencyCyclodextrin

The invention provides a lithium nickel manganese oxide positive electrode material, a preparation method thereof and a lithium ion battery. The preparation method of the lithium nickel manganese oxide positive electrode material comprises the steps that a lithium source, a nickel source, a manganese source, water, beta-cyclodextrin, a complexing agent and an alkaline regulator are subjected to a gel reaction, a precursor gel is obtained, wherein the molar ratio of lithium elements in the lithium source to nickel elements in the nickel source to manganese elements in the manganese source is (1.00-1.06): (0.45-0.55): (1.45-1.85); and dehydrating and calcining of the precursor gel are carried out to obtain the lithium nickel manganese oxide positive electrode material. According to the preparation method, anchoring of nickel and manganese can be realized, so that the probability of mixed arrangement of lithium ions and nickel ions in the lithium nickel manganese oxide positive electrode material is reduced, the structural stability of the lithium nickel manganese oxide positive electrode material is improved, a spinel type structure is formed, and the prepared lithium nickel manganese oxide positive electrode material has good first discharge efficiency, rate capability, capacity recovery and cycling stability.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

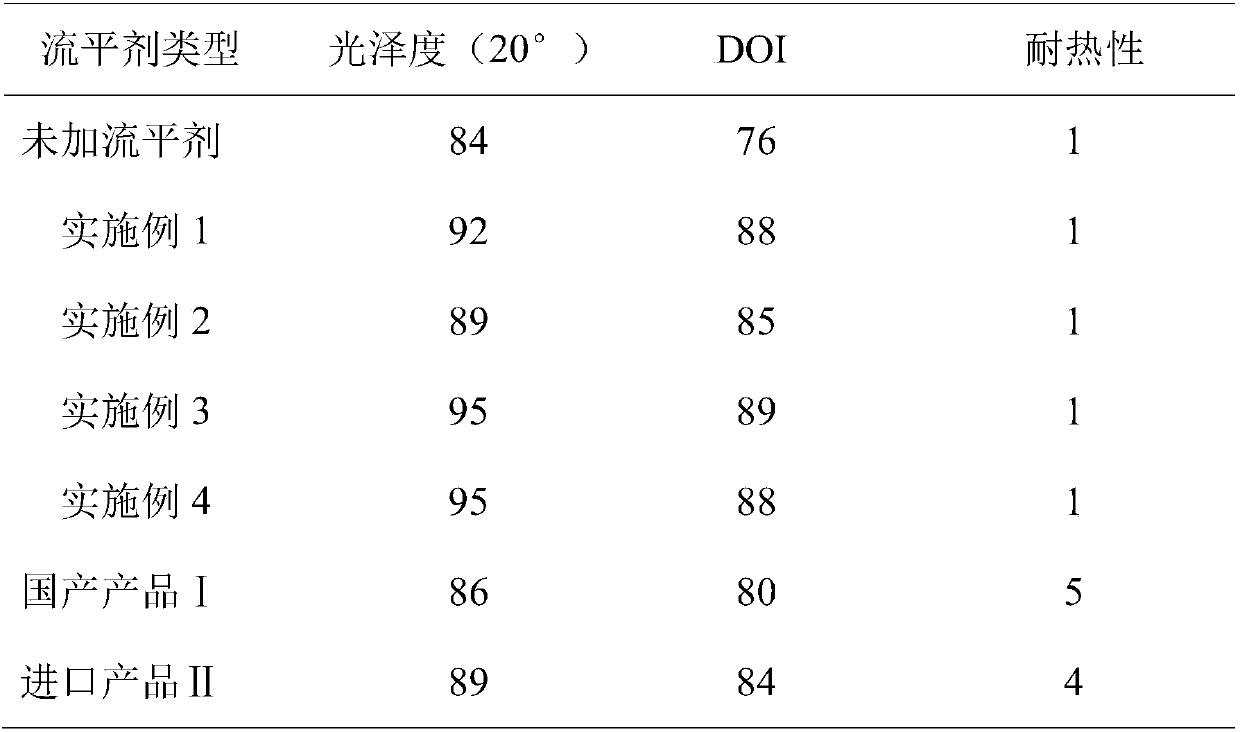

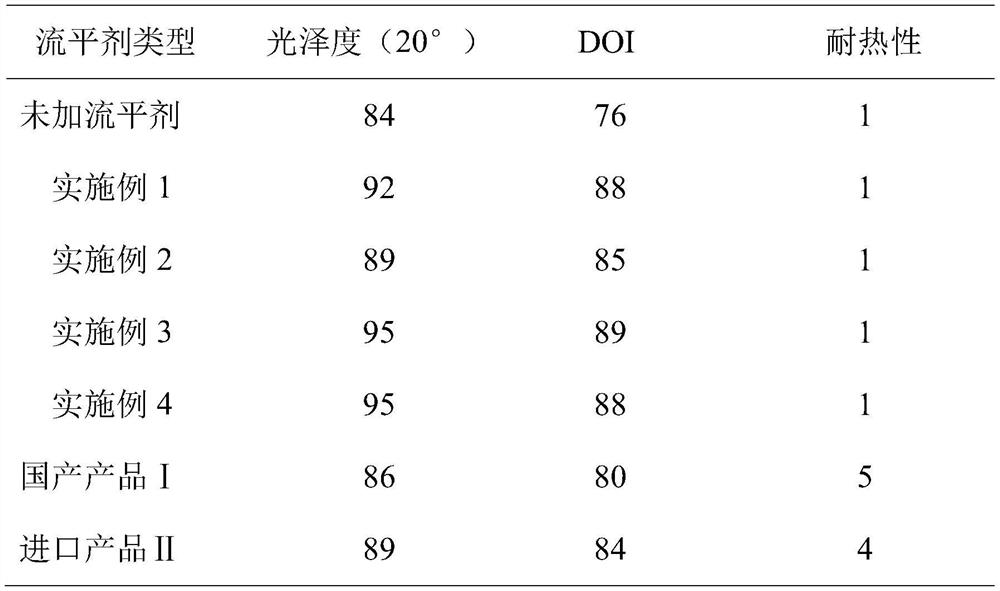

Polyester modified organosilicon levelling agent, and preparation method thereof

The invention discloses a polyester modified organosilicon levelling agent, and a preparation method thereof. According to the preparation method, the polyester modified organosilicon levelling agentis prepared from hydrogen-terminal polydimethylsiloxane and single-allyl-terminal polycaprolactone at a molar ratio of 1-1.5:2 via catalytic addition under the action of a catalyst, wherein the mass amount of the catalyst accounts for 0.001 to 0.005% of that of the total materials. Primary hydroxyl groups contained by the polyester modified organosilicon levelling agent are capable of reacting with a resin base material, anchoring of active components on coating surface is realized after film forming, excellent heat resistance is achieved, and applications can be realized in the forms of solution, water miscible liquid, or 100% stock solution.

Owner:优卡化学(上海)有限公司 +2

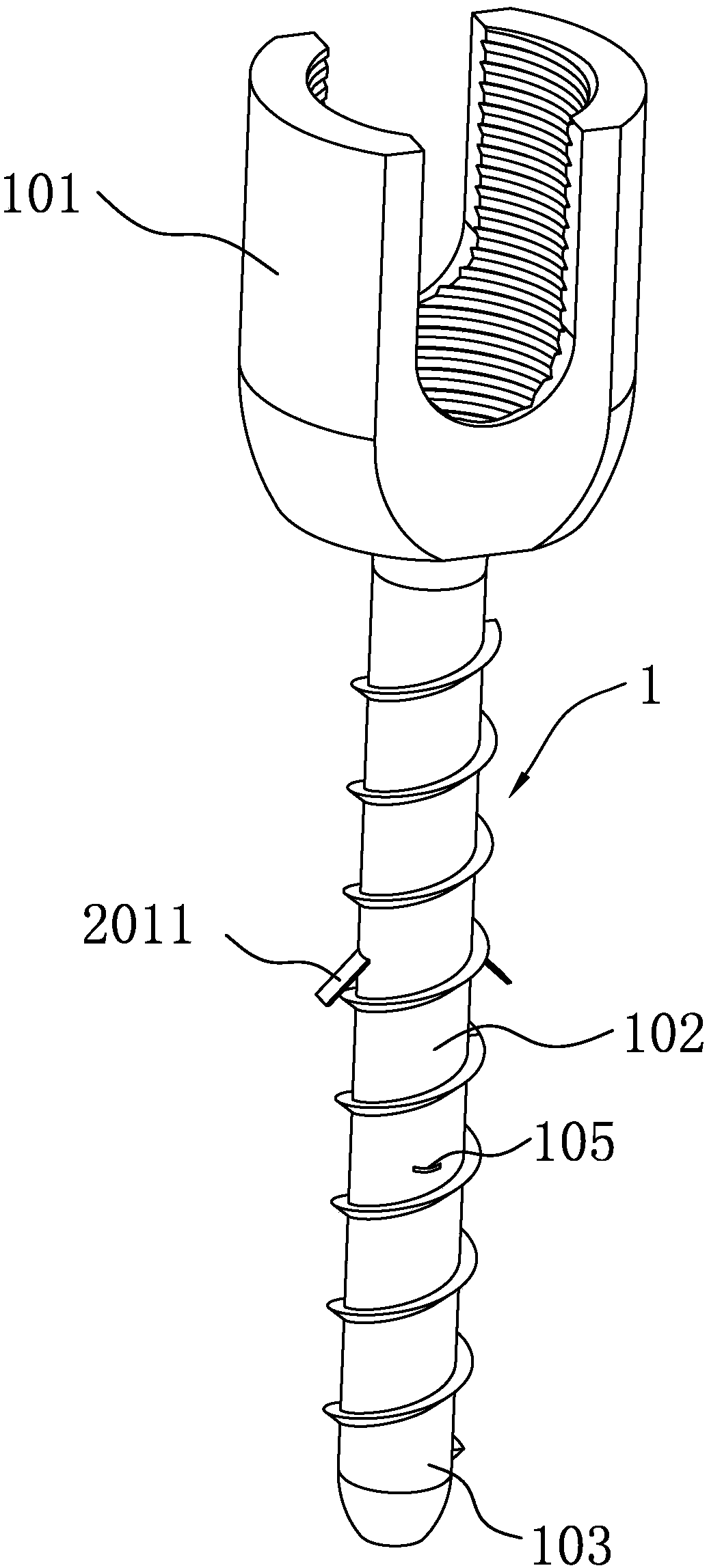

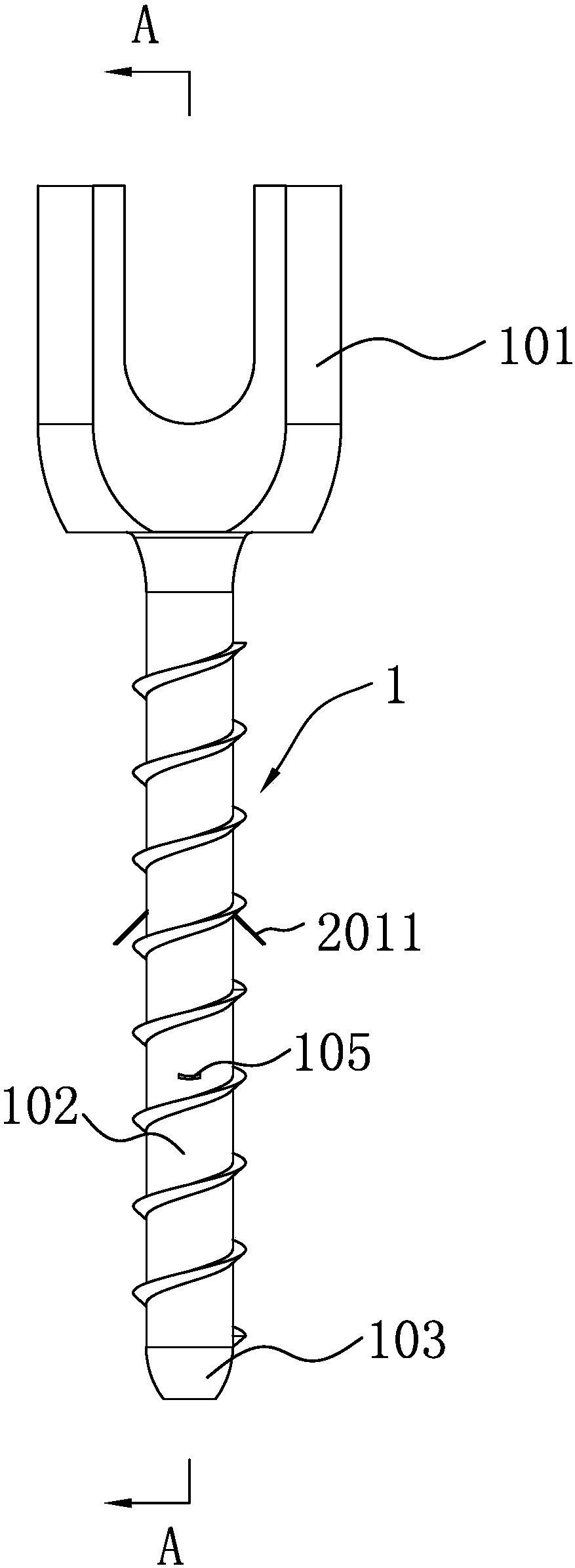

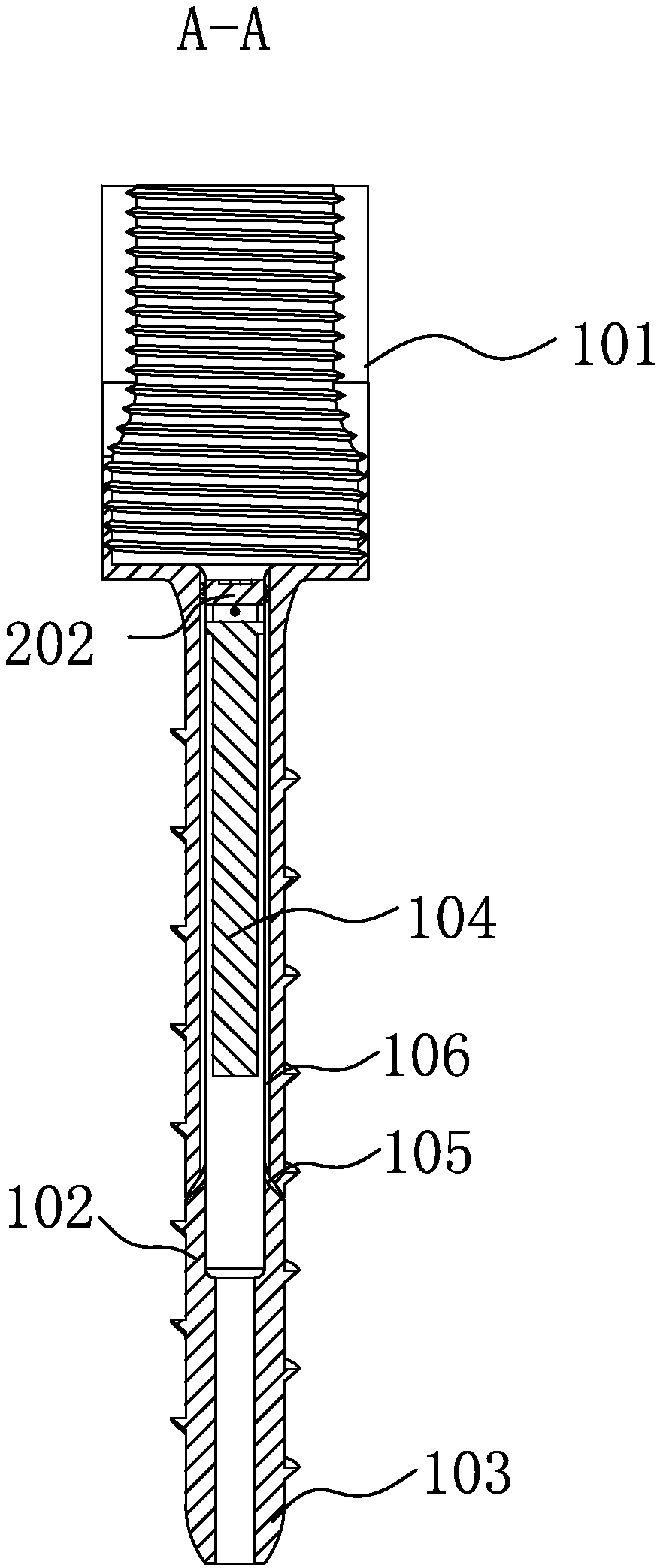

Novel expansion anchor bolt

ActiveCN108843667AControl the degree of expansionPlay the role of expansion and fixationDowelsReciprocating motionAnchor bolt

The invention provides a novel expansion anchor bolt, and belongs to the technical field of anchor bolt fixing. The novel expansion anchor bolt is used for fastening an installing base surface and comprises an anchor rod and a sleeve which is arranged on the outer surface of the anchor rod in a sleeving mode in the mode of doing reciprocating motion in the extending direction of the anchor rod, acontaining cavity is formed in the anchor rod, and expansion bodies and a cocking part used for being connected with the expansion bodies in a butting-joint mode to enable the non-hinged ends of the expansion bodies to be capable of at least partially protruding out of a containing groove; and the non-hinged end of each expansion body is provided with a guiding surface, and the guiding surfaces are used for being connected with one end of the sleeve in an abutting mode till the expansion bodies are expanded in the mode that the non-hinged ends rotate to make contact with the installing base surface. According to the novel expansion anchor bolt, the sleeve abuts against the guiding surfaces to enable the expansion bodies to be expanded, and the expanding and fixing effects are achieved. Thestructure is simple, anchoring can be achieved only by rotating or knocking the sleeve, labor is saved, and the expansion degree of the expansion bodies is controlled by controlling the abutting length of the sleeve.

