Seabed automatic drilling type piling device and method

A piling device and automatic technology, applied in drilling equipment and methods, sheet pile walls, earthwork drilling, etc., can solve the problems of inability to achieve reliable anchoring, shallow anchoring depth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

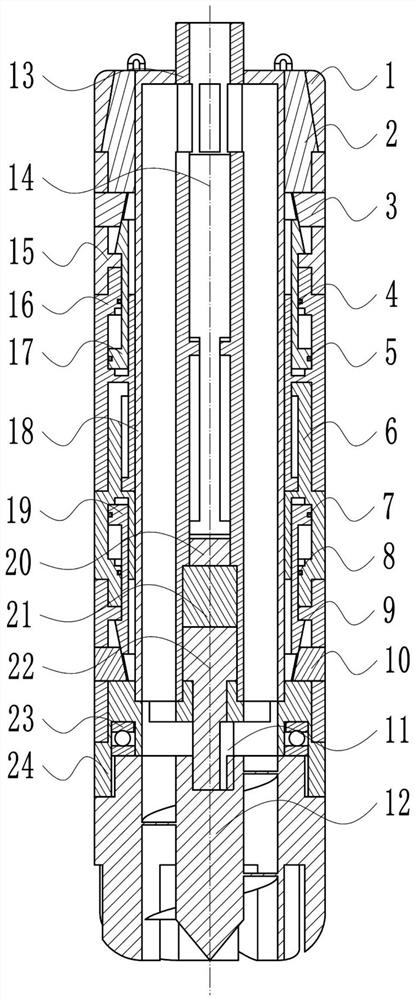

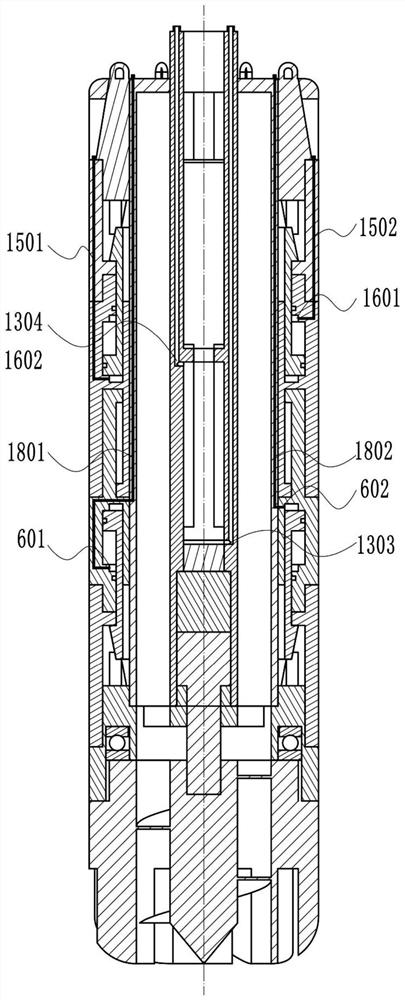

[0050] A subsea automatic drilling type piling device and method, the subsea automatic drilling type piling device includes the following components: it consists of an expansion fixing module, an upper anchoring module, a lower anchoring module, a chip removal module and a drilling module composition. The expansion fixing module is composed of an expansion cover (1) and an extrusion head (2). The inner side of the expansion cover (1) is a conical surface, which cooperates with the outer conical surface of the extrusion head (2) to achieve radial positioning. The extrusion head (2) There are lifting rings (201) distributed at equal intervals on the top, and slide grooves (202) distributed at equal intervals on the outside, and the expansion cover (1) is installed in the slide grooves (202) through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com