A kind of polyester modified silicone leveling agent and preparation method thereof

A polyester modification, silicone technology, applied in the direction of coating, can solve the problems of easy loss of effective substances, weak bonding force between leveling agent and resin, poor heat resistance, etc., and achieves a simple and easy preparation method. Industrial production, the effect of excellent leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

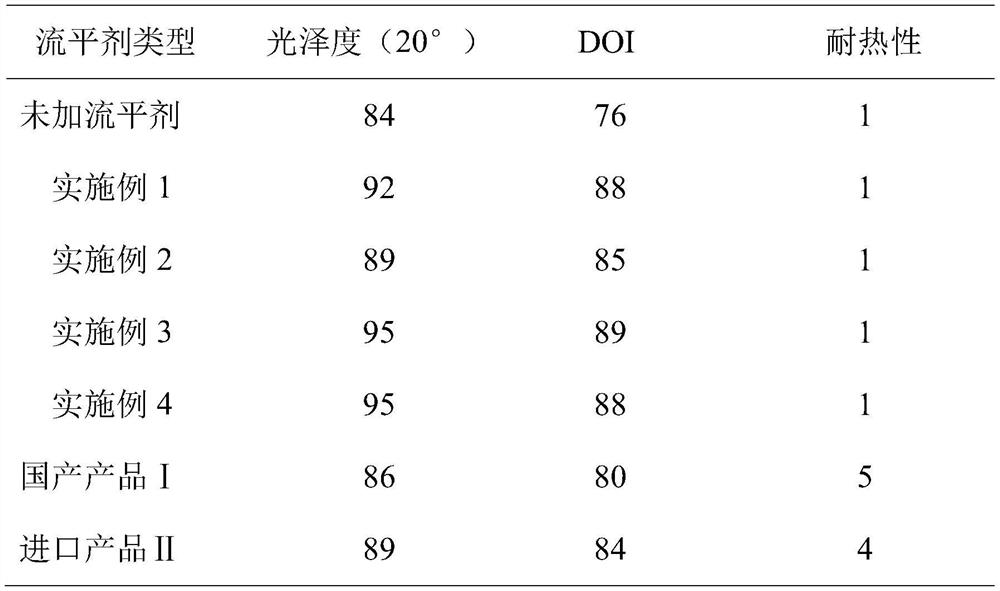

Examples

preparation example Construction

[0026] The preparation method of above-mentioned polyester modified silicone leveling agent, comprises the steps:

[0027] 1) Mix hydrogen-terminated polydimethylsiloxane with single-ended allyl polycaprolactone, and add solvent until the mixture is clear;

[0028] 2) Warm up the solution obtained in step 1) to 60-90°C, add Karstedt catalyst, and stir for 3-10 hours;

[0029] 3) Separating the reaction solution in step 2) to remove the supernatant, and distilling off low boilers under reduced pressure to obtain a polyester-modified silicone leveling agent.

[0030] The solvent is selected from one of toluene, ethyl acetate, isopropanol and tetrahydrofuran.

Embodiment 1

[0032] Mix 1 mole part of hydrogen-terminated polydimethylsiloxane (molecular weight 652, m=7) with 2 mole parts of single-ended allyl polycaprolactone (molecular weight 686, n=5), add toluene until the mixture is clear, Heat up to 90°C, add Karstedt catalyst (accounting for 0.005% of the total material mass fraction), stir and react for 3 hours, separate liquid to take the lower layer clear liquid, vacuum 0.09MPa vacuum distillation to remove low boilers, and obtain polyester modified silicone fluid leveling agent.

Embodiment 2

[0034] Mix 1.1 molar parts of hydrogen-terminated polydimethylsiloxane (molecular weight 874, m=10) with 2 molar parts of single-ended allyl polycaprolactone (molecular weight 344, n=2), and add ethyl acetate until the mixture To clarify, heat up to 70°C, add Karstedt catalyst (accounting for 0.002% of the total material mass fraction), stir and react for 6 hours, separate the liquid to remove the lower layer, and remove the low boilers by distillation under reduced pressure at a vacuum degree of 0.09MPa to obtain a polyester modified organic compound. Silicon leveling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com