Owner:百益百利(福州)幕墙工程有限公司

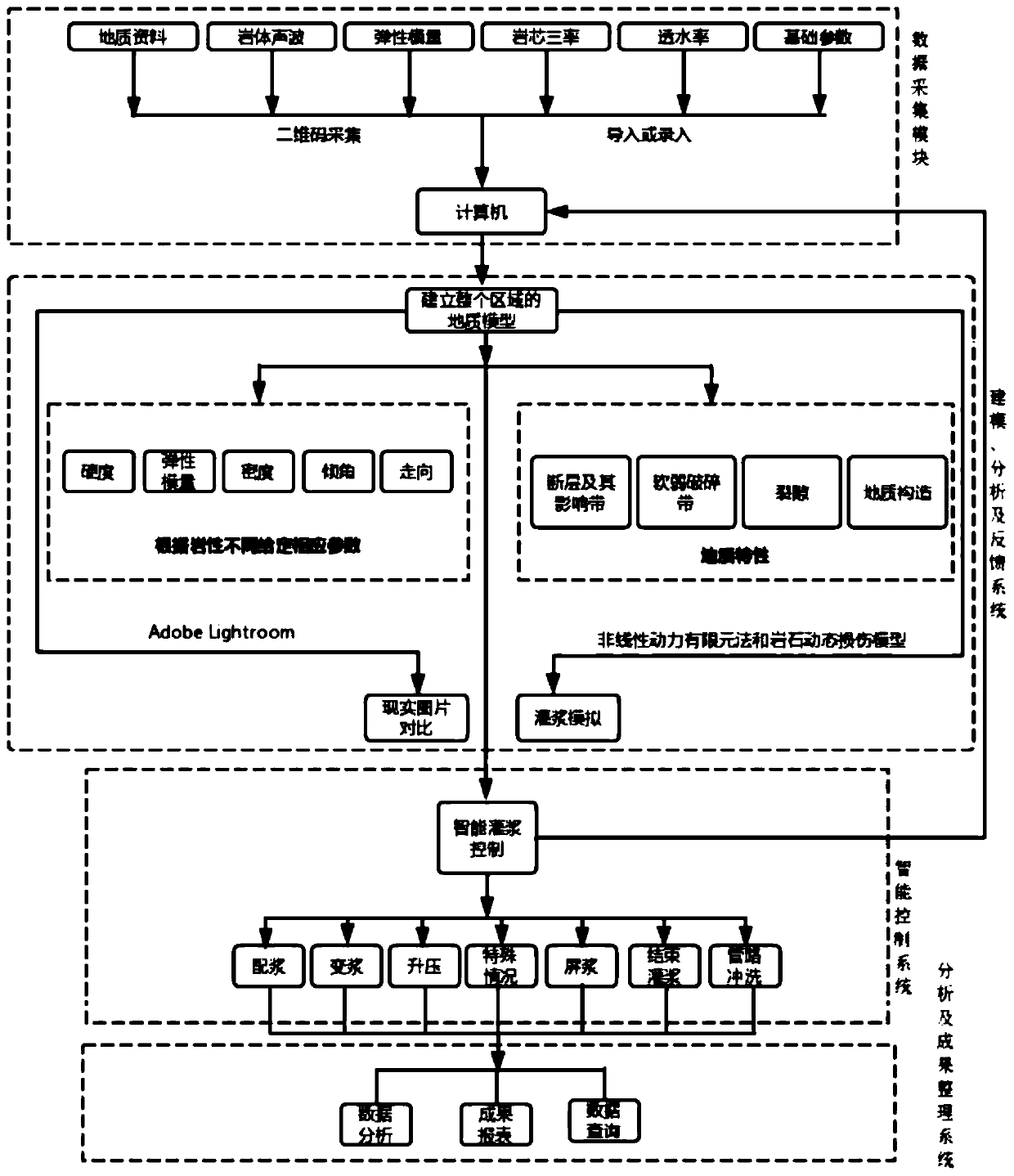

Anchoring and grouting engineering management system based on geological record big data

ActiveCN111254912AImprove construction qualityAutomatically optimize personality parametersBulkheads/pilesSoil preservationData connectionData acquisition

The invention discloses an anchoring and grouting engineering management system based on geological record big data. The anchoring and grouting engineering management system based on the geological record big data comprises a data connection and transmission module, a data acquisition module, a geological record module, a modeling, analysis and feedback module, a control module and a result analysis querying module. The anchoring and grouting engineering management system is used in industries related to anchoring and grouting engineering. For supporting of foundation pits, slopes and side walls of caverns and seepage prevention of dam foundations, and the seepage prevention capability or the integrity and deformation resistance are improved. The engineering using anchoring and grouting toachieve the strengthening purpose has good application and promotion value. The big data are used for collecting, processing and analyzing related information, construction control parameters are provided, the anchoring and grouting engineering management system is combined with an intelligent control system to form feedback to continuously optimize the process control parameters, and the corresponding recording process is monitored and fed back, the effect of anchor cable tension and grouting is improved, the standardization of the construction process is promoted, the engineering quality and efficiency are improved, and the safety risk is reduced.

Owner:中国水利水电第七工程局成都水电建设工程有限公司 +1

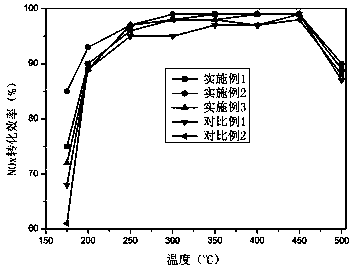

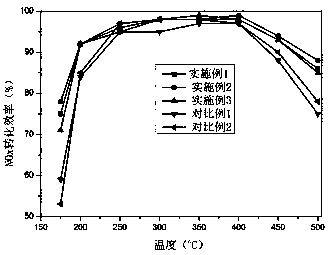

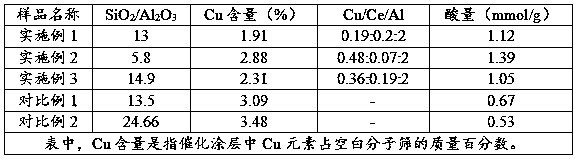

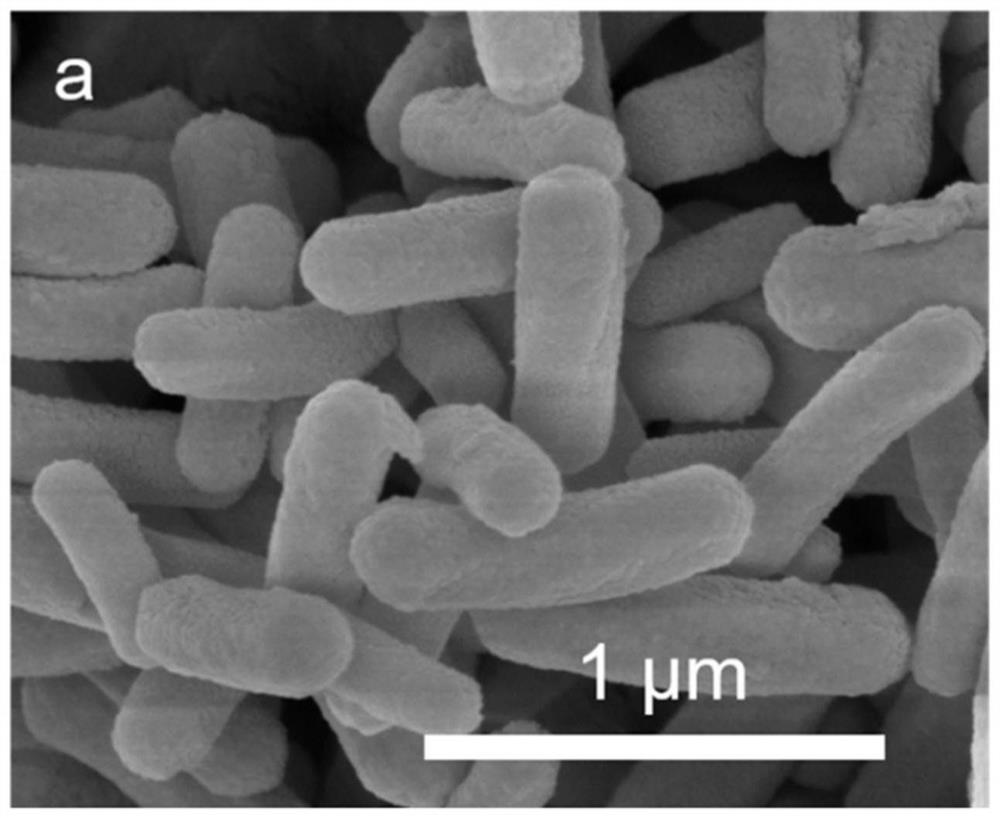

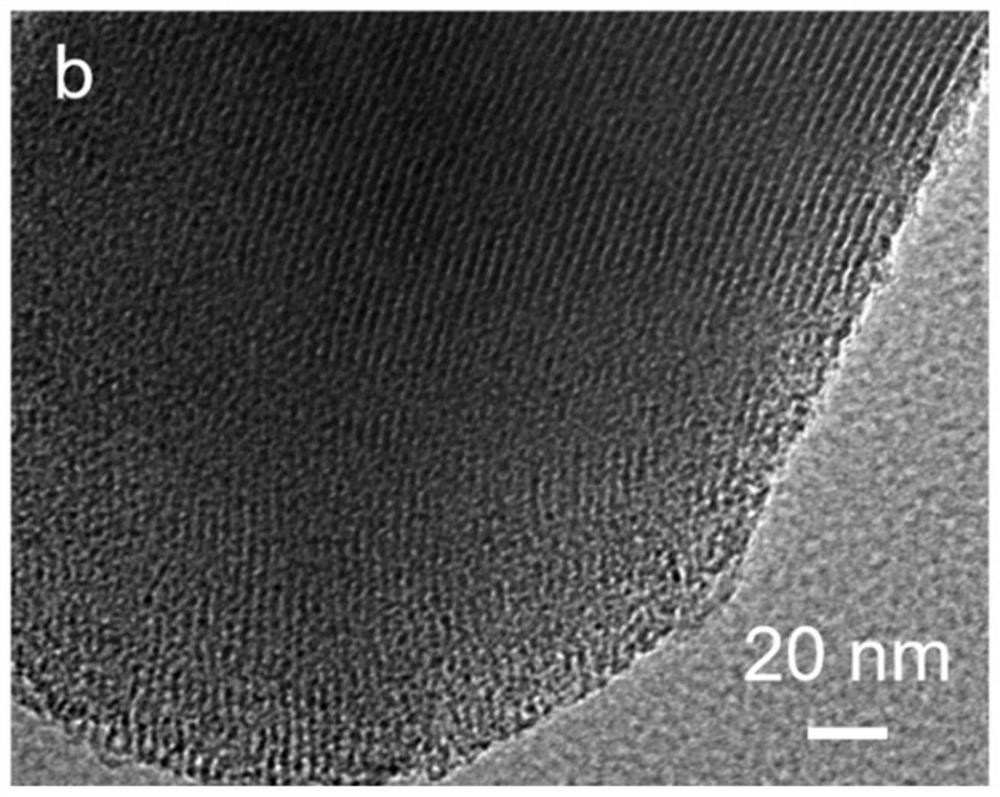

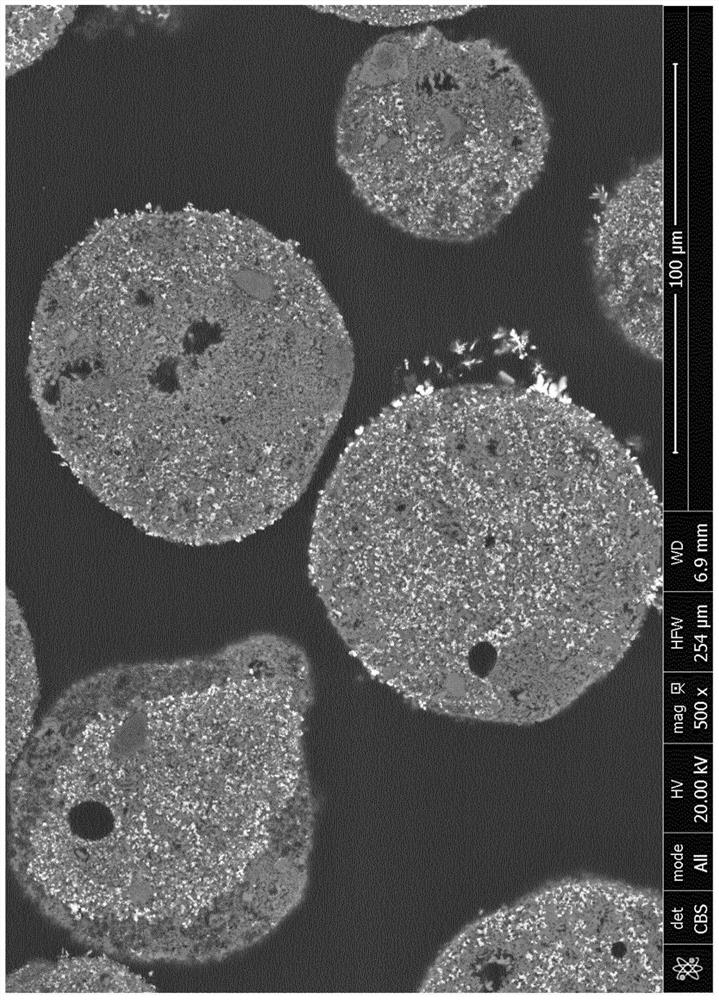

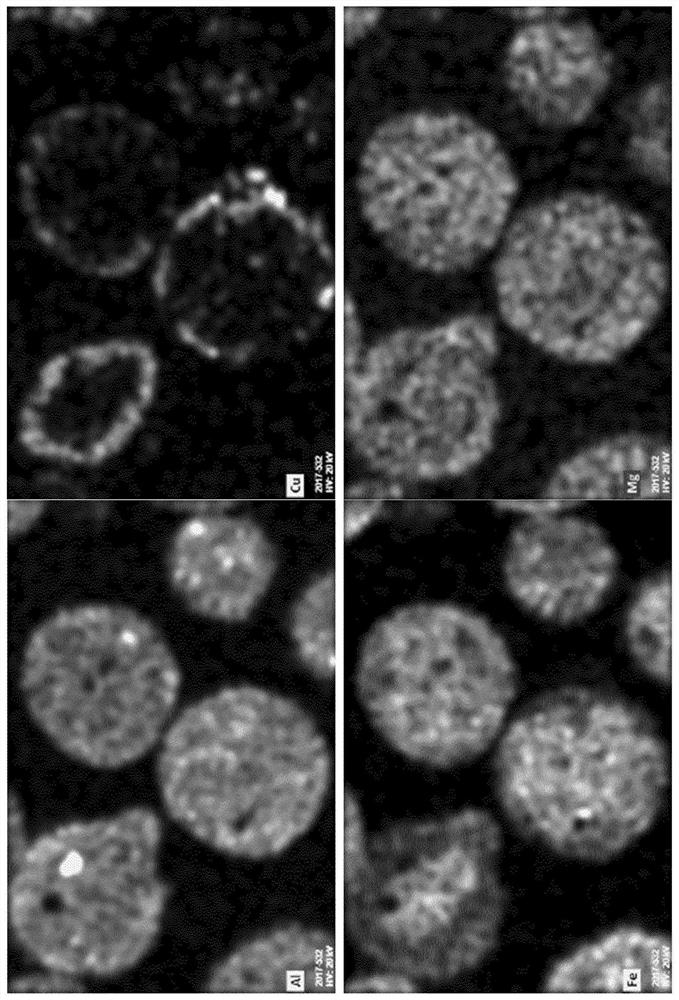

Multi-metal-CHA type molecular sieve catalyst as well as preparation method and application thereof

ActiveCN111203269AReduce manufacturing costHigh hydrothermal stabilityMolecular sieve catalystsExhaust apparatusMolecular sievePtru catalyst

The invention belongs to the technical field of catalysts, and particularly relates to a multi-metal-CHA type molecular sieve catalyst as well as a preparation method and application thereof. The catalyst comprises a first active component, a second active component, an auxiliary agent and a CHA type molecular sieve, wherein the first active component is Cu; the second active component is Ce; theauxiliary agent comprises one or more of ammonium polyacrylate, polyvinyl alcohol, polymethacrylate, maleic anhydride and ammonium polycarboxylate; the molar ratio of silicon dioxide to alumina in theCHA type molecular sieve is less than or equal to 18: 1; and the atomic number ratio of Cu to Ce to Al in the catalyst is (0.19-0.49): (0.05-0.2): 2. The provided catalyst has excellent NOx conversion efficiency and hydrothermal stability.

