External housing safety device for turbocharger with axial flow fluid compressor

A technology of compressors and turbines, applied in the field of shell inserts, can solve the problems of high cost and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

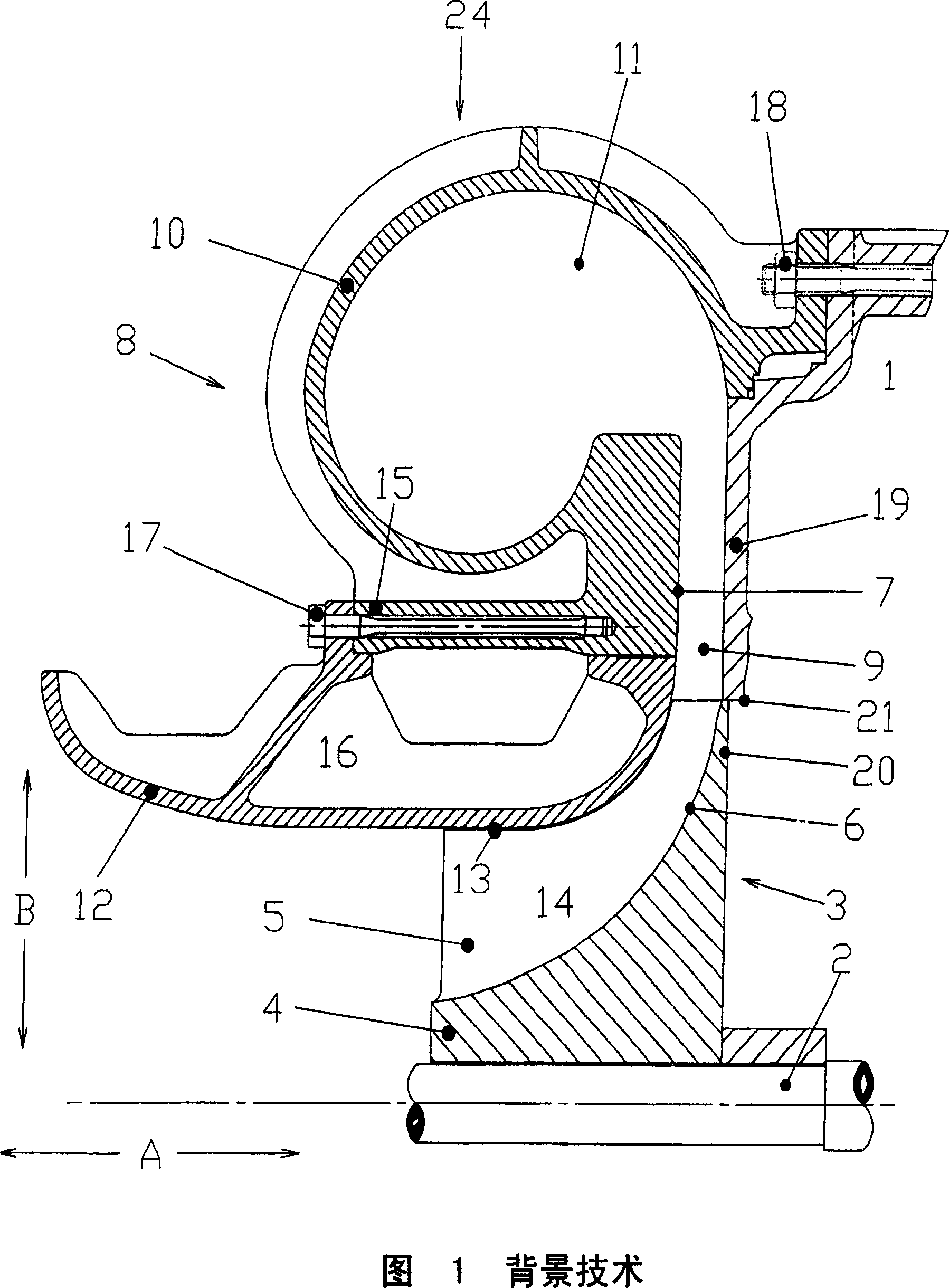

[0025] Fig. 1 shows a partial longitudinal sectional view of a centrifugal compressor in the background art. The exhaust gas turbocharger in this figure has a shaft 2 supported in a bearing housing 1 in its central longitudinal region, which supports a turbine and a turbine, not shown here, on its end protruding from the support bearing. A compressor wheel 3 through which fluid flows radially is shown schematically in the figure.

[0026] The compressor wheel 3 shown has a hub 4 mounted non-rotatably on a shaft 2 driven by a turbine, which hub has radially protruding blades 5 on the circumferential side. The outer contour 6 of the hub 4 and the inner contour 7 of the compressor housing 8 form a fluid channel 9 which narrows outwards from the axial direction A into the radial direction B, the cross section of which corresponds to the contour of the blades 5 . The compressor casing 8 is fixed to the bearing housing 1 by means of a rigid fixing device 18 . From the fluid inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com