Column joint connecting device of assembled steel structure system

A joint connection, steel structure technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of difficult processing and installation, low precision, high rigidity of welded structures, etc., to improve mechanical performance, increase assembly speed, and prevent fire. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific connection mode of the column joint connection device of the present invention will be described in detail below with reference to the accompanying drawings.

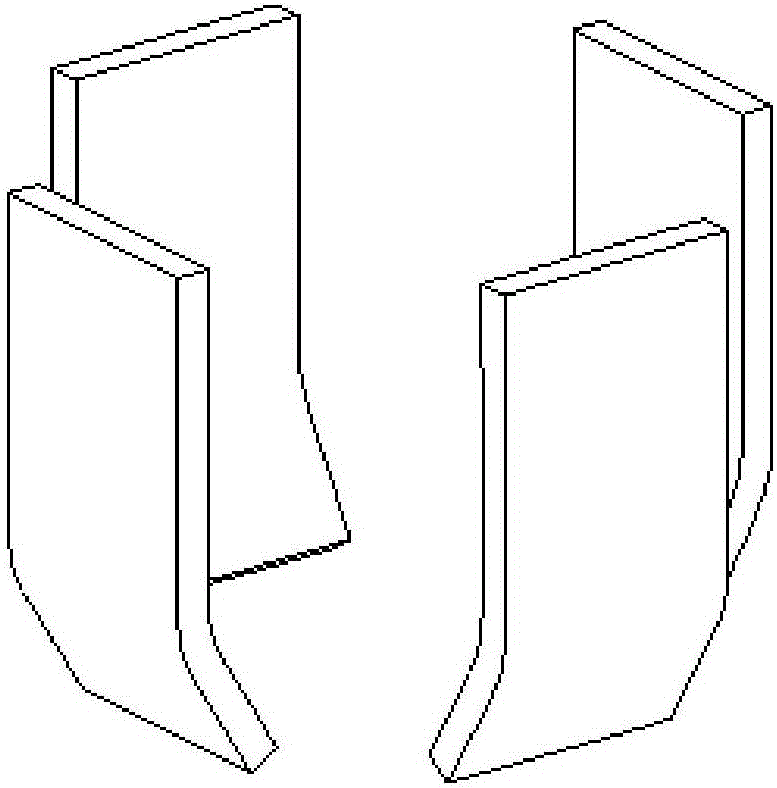

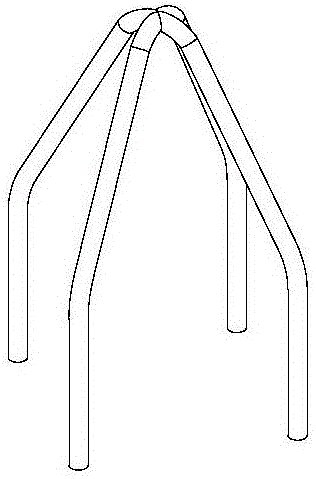

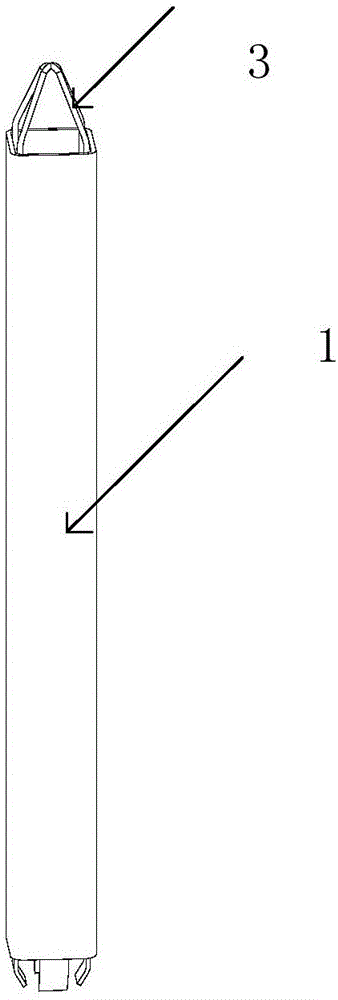

[0023] as attached Figure 1~5 As shown, a column joint connecting device of an assembled steel structure system of the present invention includes a lower column (1), an upper column (2), a lower column hook (3), and an upper column bent plate (4).

[0024] The lower column (1) and the lower column hook (3) are welded together at the factory to form a component A1; the upper column (2) and the upper column bent plate (4) are welded together at the factory to form a component A2.

[0025] After the components A1 and A2 are hoisted on site, concrete is poured inside the column for connection.

[0026] The above is a typical embodiment of the present invention, and the practice of the present invention is not limited thereto.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com