Owner:稀土催化创新研究院(东营)有限公司 +2

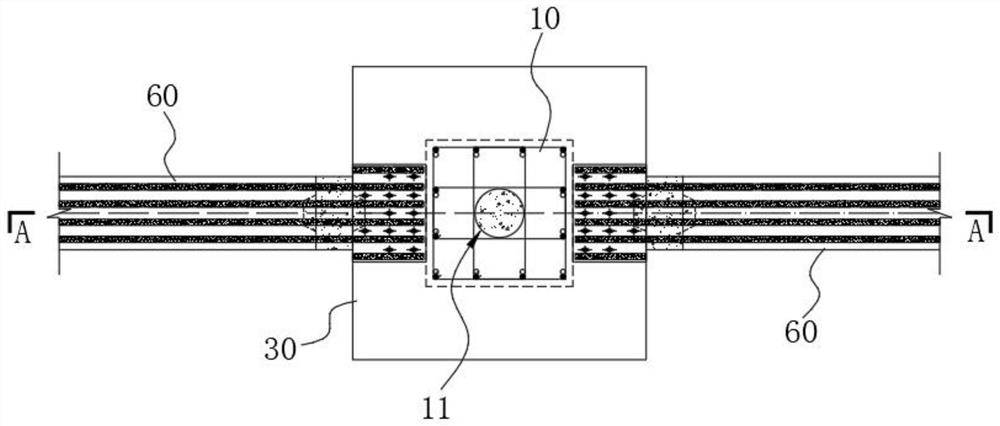

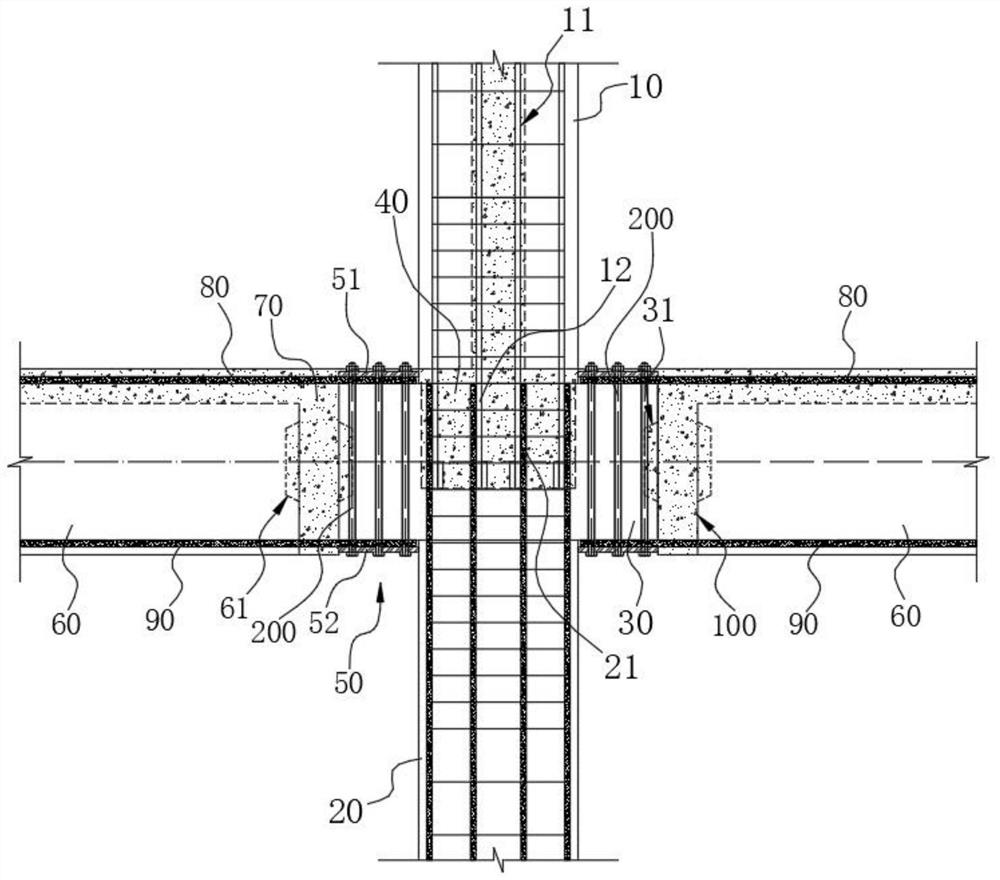

Assembly type reinforced concrete frame beam-column joint connecting structure

PendingCN113123524ASolve stitching problemsResolve connectionStrutsGirdersRc framesArchitectural engineering

The invention provides an assembly type reinforced concrete frame beam-column joint connecting structure. The assembly type reinforced concrete frame beam-column joint connecting structure comprises a prefabricated column, a connecting steel plate set and prefabricated beams, the prefabricated column comprises a prefabricated upper column, a prefabricated lower column, a prefabricated column cap and a first post-pouring section, the prefabricated column cap is formed at the upper end of the prefabricated lower column, the first post-pouring section is formed inside the prefabricated column cap, and the prefabricated upper column is fixedly connected with the prefabricated lower column through the first post-pouring section; the connecting steel plate set is arranged on the outer side of the prefabricated column cap; and the prefabricated beams are arranged on one side of the prefabricated column cap in parallel at intervals, the prefabricated beams and the prefabricated column cap are connected through a second post-pouring section, a beam longitudinal bar set extends out of the end, facing the prefabricated column cap, of each prefabricated beam, and the beam longitudinal bar sets are locked and fixed to the connecting steel plate set through bolt assemblies. Splicing of the prefabricated column is achieved through lap joint of the prefabricated upper column and the prefabricated lower column and the first post-pouring section formed in the prefabricated column cap, and connection between the prefabricated beams and the prefabricated column achieves anchoring of the beam longitudinal bar sets through friction force formed by the beam longitudinal bar sets and the connecting steel plate set under the pretension action of high-strength bolt assemblies.

