Multi-metal-CHA type molecular sieve catalyst as well as preparation method and application thereof

A molecular sieve and catalyst technology, applied in the field of multi-metal-CHA molecular sieve catalyst and its preparation, can solve the problems of active metal migration, product appearance, fresh activity, hydrothermal stability, etc., to achieve hydrothermal stability improvement and low price Inexpensive, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing the polymetallic-CHA molecular sieve catalyst described in the technical solution, comprising the following steps:

[0048] a) mixing the first active substance, the second active substance, the auxiliary agent and water to obtain a mixed liquid;

[0049] The first active material is a Cu source; the second active material is a Ce source;

[0050] b) impregnating the CHA-type molecular sieve into the mixed solution, and then spray-drying the mixed solution containing the CHA-type molecular sieve to obtain a multi-metal-CHA-type molecular sieve catalyst.

[0051] In the catalyst preparation method provided by the present invention, firstly, the first active substance, the second active substance, the auxiliary agent and water are uniformly mixed to obtain a mixed liquid. Wherein, the first active substance is a Cu source, preferably including a soluble salt of copper and / or a soluble salt of cuprous, more prefer...

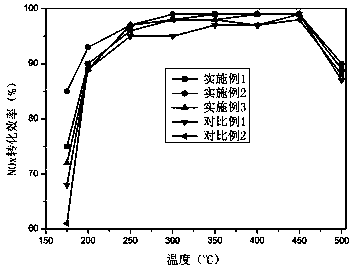

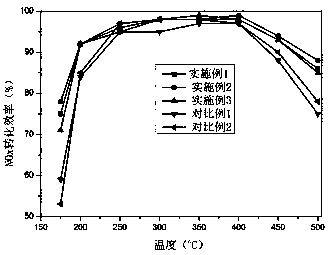

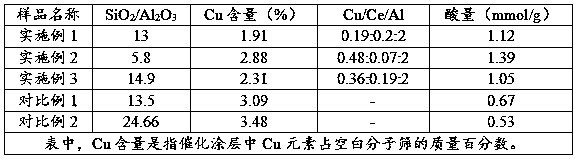

Embodiment 1

[0062] Prepare 1500mL of 0.02mol / L copper nitrate aqueous solution, and then calculate the required ratio of cerium nitrate and SSZ-13 molecular sieve dry powder (silicon-aluminum ratio is 13) according to Cu:Ce:Al atomic number ratio=0.19:0.2:2 Dosage: Dissolve cerium nitrate in proportion to the above copper nitrate aqueous solution and stir evenly, then add polyvinyl alcohol (polymerization degree 1500) dry powder, the amount of dry powder added is 0.1% of the mass of SSZ-13 molecular sieve, and stir evenly to obtain an active substance aqueous solution ; Add SSZ-13 molecular sieve dry powder (silicon-alumina ratio: 13) to the active substance aqueous solution in proportion, and soak at room temperature for 24 hours; then spray-dry the impregnated mixture to obtain dry catalyst powder.

[0063] The above catalyst dry powder, Al 2 o 3 Dry binder powder and deionized water are stirred evenly in a stirrer according to the mass ratio of 30:5:65 to prepare a catalytic slurry; ...

Embodiment 2

[0065] Prepare 1000mL of 0.015mol / L copper acetate aqueous solution, and then calculate the required ratio of cerium nitrate and SSZ-13 molecular sieve dry powder (silicon-aluminum ratio is 5.8) according to Cu:Ce:Al atomic number ratio=0.48:0.07:2 Dosage: Dissolve cerium nitrate in proportion to the above copper acetate aqueous solution and stir evenly, then add high-molecular polycarboxylate ammonium salt (polymerization degree 2000) dry powder. SSZ-13 molecular sieve dry powder (silicon-alumina ratio: 5.8) was added in proportion to the active substance aqueous solution, and soaked at room temperature for 24 hours; after that, the impregnated mixture was spray-dried to obtain dry catalyst powder.

[0066] The above catalyst dry powder, Al 2 o 3 Dry binder powder and deionized water are stirred evenly in a stirrer according to the mass ratio of 30:5:65 to prepare a catalytic slurry; 2 On a cordierite honeycomb ceramic carrier with a volume of 38.6mL, the coating amount is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com