Post-anchoring construction method and processing equipment for threaded connection

A construction method and threaded connection technology, applied in the field of new post anchorage, can solve the problems of limited service life, limited use, poor effect, etc., and achieve the effect of convenient disassembly and replacement, strong bearing capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

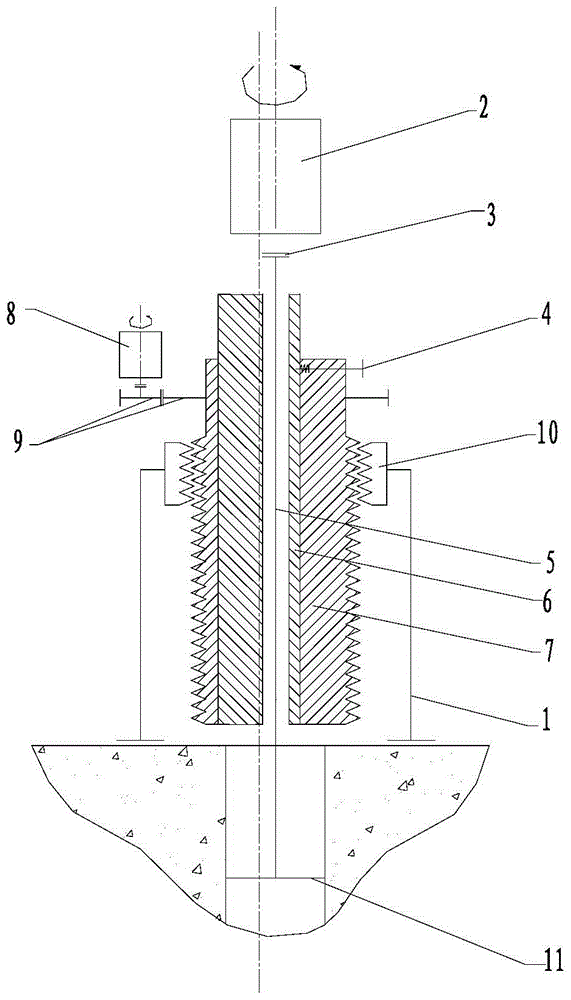

Method used

Image

Examples

Embodiment 1

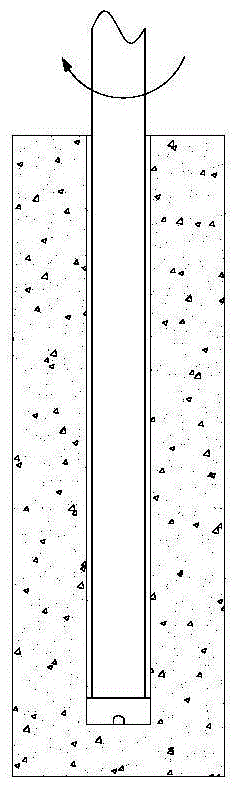

[0049] Such as Figure 8As shown, the threaded connection and anchoring construction method of installing the pipe hanger on the concrete floor, the specific steps are as follows:

[0050] 1. M16 stud bolts are selected for construction, T24X20X14X2 screw cores are selected according to Table 1, and holes are drilled with water drills at the predetermined positions of the concrete floor according to Table 2, with a diameter of 20mm and a depth of 100mm;

[0051] 2. Insert the spindle of the internal screw milling machine into the hole, and process a large-pitch trapezoidal thread T24X20X14X2 on the smooth inner hole;

[0052] 3. Screw in the metal screw core T24X20X14X2 matched with the trapezoidal thread in the trapezoidal threaded hole with an inner hexagonal wrench, and the inner hole of the metal screw core is processed with a standard thread M16;

[0053] 4. Connect one end of the stud bolt M16 X120 to the metal screw core, and the other end to the pipe hanger, fix the p...

Embodiment 2

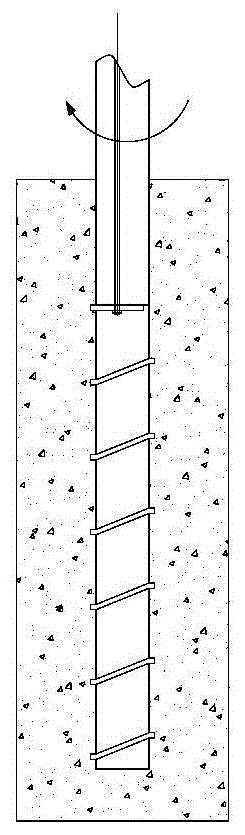

[0055] Such as Figure 9 As shown, the anchoring construction method of the stone back bolt after threaded connection, the specific steps are as follows:

[0056] 1. Choose M10 back bolts for construction, choose T20X16X12X2 screw cores according to Table 1, and drill holes with water drills at the predetermined positions of the stone according to Table 2, with a diameter of 16mm and a depth of 30mm;

[0057] 2. Insert the spindle of the internal screw milling machine into the hole, and process a large-pitch trapezoidal thread T20X16X12X2 on the smooth inner hole;

[0058] 3. Screw in the metal screw core T20X16X12X2 matched with the trapezoidal thread in the trapezoidal thread hole with an inner hexagonal wrench, and the inner hole of the metal screw core is processed with a standard thread M10;

[0059] 4. Connect one end of the back bolt M10 X80 to the metal screw core, and the other end to the steel structure frame of the concrete stone column or building mortar, and fix ...

Embodiment 3

[0061] Such as Figure 10 As shown, the construction method of anchoring after threaded connection of porcelain terminal blocks, the specific steps are as follows:

[0062] 1. M8 stud bolts are selected for construction, T20X16X12X2 screw cores are selected according to Table 1, and holes are drilled with water drills at the predetermined positions of the porcelain terminals according to Table 2, with a diameter of 16mm and a depth of 80mm;

[0063] 2. Insert the spindle of the internal screw milling machine into the hole, and process a large-pitch trapezoidal thread T20X16X12X2 on the smooth inner hole;

[0064] 3. Screw in the metal screw core T20X16X12X2 matched with the trapezoidal thread in the trapezoidal thread hole with a flat wrench, and the inner hole of the metal screw core is processed with standard thread M8;

[0065] 4. Connect one end of the stud bolt M8X100 to the metal screw core, and the other end extends out of the porcelain terminal for fixing on the platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com