Owner:CCCC FHDI ENG

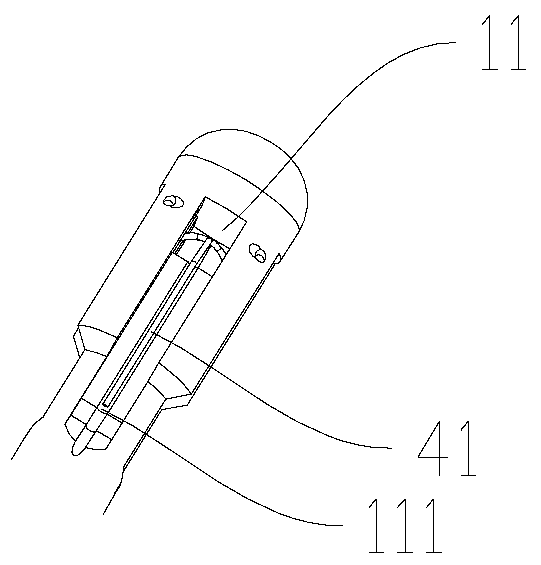

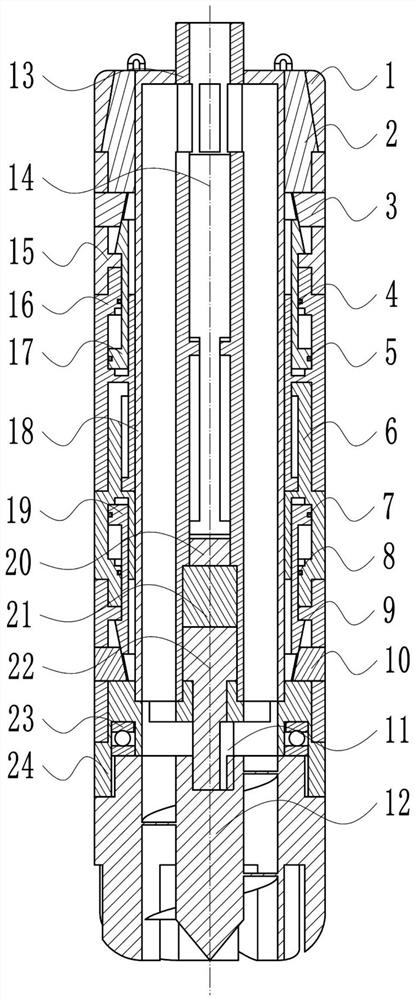

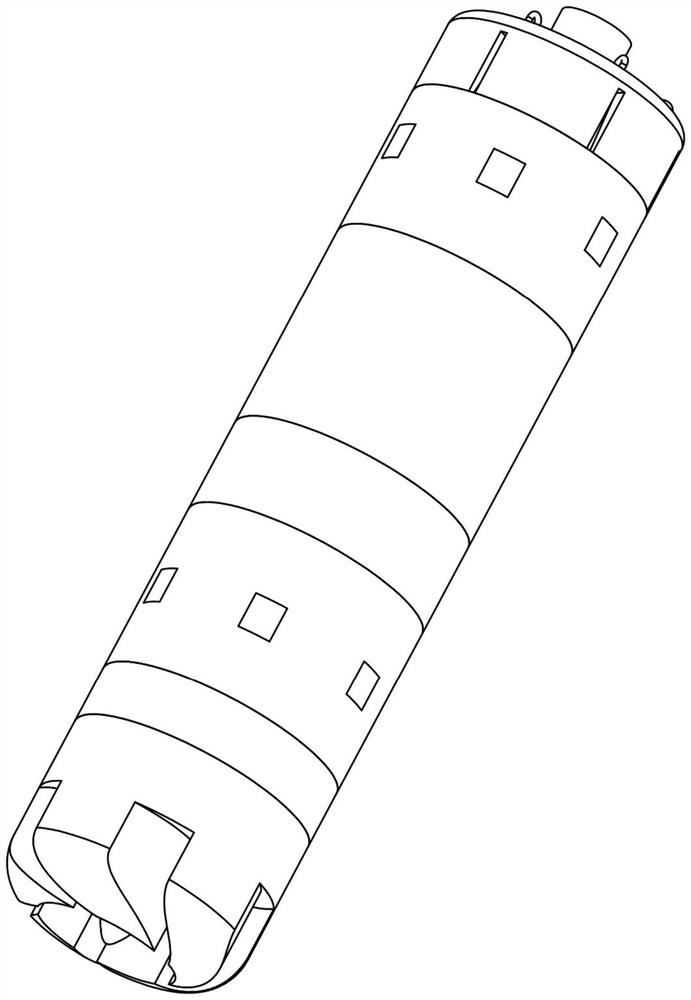

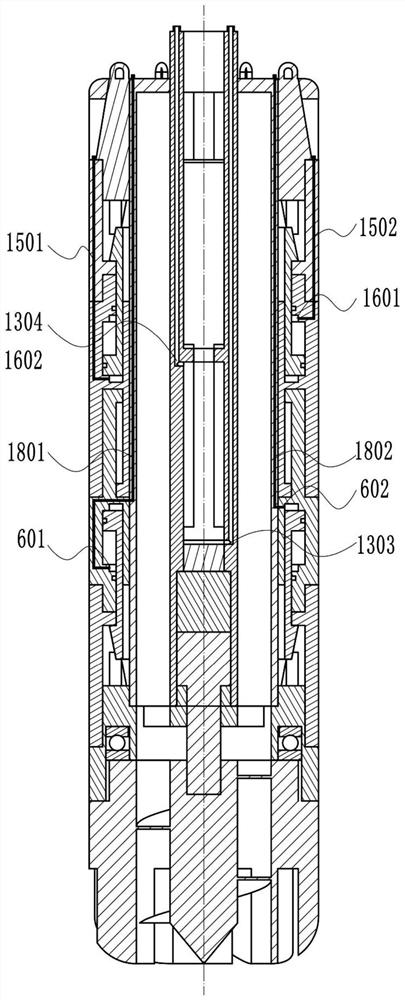

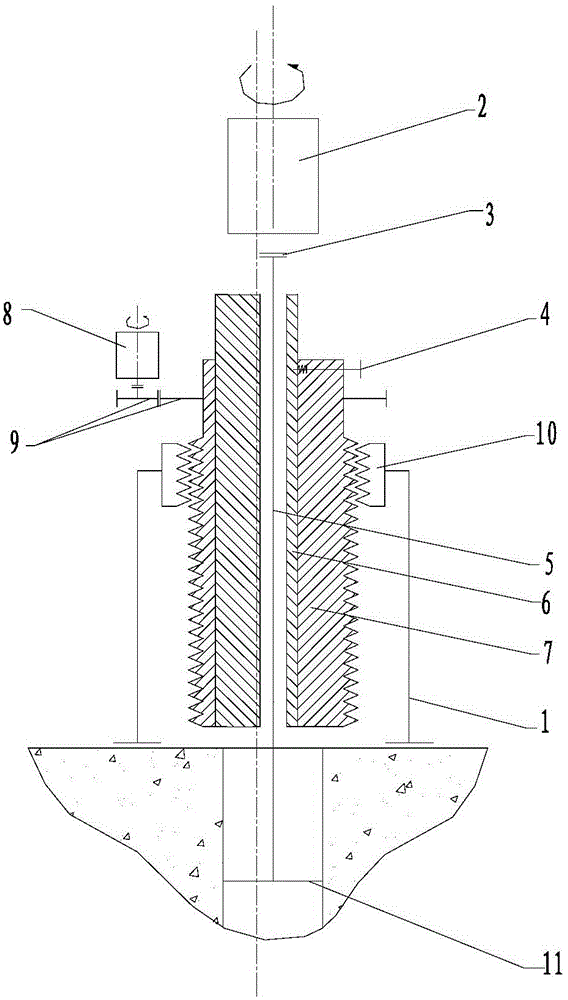

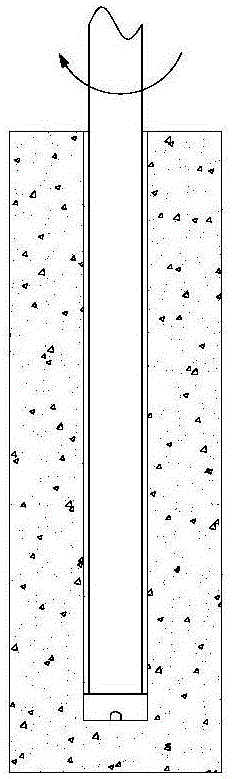

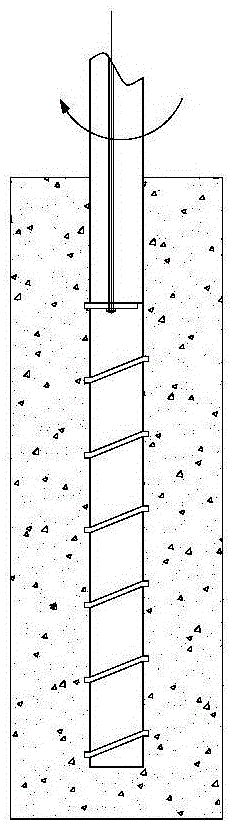

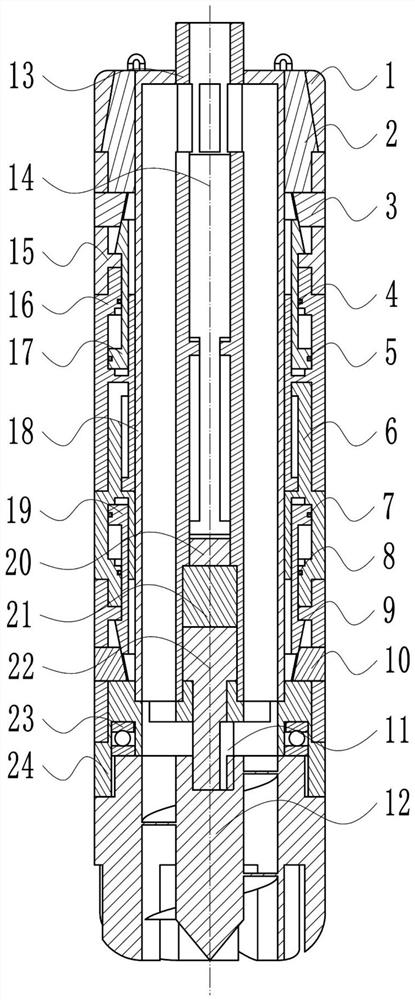

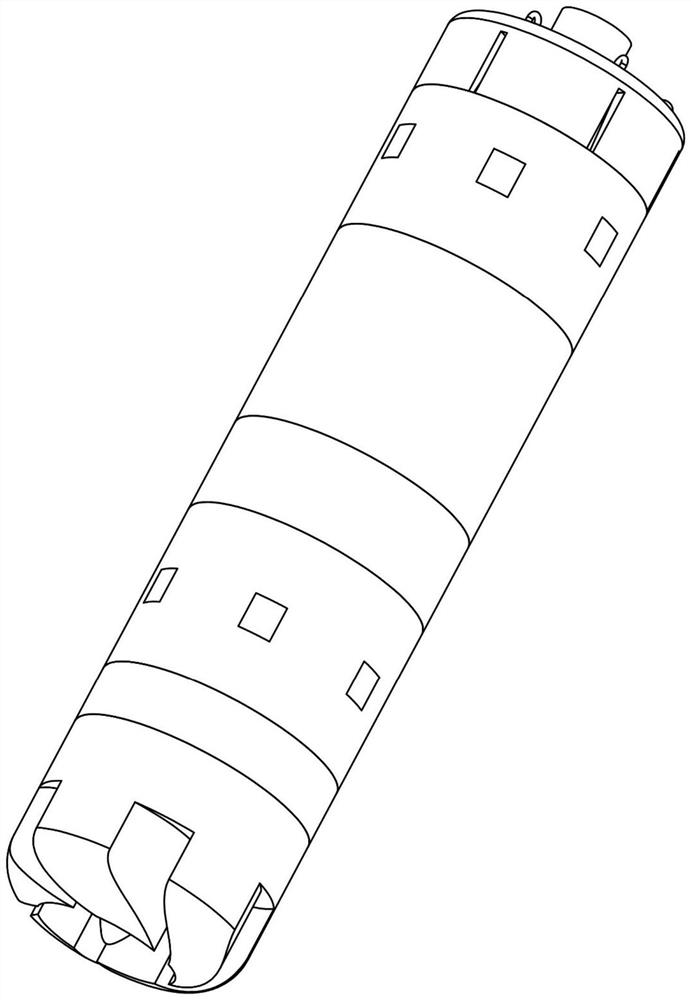

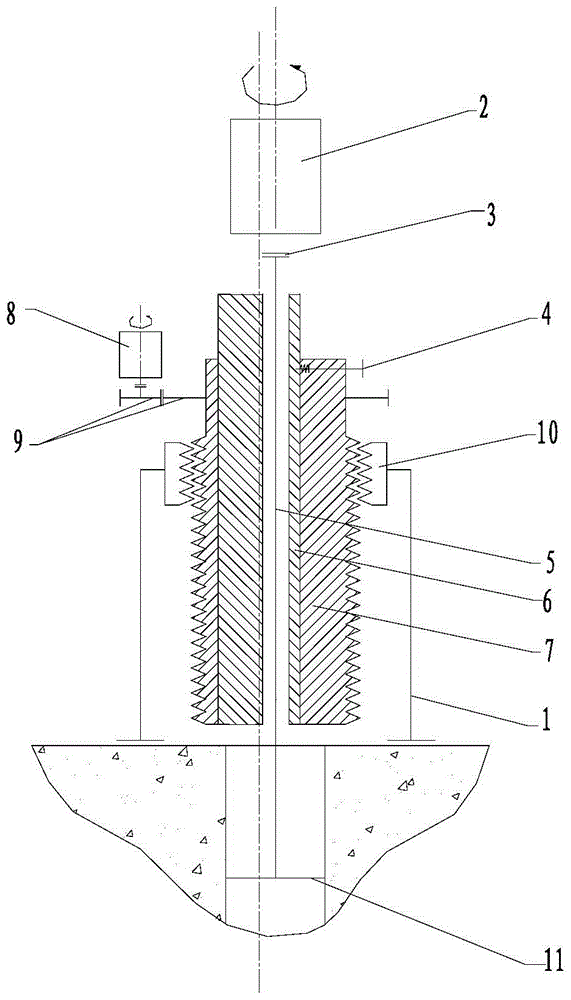

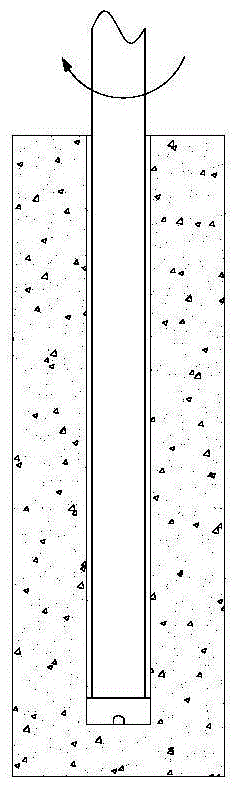

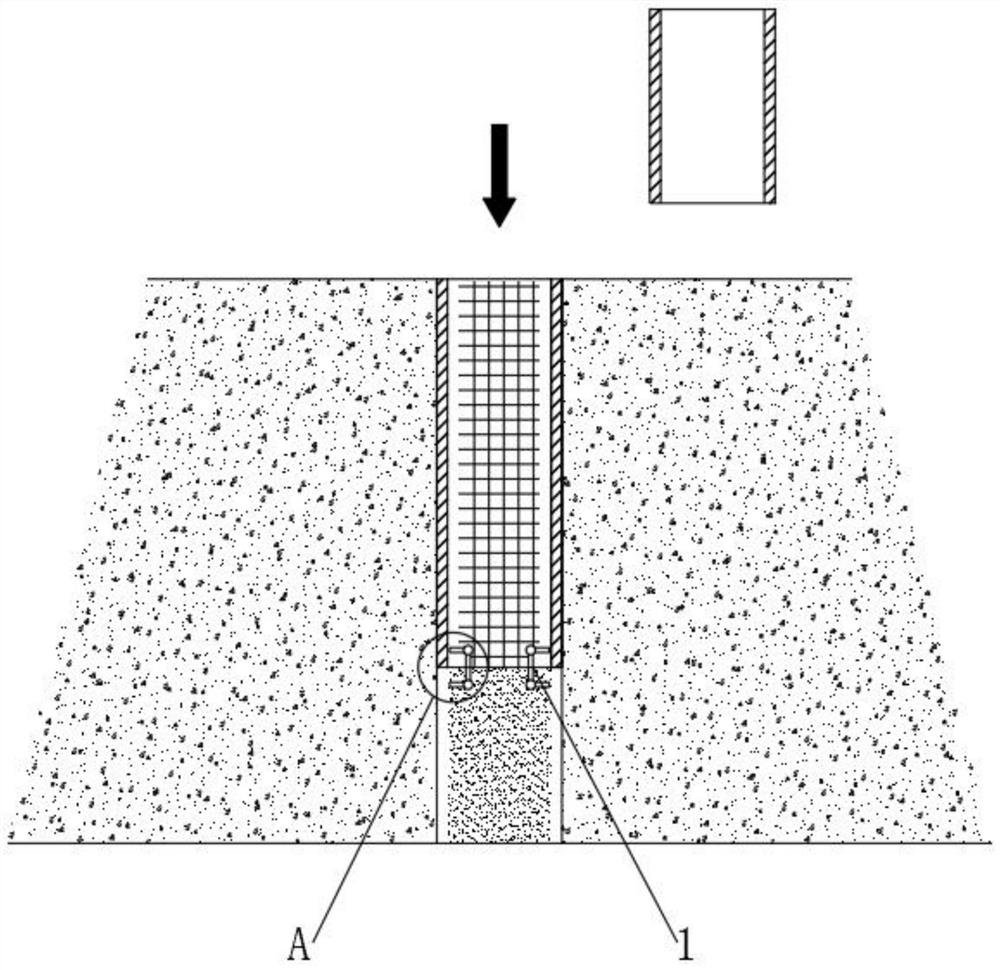

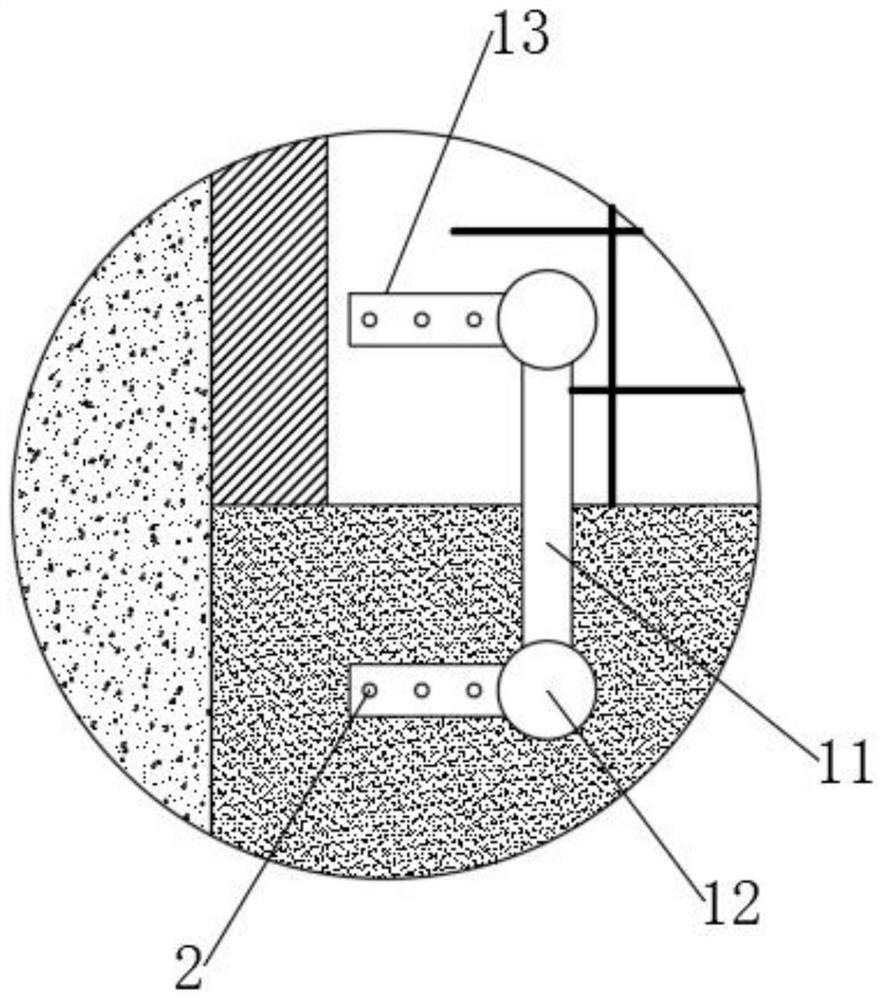

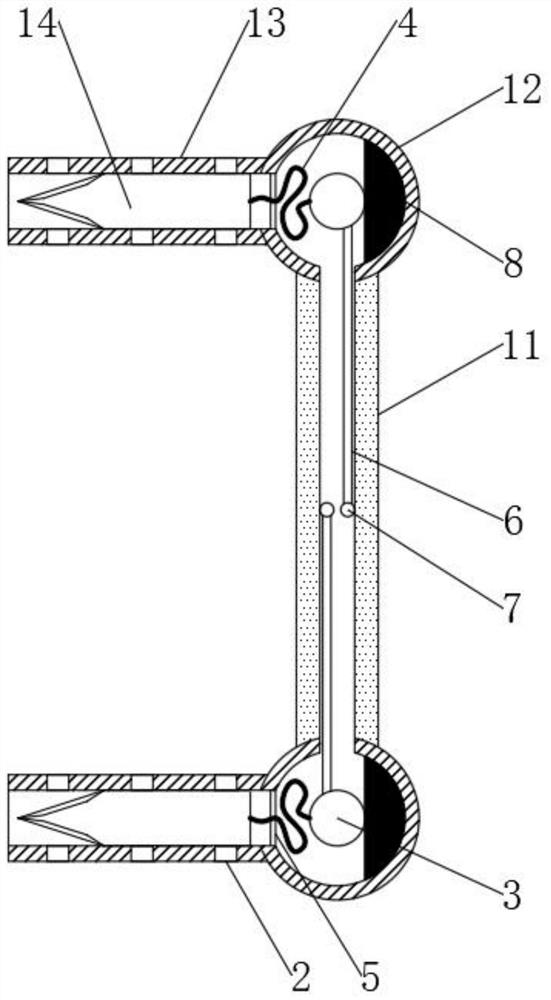

Seabed automatic drilling type piling device and method

ActiveCN113073644APile driving method is safeAchieve anchoringBulkheads/pilesDrilling machines and methodsLithologyMooring

The invention discloses a seabed automatic drilling type piling device and method. The seabed automatic drilling type piling device comprises an expansion fixing module, an upper anchoring module, a lower anchoring module, a chip removal module and a drilling module, and a mooring rope can be dragged to automatically drill into a seabed rock stratum to achieve anchoring; the drilling module can drill the seabed rock stratum; the chip removal module can automatically transfer rock chips to the rear of the device, so that efficient chip removal and drilling are realized; the upper anchoring module and the lower anchoring module play a role of fixing the device during drilling, and can assist in anchoring after drilling to a specified anchoring depth; when an extrusion head is subjected to upward pulling force applied by the mooring rope, an expansion cover in the expansion fixing module deforms and opens under the action of the extrusion head, the friction force between the expansion cover and the rock chips is increased, and therefore reliable anchoring is achieved. The problems of insufficient seabed shallow non-diagenetic piling depth and unreliable anchoring are mainly solved, high automation and controllable piling depth are realized, and the seabed automatic drilling type piling device and method are suitable for piling operation requirements of different water depths and various seabed lithology.

Owner:SOUTHWEST PETROLEUM UNIV

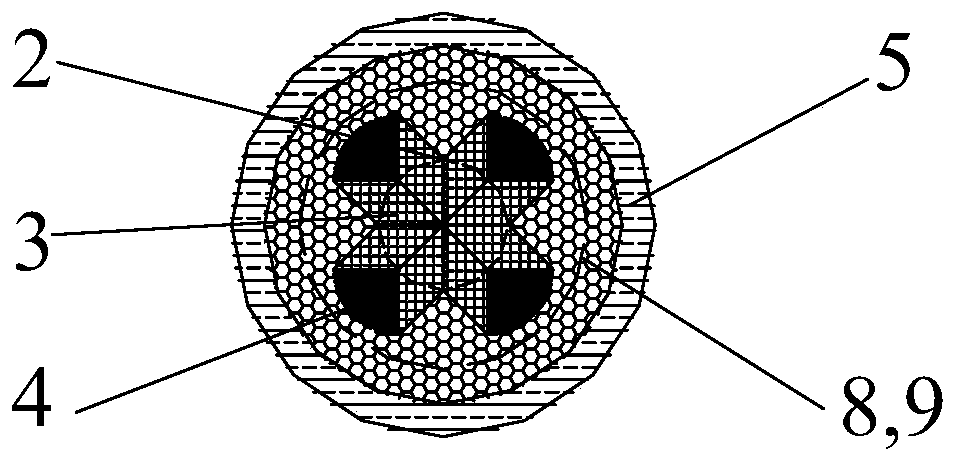

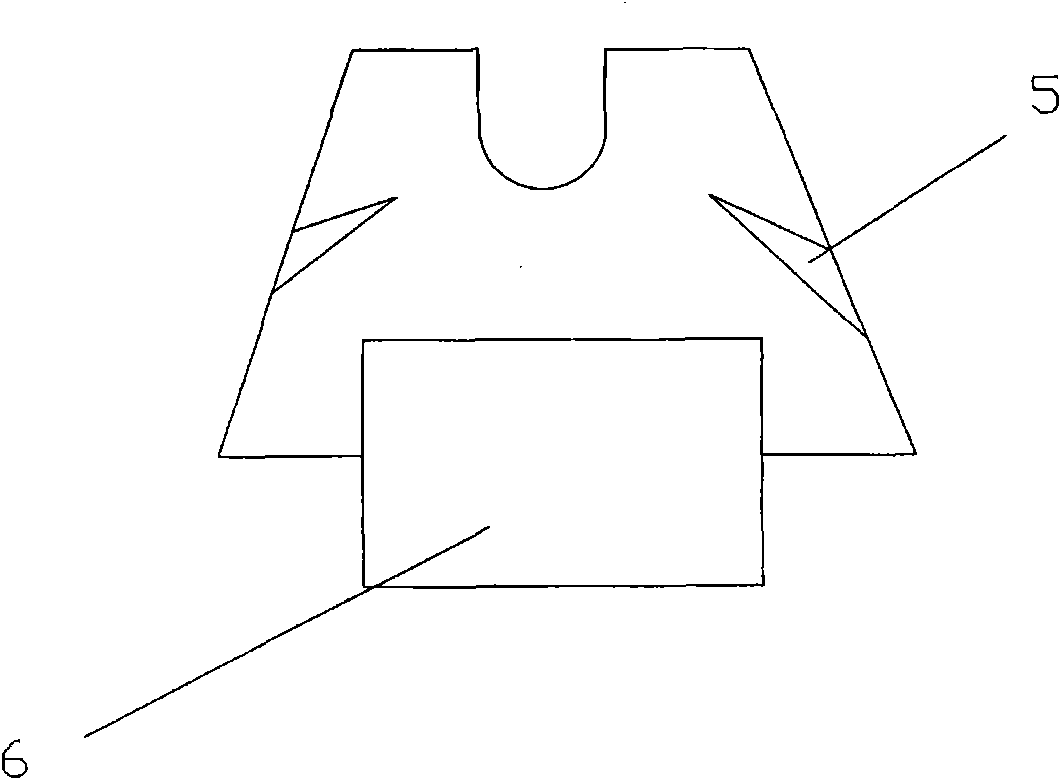

Smooth FRP bar anchoring method

ActiveCN111024491AAvoid pinchingAvoid direct clampingMaterial strength using tensile/compressive forcesFiberEngineering

The invention discloses a smooth FRP (fiber reinforced plastic) bar anchoring method which comprises the following steps: 2-4 kerfs for dividing an anchoring end of a smooth FRP bar into a plurality of parts capable of being opened are formed in the anchoring end of the smooth FRP bar along the axial direction of the bar from the end surface; filler is arranged among a plurality of expandable parts of the anchoring end to enable the anchoring end to form an expanded end, and the expanded end is anchored through a sleeve arranged at the anchoring end in a sleeving mode. The sleeve is a steppedinner-diameter sleeve and comprises a sleeve free end and a sleeve loading end, and the inner diameter of the sleeve free end is larger than that of the sleeve loading end; the expanded end is a conical expanded end; a resin-quartz sand mixture is poured into a gap between the free end of the sleeve and the conical expanded end, and the gap between the loading end of the sleeve and the smooth FRPbar is filled and cured with resin. According to the smooth FRP bar anchoring method, anchoring and connecting of the smooth FRP bars can be effectively and reliably achieved, the tensile strength ofthe smooth FRP bars is brought into full play, and the smooth FRP bars are subjected to ideal middle section complete explosion breaking type damage.

Owner:SOUTHEAST UNIV

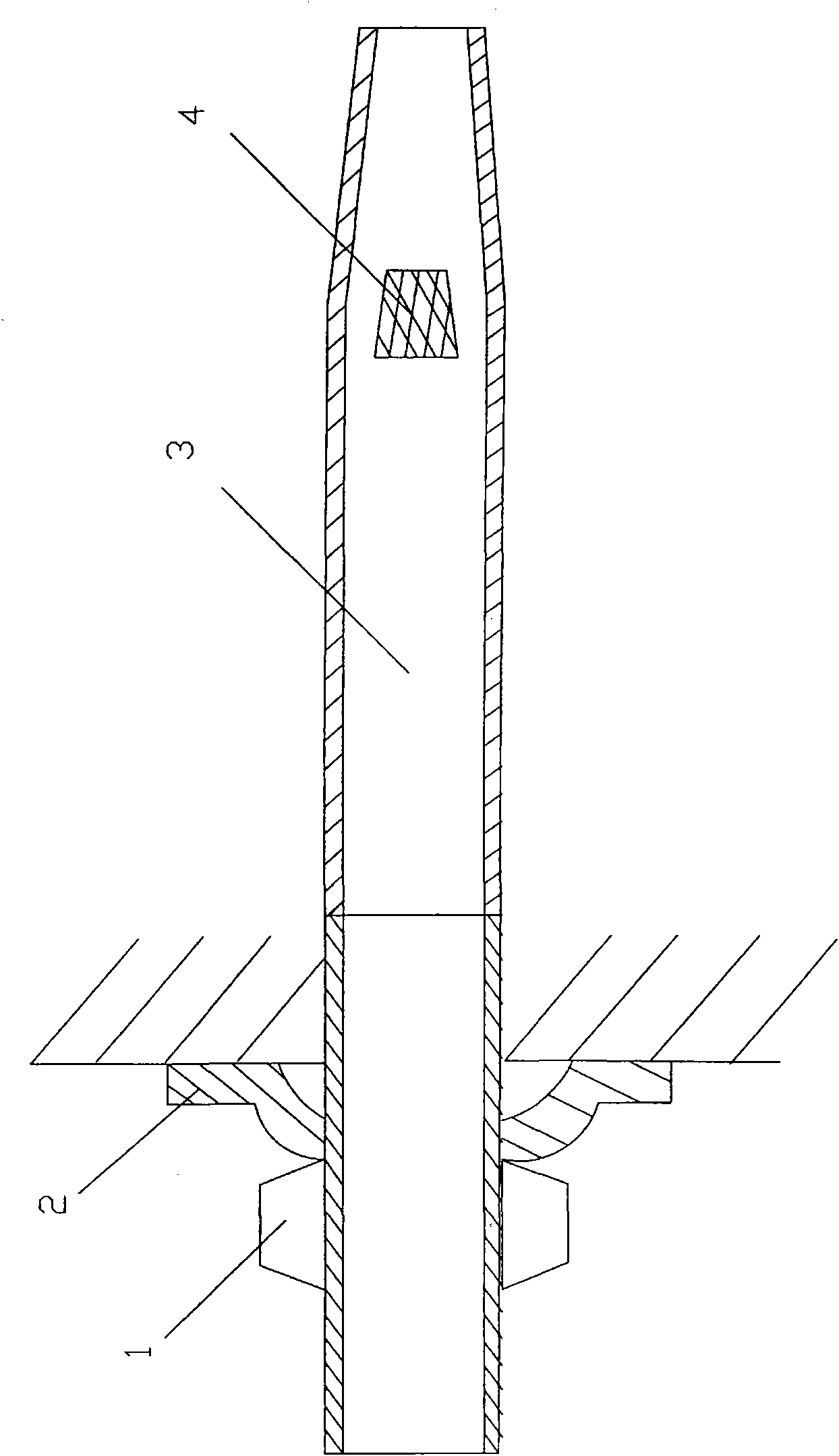

Pre-stressed anchoring conduit

The invention relates to a pre-stressed anchoring conduit based on improvement of an existing tube seam type anchor rod. The pre-stressed anchoring conduit comprises a rod body, an expanding core, a base plate and a nut, wherein the front half section of the rod body is a tubular rod body with a longitudinal joint, the rear half section of the rod body is a hollow anchor rod body in a full thread shape and made and rolled from a seamless steel tube, the tubular rod body and the hollow anchor rod body are welded into a whole, the expanding core is arranged at the front end of the conduit, and the nut and the base plate are arranged at the rear end of the conduit. According to the pre-stressed anchoring conduit, top anchoring can be achieved, anchoring force is obviously increased, and grouting to a rock stratum can be achieved through the hollow anchor rod body. Due to the fact that a pull ring is replaced with the nut at the tail end, stability is improved. The pre-stressed anchoring conduit is low in manufacturing cost, capable of greatly improving the anchoring effect of the tube seam type anchor rod, and quite high in economic benefit.

