Steamed bun modifier and application method thereof in making southern steamed buns

The invention relates to an application method and technology of improving agent, which are applied to a steamed bun improver and its application field in making southern steamed buns, which can solve the problems that the quality of finished steamed buns cannot be achieved, calcium peroxide is not allowed to be added, and the like, and achieve uniform structure and texture of steamed buns. Soft and elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment one: the raw material described in the embodiment of the present invention consists of: corn starch: 90%, calcium dihydrogen phosphate: 3%, calcium sulfate: 5%, vitamin C: 1%, fungal amylase: 0.3%, lipase : 0.2%, xylanase: 0.2%, glucose oxidase: 0.3%.

[0032] The application method of the steamed bun improver of the present invention in making southern steamed buns comprises the following steps:

[0033] S1: Weigh 500g of flour, 4g of yeast, 1.5g of salt, 75g of white granulated sugar, 230g of cold water and 1.5g of steamed bread improver by weight of flour.

[0034] S2: Mix the weighed yeast, salt, white sugar and cold water to form an aqueous solution.

[0035] S3: Pour flour and steamed bread improver into the dough mixer, and pour in the dissolved aqueous solution, and stir to form a dough.

[0036] S4: Take out the dough, and press the dough through a noodle press for 12 times to make the dough even and smooth.

[0037] S5: Divide the dough into smal...

Embodiment 2

[0041] Embodiment 2: The raw materials described in the embodiment of the present invention are composed of: corn starch: 90%, calcium dihydrogen phosphate: 3%, calcium sulfate: 4%, vitamin C: 2%, fungal amylase: 0.2%, lipase : 0.3%, xylanase: 0.3%, glucose oxidase: 0.2%.

[0042] The application method of the steamed bun improving agent of this embodiment in making southern steamed buns is the same as that of the first embodiment.

Embodiment 3

[0043] Embodiment 3: The raw materials described in the embodiment of the present invention are composed of: corn starch: 90%, calcium dihydrogen phosphate: 3%, calcium sulfate: 4%, vitamin C: 2.5%, fungal amylase: 0.2%, lipase : 0.1%, xylanase: 0.1%, glucose oxidase: 0.1%.

[0044] The application method of the steamed bun improving agent of this embodiment in making southern steamed buns is the same as that of the first embodiment.

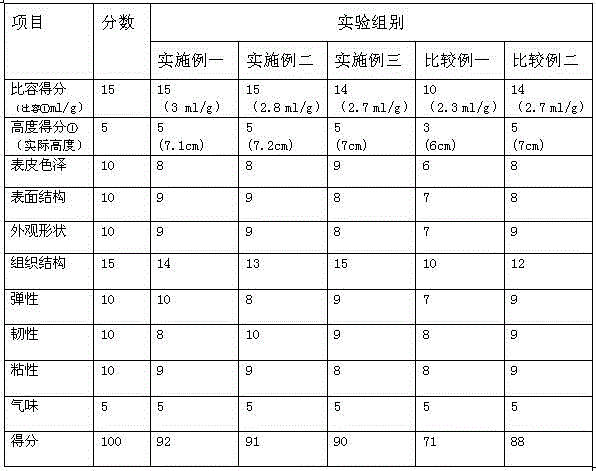

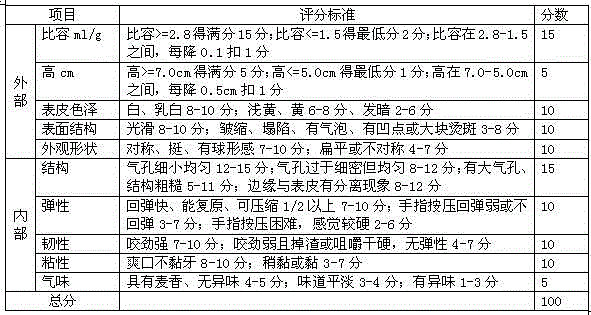

[0045] Experimental comparison:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com