High-elasticity composite material for gloves

A composite material and high-elasticity technology, applied in protective clothing and other directions, can solve the problems of gloves not having resilience, damage, and easy electrostatic adhesion, etc., and achieve good internal and external lubrication effect, good processability, and easy to put on and take off.

Inactive Publication Date: 2017-05-10

惠州市纳米金塑胶科技有限公司

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Disposable gloves are thin and easy to break during wearing, and disposable gloves on the market have no resilience, making it difficult to put on and take off, especially when taking calls during meals or needing to take off gloves temporarily

It cannot be worn again, causing waste

[0005] Disposable gloves currently sold on the market are all made of PE. Gloves made of PE materials do not have resilience, and because the gloves are thin and tough enough, they are easy to be damaged during wearing or encountering sharp objects. Gloves made of PE materials have no antistatic effect, and they will easily stick together due to static electricity when they are piled up together.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

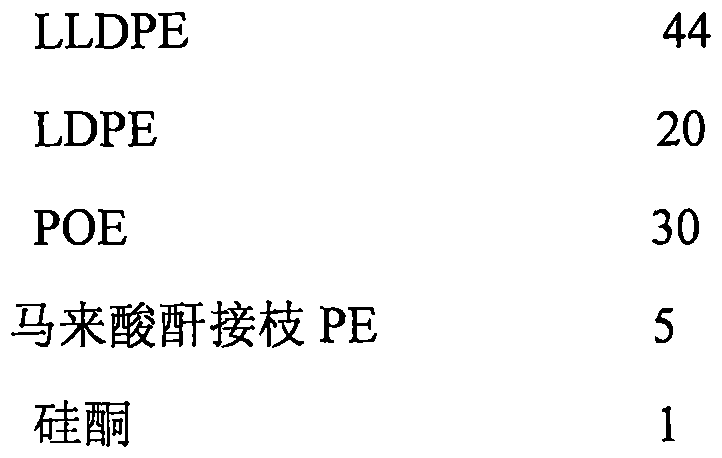

Embodiment 1

[0017]

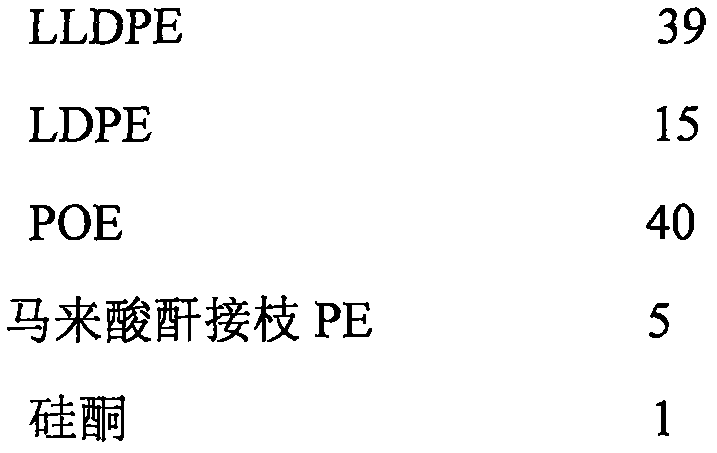

Embodiment 2

[0019]

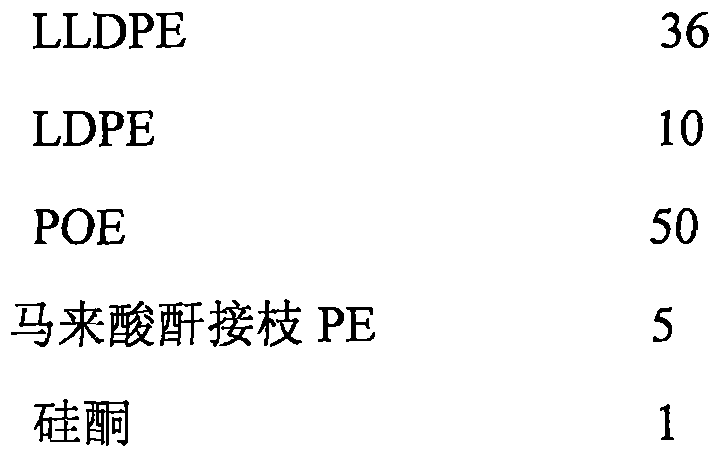

Embodiment 3

[0021]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

A high-elasticity composite material for gloves comprises, by weight, 30-60% of resin, 30-60% of POE, 3-10% of compatilizer and 1-3% of lubricant. Disposable gloves made of the material have the advantages of convenience for taking on and off, high comfort and high resilience.

Description

[0001] Technical field: [0002] The invention belongs to the field of polymer materials, and in particular relates to a high-elastic composite material for gloves, which is mainly used in disposable gloves. [0003] Background technique: [0004] Disposable gloves have the advantages of low cost, no need for cleaning and disinfection, and convenient use, and are widely used in various industries, such as food handling, food service, etc. For example, the catering industry in society is developing very rapidly, and disposable gloves are used more and more frequently in dietary life. They can be seen everywhere in our daily life. When we taste food such as crayfish, duck necks, and crabs, we often need to wear plastic once. Sex gloves for eating, but there will be a lot of inconvenience in the process of use. When using disposable gloves, because the disposable gloves are thin, it is easy to stick multiple plastic gloves together and take them out together. Disposable gloves a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/08C08L23/06C08L51/06C08L51/08C08L83/04C08K5/20A41D19/015

CPCC08L23/0815A41D19/0055C08L2201/04C08L2205/02C08L2205/025C08L2205/035C08L2314/06C08L23/06C08L51/06C08L83/04

Inventor 彭军陈向文彭政

Owner 惠州市纳米金塑胶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com