Owner:洛阳工岩科技有限公司

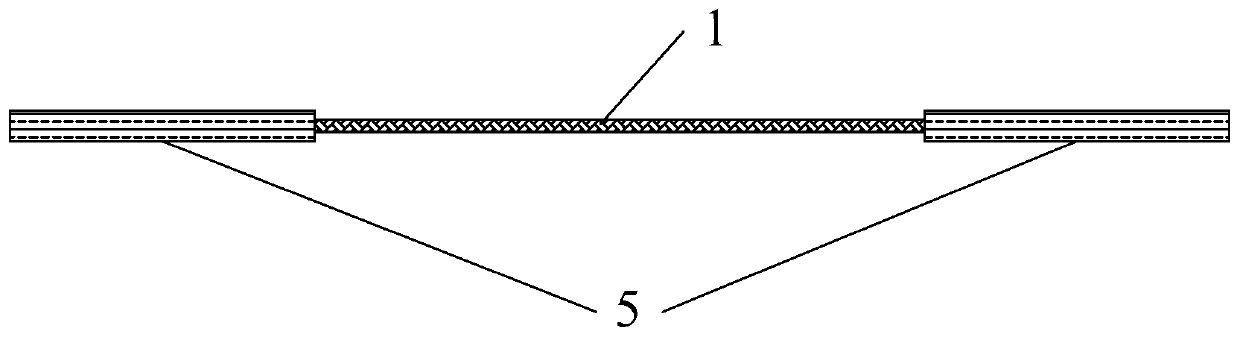

Device and method for mounting wire rope of architectural veneer

The invention discloses a device and method for mounting a wire rope of an architectural veneer. The device for mounting the wire rope of the architectural veneer comprises the veneer and is characterized in that: a connecting groove with a small opening and a large inside is arranged on the back of the veneer, not close to the edge; a connecting piece can be arranged in the connecting groove with a small opening and a large inside arranged on the back of the veneer, not close to the edge; the shape and the size of the cross section of the connecting piece are matched with those of the cross section of the connecting groove arranged on the back of the veneer, not close to the edge; the connecting piece is transversely inserted into the connecting groove; the direction of the connecting piece is changed from transverse to vertical so as to reach the top position of the connecting piece; the top position of the connecting piece is just positioned at a position with largest width in the connecting groove, and thus the connecting piece is buckled into the connecting groove; and one end of the wire rope is fixedly connected with the connecting piece, and the other end of the wire rope is connected with a building body. Therefore, perforating positions of the veneer and the building body do not need to be too precise and can be subjected to fine adjustment through the deformation ofthe wire rope when the veneer and the building body are connected with each other, thereby the accurate positioning and the firm connection between the veneer and the building body can be achieved. Moreover, the device for mounting the wire rope of the architectural veneer has the characteristics of simple structure, convenient construction and installation, and the like.

Owner:福建省兴雅达建设发展有限公司

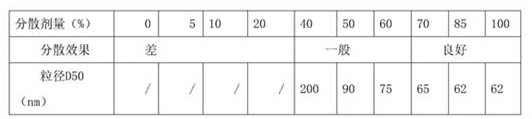

Preparation method of carbon black dispersion liquid for black polyimide film

The invention relates to a preparation method of a carbon black dispersion liquid for a black polyimide film, which is characterized by comprising the following steps of: dissolving a diamine monomer into a strong-polarity aprotic organic solvent, adding a dianhydride monomer in batches, controlling the molar ratio of the dianhydride monomer to the diamine monomer to be 0.7-0.98, controlling the reaction temperature to be 40-50 DEG C, and reacting for 40-60 minutes to obtain a carbon black dispersing agent of a polyamide acid system; the preparation method comprises the following steps: adding carbon black into a carbon black dispersant of a polyamide acid system, stirring, and grinding for 9-11 hours by using a grinding machine to obtain a carbon black dispersion liquid; the carbon black can realize high-stability dispersion in the aspect of preparing modified polyimide, and stable preparation of the high-performance carbon black-polyimide composite material is realized.

Owner:山东万达微电子材料有限公司

Carbon nanotube/nylon composite material as well as preparation method and conductive application thereof

ActiveCN112266488AGood electrical conductivity and impact toughnessLow resistivityPolyolefinSilane coupling

The invention relates to a carbon nanotube / nylon composite material as well as a preparation method and conductive application thereof, and belongs to the field of polymer conductive composite materials. The preparation method comprises the following steps: performing surface modification on a carbon nanotube by adopting plasma; carrying out grafting treatment on a surface-modified carbon nanotubeby adopting a silane coupling agent containing double bonds to obtain a polar carbon nanotube containing double-bond functional groups on the surface; and melting and mixing the polar carbon nanotubecontaining the double-bond functional group on the surface with a polyolefin toughening agent, nylon and an initiator, and carrying out extrusion molding to obtain the product. The carbon nanotube isanchored on the surface of the polyolefin elastomer, and finally the purpose of limiting the carbon nano tube at the nylon / toughening agent interface is achieved, so that the elastomer does not wrapthe carbon nano tube, and the conductive efficiency of the carbon nano tube is remarkably improved.

Owner:山东科华赛邦新材料股份有限公司

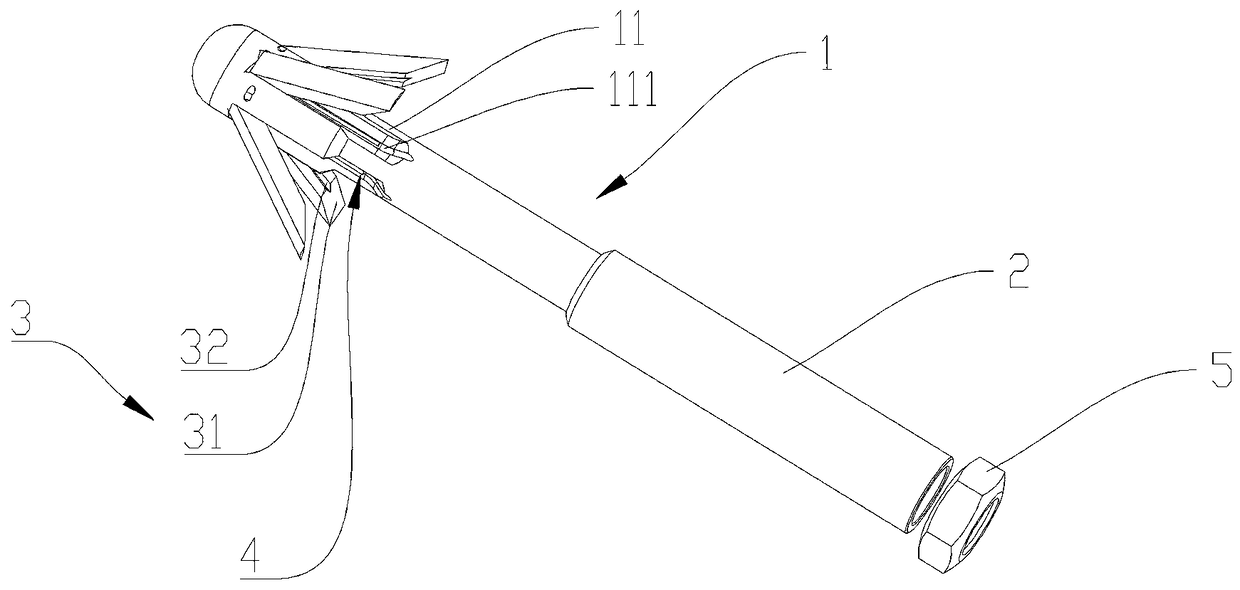

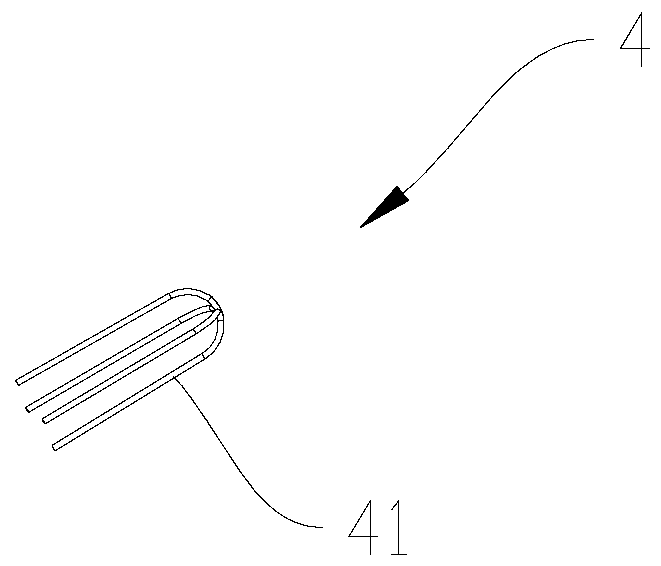

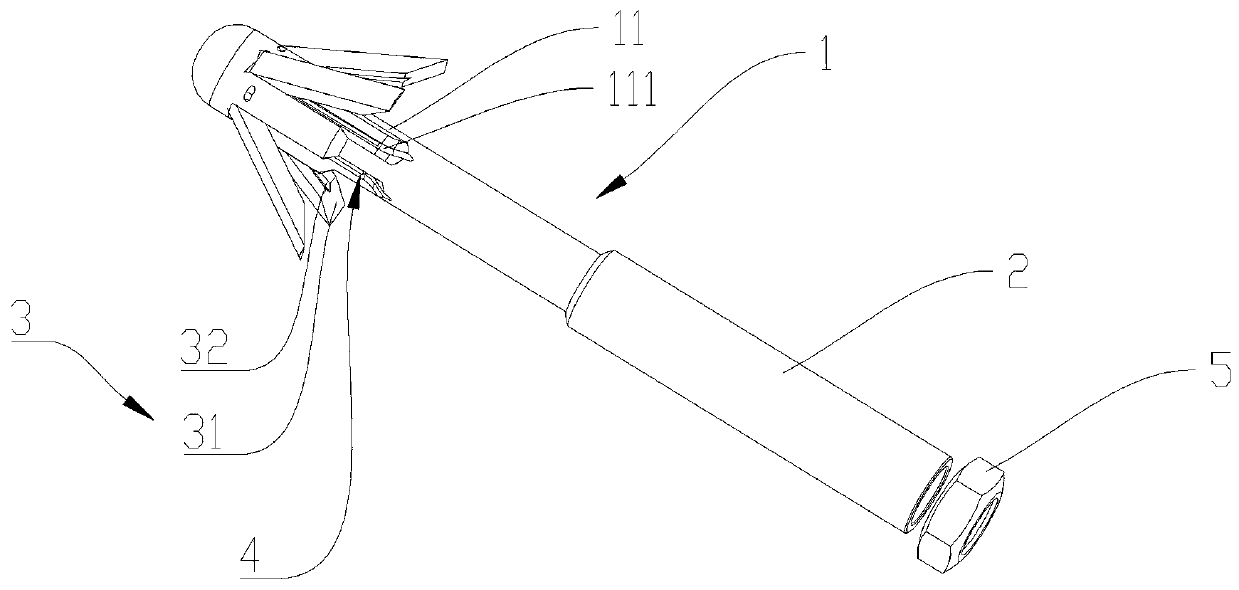

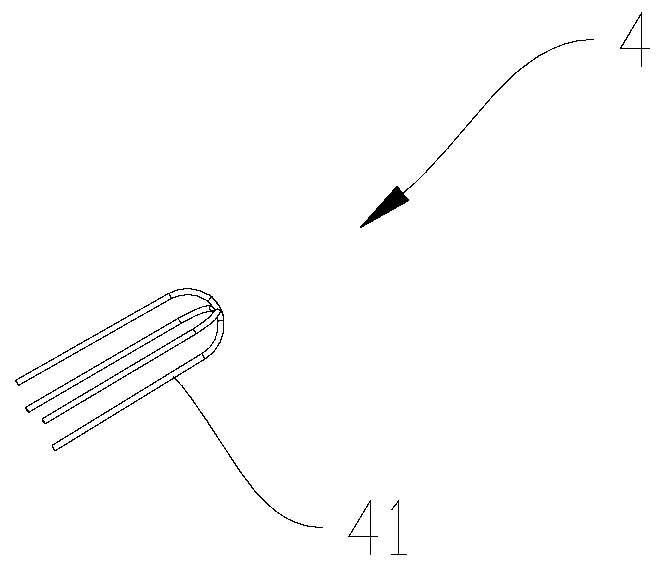

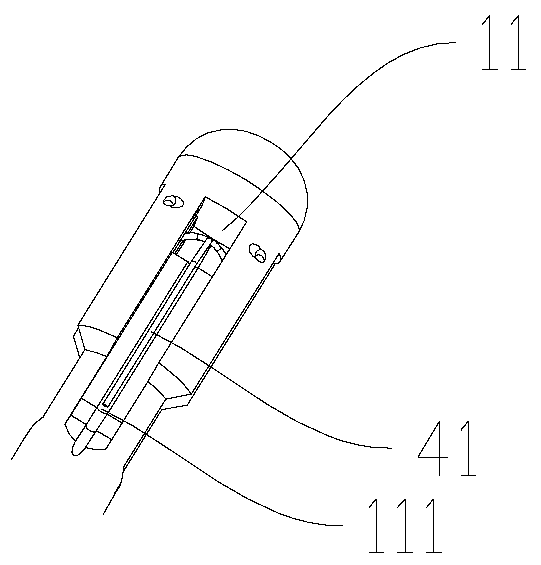

Bone bolt with reinforced anchoring sheets

InactiveCN108013923AImprove biomechanical stabilityAchieve anchoringInternal osteosythesisFastenersWhole bodyEngineering

The invention relates to the field of orthopedic surgery machinery, in particular to a bone bolt with reinforced anchoring sheets. The bone bolt includes a bone bolt body and an anchoring sheet assembly, the anchoring sheet assembly includes a core rod and a driving component used for driving the core rod to axially move in an assembly containing cavity, the whole body of the core rod is cylindrical, and a pair of strip-shaped platy components with certain width and suspended front ends obliquely extend outwards, are arranged at the two sides of the core rod and form the anchoring sheets; a pair of anchoring sheet slot holes running through the side walls are obliquely formed in the inner wall of the assembly containing cavity. By driving the driving component and utilizing the screw-thread fit between the driving component and the inner wall of the assembly containing cavity, the driving component is rotated to jack the core rod forward into the assembly containing cavity, the anchoring sheets are pushed to move forwards, and when reaching appropriate positions, the anchoring sheets can extend out of the bolt body along the anchoring sheet slot holes which are obliquely formed andrun through the side walls, so that an anchoring function is achieved. The biomechanical stability effect of bolt fixation can be improved.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

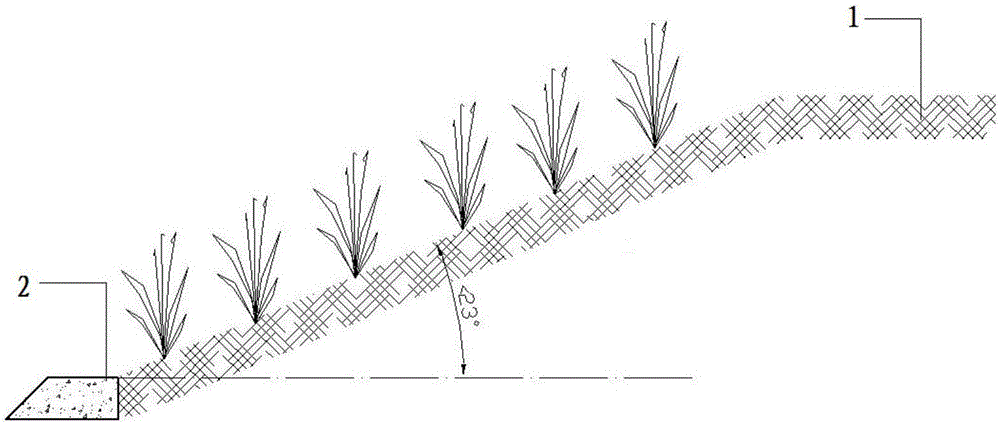

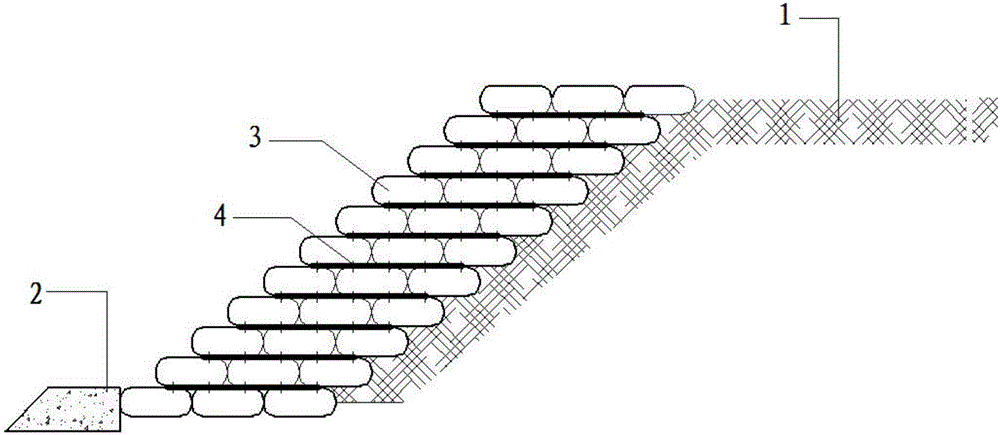

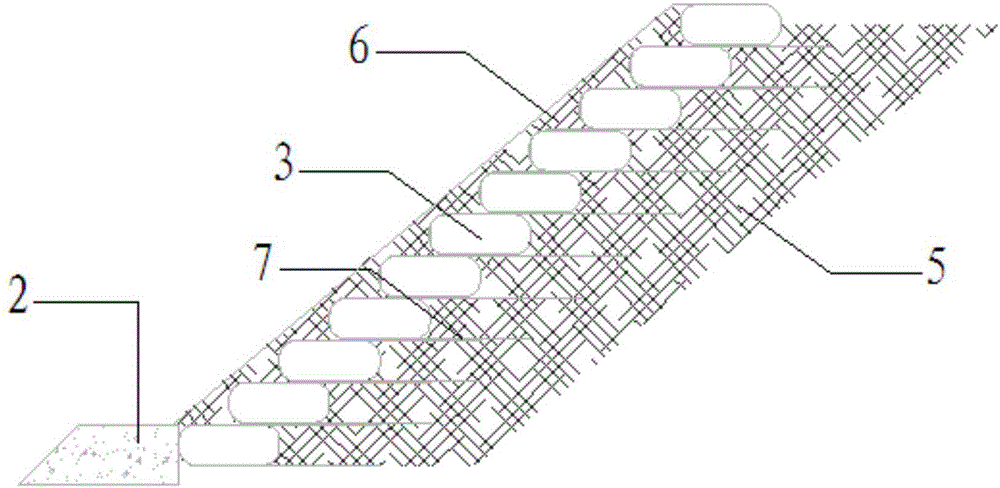

Ecological bag ecological slope protection system and construction method thereof

InactiveCN106400817AReduce usageSmall footprintExcavationsCultivating equipmentsLap jointEngineering

The invention discloses an ecological bag ecological slope protection system and a construction method thereof. The ecological bag ecological slope protection system comprises ecological bags staggered and stacked layer upon layer along the surface of a slope, and only one layer of ecological bags is arranged in the horizontal direction. The ecological bag ecological slope protection system further comprises geogrids. After one end of each geogrid is wound around the corresponding ecological bags, the two ends of the geogrid are anchored in the slope together. The length-width ratio of the ecological bags is 10 or above. The width of the parts, in the length direction of the ecological bags, of the geogrids exceeds the length of the ecological bags by 0.2 m or above. The sides of every two left-right adjacent geogrids are in lap joint in the middle of the corresponding ecological bags, and the lap width of the sides of every two left-right adjacent geogrids is 0.1 m or above. According to the ecological bag ecological slope protection system, the usage quantity of the ecological bags can be reduced, the construction cost can be reduced, and the occupied area of the slope protection system can be reduced.

