Concrete structure reinforcing method based on near surface mounted prestressed FRP (Fiber Reinforced Polymer)

A concrete structure and prestressing technology, applied in the direction of building construction, building maintenance, construction, etc., can solve the problems of loss of bearing capacity, uncoordinated strength, limited bonding ability, etc., to enhance the bonding ability, avoid peeling damage, The effect of saving reinforcement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

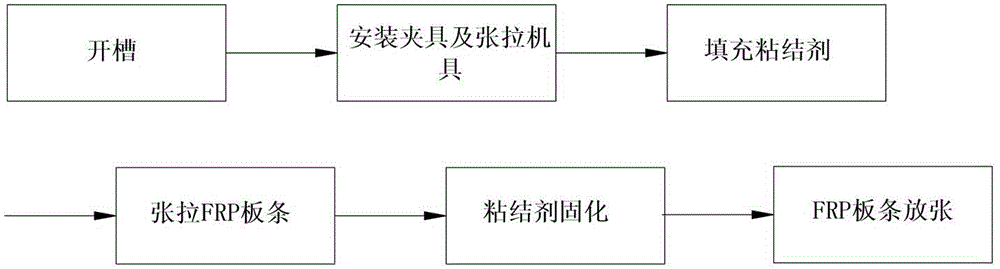

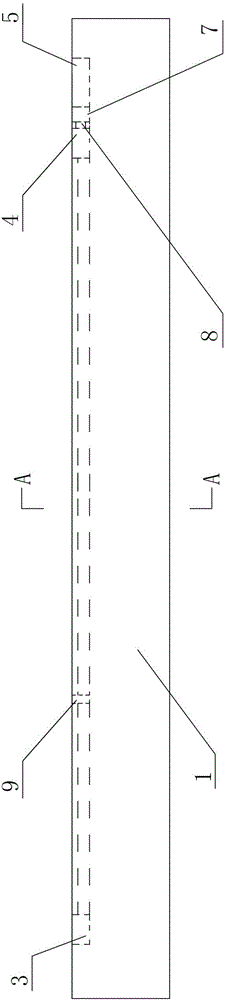

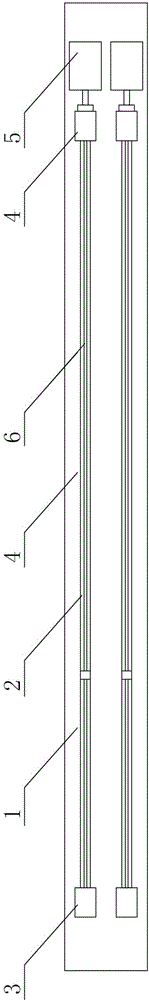

[0028] Such as Figure 1 to Figure 5 Shown, the concrete structure reinforcing method based on surface layer embedding prestressed FRP lath of the present invention, its steps are:

[0029] (1), slotting;

[0030] Take the concrete structure to be reinforced as the beam 1 to be reinforced as an example. Use a slotting machine to open more than one prefabricated groove 2 at a predetermined position on the beam 1 to be reinforced. The depth, width, length, spacing and quantity of the prefabricated groove 2 are determined according to the relevant technical requirements and the structural reinforcement plan; and in the prefabricated groove 2 Mounting locations for FRP slat clamps are pre-chiseled at both ends. After the opening of the prefabricated tank 2, use compressed air to remove the residual concrete dust in the prefabricated ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com