Owner:GUANGZHOU CITY CONSTR COLLEGE

Thread-connection post-anchoring construction method and machining equipment

ActiveCN105128154ASolve the problem of safe and reliable screw fixingAchieve anchoringBuilding material handlingStone-like material working toolsWrenchMetal

The invention relates to a thread-connection post-anchoring construction method. The method comprises the steps that firstly, a hole is drilled in the designated position of a concrete, building stone and ceramic material base body through a water drill, wherein the diameter and depth of the hole correspond to a selected standard bolt and a metal screw core in specification; secondly, an internal screw milling machine spindle is inserted into the hole, large-pitch trapezoid threads are machined on the smooth inner hole; thirdly, a metal screw core matched with the trapezoid threads is screwed in the trapezoid thread hole through an inner hexagonal or linear spanner, and standard threads are machined on an inner hole of the metal screw core; fourthly, one end of the standard bolt is connected to the metal screw core, the other end of the standard bolt is connected with a connected object, the connected object is fixed to the base body, and a grouting material is used for grouting after installation on the occasion that disassembly is not needed. The large-pitch trapezoid thread metal screw core is used as post-anchoring parts to be installed inside the concrete, building stone and ceramic material base body, the external standard bolt is used as a connecting part, the fixed object is firmly fixed to the base body, and therefore the anchoring effect is achieved.

Owner:崔景宽

A seabed automatic drilling type piling device and method

ActiveCN113073644BPile driving method is safeAchieve anchoringBulkheads/pilesDrilling machines and methodsLithologyMechanical engineering

The invention discloses a seabed automatic drilling type piling device and method, which is composed of an expansion fixing module, an upper anchoring module, a lower anchoring module, a chip removal module and a drilling module, and can automatically drill into the seabed by dragging a cable Anchoring is realized in the rock formation; the drilling module can drill through the seabed rock formation, and the chip removal module can automatically move the cuttings to the rear of the device to achieve efficient chip removal and drilling; the upper anchor module and the lower anchor module It acts as a fixing device and can assist anchoring after drilling to the specified anchoring depth; when the extrusion head is subjected to the upward pull force exerted by the cable, the expansion cover in the expansion fixation module will deform and open under the action of the extrusion head, Increase the friction between the expansion cap and cuttings, so as to achieve reliable anchoring. The invention mainly solves the problems of insufficient non-diagenetic piling depth and unreliable anchoring in the shallow seabed, realizes high automation and controllable piling depth, and is suitable for piling operation requirements of different water depths and various types of seabed lithology.

Owner:SOUTHWEST PETROLEUM UNIV

Column joint connecting device of assembled steel structure system

InactiveCN106759860AImprove assembly speedImprove assembly qualityStrutsBuilding material handlingReinforced concreteRebar

The invention discloses a column joint connecting device of an assembled steel structure system and belongs to the technical field of structural engineering. The column joint connecting device comprises a lower column, an upper column, a lower column lifting hook and an upper column bent plate, the lower column and the lower column lifting hook are welded into a whole in a factory, and the upper column and the upper column bent plate are welded into a whole in the factory. Welding is completed in the factory, lifting is adopted for on-site assembly, and concrete is fully poured into the insides of the columns. A column joint is around a point of inflection, so that the point of inflection is slightly stressed; the concrete has certain connecting effect with reinforced concrete formed by the bent plate and the lifting hook inside the columns, and both size and length of the lifting hook and the bent plate can be adjusted to adjust connecting force, so that welding between the upper column and the lower column is not a must and depends on stress of the columns. The column joint connecting device can greatly improve construction speed and quality and can adapt to development of assembled steel structures.

Owner:BEIJING UNIV OF TECH

pre-anchor catheter

ActiveCN103161485BWith grouting functionAchieve anchoringAnchoring boltsEngineeringMechanical engineering

The present invention relates to a pre-anchored conduit, which is an improvement to the existing pipe-slit anchor, comprising: a rod body, an expansion core, a backing plate, and a nut; the front half of the rod body is a tubular rod body with a longitudinal seam , the second half is a hollow bolt body made of seamless steel pipe and rolled into a fully threaded shape, which is connected into a whole by welding. The front end of the rod body is provided with an expansion core, and the rear end of the rod body is provided with a nut and a backing plate . The bolt can realize top fixing, significantly increase the anchoring force, and at the same time, the hollow bolt body can be used for grouting to the rock formation. In addition, the tail end uses a nut to replace the pull ring, which is more stable. The anchor rod has low production cost, can significantly improve the anchoring effect of the pipe-slit anchor rod, and has high economic benefits.

Owner:洛阳工岩科技有限公司

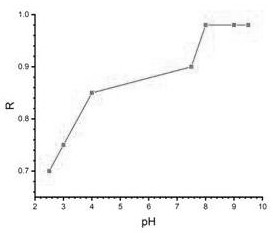

Composite proton exchange membrane and preparation method thereof

ActiveCN110676496BAchieve anchoringLimit water swellingFuel cellsPoly ether ether ketonePhysical chemistry

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A New Expansion Anchor

ActiveCN108843667BControl the degree of expansionPlay the role of expansion and fixationDowelsReciprocating motionEngineering

The invention provides a novel expansion anchor bolt, and belongs to the technical field of anchor bolt fixing. The novel expansion anchor bolt is used for fastening an installing base surface and comprises an anchor rod and a sleeve which is arranged on the outer surface of the anchor rod in a sleeving mode in the mode of doing reciprocating motion in the extending direction of the anchor rod, acontaining cavity is formed in the anchor rod, and expansion bodies and a cocking part used for being connected with the expansion bodies in a butting-joint mode to enable the non-hinged ends of the expansion bodies to be capable of at least partially protruding out of a containing groove; and the non-hinged end of each expansion body is provided with a guiding surface, and the guiding surfaces are used for being connected with one end of the sleeve in an abutting mode till the expansion bodies are expanded in the mode that the non-hinged ends rotate to make contact with the installing base surface. According to the novel expansion anchor bolt, the sleeve abuts against the guiding surfaces to enable the expansion bodies to be expanded, and the expanding and fixing effects are achieved. Thestructure is simple, anchoring can be achieved only by rotating or knocking the sleeve, labor is saved, and the expansion degree of the expansion bodies is controlled by controlling the abutting length of the sleeve.

Owner:百益百利(福州)幕墙工程有限公司

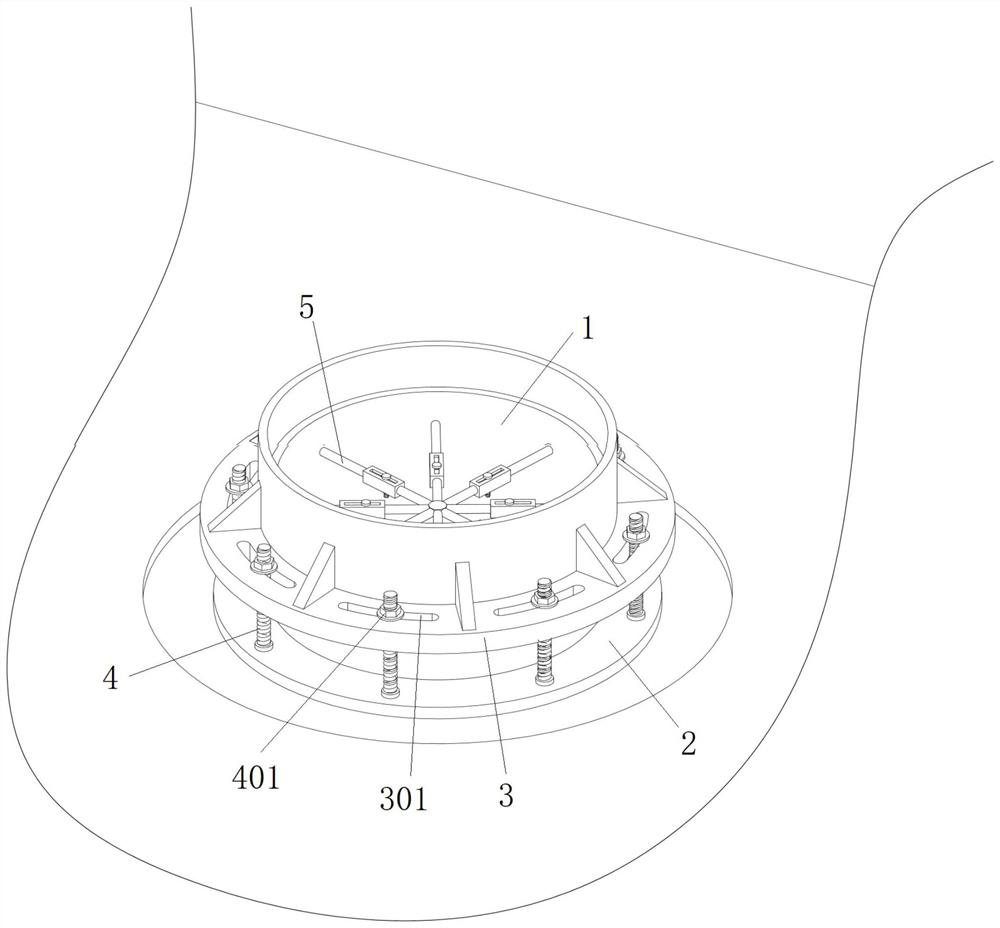

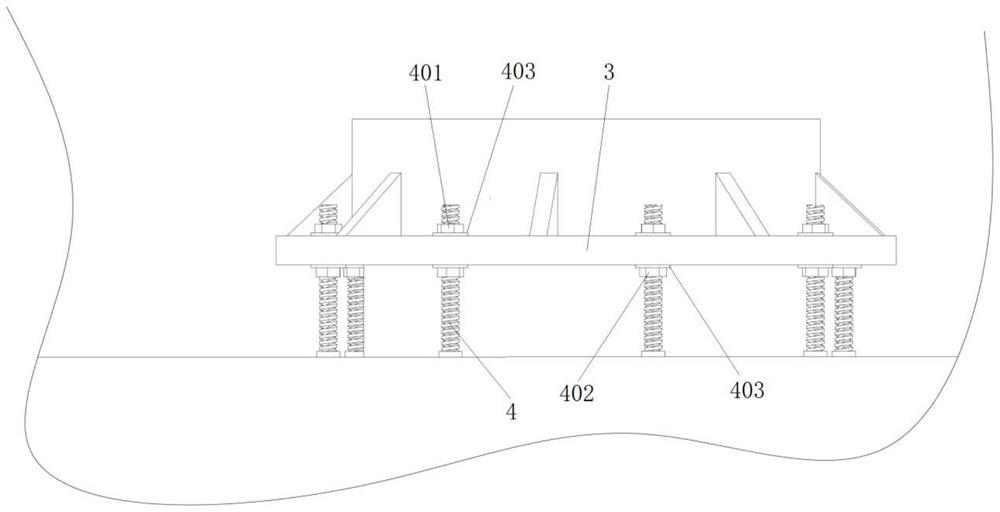

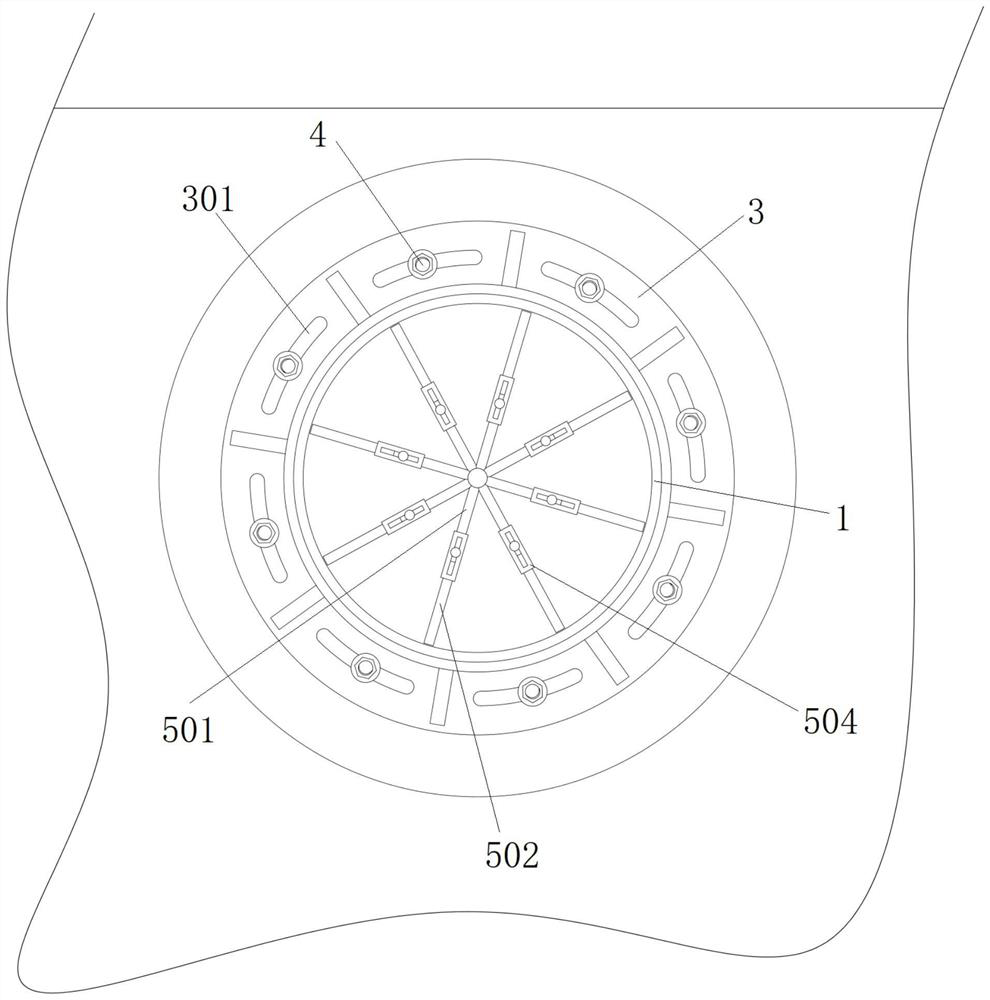

Adjustable well seat for municipal road

PendingCN114457851AAvoid jumpingEnsure driving stabilityArtificial islandsSewerage structuresAgricultural engineeringStructural engineering

The invention discloses an adjustable well seat for municipal roads. The adjustable well seat comprises a shaft template, a supporting seat and a well seat body, and an adjusting assembly is arranged between the supporting seat and the well seat body; the adjusting assembly comprises a plurality of adjusting studs, and the well seat body is provided with a plurality of arc-shaped holes in one-to-one correspondence with the adjusting studs. The upper ends of the adjusting studs penetrate through the corresponding arc-shaped holes, a positioning nut is arranged on the adjusting stud at the upper part of each arc-shaped hole, and an adjusting nut is arranged on the adjusting stud at the lower part of each arc-shaped hole; and the positioning nut and the adjusting nut on the adjusting stud can clamp the well seat body. By adjusting the height of the adjusting nut on each adjusting stud, the height of the top of the well seat body in each direction can be adjusted, then it can be guaranteed that the height of the top of the well seat body and the height of the surrounding road surface in each direction are approximately consistent, and finally it is avoided that a large height difference exists between the well seat body and the road surface in a certain direction; therefore, the bumping of the passing vehicles is prevented, and the driving stability is ensured.

Owner:王伟

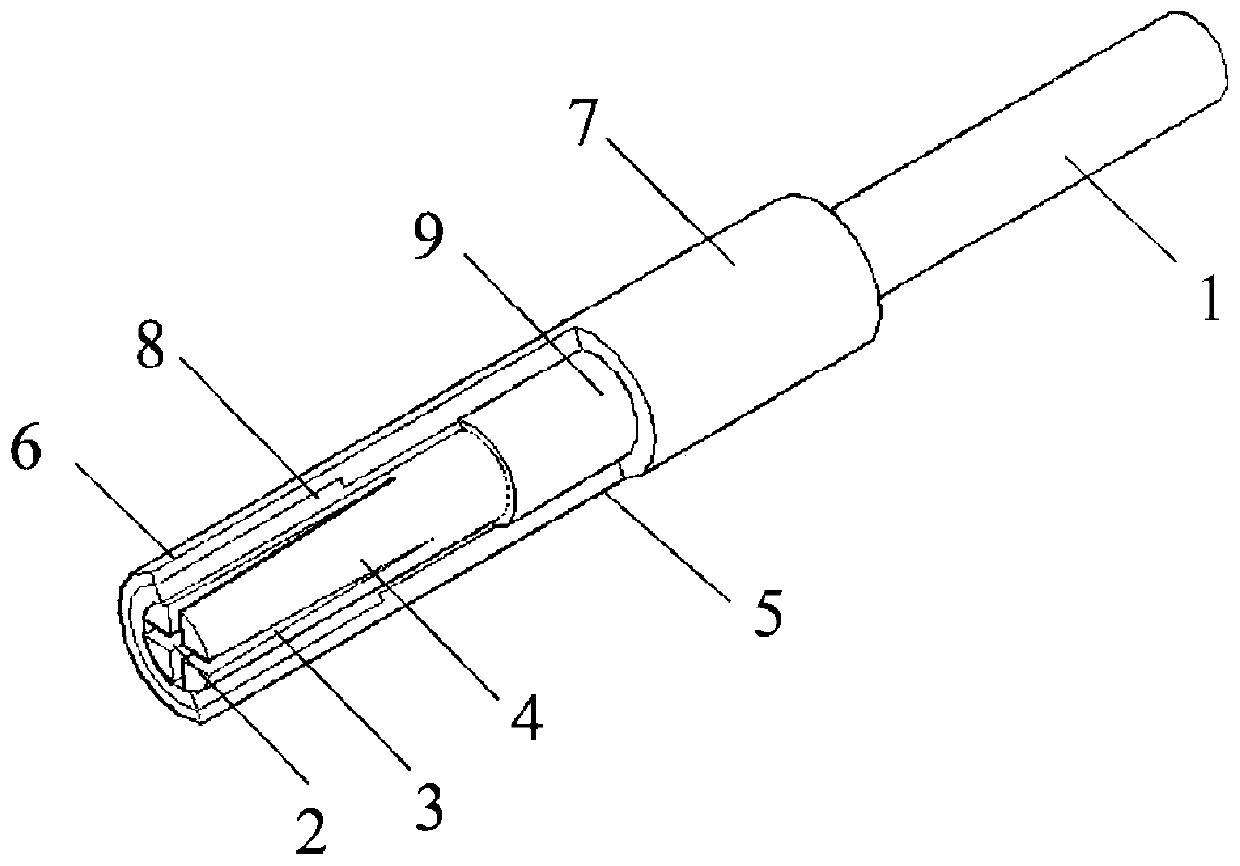

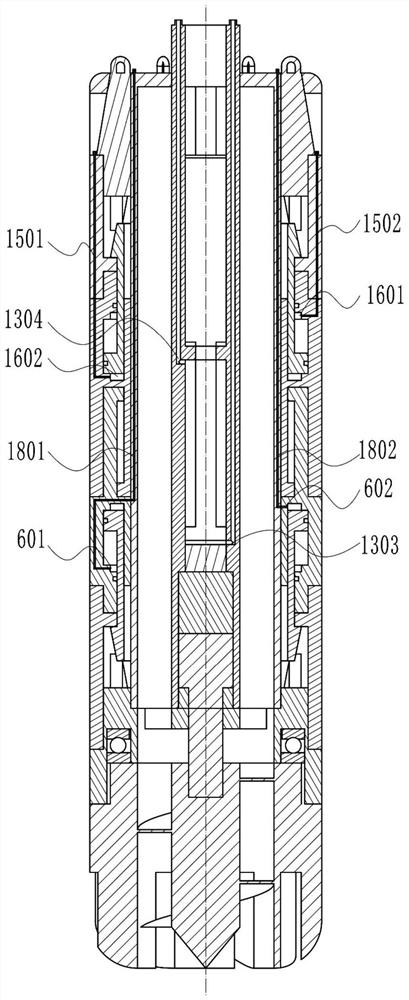

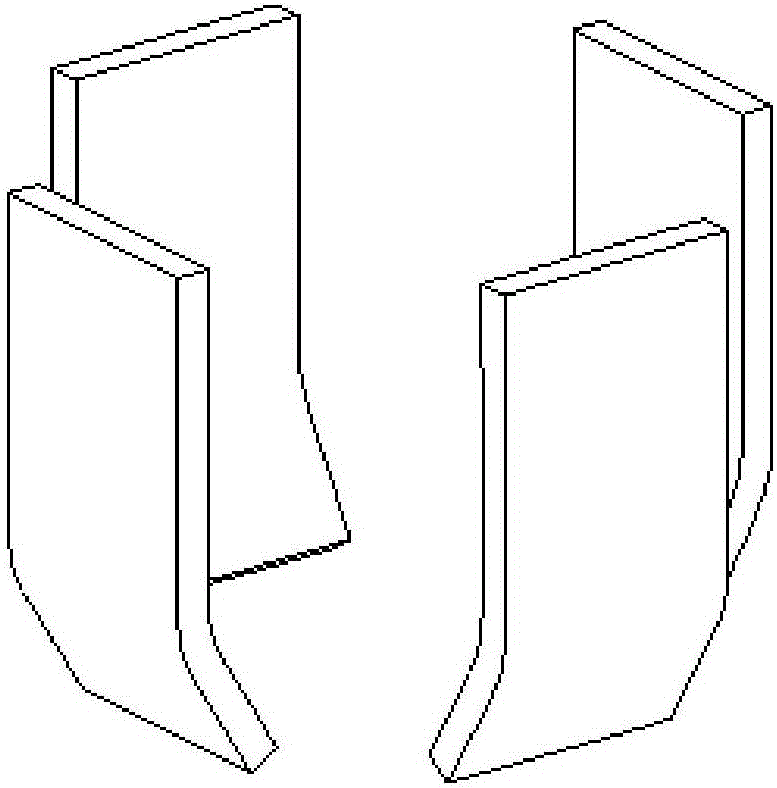

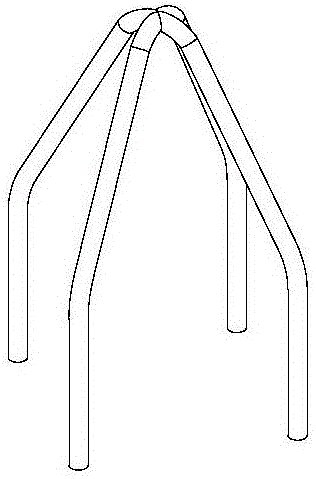

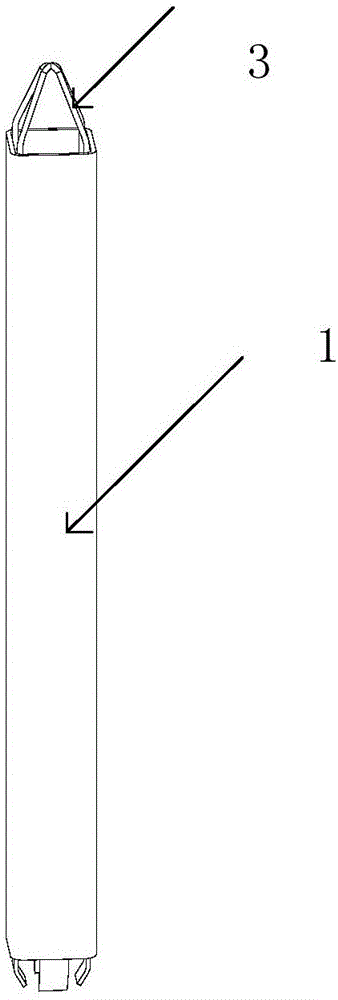

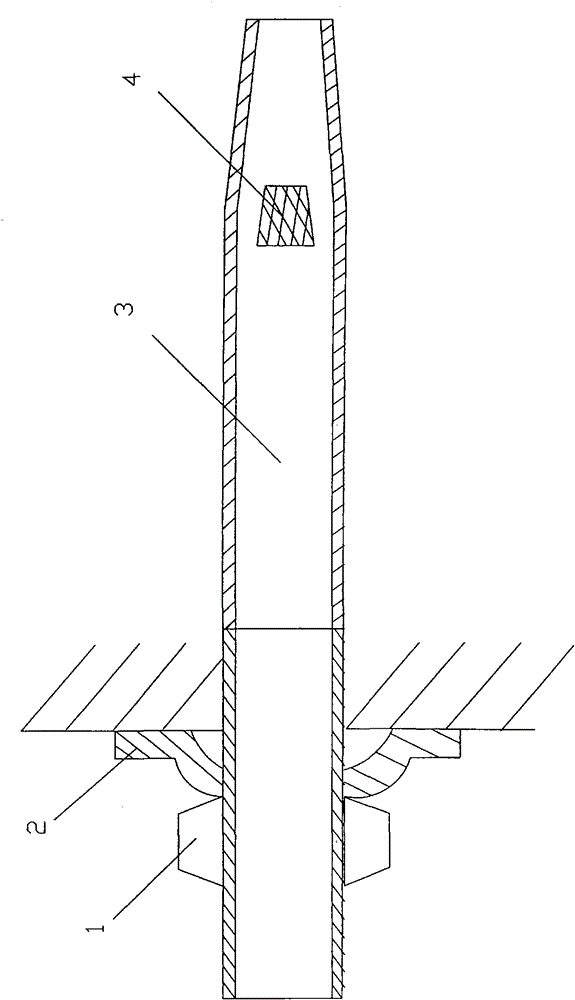

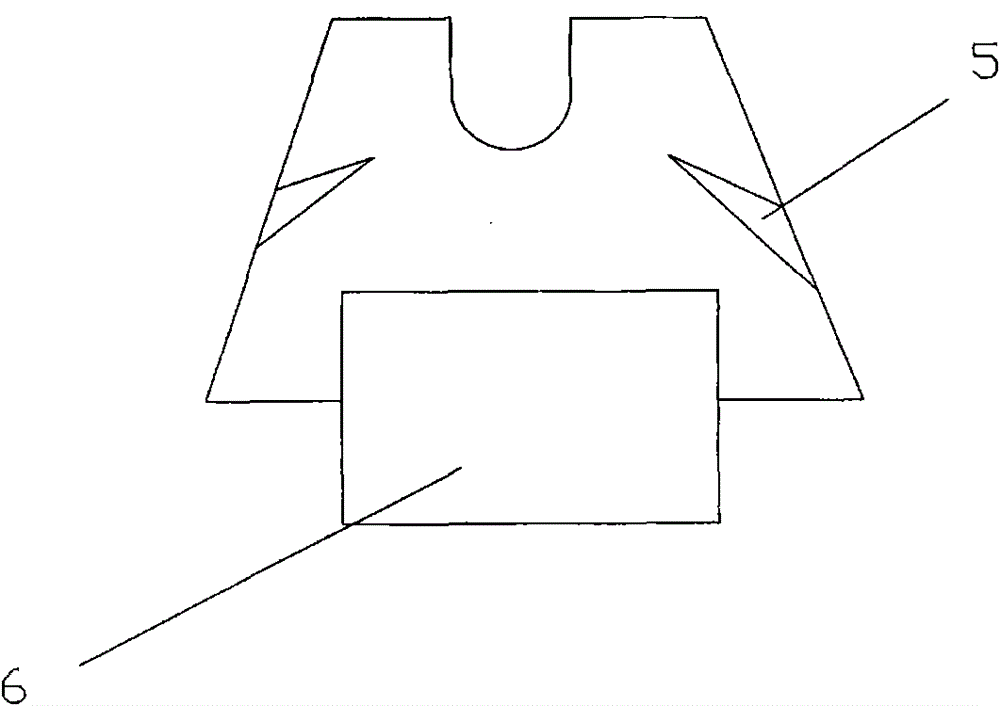

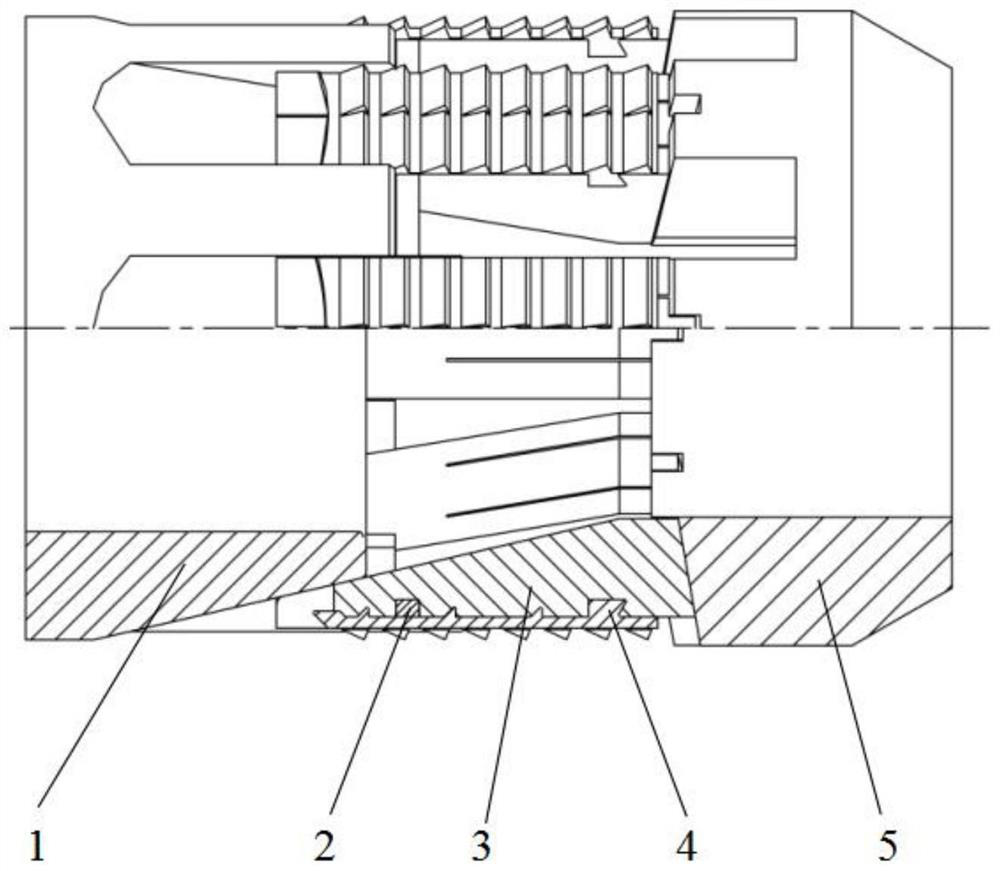

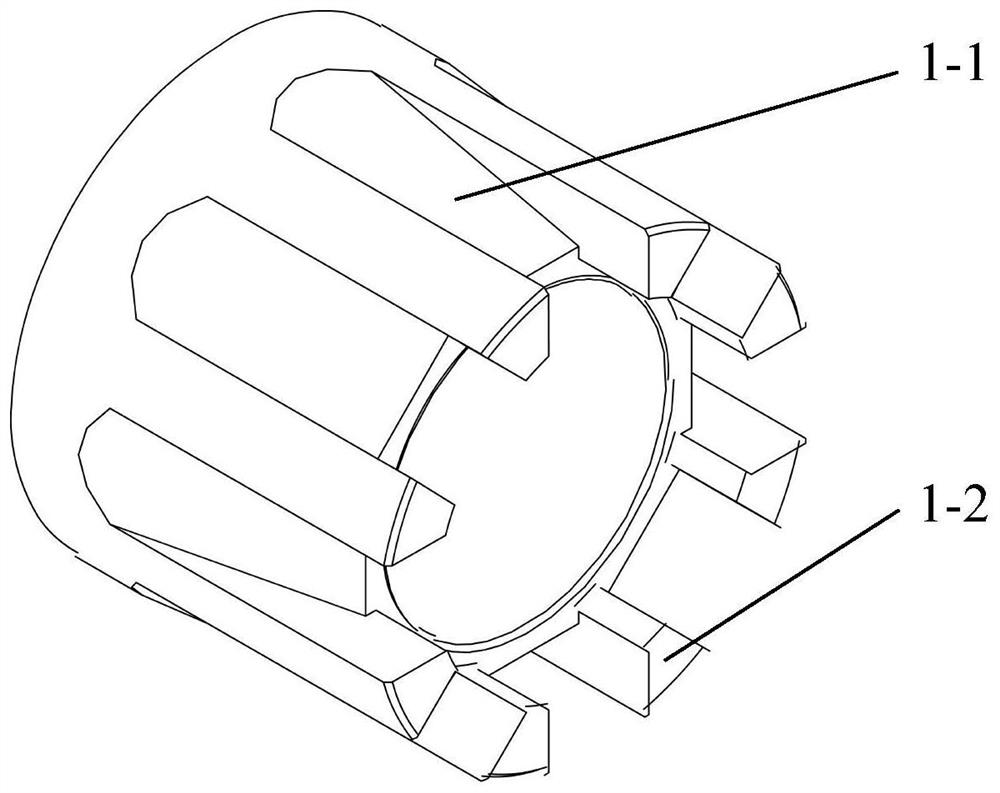

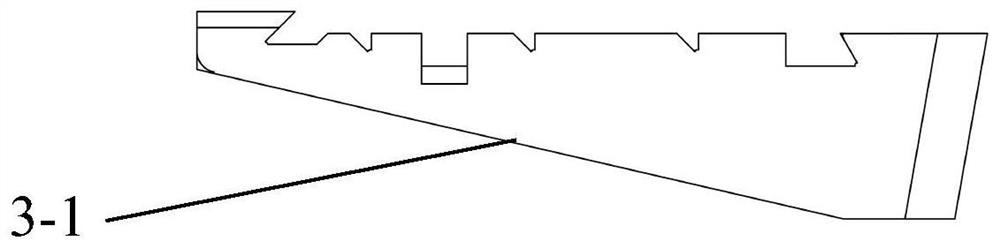

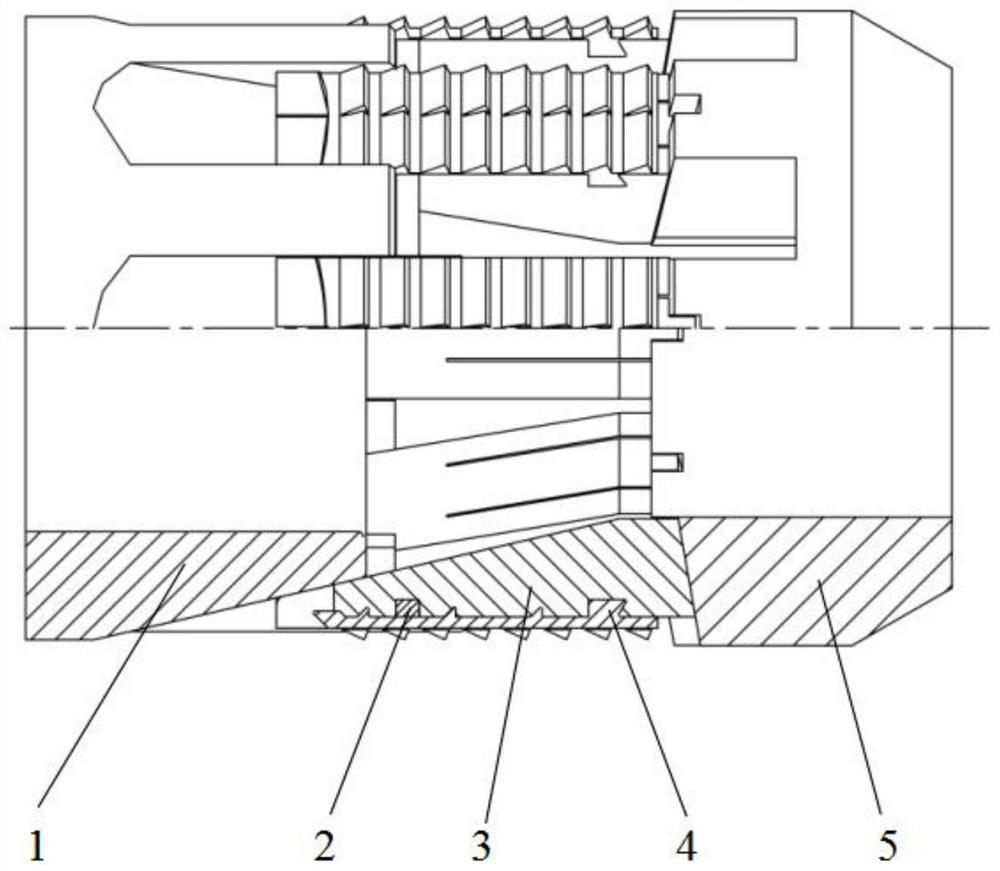

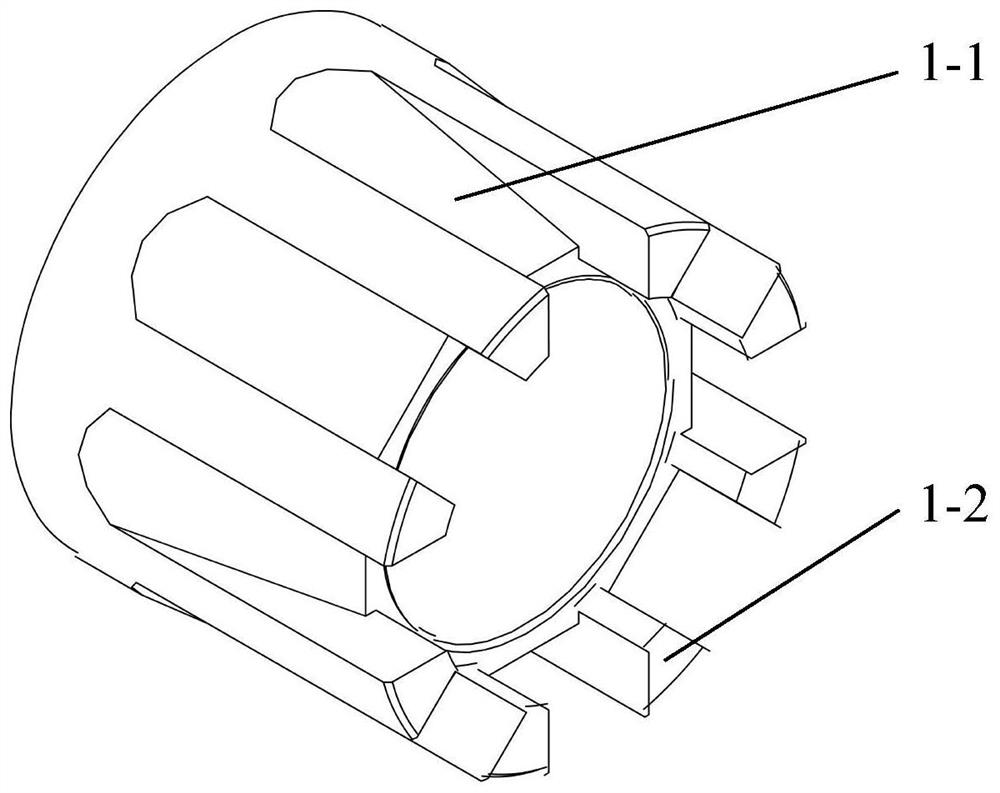

Slip assembly capable of being rapidly milled for downhole tool

ActiveCN112031699ASimple structureEasy to mass produce and assembleSealing/packingOil fieldEngineering

The invention relates to the field of oil field oil production engineering, and belongs to a slip assembly capable of being rapidly milled for a downhole tool. The slip assembly solves the problem that an integral slip and a block type slip used on a common bridge are not easy to mill. The slip assembly comprises a cone (1), a main body assembly and an inclined body (5), wherein the cone (1) is used for expanding and supporting a slip base body (3) during setting, and limiting the circumferential displacement of the slip base body (3); the main body assembly is inserted between the cone (1) and the inclined body (5); the inclined body (5) is used for supporting the tail part of the slip base body (3); the main body assembly comprises a fixing ring (2), the slip base body (3) and a slip piece (4); and the fixing ring (2) hoops the slip base body (3) into a circle, and the slip piece (4) is inserted into the upper surface of the slip base body (3). The slip assembly has the advantages ofbeing simple in structure, safe, reliable, capable of being rapidly milled, small in size of the rest part of the slip base body after milling and the like.

Owner:PETROCHINA CO LTD +1

Post-anchoring construction method and processing equipment for threaded connection

ActiveCN105128154BSolve the problem of safe and reliable screw fixingAchieve anchoringBuilding material handlingStone-like material working toolsScrew threadIndustrial engineering

The invention relates to a thread-connection post-anchoring construction method. The method comprises the steps that firstly, a hole is drilled in the designated position of a concrete, building stone and ceramic material base body through a water drill, wherein the diameter and depth of the hole correspond to a selected standard bolt and a metal screw core in specification; secondly, an internal screw milling machine spindle is inserted into the hole, large-pitch trapezoid threads are machined on the smooth inner hole; thirdly, a metal screw core matched with the trapezoid threads is screwed in the trapezoid thread hole through an inner hexagonal or linear spanner, and standard threads are machined on an inner hole of the metal screw core; fourthly, one end of the standard bolt is connected to the metal screw core, the other end of the standard bolt is connected with a connected object, the connected object is fixed to the base body, and a grouting material is used for grouting after installation on the occasion that disassembly is not needed. The large-pitch trapezoid thread metal screw core is used as post-anchoring parts to be installed inside the concrete, building stone and ceramic material base body, the external standard bolt is used as a connecting part, the fixed object is firmly fixed to the base body, and therefore the anchoring effect is achieved.

Owner:崔景宽

A kind of polyester modified silicone leveling agent and preparation method thereof

The invention discloses a polyester modified silicone leveling agent and a preparation method thereof. The leveling agent is composed of hydrogen-terminated polydimethylsiloxane and single-ended allyl polycaprolactone under the action of a catalyst, through It is obtained by catalytic addition reaction, wherein the molar ratio of hydrogen-terminated polydimethylsiloxane to single-ended allyl polycaprolactone is 1-1.5:2; the mass fraction of the catalyst in the total material is 0.001-0.005%. The primary hydroxyl group contained in the polyester modified silicone leveling agent can react with the resin base material, and realize the anchoring of the active ingredient on the coating surface after film formation. It has excellent heat resistance and can be used as a solution, water emulsion or 100% It is used in the form of stock solution.

Owner:优卡化学(上海)有限公司

A fast millable slip assembly for downhole tools

The invention relates to the field of oilfield oil production engineering, and belongs to a slip component which can be quickly milled and milled for downhole tools. The invention solves the problem that the integral slips and segmented slips used on common bridge plugs are not easy to be milled, and includes: a cone (1), a main assembly and an italic body (5). Expand and support the slip base (3) during setting, while limiting the circumferential displacement of the slip base (3); the main body assembly is inserted and installed between the cone (1) and the italic body (5); the italic body (5) It is used to support the tail of the slip base (3); the main body assembly includes a fixing ring (2), a slip base (3), and a slip sheet (4); wherein the fixing ring (2) attaches the slip base ( 3) Hoop into a circle, and insert the slip sheet (4) on the upper surface of the slip base (3). The invention has the advantages of simple structure, safety and reliability, rapid milling and small volume of the remaining part of the slip base after milling.

Owner:PETROCHINA CO LTD +1

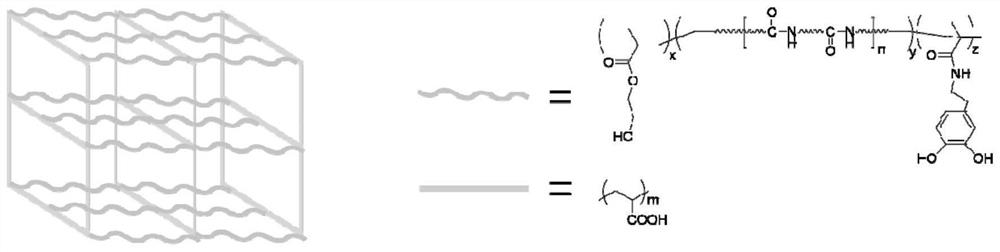

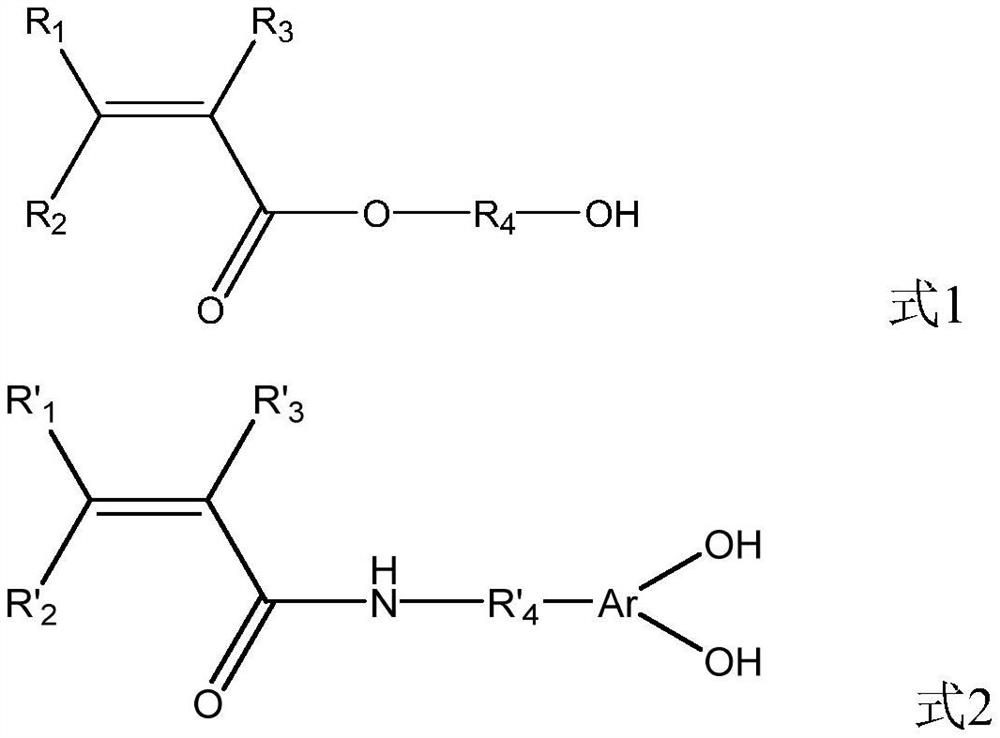

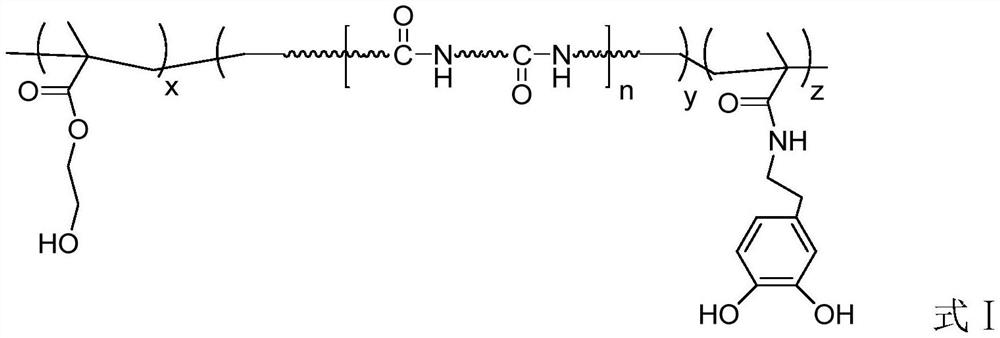

Binder and battery containing same

PendingCN114373931AImprove toughnessImprove self-healing abilityCell electrodesPolymer sciencePolymer chemistry

The invention provides a binder and a battery containing the binder. The binder has a three-dimensional network structure, a skeleton of the three-dimensional network structure is formed by a first polymer, the skeletons are connected through a second polymer, and the first polymer and the second polymer are cross-linked through a hydrogen bond; wherein the first polymer is selected from an acrylic polymer; and the second polymer is selected from a polyurethane ternary polymer. The binder provided by the invention can effectively improve deformation caused by volume change of a negative electrode active material, so that the cycle life of the battery is prolonged.

Owner:ZHUHAI COSMX BATTERY CO LTD

High-stability sectional type cast-in-situ bored pile construction method

InactiveCN111997046AImprove subsidenceImprove stabilityBulkheads/pilesArchitectural engineeringRemedial action

The invention discloses a high-stability sectional type cast-in-situ bored pile construction method, and belongs to the technical field of concrete piles. According to the construction method, innovation can be realized, a sectional pouring mode is adopted, and a double-effect monitoring rod is mounted on a reinforcement cage, and is synchronously pre-buried along with sectional pouring, so that the sedimentation phenomenon of a concrete pipe pile in a foundation environment is effectively improved, along with pouring of concrete, the hydration heat phenomenon of the concrete is utilized for absorbing heat and triggering the anchoring action, high-strength combination with the hole wall is achieved, and meanwhile, the concrete at the upper end and concrete at the lower end are connected, in addition, bending and settlement monitoring can be carried out at the same time when the cast-in-place pile is pre-buried inside the concrete, when bending and settlement happen to the cast-in-placepile, an alarm circuit can be triggered, an alarm signal is sent to the outside, and technicians can take remedial measures in time, so that the stability and the safety of the cast-in-situ bored pile are effectively improved, the construction difficulty is reduced, and the construction cost is controlled.

Owner:李用浩

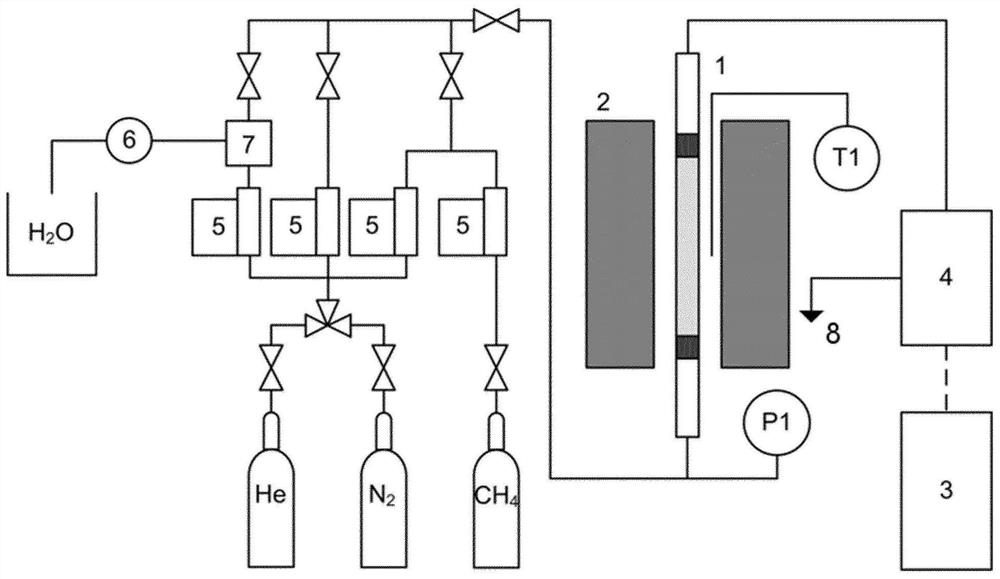

Redox preparation process of an oxygen carrier for a chemical looping process

PendingCN113631262AEliminate energy-consuming stepsAchieve anchoringHydrogenCatalyst regeneration/reactivationRedoxChemical element

The invention is directed to a process for the preparation of an oxygen carrier for a chemical looping process comprising: (a) providing a material A comprising at least one first transition metal and / or an oxide of the at least one first transition metal, wherein the at least one first transition metal is selected from one or more of chemical element groups 6-11 of the Periodic System, wherein the at least one first transition metal and / or oxide of at least one first transition metal is optionally supported on one or more support materials, (b) subjecting material A to a reaction with H2 to cause at least partial reduction of the at least one first transition metal and / or at least one first transition metal oxide to form a reduced material B, (c) treating reduced material B with a solution of a salt of at least one second transition metal, wherein the at least one second transition metal is selected such that it has a standard reduction potential that is larger than a standard reduction potential of the first transition metal, wherein a portion of the at least one first transition metal in the reduced material B is replaced by the at least one second transition metal, wherein a molar ratio of the at least one first transition metal with respect to the at least one second transition metal in the reduced material B ranges between 2:1 and 100:1, and (d) washing and optionally drying the thus obtained oxygen carrier. The invention also relates to an oxygen carrier obtained with this method and to a method for regeneration of the oxygen carrier using steam.

Owner:威妥有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com